McCann, Michael

Address: 77 Seventh Avenue #PhG, New York, New York 10011-6645

Country: United States

Phone: 1 (212) 255-0615

Fax: 1 (212) 691-5490

E-mail: michael.mccann@worldnet.alt.net

Past position(s): Executive Director, Center for Safety in the Arts

Education: BSc, 1964, University of Calgary, Country: Canada; PhD, 1972, Columbia University

Areas of interest: Arts and crafts; entertainment; education; small shops; Internet; health and safety information

Environmental Protection and Public Health Issues

The treatment and processing of animal skins and hides can be a source of considerable environmental impact. Discharged wastewater contains pollutants from the hides, products from their decomposition and chemicals and various spent solutions used for hide preparation and during the tanning process. Solid wastes and some atmospheric emissions also may arise.

The major public concern over tanneries has traditionally been about odours and water pollution from untreated discharges. Other issues have arisen more recently from the increasing use of synthetic chemicals such as pesticides, solvents, dyes, finishing agents and new processing chemicals which introduce problems of toxicity and persistence.

Simple measures intended to control pollution can themselves create secondary cross-media environmental impacts such as groundwater pollution, soil contamination, sludge dumping and chemical poisoning.

Tanning technology that is now available, based on a lower chemical and water consumption, has less impact on the environment than traditional processes. However, many obstacles remain to its widespread application.

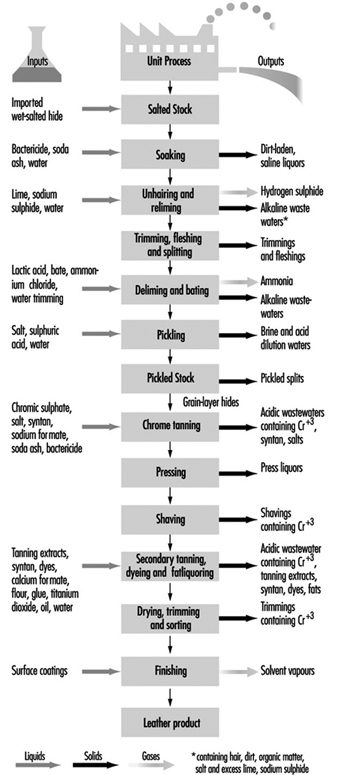

Figure 1 presents the different wastes and environmental impacts associated with the various processes used in the tanning industry.

Figure 1. Environmental impacts & tannery operations

Pollution Control

Water pollution control

Untreated tannery wastes in surface waters can bring about a rapid deterioration of their physical, chemical and biological properties. Simple end-of-pipe effluent treatment processes can remove over 50% of suspended solids and biochemical oxygen demand (BOD) of effluent. More sophisticated measures are capable of higher levels of treatment.

As tannery effluents contain several chemical constituents that need to be treated, a sequence of treatment processes in turn must be used. Flow segregation is useful to allow separate treatment of concentrated waste streams.

Table 1 summarizes technological choices available for treatment of tannery effluents.

Table 1. Technological choices for treatment of tannery effluents

|

Pre-treatment settling |

Mechanical screening to remove coarse material Flow equalization (balancing) |

|

Primary treatment |

Sulphide removal from beamhouse effluents Chromium removal from tanning effluents Physical-chemical treatment for BOD removal and neutralization |

|

Secondary treatment |

Biological treatment Activated sludge (oxidation ditch) Activated sludge (conventional) Lagooning (aerated, facultative or anaerobic) |

|

Tertiary treatment |

Nitrification and denitrification |

|

Sedimentation and sludge handling |

Different shapes and dimensions of tanks and basins |

Air pollution control

Air emissions fall into three broad groups: odours, solvent vapours from finishing operations and gas emissions from the incineration of wastes.

Biological decomposition of organic matter as well as sulphide and ammonia emissions from wastewaters are responsible for the characteristic objectionable odours arising from tanneries. The siting of installations has been an issue because of the odours that have historically been associated with tanneries. Reduction of these odours is more a question of operational maintenance than of technology.

Solvent and other vapours from the finishing operations vary with the type of chemicals used and the technical methods employed to reduce their generation and release. Up to 30% of the solvent used may be wasted through emissions, while modern processes are available to reduce this to around 3% in many cases.

The practice by many tanneries of incinerating solid wastes and offcuts raises the importance of adopting good incinerator design and following careful operating practices.

Waste management

Treatment of sludge constitutes the largest disposal problem, apart from effluent. Sludges of organic composition, if free from chrome or sulphides, have value as a soil conditioner as well as a small fertilizer effect from nitrogenous compounds contained therein. These benefits are best realized by ploughing immediately after application. Agricultural use of chrome-containing soils has been a matter of controversy in various jurisdictions, where guidelines have determined acceptable applications.

Various markets exist for the conversion of trimmings and fleshings into by-products used for a variety of purposes, including the production of gelatin, glue, leatherboard, tallow grease and proteins for animal feed. Process effluents, subject to suitable treatment and quality control, are sometimes used for irrigation where water is in short supply and/or effluent disposal is severely restricted.

To avoid problems of leachate generation and odour, only solids and dewatered sludges should be disposed of at landfill sites. Care must be taken to ensure that tannery wastes do not react with other industrial residues, such as acidic wastes, which can react to create toxic hydrogen sulphide gas. Incineration under uncontrolled conditions may lead to unacceptable emissions and is not recommended.

Pollution Prevention

Improving production technologies to increase environmental performance can achieve a number of objectives, such as:

- increasing the efficiency of chemical utilization

- reducing water or energy consumption

- recovering or recycling rejected materials.

Water consumption can vary considerably, ranging from less than 25 l/kg of raw hide to greater than 80 l/kg. Water use efficiency can be improved through the application of techniques such as increased volume control of processing waters, “batch” versus “running water” washes, low float modification of existing equipment; low float techniques using updated equipment, re-use of wastewater in less critical processes and recycling of individual process liquors.

Traditional soaking and unhairing account for over 50% of the BOD and chemical oxygen demand (COD) loads in typical tanning effluents. Various methods can be employed to substitute for sulphide, to recycle lime/sulphide liquors and to incorporate hair-saving techniques.

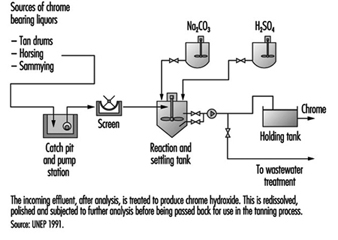

Reduction in chromium pollution can be achieved through measures to increase the levels of chrome that are fixed in the tanning bath and reduce the amounts that are “bled out” in subsequent processes. Other methods to reduce release of chromium are through direct recycling of used chrome liquors (which also reduces salinity of waste effluent) and the treatment of collected chrome-bearing liquors with alkali to precipitate the chromium as hydroxide, which can then be recycled. An illustration of a communal chrome recovery operation is shown in figure 2.

Figure 2. Flow chart for a communal plant for chrome recovery

Where vegetable tanning is employed, preconditioning of hides can enhance the penetration and fixation of hides and contribute to decreased tannin concentrations in effluents. Other tanning agents such as titanium have been used as substitutes for chromium to produce salts of generally lower toxicity and to generate sludges that are inert and safer to handle.

Environmental Protection and Public Health Issues

Overview

The food industry is directly dependent on the natural environment for a supply of raw materials to produce contaminant-free products for human consumption. Due to the extensive processing of a great volume of materials, potential impact on the environment is considerable. This is also true of the beverage industry.

Environmental concern with respect to the food industry focuses more on organic pollutant loadings than on the impact of toxic substances. If pollutant loadings are inadequately prevented or controlled, they will strain community pollution control infrastructure or produce negative impacts on local ecosystems. Production techniques that control product losses serve the double function of improving yield and efficiency while at the same time reducing potential waste and pollution problems.

