Food and Fibre Crops

Rice

Rice is the staple food for Asian people; it is prepared by cooking or ground as flour for bread making, thus helping to feed the rest of the world population. Various kinds of rice are produced to suit the taste of the consumers. Rice cultivation is done either in marshy, lowland areas with plenty of water or in plateau or hilly regions where natural rainfall provides adequate amounts of water.

Cultivation Process

Rice can be cultivated either by hand or by partial or full mechanization, according to the technological development of the country and the need for productivity. Whatever kind of operation is done, the following step-by-step processes are necessary.

- Ploughing. The land is ploughed in three stages to eliminate lumps and to make soil as soft and muddy as possible. Buffalo, oxen or cows usually pull the ploughs, though the use of mechanical equipment is increasing.

- Weeding is carried out three times by irrigating the land for 5 days at a time and then letting it dry for 5 days. At the end of each cycle, the land is beaten with a heavy wooden tool to kill off young weeds so they may be used as natural fertilizer.

- Preparation of seedlings. The seeds are soaked in a large water-filled jar with appropriate concentrations of salt added to make the healthy seeds sink. These healthy seeds are then thoroughly washed, soaked overnight, wrapped in a thick cloth or sack for 2 nights to germinate, sown in the area prepared for them and left to grow for approximately 30 days.

- Transplantation. The young plants, in bunches of 3 to 5, are thrust into the mud in rows and grown for 10 days. After about a total of 45 days, the plant is fully grown and begins to bear seeds.

- Harvesting. When the plant is about 100 days old, it is usually reaped by hand (see figure 1); sickles or similar tools are used for cutting the bearing grains off.

- Drying is done in the open air in the sun, to make the moisture content fall below 15%.

- Threshing separates the grain, with its husk or glume, from the stalk. Traditionally, buffaloes or oxen are used to slowly drag the threshing combs over the stalk to force out the grain. Many places use locally made machines for this.

- Storage. Grains and hays are stored in barns or silos.

Figure 1. Harvesting of rice plants by hand in China, 1992

Lenore Manderson

Hazards

Common and specific hazards are as follows:

- Poor housing, low sanitary standards, inadequate nourishment and the need to drink large quantities of water, which is not always pure, lead to general weakness and fatigue, possible sunstroke, intestinal troubles and diarrhoea.

- Most injuries caused by farm machinery occur when the workers are not familiar with the machines. Muscles, bones and joints are intensively used, both in dynamic and static loads, causing physical fatigue and resulting in the reduction of work capacity and an increase in traumatic injuries and accidents. Children and adolescents, as well as migrant workers, die from farm injuries each year.

- Chemical agents, such as fertilizers, strong weedkillers, pesticides and other extensively used substances, increase the hazards both for the workers and the animal or plant foods they consume (e.g., fish, field crabs, water plants, mushrooms, medicinal herbs, field rats or even contaminated water).

- Diseases (e.g., malaria, tetanus, hookworm, schistosomiasis, leptospirosis, hay fever, farmer’s lung, dermatitis, blepharitis, conjunctivitis, common cold and sunstroke) are very common, as are nutritional disorders (e.g., protein deficiency, toxins), alcoholism, heavy smoking and other addictive habits.

- The most common occupational diseases are skin diseases. These include: redness and blisters from prickly rice leaves; abrasions and skin injuries caused by prickly plants; calluses of the palms, hands, knees and elbows caused by bad posture and the use of hand tools; skin fungal infections (tinea) due to epidermophytes and Monilia (candida), which may be complicated by secondary sensitization, redness and blisters, frequently due to Staphylococcus bacteria; vesicular dermatitis (small blisters) on the feet sometimes attributed to Rhizopus parasiticus; itch commonly caused by the penetration of the skin by Ancylostoma (hookworms); schistosome dermatitis caused directly or indirectly by contact with water containing blood flukes from nonhuman hosts; and redness, blisters and oedema resulting from insect stings.

- Respiratory diseases due to organic and inorganic dusts and synthetic chemicals are common. Gram-negative bacterial endotoxin levels in air are high in some countries. Silage gas poisoning of high nitrate soils is also a health problem.

- Climatic agents such as heat, heavy rain, humidity, high wind, storms and lightning strike both workers and cattle.

