47. Noise

Chapter Editor: Alice H. Suter

Table of Contents

Figures and Tables

The Nature and Effects of Noise

Alice H. Suter

Noise Measurement and Exposure Evaluation

Eduard I. Denisov and German A. Suvorov

Engineering Noise Control

Dennis P. Driscoll

Hearing Conservation Programmes

Larry H. Royster and Julia Doswell Royster

Standards and Regulations

Alice H. Suter

Tables

Click a link below to view table in article context.

1. Permissible exposure limits (PEL)for noise exposure, by nation

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

The Nature and Effects of Noise

The Pervasive Nature of Occupational Noise

Noise is one of the most common of all the occupational hazards. In the United States, for example, more than 9 million workers are exposed to daily average A-weighted noise levels of 85 decibels (abbreviated here as 85 dBA). These noise levels are potentially hazardous to their hearing and can produce other adverse effects as well. There are approximately 5.2 million workers exposed to noise above these levels in manufacturing and utilities, which represents about 35% of the total number of workers in US manufacturing industries.

Hazardous noise levels are easily identified and it is technologically feasible to control excessive noise in the vast majority of cases by applying off-the-shelf technology, by redesigning the equipment or process or by retrofitting noisy machines. But all too often, nothing is done. There are several reasons for this. First, although many noise control solutions are remarkably inexpensive, others can be costly, especially when the aim is to reduce the noise hazard to levels of 85 or 80 dBA.

One very important reason for the absence of noise control and hearing conservation programmes is that, unfortunately, noise is often accepted as a “necessary evil”, a part of doing business, an inevitable part of an industrial job. Hazardous noise causes no bloodshed, breaks no bones, produces no strange-looking tissue, and, if workers can manage to get through the first few days or weeks of exposure, they often feel as though they have “got used” to the noise. But what has most likely happened is that they have started to incur a temporary hearing loss which dulls their hearing sensitivity during the work day and often subsides during the night. Thus, the progress of noise-induced hearing loss is insidious in that it creeps up gradually over the months and years, largely unnoticed until it reaches handicapping proportions.

Another important reason why the hazards of noise are not always recognized is that there is a stigma attached to the resulting hearing impairment. As Raymond Hétu has demonstrated so clearly in his article on rehabilitation from noise-induced hearing loss elsewhere in this Encyclopaedia, people with hearing impairments are often thought of as elderly, mentally slow and generally incompetent, and those at risk of incurring impairments are reluctant to acknowledge either their impairments or the risk for fear of being stigmatized. This is an unfortunate situation because noise-induced hearing losses become permanent, and, when added to the hearing loss that naturally occurs with ageing, can lead to depression and isolation in one’s middle and old age. The time to take preventive steps is before the hearing losses begin.

The Scope of Noise Exposure

As mentioned above, noise is especially prevalent in the manufacturing industries. The US Department of Labor has estimated that 19.3% of the workers in manufacturing and utilities are exposed to daily average noise levels of 90 dBA and above, 34.4% are exposed to levels above 85 dBA, and 53.1% to levels above 80 dBA. These estimates should be fairly typical of the percentage of workers exposed to hazardous levels of noise in other nations. The levels are likely to be somewhat higher in less developed nations, where engineering controls are not used as widely, and somewhat lower in nations with stronger noise control programmes, such as the Scandinavian countries and Germany.

Many workers throughout the world experience some very hazardous exposures, well above 85 or 90 dBA. For example, the US Labor Department has estimated that nearly half a million workers are exposed to daily average noise levels of 100 dBA and above, and more than 800,000 to levels between 95 and 100 dBA in the manufacturing industries alone.

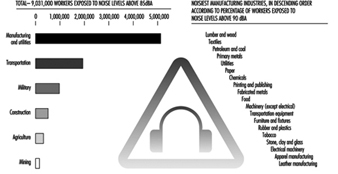

Figure 1 ranks the noisiest manufacturing industries in the United States in descending order according to the percentage of workers exposed above 90 dBA and gives estimates of noise-exposed workers by industrial sector.