While the availability of potable water is essential, the food-processing industry also requires very large volumes of water for a wide variety of non-consumption uses, such as for initial cleaning of raw material, fluming, blanching, pasteurizing, cleaning of processing equipment and cooling of finished product. Water uses are identified by quality criteria for different applications, with the highest quality uses often requiring separate treatment to assure complete freedom from odour and taste and to ensure uniform conditions.

The processing of very large volumes of material introduces a potentially great solid waste problem in the production phase. Packaging waste has been the subject of increasing concern with regard to the post-consumer phase of a product’s life cycle. In certain branches of the food industry, processing activities are also associated with potential air emissions and odour control problems.

Despite considerable variation among specific industry sub-sectors, approaches to the prevention and control of pollution share many general characteristics.

Water Pollution Control

The food-processing industry has a raw waste effluent before treatment that is extremely high in soluble organic matter. Even small, seasonal plants are likely to have waste loads comparable to those of populations of 15,000 to 25,000, with large plants approximating the population-equivalent waste load of a quarter of a million people. If a stream or waterway receiving effluent is too small and organic waste too large in volume, the organic waste will utilize the dissolved oxygen in the process of being stabilized and will pollute or degrade the water body by reducing the dissolved oxygen value below that required by normal aquatic organisms. In most cases the waste from food-processing plants is amenable to biological treatment.

The strength of wastewater varies considerably according to plant, specific process and raw product characteristics. From an economic point of view, it is normally less costly to treat a high-strength, low-volume waste than a large-volume, diluted waste. For this reason, effluent with a high biological oxygen demand (BOD), such as the blood of chickens or meat, should be kept out of poultry and meatpacking plant sewers to reduce pollution load, and retained in containers for separate disposal in a by-products or rendering plant.

Waste streams with extreme pH (acidity) values should be carefully considered because of their effect on biological treatment. The combination of acid and basic waste streams may result in neutralization, and, where possible, cooperation with adjacent industries may be very beneficial.

The liquid portion of food-processing waste is normally screened or separated after settling, as a preliminary step in any treatment process, so that these wastes can be disposed of as garbage or combined with other solids in a by-products recovery programme.

The treatment of wastewater can be accomplished by a variety of physical, chemical and biological methods. As secondary processes are more expensive, maximum use of primary treatment is critical in reducing loads. Primary treatment includes processes such as settling or plain sedimentation, filtration (single, dual and multi-media), flocculation, flotation, centrifugation ion exchange, reverse osmosis, carbon absorption and chemical precipitation. Settling facilities range from simple settling ponds to sophisticated clarifiers designed specifically for the particular waste stream characteristics.

The use of biological secondary treatment to follow primary treatment is frequently a necessity to reach wastewater effluent standards. As most food and beverage industry wastewaters contain mainly biodegradable organic pollutants, biological processes used as secondary treatment seek to reduce the BOD of the waste stream by mixing higher concentrations of organisms and oxygen in the waste stream to provide rapid oxidation and stabilization of the waste stream prior to their discharge back to the environment.

Techniques and combinations of techniques may be adapted to address specific waste situations. For example, for dairy wastes, anaerobic treatment to remove the major portion of the pollutant load, with aerobic post-treatment to further reduce the residual BOD and chemical oxygen demand (COD) down to low values and remove nutrients biologically, has proven to be effective. The biogas mixture of methane (CH4) and CO2 that is produced from anaerobic treatment can be captured and used as an alternative to fossil fuels or as a source for electrical power generation (typically 0.30 m3 biogas per kg of COD removed).

Other secondary methods that are widely used include the activated sludge process, aerobic trickling filters, spray irrigation and the use of a variety of ponds and lagoons. Odour nuisances have been associated with ponds of inadequate depth. Odours from anaerobic processes can be removed by the use of soil filters that can oxidize objectionable polar gases.

Air Pollution Control

Air pollution from the food industry generally revolves around the question of objectionable odours rather than toxic air emissions, with a few exceptions. For this reason, for example, many cities have regulated the location of slaughterhouses under their health codes. Isolation is one obvious way to reduce community complaints about odours. However, this does not remove the odour. Odour control measures such as absorbers or scrubbers may sometimes be necessary.

One major health concern in the food industries is leaks of ammonia gas from refrigeration units. Ammonia is a severe eye and respiratory irritant, and a major leak into the environment could require evacuation of local residents. A leak control plan and emergency procedures are necessary.

Food processes that use solvents (e.g., edible oil processing) may emit solvent vapours into the atmosphere. Closed systems and recycling of solvents is the best method of control. Industries such as sugar-cane refining, which use sulphuric acid and other acids, may release sulphur oxides and other contaminants into the atmosphere. Controls such as scrubbers should be used.

Solid Waste Management

Solid waste can be quite considerable. Tomato waste for canning, for example, may represent 15 to 30% of total quantity of product processed; with peas and corn, waste is in excess of 75%. By isolating solid wastes, the concentration of soluble organics in wastewater may be reduced and the drier solid wastes may be more easily used for by-product or feeding purposes and as fuel.

Utilization of process by-products in a manner that provides income will reduce the total cost of waste treatment and eventually the cost of the final product. Waste solids should be evaluated as sources of food for plants and animals. A growing emphasis has been devoted to the development of markets for by-products or for the compost produced by converting waste organic materials to an innocuous humus. Table 1 provides examples of uses for by-products from the food industry.

Table 1. Examples of uses for by-products from the food industry

|

Method |

Examples |

|

Anaerobic digestion |

Digestion by mixed bacteria population to yield methane and CO2 |

|

Animal feed |

Directly, after pressing or drying, as fodder ensiling or as supplement |

|

Composting |

Natural microbiological process in which organic components decompose under controlled aerobic conditions |

|

Edible fibre |

Method for utilizing organic solids by filtering and hydration |

|

Fermentation |

Combination of starch, sugar and alcohol-bearing substances |

|

Incineration |

Burning of biomass as fuel |

|

Pyrolysis |

Transformation of nut shells and fruit pits into charcoal briquets |

|

Soil amendment |

Fertilizing of soils with low nutrient and organic matter content |

Source: Adapted from Merlo and Rose 1992.

Water Reuse and Effluent Reduction

Extensive dependence on water by food-processing industries has encouraged the development of conservation and reuse programmes, especially in locations of water scarcity. Reuse of process water can provide substantial reductions in both water consumption and waste load, with reuse in many lower-quality applications not requiring biological treatment. However, any potential for anaerobic fermentation of organic solids must be avoided so that corrosive, odourous decomposition products do not affect equipment, work environment or product quality. Bacterial growth can be controlled by disinfection and by changing environmental factors such as pH and temperature.

Table 2 presents typical water reuse ratios. Factors such as the location of sprays, water temperature and pressure are key factors influencing the volume of water required for processing operations. For example, water used as a cooling medium to cool cans and for air conditioning may later be used for primary washing of vegetables and other products. The same water later may be used for fluming waste material, and finally a portion of it may be used to cool ashes in the powerhouse.

Table 2. Typical water reuse ratios for different industry sub-sectors

|

Sub-sectors |

Reuse ratios |

|

Beet sugar |

1.48 |

|

Cane sugar |

1.26 |

|

Corn and wheat milling |

1.22 |

|

Distilling |

1.51 |

|

Food processing |

1.19 |

|

Meat |

4.03 |

|

Poultry processing |

7.56 |

Water conservation techniques and waste prevention techniques include the use of high-pressure sprays for clean-up, elimination of excessive overflow from washing and soaking tanks, substitution of mechanical conveyors for water flumes, use of automatic shut-off valves on water hoses, separation of can cooling water from the composite waste flow and recirculation of can cooling water.

Pollution loads at processing plants can be reduced through modified processing methods. For example, most pollution load generated from fruit and vegetable processing originates in the peeling and blanching operations. By moving from conventional water or steam blanching to a hot gas blanching process, pollution loads can be reduced by as much as 99.9%. Similarly, dry caustic peeling can cut BOD by more than 90% in comparison to conventional peeling processes.