- Psychological stress factors such as economic problems, sense of insecurity, lack of social standing, lack of educational opportunities, lack of prospects and risk of unexpected calamities are particularly common in the developing countries.

Safety and Health Measures

Working conditions should be improved and the health hazards reduced through increased mechanization. Ergonomic interventions to organize the work and working equipment, and systematic training of the body and its movements to ensure good working methods, are essential.

Necessary medical preventive methods should be strictly applied, including the introduction of first aid instruction, the provision of treatment facilities, health promotion campaigns and medical surveillance of workers.

Improvement of housing, sanitary standards, accessible potable water, nutritional environmental hygiene and economic stability are essential for the quality of life of rice field workers.

Applicable International Labour Organization (ILO) Conventions and Recommendations should be followed. These include:

- The Minimum Age (Agriculture) Convention, 1921 (No.10), provides that children under the age of 14 years may not be employed or work in any public or private agricultural undertakings, or in any branch thereof, when school is in session.

- The Night Work of Children and Young Persons (Agriculture) Recommendation, 1921 (No.14), requires that each Member State regulate the employment of children under the age of 14 years in agricultural tasks at night, leaving not less than 10 consecutive hours for them to rest. For young persons between the age of 14 and 18 years, the period of rest must consist of not less than 9 consecutive hours.

- The Plantations Convention, 1958 (No.110), provides that every recruited worker shall be medically examined. This Convention is obviously of great importance for workers of all ages.

- The Maximum Weight Convention, 1967 (No.127), identified optimum loads that can be handled by 90% of workers for all routine and repetitive manual-handling tasks.

Agricultural Grains and Oilseeds

Several plants in the grass family, including wheat, rye, barley, oats, corn, rice, sorghum and millet, are valuable agricultural commodities, representing the largest effort in production agriculture. Grains provide a concentrated form of carbohydrates and are an important source of food for animals and humans.

In the human diet, grains make up about 60% of the calories and 55% of the protein, and are used for food as well as beverages. Bread is the most commonly recognized food product made from grains, although grains are also important in the production of beer and liquor. Grain is a basic ingredient in the distillation of neutral spirits that produce liquors with the taste and aroma of grain. Grains also are used to make feed for animals, including pets, working animals and animals raised in the production of meat products for human consumption.

Grain production can be traced to the beginning of civilization. In 1996, world production of cereal grains was 2,003,380,000 tonnes. This volume has increased more than 10% since the mid-1980s (FAO 1997).

Three of the major grains produced for their oil, also called oilseeds, are soybean, rapeseed and sunflower. Although ten different types of oilseed crops exist, these three account for the majority of the market, with soybean as the leader. Virtually all oilseeds are crushed and processed to produce vegetable oils and high-protein meals. Much of the vegetable oil is used as salad or cooking oils, and meal is used predominantly in animal feeds. World oilseed production in 1996 was 91,377,790 tonnes, almost a 41% increase since 1986 (FAO 1997).

The production of grains and oilseeds is affected by regional factors such as weather and geography. Dry soils and environments restrict corn production, while moist soils deter wheat production. Temperature, precipitation, soil fertility and topography also affect the type of grain or oilseed that can be successfully produced in an area.

For production of grain and oilseed crops, work falls into four areas: seed bed preparation and planting, harvest, storage and transportation of the crop to market or processing facilities. In modern agriculture, some of these processes have changed completely, but other processes have changed little since early civilization. However, the mechanization of agriculture has created new situations and safety issues.

Hazards and Their Prevention

All tools used in grain harvest—from complex combines to the simple scythe—have one aspect in common: they are hazardous. Harvest tools are aggressive; they are designed to cut, chew or chop plant materials placed into them. These tools do not discriminate between a crop and a person. Various mechanical hazards associated with grain harvesting include shear-point, pull-in, crush-point, entanglement, wrap-point and pinch-point. A combine pulls in cornstalks at a rate of 3.7 metres per second (m/s), too quickly for humans to avoid entanglement, even with a normal reaction time. Augers and PTO units used to move grain, rotate and have wrapping speeds of 3 m/s and 2 m/s, respectively, and also pose an entanglement hazard.