Figure 1. Occupational noise exposure—the US experience

Research Needs

In the following articles of this chapter, it should become clear to the reader that the effects on hearing of most types of noise are well-known. Criteria for the effects of continuous, varying and intermittent noise were developed some 30 years ago and remain essentially the same today. This is not true, however, of impulse noise. At relatively low levels, impulse noise seems to be no more damaging and possibly less so than continuous noise, given equal sound energy. But at high sound levels, impulse noise appears to be more damaging, especially when a critical level (or, more correctly, a critical exposure) is exceeded. Further research needs to be performed to define more exactly the shape of the damage/risk curve.

Another area that needs to be clarified is the adverse effect of noise, both on hearing and on general health, in combination with other agents. Although the combined effects of noise and ototoxic drugs are fairly well known, the combination of noise and industrial chemicals is of growing concern. Solvents and certain other agents appear to be increasingly neurotoxic when experienced in conjunction with high levels of noise.

Around the world, noise-exposed workers in the manufacturing industries and the military receive the major share of attention. There are, however, many workers in mining, construction, agriculture and transportation who are also exposed to hazardous levels of noise, as pointed out in figure 1. The unique needs associated with these occupations need to be assessed, and noise control and other aspects of hearing conservation programmes need to be extended to these workers. Unfortunately, the provision of hearing conservation programmes to noise-exposed workers does not guarantee that hearing loss and the other adverse effects of noise will be prevented. Standard methods to evaluate the effectiveness of hearing conservation programmes do exist, but they can be cumbersome and are not widely used. Simple evaluation methods need to be developed that can be used by small as well as large companies, and those with minimal resources.

The technology exists to abate most noise problems, as mentioned above, but there is a large gap between the existing technology and its application. Methods need to be developed by which information on all kinds of noise control solutions can be disseminated to those who need it. Noise control information needs to be computerized and made available not only to users in developing nations but to industrialized nations as well.

Future Trends

In some countries there is a growing trend to place more emphasis on non-occupational noise exposure and its contribution to the burden of noise-induced hearing loss. These kinds of sources and activities include hunting, target shooting, noisy toys and loud music. This focus is beneficial in that it highlights some potentially significant sources of hearing impairment, but it can actually be detrimental if it diverts attention from serious occupational noise problems.

A very dramatic trend is evident among the nations belonging to the European Union, where standardization for noise is progressing at an almost breathless pace. This process includes standards for product noise emissions as well as for noise exposure standards.

The standard-setting process is not moving rapidly at all in North America, especially in the United States, where regulatory efforts are at a standstill and movement toward deregulation is a possibility. Efforts to regulate the noise of new products were abandoned in 1982 when the Noise Office in the US Environmental Protection Agency was closed, and occupational noise standards may not survive the deregulatory climate in the current US Congress.

The developing nations appear to be in the process of adopting and revising noise standards. These standards are tending toward conservatism, in that they are moving toward a permissible exposure limit of 85 dBA, and toward an exchange rate (time/intensity trading relation) of 3 dB. How well these standards are enforced, especially in burgeoning economies, is an open question.

The trend in some of the developing nations is to concentrate on controlling noise by engineering methods rather than to struggle with the intricacies of audiometric testing, hearing protection devices, training and record keeping. This would appear to be a very sensible approach wherever feasible. Supplementation with hearing protectors may be necessary at times to reduce exposures to safe levels.

The Effects of Noise

Certain of the materials which follow have been adapted from Suter, AH, “Noise and the conservation of hearing”, Chapter 2 in Hearing Conservation Manual (3rd ed.), Council for Accreditation in Occupational Hearing Conservation, Milwaukee, WI, USA (1993).