Energy Conservation

Energy needs have risen with the increased sophistication of the food industry. Energy is required for a wide a variety of equipment such as gas-fired ovens; dryers; steam boilers; electrical motors; refrigeration units; and heating, ventilation and air-conditioning systems.

As the cost of energy has risen, there has been a trend to install heat recovery equipment to conserve energy and to investigate the feasibility of alternative energy sources in various food-processing situations such as cheese processing, food dehydration and water heating. Energy conservation, waste minimization and water conservation are all mutually supportive strategies.

Consumer Health Issues

The increasing separation of the consumer from the food- production sector that has accompanied urbanization globally has resulted in a loss of the traditional means used by the consumer to ensure the quality and safety of food, making the consumer dependent on a functional and responsible food-processing industry. Increased dependence on food processing has created the possibility of exposure to pathogen-contaminated food from a single production facility. To provide protection from this threat, extensive regulatory structures have been established, especially in the industrialized countries, to protect public health and to regulate the use of additives and other chemicals. Harmonization of regulations and standards across borders is emerging as an issue to ensure the free flow of food among all the world’s countries.

Dairy industry wastewater treatment

The dairy industry is made up of a large number of relatively small plants supplying products such as milk, cheese, cottage cheese, sour cream, ice cream, whey solids and lactose.

The dairy industry has long been a proponent of aerobic biological wastewater treatment. Many dairy plants have invested heavily in activated sludge, biotower, sequencing batch reactor and package treatment systems. Interest in water and energy conservation has led many dairy facilities to reduce water consumption. This trend, with the presence of normally high-strength wastewater streams in dairy plants, has resulted in the design and construction of numerous anaerobic wastewater treatment systems.

Environmental Protection and Public Health Issues

Visual Arts

The visual arts produce a wide range of potential environmental problems and raise a number of public health issues. The visual arts use a broad range of chemicals and techniques which can create air and water pollution problems similar to that of the comparable industrial processes, only on a much smaller scale.

Hazardous waste produced by artists can include: (1) toxic and extremely toxic wastes, including solvents, lead compounds, chromates and cyanide solutions; (2) flammable waste, including flammable and combustible liquids (e.g., rags soaked with oil and turpentine), oxidizing substances such as potassium chlorate and dichromates, and ignitable compressed gases; (3) corrosive waste, including acids with a pH less than 2 and alkalis with a pH greater than 12; and (4) reactive wastes, such as organic peroxides, cyanide solutions and sulphide solutions. Artists and artisans are less likely, however, to know how to dispose of this waste or even to know what is hazardous. The most common method of waste disposal for artists is pouring down the sink or onto the ground, tossing in the garbage or evaporation. Although the individual amounts of pollutants are small, cumulatively they can result in significant pollution.

In the United States and Canada and many other countries, artists working in their homes are usually exempted from industrial hazardous waste regulations under a household hazardous waste exemption. Many localities, however, do provide special household hazardous waste days when households can bring their hazardous waste to a central site for collection. However, even in countries which do regulate artists as small businesses, there is little enforcement of hazardous waste regulations for these cottage industries.

Types of waste management methods available include many of the same ones used by industry, including source reduction, waste separation and concentration, recycling, energy and material recovery, incineration or treatment, and secure land disposal. Some of these methods are more available to artists than others.

The best way of managing hazardous waste is to actually eliminate or minimize its production by substituting materials which are less toxic—for example, using lead-free glazes instead of leaded glazes in pottery and enamelling, and using water-based screen printing inks and other coating materials instead of solvent-based ones.

Separating hazardous materials from non-hazardous materials—for example, separating solvent-based paints and water-based paints—can be a simple method to reduce the amount of hazardous waste and prevent it from contaminating regular garbage.

Traditional industrial methods of concentration, such as evaporation of large volumes of photographic wastes, are usually not feasible for artists.

Recycling can involve the reusing of materials (such as solvents used for oil painting cleanup) by the individual, or the passing of unwanted materials to someone else who can use them. Large printmaking facilities, which generate many solvent- or oil-soaked rags, can contract for laundering and reuse them.

Treatment can involve several processes. The most common one used by artists is neutralization of acids or alkaline solutions. Incineration is usually restricted to burning wood dust. Evaporation of solvents is also commonly done. This reduces the amount of hazardous waste potentially contaminating water supplies, although it does contaminate the atmosphere to some degree.

The least favourable option is secure land disposal in a proper hazardous waste disposal site. This is usually not a viable option for artists, especially in developing countries.

A public health issue that is common to many of the visual arts is the problem of the exposure of children to toxic chemicals found in many art materials, including those intended for use by children. Examples include solvents in permanent felt-tip markers and lead in ceramic glazes. Children and other family members can be exposed to hazardous substances and conditions in the home.

A widespread problem in many countries is lead poisoning, including fatalities from cooking and storing food in containers that have been made with lead-containing pottery glazes. In the commercial industry, the problem of lead leaching from glazed pottery has been mostly eliminated through government regulations and good quality control. The World Health Organization has standards for lead and cadmium leaching from pottery intended for food and drink use. The cost of the testing required, however, is not feasible for craft potters, and therefore craft potters should use only lead-free glazes for food and drink containers.

Performing and Media Arts

Theatres, scenery shops and motion picture and television production areas also can produce hazardous waste, since they use many of the same chemicals as are used in the visual arts. The same solutions apply. In particular, the widespread shift from solvent-based paints to water-based paints has greatly decreased the amount of solvent pollution.

One of the main public health issues for theatres (and other places of public assembly) is fire safety. Many theatres and other performance spaces, especially small, non-commercial ones, do not meet applicable fire codes and are dangerously overcrowded. There have been many disastrous fires with numerous fatalities in the performing arts. The use of fogs and smokes for special effects in theatre and opera can also pose the risk of asthma attacks in asthmatic audience members in the front of the theatre if the building does not have adequate exhaust ventilation to prevent the fog or smoke from affecting the audience.

Entertainment Industry

Entertainment industries such as amusement and theme parks can face all the solid waste and other pollution problems of a small town. Zoos, circuses and other types of entertainment involving animals can have many of the same pollution problems as livestock raising, but on a smaller scale.

A public health concern at all entertainment events where food is sold is the possibility of developing salmonella poisoning, hepatitis or other diseases if there are not adequate public health controls.

Crowd control is another major public health concern in many large entertainment events, such as certain types of popular concerts and sports events. Widespread use of drugs and alcohol, overcrowding, allowing extensive standing room (festival seating) and lack of adequate preplanning have led to many incidents involving riots and panic, with resulting multiple injuries and fatalities. In addition, lack of adequate construction standards has caused fires and collapses of seating areas in several countries. There is a need for better regulations and provision of proper crowd control measures in these situations.

Visitors to parks and zoos can also present hazards to themselves. There have been many incidents where zoo visitors have been maimed or killed after entering animal enclosures. Visitors who get too close to wild animals in the parks have also experienced attacks, many of which have been fatal. The problems of inexperienced parks visitors getting lost, caught in storms, or falling from mountains is also a constant public health risk which can use up extensive resources for rescue.

The sex industry, especially prostitution, is particularly infamous for the possibility of patrons being robbed and possibly contracting sexually transmitted diseases. This is particularly true in countries where prostitution is not legally controlled. Criminal activities are often associated with prostitution.

Bullfighting and Rodeos

Bullfighting, or the corrida as it is commonly called, is popular in Spain, Spanish-speaking countries in Latin America (especially Mexico), southern France and Portugal. It is highly ritualized, with pageants, well-defined ceremonies and colourful traditional costumes. Matadors are highly respected and often begin their training at an early age in an informal apprenticeship system.

Rodeos, on the other hand, are a more recent sports event. They are an outgrowth of skills contests between cowboys illustrating their everyday activities. Today, rodeos are formalized sports events popular in the western United States, western Canada and Mexico. Professional rodeo cowboys (and some cowgirls) travel the rodeo circuit from one rodeo to another. The most common rodeo events are bronco riding, bull riding, steer wrestling (bulldogging) and calf roping.