Agricultural workers also can experience noise-induced hearing loss from large-horsepower machinery and equipment used in crop production. Axial-vane fans that force heated air through a bin or storage structure to dry grain can generate noise levels of 110 dBA or more. Since grain-drying units often are located near living quarters and are operated continuously throughout a season, they often result in substantial hearing loss in farmworkers as well as family members over long periods of time. Other sources of noise that can contribute to hearing loss are machinery such as tractors, combines and conveying equipment, and grain moving through a gravity spout.

Agricultural workers also can be exposed to significant suffocation hazards by engulfment either in flowing grain or collapsing grain surfaces. A person caught in grain is almost impossible to rescue because of the tremendous weight of grain. Workers can prevent engulfment in flowing grain by always turning off all power sources to the unloading and transporting equipment before they enter an area and locking shut all gravity flow gates. Engulfment in a collapsed grain surface is difficult to prevent, but workers can avoid the situation by knowing the history of the storage structure and the grain it contains. All workers should follow confined-space entry procedures for physical engulfment hazards when working with grain.

During the harvest, storage and transportation of grains and oilseeds, agricultural workers are exposed to dusts, spores, mycotoxins and endotoxins that can be harmful to the respiratory system. Biologically active dust is capable of producing irritation and/or allergic, inflammatory or infectious responses in the lungs. Workers can avoid or reduce their exposure to dust, or wear personal protective equipment such as mechanical filter respirators or air-supplied respirators in dusty environments. Some handling and storage systems minimize the creation of dust, and additives such as vegetable oils can keep dust from becoming airborne.

In some conditions during storage, grain can spoil and emit gases that pose a suffocation hazard. Carbon dioxide (CO2) can collect above a grain surface to displace oxygen, which can cause impairment in workers if oxygen levels drop below 19.5%. Mechanical filter respirators are useless in these situations.

Another hazard is the potential for fires and explosions that can occur when grains or oilseeds are stored or handled. Dust particles that become airborne when grain is moved create an atmosphere ripe for a powerful blast. Only an ignition source is needed, such as an overheated bearing or a belt rubbing against a housing component. The biggest hazards exist at large port elevators or inland community elevators where huge volumes of grain are handled. Regular preventive maintenance and good housekeeping policies minimize the risk of possible ignition and explosive atmospheres.

Chemicals used at the beginning of the crop production cycle for seed-bed preparation and planting also can pose hazards for agricultural workers. Chemicals can increase soil fertility, reduce competition from weeds and insects and boost yields. The biggest concern for agricultural chemicals hazards is long-term exposure; however, anhydrous ammonia, a compressed liquid fertilizer, can cause immediate injury. Anhydrous ammonia (NH3) is a hygroscopic, or water-seeking, compound, and caustic burns result when it dissolves body tissue. Ammonia gas is a strong lung irritant, but has good warning properties. It also has a low boiling point and freezes on contact, causing another type of severe burn. Wearing protective equipment is the best way to reduce risk of exposure. When exposure occurs, first aid treatment requires immediately flushing of the area with plenty of water.

Grain production workers also are exposed to potential injury from slips and falls. A person can die from injuries in a fall from a height as low as 3.7 m, which is easily exceeded by operator’s platforms on most machinery or grain storage structures. Grain storage structures are at least 9 and up to 30 m tall, reachable only by ladders. Inclement weather can cause slippery surfaces from rain, mud, ice or snow build-up, so the use of guards, handrails and footwear with non-slip soles is important. Devices such as a body harness or lanyard also can be used to arrest the fall and minimize injury.

Sugar Cane Cultivation and Processing

Adapted from 3rd edition, “Encyclopaedia of Occupational Health and Safety”.

Cultivation

Sugar cane is a hardy crop that is cultivated in tropical and sub-tropical regions for its sucrose content and by-products such as molasses and bagasse (the waste fibrous residue). The plant grows in clumps of cylindrical stalks measuring from 1.25 to 7.25 cm in diameter and reaching 6 to 7 m in height. The cane stalks grow straight upward until the stalk becomes too heavy to hold itself up. It then lies on its side and continues to grow upward. This results in a mature cane field lying on top of itself in a mesh pattern. The sugar cane stalks contain a sap from which sugar is processed. Sugar cane is grown throughout the Caribbean, Central and South America, India, the Pacific Islands, Australia, Central and South Africa, Mauritius and the southern United States. Sugar cane’s main use is for sugar; however, it can be fermented and distilled to produce rum. Bagasse, the cellulose material that remains after pressing, may be used in the production of paper and other products or as a fuel source.