Loss of hearing is certainly the most well-known adverse effect of noise, and probably the most serious, but it is not the only one. Other detrimental effects include tinnitus (ringing in the ears), interference with speech communication and with the perception of warning signals, disruption of job performance, annoyance and extra-auditory effects. Under most circumstances, protecting workers’ hearing should protect against most other effects. This consideration provides additional support for companies to implement good noise control and hearing conservation programmes.

Hearing impairment

Noise-induced hearing impairment is very common, but it is often underrated because there are no visible effects and, in most cases, no pain. There is only a gradual, progressive loss of communication with family and friends, and a loss of sensitivity to sounds in the environment, such as birdsong and music. Unfortunately, good hearing is usually taken for granted until it is lost.

These losses may be so gradual that individuals do not realize what has happened until the impairment becomes handicapping. The first sign is usually that other people do not seem to speak as clearly as they used to. The hearing-impaired person will have to ask others to repeat themselves, and he or she often becomes annoyed with their apparent lack of consideration. Family and friends will often be told, “Don’t shout at me. I can hear you, but I just can’t understand what you’re saying.”

As the hearing loss becomes worse, the individual will begin to withdraw from social situations. Church, civic meetings, social occasions and theatre begin to lose their attraction and the individual will choose to stay at home. The volume of the television becomes a source of contention within the family, and other family members are sometimes driven out of the room because the hearing-impaired person wants it so loud.

Presbycusis, the hearing loss that naturally accompanies the ageing process, adds to the hearing handicap when the person with noise-induced hearing loss becomes older. Eventually, the loss may progress to such a severe stage that the individual can no longer communicate with family or friends without great difficulty, and then he or she is indeed isolated. A hearing aid may help in some cases, but the clarity of natural hearing will never be restored, as the clarity of vision is with eyeglasses.

Occupational hearing impairment

Noise-induced hearing impairment is usually considered an occupational disease or illness, rather than an injury, because its progression is gradual. On rare occasions, an employee may sustain immediate, permanent hearing loss from a very loud event such as an explosion or a very noisy process, such as riveting on steel. In these circumstances the hearing loss is sometimes referred to as an injury and is called “acoustic trauma”. The usual circumstance, however, is a slow decrease in hearing ability over many years. The amount of impairment will depend on the level of the noise, the duration of the exposure and the susceptibility of the individual worker. Unfortunately, there is no medical treatment for occupational hearing impairment; there is only prevention.

The auditory effects of noise are well documented and there is little controversy over the amount of continuous noise that causes varying degrees of hearing loss (ISO 1990). That intermittent noise causes hearing loss is also uncontested. But periods of noise that are interrupted by periods of quiet can offer the inner ear an opportunity to recover from temporary hearing loss and may therefore be somewhat less hazardous than continuous noise. This is true mainly for outdoor occupations, but not for inside settings such as factories, where the necessary intervals of quiet are rare (Suter 1993).

Impulse noise, such as the noise from gunfire and metal stamping, also damages hearing. There is some evidence that the hazard from impulse noise is more severe than that from other types of noise (Dunn et al. 1991; Thiery and Meyer-Bisch 1988), but this is not always the case. The amount of damage will depend mainly on the level and duration of the impulse, and it may be worse when there is continuous noise in the background. There is also evidence that high-frequency sources of impulse noise are more damaging than those composed of lower frequencies (Hamernik, Ahroon and Hsueh 1991; Price 1983).

Hearing loss due to noise is often temporary at first. During the course of a noisy day, the ear becomes fatigued and the worker will experience a reduction in hearing known as temporary threshold shift (TTS). Between the end of one workshift and the beginning of the next the ear usually recovers from much of the TTS, but often, some of the loss remains. After days, months and years of exposure, the TTS leads to permanent effects and new amounts of TTS begin to build onto the now permanent losses. A good audiometric testing programme will attempt to identify these temporary hearing losses and provide for preventive measures before the losses become permanent.