Bullfights. Participants in a bullfight include the matadors, their assistants (the banderilleros and picadors) and the bulls. When the bull first enters the arena from the bull pen gate, the matador attracts its attention with a series of passes with his large cape. The bull is attracted by the movement of the cape, not the colour, since bulls are colour-blind. The matador’s reputation is based on how close he gets to the horns of the bull. These fighting bulls have been bred and trained for centuries for their aggressiveness. The next part of the bullfight involves the weakening of the bull by mounted picadors placing lances in the bull, and then banderilleros, working on foot, placing barbed sticks called banderillas in the bull’s shoulder in order to lower the bull’s head for the kill.

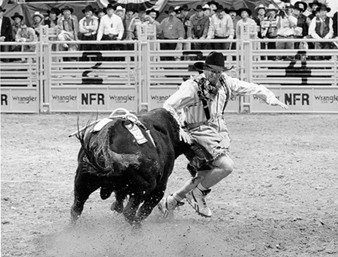

The final stage of the fight involves the matador trying to kill the bull by inserting his sword blade between the shoulder blades of the bull into the aorta. This stage involves many formalized passes with the cape before the final kill. The greater the risks taken by the matador, the greater the acclaim, and of course the greater the risk of being gored (see figure 1). Bullfighters generally receive at least one goring per season, which could involve as many as 100 bullfights per year per matador.

Figure 1. Bullfighting.

El Pais

The primary hazard facing the matadors and their assistants is being gored or even killed by the bull. Another potential hazard is tetanus from being gored. One epidemiological study in Madrid, Spain, indicated that only 14.9% of bullfighting professionals had complete anti-tetanus vaccination, while 52.5% had suffered occupational injuries (Dominguez et al. 1987). Few precautions are taken. The mounted picadors wear steel leg armour. Otherwise, the bullfighting professionals depend on the training and skills of themselves and their horses. One essential precaution is adequate planning for onsite emergency medical care (see “Motion picture and television production” in this chapter).

Rodeos. The most hazardous common rodeo events are bronco or bull riding and steer wrestling. In bronco or bull riding, the purpose is to stay on the bucking animal for a predetermined time. Bronco riding can be either bareback or with a saddle. In steer wrestling, a rider on horseback attempts to throw the steer to the ground by diving off the horse, grabbing the bull by its horns and wrenching it to the ground. Calf roping involves roping a calf from horseback, jumping off the horse and then hog-tying the front and back legs of the calf together in the shortest possible time.

Besides the rodeo contestants, those at risk include the pickup riders or outriders, whose role is to rescue the thrown rider and capture the animal, and the rodeo clowns, whose job is to distract the animal, especially bulls, to give the thrown rider a chance to escape (figure 2). They do this while on foot and dressed in a colourful costume to attract the animal’s attention. Hazards include being trampled, being gored by the bull’s horns, injuries from being bucked off, knee injuries from jumping off the horse, elbow injuries in bronco and bull riders from holding on to the animal with one hand and facial injuries from bulls tossing their heads back. Injuries also occur from bronco or bull riders being smashed against the sides of the chute while waiting for the gate to open and the animal to be released. Severe injuries and fatalities are not infrequent. Bull riders sustain 37% of all rodeo-related injuries (Griffin et al. 1989). In particular, brain and spinal cord injuries are of concern (MMWR 1996). One study of 39 professional rodeo cowboys showed a total of 76 elbow abnormalities in 29 bronco and bull riders (Griffin et al. 1989). They concluded that the injuries were a result of constant hyperextension of the arm gripping the animal, as well as injuries in falls.

Figure 2. Rodeo clown distracting a bull from a fallen rider.

Dan Hubbell

The main way of preventing injuries lies in the skills of the rodeo cowboys, pickup riders and rodeo clowns. Well-trained horses are also essential. Taping elbows and wearing elbow pads has also been recommended for bronco and bull riding. Safety vests, mouth guards and safety helmets are rare, but becoming more accepted. Face masks have occasionally been used for bull riding. As in bullfighting, an essential precaution is adequate planning for on-site emergency medical care.

In both rodeos and bullfighting, of course, the animal keepers, feeders and so on are also at risk. For more information on this aspect, see “Zoos and aquariums” in this chapter.

Motion Picture and Television Production

The motion picture and television industry is found throughout the world. Motion picture production can take place in fixed studios, on large commercial studio lots or on location anywhere. Film production companies range in size from large corporations’ own studios to small companies that rent space in commercial studios. The production of television shows, soap operas, videos and commercials has much in common with motion picture production.

Motion picture production involves many stages and a crew of interacting specialists. The planning stages include obtaining a finished script, determining the budget and schedule, choosing types of location and studios, designing the scene-by-scene appearance of the film, selecting costumes, planning sequence of action and camera locations and lighting schemes.

Once the planning is completed, the detailed process of choosing the location, building sets, gathering the props, arranging the lighting and hiring the actors, stunt performers, special effects operators and other needed support personnel begins. Filming follows the preproduction stage. The final step is film processing and editing, which is not discussed in this article.

Motion picture and television production can involve a wide variety of chemical, electrical and other hazards, many of which are unique to the film industry.

Hazards and Precautions

Filming location

Filming in a studio or on a studio lot has the advantage of permanent facilities and equipment, including ventilation systems, power, lighting, scene shops, costume shops and more control over environmental conditions. Studios can be very large in order to accommodate a variety of filming situations.

Filming on location, especially outdoors in remote locations, is more difficult and hazardous than in a studio because transportation, communications, power, food, water, medical services, living quarters and so on must be provided. Filming on location can expose the film crew and actors to a wide variety of hazardous conditions, including wild animals, poisonous reptiles and plants, civil unrest, climate extremes and adverse local weather conditions, communicable diseases, contaminated food and water, structurally unsafe buildings, and buildings contaminated with asbestos, lead, biological hazards and so on. Filming on water, in the mountains, in deserts and other dangerous locales poses obvious hazards.

The initial survey of possible filming locations should involve evaluating these and other potential hazards to determine the need for special precautions or alternative locations.

Fabricating scenery for motion pictures can involve constructing or modifying a building or buildings, building of indoor and outdoor sets and so on. These can be full size or scaled down. Stages and scenery should be strong enough to bear the loads under consideration (see “Scenery shops” in this chapter).

Life safety

Basic life safety includes ensuring adequate exits, keeping access routes and exits marked and clear of equipment and electrical cables and removal or proper storage and handling of combustible materials, flammable liquids and compressed gases. Dry vegetation around outdoor locations and combustible materials used in filming such as sawdust and tents must be removed or flame-proofed.

Automobiles, boats, helicopters and other means of transportation are common on film locations and a cause of many accidents and fatalities, both when used for transportation and while filming. It is essential that all drivers of vehicles and aircraft be fully qualified and obey all relevant laws and regulations.

Scaffolding and rigging

On location and in studios, lights are rigged to sets, scaffolding or permanent overhead grids, or are free standing. Rigging is also used to fly scenery or people for special effects. Hazards include collapsing scaffolds, falling lights and other equipment and failures of rigging systems.

Precautions for scaffolds include safe construction, guardrails and toeboards, proper supporting of rolling scaffolds and securing of all equipment. Construction, operation, maintenance, inspection and repair of rigging systems should be done only by properly trained and qualified persons. Only assigned personnel should have access to work areas such as scaffolds and catwalks.

Electrical and lighting equipment

Large amounts of power are usually needed for camera lights and everyday electrical needs on a set. In the past direct current (DC) power was used, but alternating current (AC) power is common today. Often, and especially on location, independent sources of power are used. Examples of electrical hazards include shorting of electrical wiring or equipment, inadequate wiring, deteriorated wiring or equipment, inadequate grounding of equipment and working in wet locations. Tie-ins to the power sources and un-ties at the end of filming are two of the most dangerous activities.

All electrical work should be done by licensed electricians and should follow standard electrical safety practices and codes. Safer direct current should be used around water when possible, or ground fault circuit interrupters installed.