Under favourable conditions and the appropriate use of pesticides and fertilizers, cane grows rapidly. To ensure the maximum sugar content of 1 to 17% of total weight, the cane must be harvested immediately after it reaches its final growth period. The cane fields are burned prior to harvest, to eliminate weeds (without destroying the crop) and to destroy snakes, dangerous insects and other pests that live in the dense growth of the cane fields. Harvesting is done either by hand (machetes are used to cut the cane) or by a sugar cane harvesting machine. Mechanization of sugar cane harvesting has become more prevalent during the 1990s. However, hand harvesting still occurs in many parts of the world, as well as in field locations that are not conducive for harvesting equipment. Large numbers of seasonal or migrant labourers are employed during cane harvesting, especially in areas of hand harvesting.

To retain the sugar content, the cane has to be processed as soon as possible after harvesting; therefore the processing plants (mills) are located near the major areas of sugar cane production. The crop is transported to the mills by tractors, semi trucks or, in some areas, by internal rail systems.

Hazards and their prevention

In areas where hand harvesting prevails, many of the injuries are machete related. These injuries can range from minor cuts to the severing of body parts. Also, the machete is the tool that is most commonly used by the less skilled workers on the farm or plantation. Keeping the machete sharp aids in reducing injuries, since with a sharp machete the worker does not have to swing as hard and can maintain better control over the machete. There are also instances of workers getting into fights with machetes. Safety gloves armoured with chain mesh have been developed to provide protection for the hand from machete-related injuries. The use of steel-toed boots and arm and leg guards will also reduce these types of injuries. Boots will also provide some protection from snake bites. Working with cane also can very easily produce injuries and cuts to the eyes. Eye protection is recommended during hand harvesting, where workers are exposed to the cane stalks. Since cane is grown in tropical and sub-tropical locations, workers also need to be concerned about heat-related health problems. This can be exacerbated due to use of the necessary protective clothing. These regions are also areas of high levels of sun exposure, which can result in various types of skin cancer conditions. Precautions need to be taken to limit or protect against sun exposure.

Manual harvesting with machetes can also result in musculoskeletal injuries from the repetitive motions and physical effort. The size of the machete, sharpness and frequency of cutting strokes are factors that affect this. See also the article “Manual operations in farming” in this chapter.

Precautions need to be taken to prevent infection when cuts and abrasions occur. Where the harvesting has become mechanized, hazards exist that are associated with the particular machine being used. These are similar to those of other agricultural harvesting equipment.

Pesticides and other chemicals may involve toxic risks that can lead to poisoning through skin absorption or inhalation. People who apply the pesticides need to be instructed on the hazards of the operation and provided with protective clothing and adequate washing facilities. Their equipment needs to be maintained and repaired as needed in order to prevent spills. Back-pack sprayers are particularly prone to develop leaks that will cause spillage onto the person. Aerial applications of pesticides can affect other people that are in the area of the application. Also, when pesticides are applied, the product label provides both legal and practical requirements for handling and disposal after use, as well as listing time intervals after which it is safe for people to re-enter the field.

Sugar Cane Mills (Processing Plants)

The sugar cane industry is concerned with more than the production of food for human consumption. Certain kinds of sugar and sugar residues provide nutritious supplementary food for animals, and various products of commercial significance are obtained from the raw material and its by-products.

Principal by-products are saccharose, glucose, levulose, raffinose, pectin, waxes and betaines. Subproducts are stalks (used for fodder), bagasse, rum and molasses. Among products manufactured on an industrial scale are saccharose octacetate, ethyl alcohol and acetic, citric, glutamic, oxalic, formic and saccharic acids. Paper and hardboard are produced industrially from bagasse. Bagasse can also, when dried, be used as a biogas source or as fuel in the sugar mill.

In the sugar mill, the cane is crushed and the juice extracted by heavy rollers. The juice contains saccharose, glucose, levulose, organic salts and acids in solution, and is mixed with bagasse fibres, grit, clay, colouring matter, albumin and pectin in suspension. Because of the properties of albumin and the pectin, the juice cannot be filtered cold. Heat and chemicals are required to eliminate the impurities and to obtain saccharose.