Experimental evidence indicates that several industrial agents are toxic to the nervous system and produce hearing loss in laboratory animals, especially when they occur in combination with noise (Fechter 1989). These agents include (1) heavy metal hazards, such as lead compounds and trimethyltin, (2) organic solvents, such as toluene, xylene and carbon disulphide, and (3) an asphyxiant, carbon monoxide. Recent research on industrial workers (Morata 1989; Morata et al. 1991) suggests that certain of these substances (carbon disulphide and toluene) can increase the damaging potential of noise. There is also evidence that certain drugs which are already toxic to the ear can increase the damaging effects of noise (Boettcher et al. 1987). Examples include certain antibiotics and cancer chemotherapy drugs. Those in charge of hearing conservation programmes should be aware that workers exposed to these chemicals or using these drugs may be more susceptible to hearing loss, especially when exposed to noise in addition.

Non-occupational hearing impairment

It is important to understand that occupational noise is not the only cause of noise-induced hearing loss among workers, but hearing loss can also be caused by sources outside the workplace. These sources of noise produce what is sometimes called “sociocusis”, and their effects on hearing are impossible to differentiate from occupational hearing loss. They can only be surmised by asking detailed questions about the worker’s recreational and other noisy activities. Examples of sociocusic sources could be woodworking tools, chain saws, unmuffled motorcycles, loud music and firearms. Frequent shooting with large-calibre guns (without hearing protection) may be a significant contributor to noise-induced hearing loss, whereas occasional hunting with smaller-calibre weapons is more likely to be harmless.

The importance of non-occupational noise exposure and the resulting sociocusis is that this hearing loss adds to the exposure that an individual might receive from occupational sources. For the sake of workers’ overall hearing health, they should be counselled to wear adequate hearing protection when they engage in noisy recreational activities.

Tinnitus

Tinnitus is a condition that frequently accompanies both temporary and permanent hearing loss from noise, as well as other types of sensorineural hearing loss. Often referred to as a “ringing in the ears”, tinnitus may range from mild in some cases to severe in others. Sometimes individuals report that they are more bothered by their tinnitus than they are by their hearing impairment.

People with tinnitus are likely to notice it the most in quiet conditions, such as when they are trying to go to sleep at night, or when they are sitting in a sound-proof booth taking an audiometric test. It is a sign that the sensory cells in the inner ear have been irritated. It is often a precursor to noise-induced hearing loss and therefore an important warning signal.

Communication interference and safety

The fact that noise can interfere with or “mask” speech communication and warning signals is only common sense. Many industrial processes can be carried out very well with a minimum of communication among workers. Other jobs, however, such as those performed by airline pilots, railroad engineers, tank commanders and many others rely heavily on speech communication. Some of these workers use electronic systems that suppress the noise and amplify the speech. Nowadays, sophisticated communication systems are available, some with devices that cancel unwanted acoustic signals so that communication can take place more easily.

In many cases, workers just have to make do, straining to understand communications above the noise and shouting above it or signalling. Sometimes people may develop hoarseness or even vocal nodules or other abnormalities on the vocal cords from excessive strain. These individuals may need to be referred to for medical care.

People have learned from experience that in noise levels above about 80 dBA they have to speak very loudly, and in levels above 85 dBA they have to shout. In levels much above 95 dBA they have to move close together to communicate at all. Acoustical specialists have developed methods to predict the amount of communication that can take place in industrial situations. The resulting predictions are dependent upon the acoustical characteristics of both the noise and the speech (or other desired signal), as well as the distance between talker and listener.

It is generally known that noise can interfere with safety, but only a few studies have documented this problem (e.g., Moll van Charante and Mulder 1990; Wilkins and Acton 1982). There have been numerous reports, however, of workers who have got clothing or hands caught in machines and have been seriously injured while their co-workers were oblivious to their cries for help. To prevent communication breakdowns in noisy environments, some employers have installed visual warning devices.