Lighting can pose both electrical and health hazards. High-voltage gas discharge lamps such as neons, metal halide lamps and carbon arc lamps are especially hazardous and can pose electrical, ultraviolet radiation and toxic fume hazards.

Lighting equipment should be kept in good condition, regularly inspected and adequately secured to prevent lights from tipping or falling. It is particularly important to check high-voltage discharge lamps for lens cracks that could leak ultraviolet radiation.

Cameras

Camera crews can film in many hazardous situations, including shooting from a helicopter, moving vehicle, camera crane or side of a mountain. Basic types of camera mountings include fixed tripods, dollies for mobile cameras, camera cranes for high shots and insert camera cars for shots of moving vehicles. There have been several fatalities among camera operators while filming under unsafe conditions or near stunts and special effects.

Basic precautions for camera cranes include testing of lift controls, ensuring a stable surface for the crane base and pedestal; properly laid tracking surfaces, ensuring safe distances from high-tension electrical wires; and body harnesses where required.

Insert camera cars that have been engineered for mounting of cameras and towing of the vehicle to be filmed are recommended instead of mounting cameras on the outside of the vehicle being filmed. Special precautions include having a safety checklist, limiting the number of personnel on the car, rigging done by experts, abort procedures and having a dedicated radio communications procedure.

Actors, extras and stand-ins

See the article “Actors” in this chapter.

Costumes

Costumes are made and cared for by wardrobe attendants, who may be exposed to a wide variety of dyes and paints, hazardous solvents, aerosol sprays and so on, often without ventilation.

Hazardous chlorinated cleaning solvents should be replaced with safer solvents such as mineral spirits. Adequate local exhaust ventilation should be used when spraying dyes or using solvent-containing materials. Mixing of powders should be done in an enclosed glove box.

Special effects

A wide variety of special effects are used in motion picture production to simulate real events that would otherwise be too dangerous, impractical or expensive to execute. These include fogs, smoke, fire, pyrotechnics, firearms, snow, rain, wind, computer-generated effects and miniature or scaled-down sets. Many of these have significant hazards. Other hazardous special effects can involve the use of lasers, toxic chemicals such as mercury to give silvery effects, flying objects or people with rigging and electric hazards associated with rain and other water effects. Appropriate precautions would need to be taken with such special effects.

General precautions for hazardous special effects include adequate preplanning, having written safety procedures, using adequately trained and experienced operators and the least hazardous special effects possible, coordinating with the fire department and other emergency services, making everyone aware of the intended use of special effects (and being able to refuse to participate), not allowing children in the vicinity, running detailed rehearsals with testing of the effects, clearing the set of all but essential personnel, having a dedicated emergency communications system, minimizing the number of retakes and having procedures ready to abort production.

Pyrotechnics are used to create effects involving explosions, fires, light, smoke and sound concussions. Pyrotechnics materials are usually low explosives (mostly Class B), including flash powder, flash paper, gun cotton, black powder and smokeless powder. They are used in bullet hits (squibs), blank cartridges, flash pots, fuses, mortars, smoke pots and many more. Class A high explosives, such as dynamite, should not be used, although detonating cord is sometimes used. The major problems associated with pyrotechnics include premature triggering of the pyrotechnic effect; causing a fire by using larger quantities than needed; lack of adequate fire extinguishing capabilities; and having inadequately trained and experienced pyrotechnics operators.

In addition to the general precautions, special precautions for explosives used in pyrotechnics include proper storage, the use of appropriate type and in smallest amounts necessary to achieve the effect, and testing them in the absence of spectators. When pyrotechnics are used smoking should be banned and firefighting equipment and trained personnel should be on hand. The materials should be set off by electronic firing controls and adequate ventilation is needed.

The uses of fire effects range from ordinary gas stoves and fireplaces to the destructive fires involved in burning cars, houses, forests and even people (figure 1). In some cases, fires can be simulated by flickering lights and other electronic effects. Materials used to create fire effects include propane gas burners, rubber cement, gasoline and kerosene. They are often used in conjunction with pyrotechnic special effects. Hazards are directly related to the fire getting out of control and the heat they generate. Poor maintenance of fire generating equipment and the excessive use of flammable materials or the presence of other unintended combustible materials, and improper storage of combustible and flammable liquids and gases are all risks. Inexperienced special effects operators can also be a cause of accidents as well.

Figure 1. Fire special effect

William Avery

Special precautions are similar to those needed for pyrotechnics, such as replacing gasoline, rubber cement and other flammable substances with the safer combustible gels and liquid fuels which have been developed in recent years. All materials in the fire area should be non-combustible or flame-proofed. This precaution includes flame-proofed costumes for actors in the vicinity.

Fogs and smoke effects are common in filming. Dry ice (carbon dioxide), liquid nitrogen, petroleum distillates, zinc chloride smoke generators (which might also contain chlorinated hydrocarbons), ammonium chloride, mineral oil, glycol fogs and water mists are common fog-generating substances. Some materials used, such as petroleum distillates and zinc chloride, are severe respiratory irritants and can cause chemical pneumonia. Dry ice, liquid nitrogen and water mists represent the least chemical hazards, although they can displace oxygen in enclosed areas, possibly making the air unfit for supporting life, especially in enclosed areas. Microbiological contamination can be a problem associated with water-mist generating systems. Some evidence is forthcoming that respiratory irritation is possible from those fogs and smokes that were thought to be safest, such as mineral oil and glycols.

Special precautions include eliminating the most hazardous fogs and smoke; using a fog with the machine designed for it; limiting duration of use, including limiting the number of retakes; and avoiding use in enclosed spaces. Fogs should be exhausted as soon as possible. Respiratory protection for the camera crew should be provided.

Firearms are common in films. All types of firearms are used, ranging from antique firearms to shotguns and machine guns. In many countries (not including the United States) live ammunition is banned. However, blank ammunition, which is commonly used in conjunction with live bullet hits in order to simulate actual bullet impacts, has caused many injuries and fatalities. Blank ammunition used to consist of a metal casing with a percussion primer and smokeless powder topped with a paper wad, which could be ejected at high velocity when fired. Some modern safety blanks use special plastic inserts with a primer and flash powder, giving only a flash and noise. Blank ammunition is commonly used in conjunction with bullet hits (squibs), consisting of a plastic-cased detonator imbedded in the object to be struck by the bullet to simulate actual bullet impacts. Hazards, besides the use of live ammunition, include the effects of use of blanks at close range, mixing up live and blank ammunition or using the wrong ammunition in a firearm. Improperly modified firearms can be dangerous, as can the lack of adequate training in the use of blank-firing firearms.

Live ammunition and unmodified firearms should be banned from a set and non-firing facsimile weapons used whenever possible. Firearms that can actually fire a bullet should not be used, only proper safety blanks. Firearms should be checked regularly by the property master or other firearms expert. Firearms should be locked away, as should all ammunition. Guns should never be pointed at actors in a scene, and the camera crew and others in close proximity to the set should be protected with shields from blanks fired from weapons.

Stunts

A stunt can be defined as any action sequence that involves a greater than normal risk of injury to performers or others on the set. With increasing demands for realism in films, stunts have become very common. Examples of potentially hazardous stunts include high falls, fights, helicopter scenes, car chases, fires and explosions. About half the fatalities occurring during filming are stunt-related, often also involving special effects.

Stunts can endanger not only the stunt performer but often the camera crew and other performers may be injured as well. Most of the general precautions described for special effects also apply to stunts. In addition, the stunt performer should be experienced in the type of stunt being filmed. A stunt coordinator should be in charge of all stunts since a person cannot perform a stunt and be in adequate control of safety, especially when there are several stunt performers.

Aircraft, especially helicopters, have been involved in the most serious multiple fatality accidents in motion picture production. Pilots are often not adequately qualified for stunt flying. Acrobatic manoeuvres, hovering close to the ground, flying too close to sets using pyrotechnics and filming from helicopters with open doors or from the pontoons without adequate fall protection are some of the most dangerous situations. See the article “Helicopters” elsewhere in the Encyclopaedia.