The mixture is clarified by heating and the addition of lime-based precipitants. Once clarified, the juice is concentrated by vacuum evaporation until it precipitates in the form of grayish crystals. The concentrated juice, or molasses, is 45% water. Centrifugal treatment produces granulated sugar of a grayish hue (brown sugar), for which there is a market. White sugar is obtained by a refining process. In this process, the brown sugar is dissolved with various chemicals (sulphuric anhydride, phosphoric acid) and filtered with or without bone black, according to the purity desired. The filtered syrup evaporates under a vacuum until it crystallizes. It is then centrifuged until a white crystalline powder is obtained.

Hazards and their prevention

Worker conditions will vary according to geographical locale. Seasonal workers are especially vulnerable to living in substandard conditions. Health risks will vary in relation to the environmental factors, working conditions, living conditions and the socioeconomic class of the worker.

Due to the high temperatures in the areas where cane is produced, workers need to consume large quantities of liquid.

Fumes and gases such as carbon dioxide, sulphur dioxide, carbon monoxide and hydrochloric acid may be given off at various stages of the refining process. The high temperatures of processing can also result in fumes and steam that are not only irritating or hot, but sometimes can be toxic as well.

In some areas of the mill, there are excessive noise levels.

Bagassosis is an occupational lung disease of the extrinsic allergic alveolitis type, caused by breathing dusts containing spores of thermophilic actinomycetes which grow in stored, mouldy bagasse. Hypersensitivity pneumonitis can also result from this exposure.

In developing countries, workers may be unskilled, with no safety training. Also there may be a high turnover rate for employees, which can lead to problems in keeping up with training and increasing skill levels. Although statistical data do not show a high incidence of occupational disease, this can be due in part to reporting and calculating problems, such as the fact that the mills and refining plants are not open year-round, but only for 5 to 6 months of the year. Thus annual accident rates may appear low. During the remainder of the year, seasonal workers will be employed in entirely different jobs, while permanent employees will be maintaining and working with the machinery, equipment and facilities.

Occupational accidents, such as falls, strains, sprains and so on, differ little from those in other industrial and agricultural activities. With increasing mechanization, the occupational accidents are fewer but are often more serious. The more frequent injuries include diseases related to heat stroke or heat stress, dermatitis, conjunctivitis, burns and falls.

In order to plan and put into effect a health and safety programme for a specific sugar mill, it is necessary to conduct a qualitative and quantitative assessment of the risks and hazards involved, including identification of corrective measures, such as the use of local exhaust systems for dust, gas and fumes where appropriate. Dust control can be used effectively for controlling bagasse dust. The facility should be properly aired and ventilated to reduce excessive heat, and adequate lighting should be provided. Machinery should be properly guarded, and proper protective clothing should be provided and easily accessible to workers. Health and safety standards and regulations must be complied with. A proper safety programme, for which trained staff are responsible, to ensure the safety of the workers should be in place.

Noise is a widespread hazard. Noisy machines should be soundproofed, and, in areas where the noise level cannot be reduced adequately, hearing protection must be provided and a hearing conservation programme instituted. That programme should include audiometric testing and worker training.

Potato Harvesting

Roots and tubers are a major part of the diet, food energy and nutrient source for more than 1 billion people in the developing world. Root crops are used to produce food products including composite flours, noodles, chips and dehydrated products. They provide about 40% of the diet for half of the sub-Saharan African population. Cassava has become one of the developing world’s most important staples, providing a basic diet to about 500 million people. Cassava has also become an important export crop for animal feed in Europe.

Roots and tubers—potatoes, sweet potatoes, cassava, yams and taro—are known as the starchy foods. They are high in carbohydrates, calcium and vitamin C, but low in protein. These foods are the subsistence crops in some of the poorest countries. Several root food crops are staples in major world regions. These include the yam in Indochina, Indonesia and Africa; the potato in South America, Central America, Mexico and Europe; and the cassava and sweet potato in South America (Alexandratos 1995).

The potato was introduced into Ireland in the 1580s, and a small plot could feed a six-child family, a cow and a pig. Moreover, the crop could remain in the soil protected from the winter freezes and fires. The potato became the food of the poor in Ireland, England, France, Germany, Poland and Russia. In 1845, a blight struck the potato across Europe, which resulted in the great, fatal potato famine in Ireland, where substitute crops were unavailable (Tannahill 1973).