One precaution is to employ an independent aviation consultant, in addition to the pilot, to recommend and oversee safety procedures. Restriction of personnel within 50 feet of grounded aircraft and clear written procedures for filming on ground near aircraft with their engines running or during aircraft landings or takeoffs are other safety measures. Coordination with any pyrotechnics or other hazardous special effects operators is essential, as are procedures to ensure the safety of camera operators filming from aircraft. Procedures for aborting an operation are needed.

Vehicle action sequences have also been a source of many accidents and fatalities. Special effects, such as explosions, crashes, driving into rivers and car chase scenes with multiple cars, are the most common cause of accidents. Motorcycle scenes can be even more hazardous than automobiles because the operator of the motorcycle suffers from the lack of personal protection.

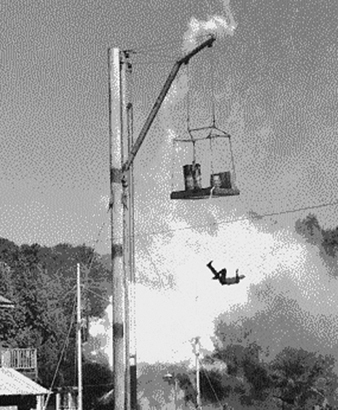

Special precautions include using camera cars. Using stunt drivers for all cars in a stunt scene can lower the accident rate, as can special training for non-stunt passengers. Other safety rules include proper safety equipment, inspection of all ramps and other equipment to be used during a stunt, using dummies in cars during crashes, explosions and other extremely high risk sequences and not driving cars directly towards cameras if there is a camera operator behind the camera. See figure 2 for an example of using dummies in a roller coaster stunt. Adequate ventilation is needed for automobiles that are being filmed indoors with engines running. Stunt motorcycles should be equipped with a deadman switch so that the motor shuts off when the rider separates from the motorcycle.

Figure 2. Using dummies for a roller coaster stunt.

William Avery

Stunts using fire and explosion place performers at higher risk and require special precautions beyond those used just for the special effects. Protection for stunt performers directly exposed to flames includes wearing a protective barrier gel (e.g., Zel Jel) on the hair, the skin, clothing and so on. Proper protective clothing, including fireproof suits under costumes; flame-resistant gloves and boots; and sometimes hidden oxygen tanks, should be supplied. Specially trained personnel equipped with carbon dioxide fire extinguishers should be on hand in case of an emergency.

Fight scenes can involve performers in fistfights or other unarmed combat or the use of knives, swords, firearms and other combat equipment. Many film and stage fights do not involve the use of stunt performers, thus increasing the risk of injury because of the lack of training.

Simulated weapons, such as knives and swords with retractable blades, are one safeguard. Weapons should be stored carefully. Training is key. The performer should know how to fall and how to use specific weapons. Adequate choreography and rehearsals of the fights is needed, as is proper protective clothing and equipment. A blow should never be aimed directly at an actor. If a fight involves a high degree of hazard, such as falling down a flight of stairs or crashing through a window, a professional stunt double should be used.

Falls in stunts can range from falling down a flight of stairs to falling off a horse, being thrown through the air by a trampoline or ratchet catapult system, or a high fall off a cliff or building (figure 3). There have been many injuries and fatalities from poorly prepared falls.

Figure 3. High fall stunt.

Only experienced stunt performers should attempt fall stunts. When possible, the fall should be simulated. For example, falling down a flight of stairs can be filmed a few stairs at a time so the stunt performer is never out of control, or a fall off a tall building simulated by a fall of a few feet onto a net and using a dummy for the rest of the fall. Precautions for high falls involve a high fall coordinator and a specialized fall/arrest system for safe deceleration. Falls of more than 15 feet require two safety spotters. Other precautions for falls include airbags, crash pads of canvas filled with sponge rubber, sand pits and so on, depending on the type of fall. Testing of all equipment is crucial.

Animal scenes are potentially very hazardous because of the unpredictability of animals. Some animals, such as large cats, can attack if startled. Large animals like horses can be a hazard just because of their size. Dangerous, untrained or unhealthy animals should not be used on sets. Venomous reptiles such as rattlesnakes are particularly hazardous. In addition to the hazards to personnel, the health and safety of the animals should be considered.

Only trained animal handlers should be allowed to work with animals. Adequate conditions for the animals are needed, as is basic animal safety equipment, such as fire extinguishers, fire hoses, nets and tranquilizing equipment. Animals should be allowed adequate time to become familiar with the set, and only required personnel should be permitted on the set. Conditions that could upset animals should be eliminated and animals kept from exposure to loud noises or light flashes whenever possible, thus ensuring the animals will not be injured and will not become unmanageable. Certain situations—for example, those using venomous reptiles or large numbers of horses—will require special precautions.

Water stunts can include diving, filming in fast-moving water, speedboat stunts and sea battles. Hazards include drowning, hypothermia in cold water, underwater obstructions and contaminated water. Emergency teams, including certified safety divers, should be on hand for all water stunts. Diver certification for all performers or camera operators using self-contained underwater breathing apparatus (SCUBA) and provision of standby breathing equipment are other precautions. Emergency decompression procedures for dives over 10 m should be in place. Safety pickup boats for rescue and proper safety equipment, such as use of nets and ropes in fast-moving water, are needed.

Health and Safety Programmes

Most major film studios have a full-time health and safety officer to oversee the health and safety programme. Problems of responsibility and authority can occur, however, when a studio rents facilities to a production company, as is increasingly common. Most production companies do not have a health and safety programme. A health and safety officer, with authority to establish safety procedures and to ensure they are carried out, is essential. There is a need to coordinate the activities of others charged with production planning, such as stunt coordinators, special effects operators, firearms experts and the key grip (who is usually the individual most responsible for the safety of sets, cameras, scaffolding, etc.), each of whom has specialized safety knowledge and experience. A health and safety committee that meets regularly with representatives from all departments and unions can provide a conduit between the management and employees. Many unions have an independent health and safety committee which can be a source of health and safety expertise.

Medical services

Both non-emergency and emergency medical services are essential during film production. Many film studios have a permanent medical department, but most production companies do not. The first step in determining the degree of on-location medical services to be provided is a needs assessment, to identify potential medical risks, including the need for vaccination in certain countries, possible local endemic diseases, evaluation of local environmental and climate conditions, and an evaluation of the quality of local medical resources. The second, pre-planning stage involves a detailed analysis of major risks and availability of adequate emergency and other medical care in order to determine what type of emergency planning is essential. In situations where there are high risks and/or remote locations, trained emergency physicians would be needed on location. Where there is quick access to adequate emergency facilities, paramedics or emergency medical technicians with advanced training would suffice. In addition, adequate emergency transportation should be arranged beforehand. There have been several fatalities due to the lack of adequate emergency transportation (Carlson 1989; McCann 1989).

Standards

There are few occupational safety and health regulations aimed specifically at the film production industry. However, many general regulations, such as those affecting fire safety, electrical hazards, scaffolding, lifts, welding and so on, are applicable. Local fire departments generally require special fire permits for filming and may require that standby fire personnel be present on filming sites.

Many productions have special requirements for the licensing of certain special effects operators, such as pyrotechnicians, laser operators and firearms users. There can be regulations and permits required for specific situations, such as the sale, storage and use of pyrotechnics, and the use of firearms.

Scenery Shops

Theatres, motion pictures, television, theme and amusement parks and similar entertainment enterprises all build and paint scenery and make props for their presentations. In many cases, these are made in-house. There are also commercial scenic shops that specialize in making large scenery which is then transported to the site. The major difference between making scenery backstage in a small theatre and building huge sets or even houses for a motion picture, for example, is the scale of the work and who does the work. In small theatres, there is little division of tasks, whereas in larger facilities, there would be a division of labour among carpenters, scenic painters, welders, prop makers and so on.

The scenery for a theatre play, motion picture set or television studio might look realistic, but is often an illusion. The walls of a room are usually not solid but are composed of lightweight flats (panels of painted canvas stretched on wooden frames). Background scenery often consists of backdrops (huge curtains painted to represent the background) which can be lowered and raised for different scenes. Other solid-looking props, such as trees, rocks, vases, mouldings, sculptures and so forth, might be made out of papier mâché, plaster, polyurethane foam or other materials. Today, a wide variety of materials are used to make scenery, including wood, metal, plastics, synthetic fabrics, paper and other modern industrial products. For scenery which performers will walk or climb on, the structures must be solid and meet proper safety standards.

The basic processes and chemicals used for making sets and props tend to be similar for the various types of entertainment facilities. Outdoor sets, however, can often use heavy construction materials such as cement on a large scale, which would be impractical inside due to smaller load-bearing capacities. The degree of hazard depends on the types and amounts of chemicals used, and the precautions taken. A theatre might use quarts of polyurethane foam resin for making small props, while the inside of a tunnel in a theme park set might use hundreds of gallons of the resin. Small in-house shops tend to have less awareness of the hazards, and overcrowding often creates additional hazards due to the proximity of incompatible processes such as welding and use of flammable solvents.

Woodworking

Wood, plywood, particle board and Plexiglas are commonly used in constructing sets. Hazards include: accidents with woodworking machinery, power tools and hand tools; electrical shock; fire from combustible wood dust; and toxic effects from inhalation of wood dust, formaldehyde and methyl methacrylate decomposition products from machining plywood, particle board and Plexiglas, and solvents used with contact adhesives.

Precautions include machine guards, proper electrical safety, housekeeping and adequate storage to reduce fire hazards, dust collectors, adequate ventilation and eye protection.

Welding, Cutting and Brazing

Steel and aluminium frameworks are commonly used for the construction of sets. These are often welded using oxyacetylene torches and arc welders of various types. Injury hazards include fire from flying sparks, fire and explosion from compressed gases, and electrical shock from arc welders; health hazards include metal fumes, fluxes, welding gases (ozone, nitrogen oxides, carbon monoxide) and ultraviolet radiation.

Precautions include removal or protection of combustible materials, proper storage and handling of compressed gas cylinders, electrical safety, adequate ventilation and personal protective equipment.

Scenic Painting

Paints, lacquers, varnishes, dye solutions and other coatings are used for painting scenery flats and fabric drops. The paints and dye solutions can be either solvent based or water based. Powdered pigments and dyes are usually mixed in the shop, with the use of lead chromate pigments still being common. Large flats and drops are often sprayed. Solvents are used for dissolving dyes and resins, thinning, removing paint and other coatings and for cleaning tools, brushes and even hands. Hazards include skin contact with solvents and inhalation of solvent vapours, spray mists and powdered dyes and pigments. Solvents are also fire hazards, particularly when sprayed.

Precautions include elimination of lead pigments, using water-based paints and dyes, adequate ventilation for use of solvents, respiratory protection for spraying, proper storage and handling of flammable liquids and proper disposal of waste solvents and paints.

Plastic Resins

Polyurethane foam resins, epoxy resins, polyester resins and other resins are commonly used to make large sets and props. Spraying of polyurethane foam resins containing diphenylmethane diisocyanate (MDI) is particularly dangerous, with hazards of chemical pneumonia and asthma. Epoxy resins, polyester resins and solvents have skin, eye and inhalation hazards, and are fire hazards.

Precautions include substitution of safer materials (such as cement or celastic instead of spray polyurethane foams, or water-based materials to replace solvent-based types), local exhaust ventilation, proper storage and handling, proper disposal of waste materials and adequate personal protective equipment.

Props and Models

Plastic resins are also used to make body armour, face masks, breakaway glass and other props and models, as are wood, plaster, metal, plastics and so on. A variety of water-based and solvent-based adhesives are also used. Solvents are used in cleanup. Precautions are similar to those already discussed.

Woodworking

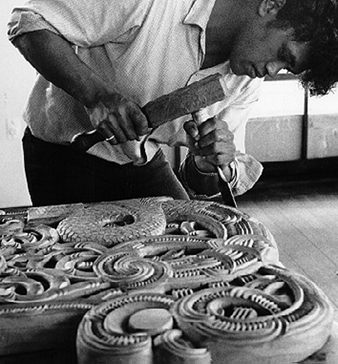

Woodworking is practised as an art form and utilitarian craft all over the world. It includes wood sculpture, furniture and cabinet making (figure 1), musical instrument making and so on. Techniques include carving (figure 2), laminating, joining, sawing, sanding, paint removing, painting and finishing. Woodworking uses a large number of different types of hard and soft woods, including many exotic tropical woods, plywood and composition boards, and sometimes woods treated with pesticides and wood preservatives.

Figure 1. Furniture making.

Figure 2. Carving wood with hand tools.

Hazards and Precautions

Woods

Many woods are hazardous, especially tropical hardwoods. Types of reactions can include skin allergies and irritation from the sap, wood dust or sometimes the wood, as well as conjunctivitis, respiratory allergies, hypersensitivity pneumonia and toxic reactions. Inhalation of hardwood dust is associated with a particular type of nasal and nasal sinus cancer (adenocarcinoma). See the chapter Woodworking industry.

Precautions include avoiding use of sensitizing woods for people who have a history of allergies, or for objects where people would be in frequent contact with the wood, and controlling dust levels by using local exhaust ventilation or wearing a toxic-dust respirator. When handling woods that can cause skin irritation or allergies, the artist should wear gloves or apply a barrier cream. Hands should be washed carefully after work.

Plywoods and composition board

Plywood and composition board (e.g., particle board) are made by gluing thin sheets of wood, or wood dust and chips, together with either urea-formaldehyde glues or phenol-formaldehyde glues. These materials can emit unreacted formaldehyde for some years after manufacture, with composition board emitting more formaldehyde. Heating these materials or machining them can cause decomposition of the glue to release formaldehyde. Formaldehyde is a skin, eye and respiratory irritant and strong sensitizer, and a probable human carcinogen.

Precautions include using low-formaldehyde products whenever possible, not storing large amounts of plywood or composition board in the shop, and using dust collectors connected to woodworking machines that are exhausted to the outside.

Wood preservatives and other treatments

Pesticides and preservatives are often applied to wood when it is being timbered, processed or shipped. Pentachlorophenol and its salts, creosote and chromated copper arsenate (CCA) have been banned for sale in the United States as wood preservatives because of possible carcinogenicity and reproductive hazards. They can, however, still be found in older woods, and chromated copper arsenate is still allowed as a commercial treatment (e.g., “green” lumber, playground equipment and other outdoor uses). A variety of other chemicals can be used in treating wood, including fire retardants and bleaches.

Precautions include not handling woods that have been treated with pentachlorophenol or creosote, using local exhaust ventilation when machining CCA-treated wood or wearing a respirator with high-efficiency filters. Wood that has been treated with creosote, pentachlorophenol or chromated copper arsenate should not be burned.

Carving and machining wood

Woods can be hand carved with chisels, rasps, hand saws, sandpaper and the like, or they can be machined with electric saws, sanders and other woodworking machines. Hazards include exposure to wood dusts, excessive noise levels from woodworking machines, accidents from using tools and machines, electrical shock or fire from faulty wiring, and wood fires. Vibrating tools—for example, chain saws—can cause “white fingers” (Raynaud’s phenomenon), involving numbness of the fingers and hands.

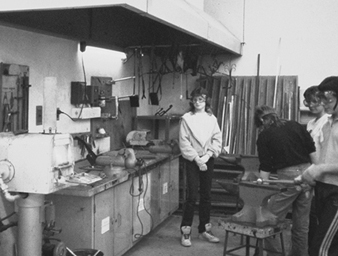

Precautions include equipping woodworking machines with dust collectors (figure 3) and machine guards, cleaning up sawdust to avoid fire hazards, wearing goggles (and sometimes face shields) and reducing noise. Using the appropriate machine for the desired operation, and repairing defective machines immediately; keeping hand tools sharpened, and using them safely; keeping all electrical equipment and wiring in good repair, and avoiding extension cords which can be tripped over; not wearing ties, long loose hair, loose sleeves or other items that could catch in machinery are some other precautions.