The potato is still a principal crop in the developed world. Its production continues to increase in the United States, and much of this increase is attributed to processed potatoes. Growth in processed potatoes is occurring in chips and shoestrings, frozen French fries, other frozen products and canned potatoes. The principal occupational hazards are related to injury and are experienced during the mechanical harvesting operation. In a Canadian study, potato farmers were found to be at elevated risk of pancreatic cancer, but no association was made with an exposure.

Hazards

Each moving part of the potato harvester carries the potential for injury. The tractor’s PTO shaft, which connects the tractor and the harvester by universal joints or yokes, is the source of kinetic energy and of injuries. The PTO shaft should be shielded. The most common injury on a PTO shaft occurs when the yoke catches a loose piece of clothing, entangling the wearer.

All hydraulic systems operate under pressure, even as much as 2,000 pounds per square inch (14,000 Kpa), which is three times the pressure needed to penetrate skin. Thus a worker should never cover a leaking hydraulic hose with a finger since the fluid could be injected through the skin. If any fluid is injected into the skin, it must be surgically removed within a few hours or gangrene may develop. If any point in the hydraulic system fails, a serious injury can occur. A ruptured hydraulic hose can spray fluid a great distance. Hydraulic systems store energy. Careless servicing or adjusting can lead to injury.

A pinch-type injury can occur where two machinery parts move together and at least one of them moves in a circle. Gear and belt drives are examples of pinch points. Clothing or body parts can catch and become drawn into the gears. Proper guarding of potato harvester parts reduces the chance of a pinch-type injury.

A wrap-type injury can occur when an exposed, unshielded rotating component, such as a PTO shaft, entangles a loose piece of clothing: a sleeve, a shirt-tail, a frayed piece of clothing or even long hair. Smooth PTO shafts with rust or nicks can be rough enough to catch clothing; a slowly rotating PTO shaft must still be regarded with caution. However, the rounder, smoother shafts are less likely to catch clothing than square shafts. The universals at the end of the PTO shafts are the most likely to catch loose clothing and cause a wrap-type injury. These bulky parts extend beyond the PTO shaft and can cause a wrap-type injury even if one is clear of the PTO shaft. PTO shafts from the tractor to the potato harvester must be guarded. No one should work amid unsafe conditions such as unshielded PTO shafts.

Shear points are areas where two pieces move in a cutting motion. A finger placed in a boom joint or between a fan belt and the pulley would be quickly severed. The belt, turned by the engine that drives the fan, is a site for amputation as well as other bodily injuries. Again, proper shielding of potato harvester parts reduces the chance of a shear injury.

Crush points are found where two objects move towards each other, or an object moves toward a stationary object. Big trucks are involved in a potato harvest. Movement in the field and especially in a closed facility such as a potato storage building can lead to runovers and crushed feet or legs.

A pull-in injury occurs when a worker is pulled into machinery. Pull-in injuries can occur any time there is an attempt to remove something from a potato harvester while it is operating, even if it is not moving forward.

Thrown-object injuries occur when projectiles are hurled. Air-assisted potato harvesters routinely throw soil and small rocks in the process of separating potato tubers from rocks. The soil and debris are thrown with enough force to cause eye injuries.

Prevention

Fortunately, there is a great deal that can be done to avoid injuries. Clothing can make the difference between being caught in a pinch or wrap point and being safe. Loose, long hair can catch in wrap and pinch points and drag the worker’s head into a dangerous spot. Long hair should be securely tied. Skid-resistant shoes help keep the worker from slipping while standing on the sorting platform, which may be treacherous with mud and vines. Gloves, if worn while working on the sorting table, should be tight fitting and not have frayed edges or floppy cuffs.

Attitude, alertness and avoiding dangerous situations complement safe attire. No one should ever mount or dismount a potato harvester while it is in motion. The rider must wait until the harvester stops. Many of the serious and debilitating injuries occur from falling and being crushed while attempting to mount or dismount a moving harvester. One should try to be in a stable position before the tractor starts to pull the potato harvester. This will reduce the possibility of falling down as the tractor jerks forward. No one should ever be between the tractor and the harvester while they are in motion or when they are started. The tractor operator or the workers riding the potato harvester should never be close enough to touch the PTO shaft while it is running or when it is started. Harvesters should not be lubricated, adjusted or repaired while running. No attempt to dislodge anything from the belts should be made while they are in motion.