Figure 3. Woodworking machines with dust collector.

Michael McCann

Gluing wood

A variety of glues are used for laminating and joining wood, including contact adhesives, casein glue, epoxy glues, formaldehyde-resin glues, hide glues, white glue (polyvinyl acetate emulsion) and the cyanoacrylate “instant” glues. Many of these contain toxic solvents or other chemicals, and can be skin, eye and respiratory hazards.

Precautions include avoiding formaldehyde resin glues; using water-based glues rather then solvent-type glues; wearing gloves or barrier creams when using epoxy glues, solvent-based adhesives or formaldehyde-resin glues; and having good ventilation when using epoxy glues, cyanoacrylate glues and solvent-based glues. Sources of ignition should be avoided when using flammable solvents.

Painting and finishing

Wood can be painted with most types of paint; can be stained, lacquered or varnished; and can be treated with linseed or other types of oil. Other materials that are used in finishing wood include shellacs, polyurethane coatings and waxes. Many materials are sprayed. Some woodworkers mix their own paints from dry pigments. Hazards include inhalation of toxic pigment powder (especially lead chromate pigments), skin and inhalation hazards from solvents, fire hazards from flammable solvents, and spontaneous combustion from rags soaked with oil or turpentine.

Precautions include using ready-made paints rather than mixing your own; avoiding eating, drinking or smoking in the work area; using water-based paints rather than solvent-based ones; and placing oil- and solvent-soaked rags in self-closing oily-waste cans, or even a pail of water.

Precautions with solvents include wearing gloves and goggles, as well as having adequate ventilation; doing the operation outside; or wearing a respirator with organic vapour cartridges. Materials should be brushed on whenever possible, to avoid the hazards of spraying. Spraying finishes inside an explosion-proof spray booth, or wearing a respirator with organic vapour cartridges and spray filters; avoiding open flames, lit cigarettes and other sources of ignition (e.g., lit pilot lights) in the area when applying flammable finishes, or when spraying, are other precautions to be taken.

Paint stripping

Stripping old paint and varnish from wood and furniture is done with paint and varnish removers containing a wide variety of toxic and often flammable solvents. “Non-flammable” paint strippers contain methylene chloride. Caustic soda (sodium hydroxide), acids, blowtorches and heat guns are also used to remove old paint. Old stains on wood are often removed with bleaches, which can contain corrosive alkalis and oxalic acid, hydrogen peroxide or hypochlorite. Heat guns and torches can vaporize the paint, possibly causing lead poisoning with lead-based paint, and are a fire hazard.

See the previous section for precautions with solvent-based paint strippers. Gloves and goggles should be worn when handling caustic soda, oxalic acid bleaches or chlorine-type bleaches. An eyewash fountain and emergency shower should be available. Avoid using torches or heat guns to remove lead-containing paint.

Entertainment and the Arts

Entertainment and the arts have been a part of human history ever since prehistoric people drew cave paintings of animals they hunted or acted out in song and dance the success of the hunt. Every culture from earliest times has had its own style of visual and performing arts, and decorated everyday objects like clothing, pottery and furniture. Modern technology and more leisure time has led to a major part of the world’s economy being devoted to satisfying the need for people to see or own beautiful objects and to be entertained.

The entertainment industry is a miscellaneous grouping of non-commercial institutions and commercial companies that provide these cultural, amusement and recreational activities for people. By contrast, artists and craftspeople are workers who create artwork or handicrafts for their own pleasure or for sale. They usually work alone or in groups of fewer than ten people, often organized around families.

The people who make this entertainment and art possible—artists and craftspeople, actors, musicians, circus performers, park attendants, museum conservators, professional sports players, technicians and others—often face occupational hazards that can result in injuries and illnesses. This chapter will discuss the nature of those occupational hazards. It will not discuss the hazards to people doing arts and crafts as hobbies or attending these entertainment events, although in many instances the hazards will be similar.

Entertainment and the arts can be thought of as a microcosm of all industry. The occupational hazards encountered are, in most instances, similar to those found in more conventional industries, and the same types of precautions can be used, although costs may be prohibitive factors for some engineering controls in the arts and crafts. In these instances, emphasis should be on substitution of safer materials and processes. Table 1 lists standard types of precautions associated with the various hazards found in the arts and entertainment industries.

Table 1. Precautions associated with hazards in the arts and entertainment industries.

|

Hazard |

Precautions |

|

Chemical hazards |

|

|

General |

Training in hazards and precautions Substitution of safer materials Engineering controls Adequate storage and handling No eating, drinking or smoking in work areas Personal protective equipment Spill and leak control procedures Safe disposal of hazardous materials |

|

Airborne contaminants (vapours, gases, spray mists, fogs, dusts, fumes, smoke) |

Enclosure Dilution or local exhaust ventilation Respiratory protection |

|

Liquids |

Cover containers Gloves and other personal protective clothing Splash goggles and face shields as needed Eyewash fountain and emergency showers when needed |

|

Powders |

Purchasing in liquid or paste form Glove boxes Local exhaust ventilation Wet mopping or vacuuming Respiratory protection |

|

Solids |

Gloves |

|

Physical hazards |

|

|

Noise |

Quieter machinery Proper maintenance Sound dampening Isolation and enclosure Hearing protectors |

|

Ultraviolet radiation |

Enclosure Skin protection and UV goggles |

|

Infrared radiation |

Skin protection and infrared goggles |

|

Lasers |

Using lowest-power laser possible Enclosure Beam restrictions and proper emergency cutoffs Laser goggles |

|

Heat |

Acclimatization Light, loose clothing Rest breaks in cool areas Adequate liquid intake |

|

Cold |

Warm clothing Rest breaks in heated areas |

|

Electrical hazards |

Adequate wiring Properly grounded equipment Ground fault circuit interrupters where needed Insulated tools, gloves, etc. |

|

Ergonomic hazards |

Ergonomic tools, instruments, etc., of proper size Properly designed work stations Proper posture Rest breaks |

|

Safety hazards |

|

|

Machinery |

Machine guards Accessible stop switch Good maintenance |

|

Flying particles (e.g., grinders) |

Enclosure Eye and face protection as needed |

|

Slips and falls |

Clean and dry walking and working surfaces Fall protection for elevated work Guardrails and toeboards on scaffolds, catwalks, etc. |

|

Falling objects |

Safety hats Safety shoes |

|

Fire hazards |

Proper exit routes Proper fire extinguishers, sprinklers, etc. Fire drills Removal of combustible debris Fireproofing of exposed materials Proper storage of flammable liquids and compressed gases Grounding and bonding when dispensing flammable liquids Removal of sources of ignition around flammables Proper disposal of solvent- and oil-soaked rags |

|

Biological hazards |

|

|

Moulds |

Humidity control Removal of standing water Cleanup after flooding |

|

Bacteria, viruses |

Vaccination where appropriate Universal precautions Disinfection of contaminated materials, surfaces |

Arts and Crafts

Artists and craftspeople are usually self-employed, and the work is done in homes, studios or backyards, using small amounts of capital and equipment. Skills are often handed down from generation to generation in an informal apprenticeship system, particularly in developing countries (McCann 1996). In industrialized countries, artists and craftspeople often learn their trade in schools.

Today, arts and crafts involve millions of people across the world. In many countries, craftwork is a major part of the economy. However, few statistics are available on the number of artists and craftspeople. In the United States, estimates gathered from a variety of sources indicate there are at least 500,000 professional artists, craftspeople and art teachers. In Mexico, it has been estimated that there are 5,000 families involved in the home-based pottery industry alone. The Pan American Health Organization found that 24% of the workforce in Latin America from 1980 to 1990 were self-employed (PAHO 1994). Other studies of the informal sector have found similar or higher percentages (WHO 1976; Henao 1994). What percentage of these are artists and craftspeople is unknown.