Vegetables and Melons

A wide variety of vegetables (herbaceous plants) is grown for edible leaves, stems, roots, fruits and seeds. Crops include leafy salad crops (e.g., lettuce and spinach), root crops (e.g., beets, carrots, turnips), cole crops (cabbage, broccoli, cauliflower) and many others grown for their fruit or seed (e.g., peas, beans, squashes, melons, tomatoes).

Since the 1940s, the nature of vegetable farming, particularly in North America and Europe, has changed dramatically. Previously, most fresh vegetables were grown close to population centres by garden or truck farmers and were available only during or shortly after harvest. The growth of supermarkets and the development of large food-processing companies created a demand for steady, year-round supplies of vegetables. At the same time, large-scale vegetable production on commercial farms became possible in areas far from major population centres because of rapidly expanding irrigation systems, improved insect sprays and weed control, and the development of sophisticated machinery for planting, spraying, harvesting and grading. Today, the main source of fresh vegetables in the United States is long-season areas, such as the states of California, Florida, Texas and Arizona, and Mexico. Southern Europe and North Africa are major vegetable sources for northern Europe. Many vegetables are also grown in greenhouses. Farmers’ markets selling local produce, however, remain the major outlet for vegetable growers throughout much of the world, particularly in Asia, Africa and South America.

Vegetable farming requires substantial skills and care to ensure production of high-quality vegetables that will sell. Vegetable farming operations include soil preparation, planting and growing crops, harvesting, processing and transportation. Weed and pest control and water management are crucial.

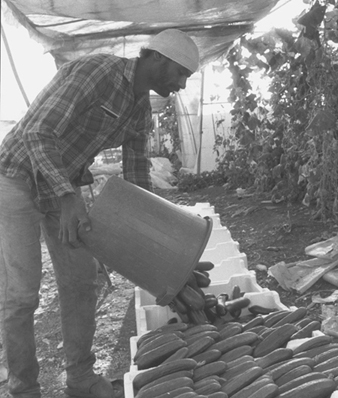

Vegetable and melon workers are exposed to many occupational hazards in their working environment, which include plants and their products, agrochemicals for controlling pests and oils and detergents for maintaining and repairing machinery. Manual or automatic work also forces the workers into uncomfortable positions (see figure 1). Musculoskeletal disorders such as low-back pain are important health problems in these workers. Agricultural tools and machines used with vegetables and melons give rise to high risks for traumatic injuries and various health impairments similar to those seen in other agricultural work. In addition, outdoor growers are exposed to solar radiation and heat, whereas exposure to pollens, endotoxins and fungi should be taken into account among greenhouse farmers. Therefore, a wide variety of work-related disorders can be found in those populations.

Figure 1. Manual labour on a vegetable farm near Assam, Jordan

Food allergies to vegetables and melons are well known. They are mostly provoked by vegetable allergens and can cause an immediate reaction. Clinically, mucocutaneous and respiratory symptoms appear in most patients. Occupational allergy among vegetable workers differs from food allergy in several ways. Occupational allergens are diverse, including those of vegetable origin, chemicals and biological derivatives. Artichoke, brussels sprouts, cabbage, carrot, celery, chicory, chive, endive, garlic, horseradish, leek, lettuce, okra, onion, parsley and parsnip have been reported to contain vegetable allergens and to sensitize vegetable workers. Occupational allergies to melon allergens, however, are seldom reported. Only a few allergens from vegetables and melons have been isolated and identified because of the difficulty and complexity of the laboratory techniques required. Most allergens, especially those of vegetable origin, are fat soluble, but a few are water soluble. The ability to sensitize also varies depending on botanical factors: The allergens may be sequestered in resin canals and released only when the vegetables are bruised. However, in other cases they may be readily released by fragile grandular hairs, or be excreted onto the leaf, coat the pollens or be widely disseminated by the action of wind on trichomes (hair-like growths on the plants).

Clinically, the most common occupational allergic diseases reported in the vegetable workers are allergic dermatitis, asthma and rhinitis. Extrinsic allergic alveolitis, allergic photodermatitis and allergic urticaria (hives) can be seen in some cases. It should be emphasized that vegetables, melons, fruits and pollens have some allergens in common or cross-reacting allergens. This implies that atopic persons and individuals with an allergy to one of those may become more susceptible than others in the development of occupational allergies. To screen and diagnose these occupational allergies, a number of immune tests are currently available. In general, the prick test, intradermal test, measurement of allergen-specific IgE antibody and in vivo allergen challenge test are used for immediate allergies, whereas the patch test can be chosen for delayed-type allergy. The allergen-specific lymphocyte proliferation test and cytokine production are helpful in diagnosing both types of allergy. These tests can be performed using native vegetables, their extracts and released chemicals.

Dermatoses such as pachylosis, hyperkeratosis, nail injury chromatosis and dermatitis are observed in vegetable workers. In particular, contact dermatitis, both irritant and allergic, occurs more frequently. Irritant dermatitis is caused by chemical and/or physical factors. Vegetable parts such as thrichomes, spicules, coarse hairs, raphides and spines are responsible for most of this irritation. On the other hand, allergic dermatitis is classified into immediate and delayed types on the basis of their immunopathogenesis. The former is mediated through humoural immune responses, whereas the later is mediated through cellular immune responses.

Clinically, many patients with allergic dermatitis experience a range of symptoms including itching, erythema, rash, swelling and vesicles. The sites of lesions are mainly the hands, arms, face and neck. In a field survey of Japanese okra growers (Nomura 1993), more than 50% of farmers had skin lesions, and these appeared mostly on the hands and arms. About 20 to 30% of farmers showed a positive patch test reaction to okra pad or leaf extracts. Furthermore, proteolytic activity of okra extracts was shown to cause the skin lesions.

Agricultural chemicals are also important allergens responsible for allergic dermatitis. These include insecticides (DDVP, diazinon, EPN, malathion, naled, parathion and so on), fungicides (benomyl, captafol, captan, maneb, manzeb, nitrofen, plondrel®, thiram, zineb, ziram and so on), herbicides (carbyne, randox and so on) and fumigants (D-D® mixture of 1,3-dichloropropene and 1,1,2-dichloropropane and related compounds). Additionally, opportunistic bacteria and Streptococcus pyogenes are found to play an important role in allergic dermatitis and urticaria for vegetable workers.

Vegetable workers, especially those working in greenhouses or indoors, are exposed to many vegetable products and to compounds such as pesticides, which are responsible for increased lung diseases. In a national study conducted among Swiss farmers, it was documented that the age-standardized proportional mortality for all lung diseases, bronchitis and asthma, and asthma alone were 127, 140 and 137, respectively. Vegetable products can directly cause occupational allergic asthma, or provide non-specific irritants and/or the vehicle for other allergens including pollens, spores, mites and other substances. Vegetable products which can cause allergic asthma are bromelin, castor beans and wax, freesia, grain pollen, guar gum, papain, paprika, hops, ipecacuanha, plicatic acid, quillaic acid, saponin and sunflower pollen.

Fungi in the work environment produce many spores, some of which cause allergic asthma and/or extrinsic allergic alveolitis. However, it is rare that allergic asthma and extrinsic allergic alveolitis from those allergens occur in the same subjects. As for the causative micro-organisms, Alternaria, Aspergillus niger, Cladosporium, humidifier sludge, Merulius lacrymans, Micropolyspora faei, Paecilomyces and Verticillium have been identified. In most cases, antigens of fungal origin are present in spores and breakdown products.

Patients with occupational asthma caused by vegetable products always show elevated serum IgE antibody, eosinophilia and a positive prick test, whereas specific precipitating antibody, positive prick test and distinct radiological findings are seen in patients with extrinsic allergic alveolitis. In addition to pulmonary allergy to vegetable products and fungi spores, nasal symptoms are provoked in atopic patients when handling vegetables such as carrots and lettuce. Gastrointestinal complaints are not generally found.

Agrochemicals are applied for various purposes both in indoor and outdoor vegetable growing. Among the chemicals used, some have been found to have asthmatic potential. They include captafol, chlorothalonil, creosote, formaldehyde, pyrethrin and streptomycin. The improper uses of pesticides potentially can result in soil and vegetable contamination. The application of pesticides without suitable personal protective equipment can lead to both acute or chronic toxic effects.

" DISCLAIMER: The ILO does not take responsibility for content presented on this web portal that is presented in any language other than English, which is the language used for the initial production and peer-review of original content. Certain statistics have not been updated since the production of the 4th edition of the Encyclopaedia (1998)."