Another problem, recognized more by noise-exposed workers themselves than by professionals in hearing conservation and occupational health, is that hearing protection devices may sometimes interfere with the perception of speech and warning signals. This appears to be true mainly when the wearers already have hearing losses and the noise levels fall below 90 dBA (Suter 1992). In these cases, workers have a very legitimate concern about wearing hearing protection. It is important to be attentive to their concerns and either to implement engineering noise controls or to improve the kind of protection offered, such as protectors built into an electronic communication system. In addition, hearing protectors are now available with a flatter, more “high fidelity” frequency response, which may improve workers’ abilities to understand speech and warning signals.

Effects on job performance

The effects of noise on job performance have been studied both in the laboratory and in actual working conditions. The results have shown that noise usually has little effect on the performance of repetitive, monotonous work, and in some cases can actually increase job performance when the noise is low or moderate in level. High levels of noise can degrade job performance, especially when the task is complicated or involves doing more than one thing at a time. Intermittent noise tends to be more disruptive than continuous noise, particularly when the periods of noise are unpredictable and uncontrollable. Some research indicates that people are less likely to help each other and more likely to exhibit antisocial behaviour in noisy environments than in quiet ones. (For a detailed review of the effects of noise on job performance see Suter 1992).

Annoyance

Although the term “annoyance” is more often connected with community noise problems, such as airports or race-car tracks, industrial workers may also feel annoyed or irritated by the noise of their workplace. This annoyance may be related to the interference of speech communication and job performance described above, but it may also be due to the fact that many people have an aversion to noise. Sometimes the aversion to noise is so strong that a worker will look for employment elsewhere, but that opportunity is not often feasible. After a period of adjustment, most will not appear to be bothered as much, but they may still complain about fatigue, irritability and sleeplessness. (The adjustment will be more successful if young workers are properly fitted with hearing protectors from the start, before they develop any hearing loss.) Interestingly, this kind of information sometimes surfaces after a company starts a noise control and hearing conservation programme because the workers would have become aware of the contrast between earlier and subsequently improved conditions.

Extra-auditory effects

As a biological stressor, noise can influence the entire physiological system. Noise acts in the same way that other stressors do, causing the body to respond in ways that may be harmful in the long run and lead to disorders known as the “stress diseases”. When facing danger in primitive times, the body would go through a series of biological changes, preparing either to fight or to run away (the classic “fight or flight” response). There is evidence that these changes still persist with exposure to loud noise, even though a person may feel “adjusted” to the noise.

Most of these effects appear to be transitory, but with continued exposure some adverse effects have been shown to be chronic in laboratory animals. Several studies of industrial workers also point in this direction, while some studies show no significant effects (Rehm 1983; van Dijk 1990). The evidence is probably strongest for cardiovascular effects such as increased blood pressure, or changes in blood chemistry. A significant set of laboratory studies on animals showed chronic elevated blood pressure levels resulting from exposure to noise around 85 to 90 dBA, which did not return to baseline after cessation of the exposure (Peterson et al. 1978, 1981 and 1983).

Studies of blood chemistry show increased levels of the catecholamines epinephrine and norepinephrine due to noise exposure (Rehm 1983), and a series of experiments by German investigators found a connection between noise exposure and magnesium metabolism in humans and animals (Ising and Kruppa 1993). Current thinking holds that the extra-auditory effects of noise are most likely mediated psychologically, through aversion to noise, making it very difficult to obtain dose-response relationships. (For a comprehensive overview of this problem, see Ising and Kruppa 1993.)

Because the extra-auditory effects of noise are mediated by the auditory system, meaning that it is necessary to hear the noise for adverse effects to occur, properly fitted hearing protection should reduce the likelihood of these effects in just the way it does with hearing loss.

Noise Measurement and Exposure Evaluation

For the prevention of adverse effects of noise on workers, attention should be paid to the choice of appropriate instrumentation, measuring methods and procedures for evaluating workers’ exposures. It is important to evaluate correctly the different types of noise exposures, such as continuous, intermittent and impulse noise, to distinguish noise environments with differing frequency spectra, as well as to consider the variety of working situations, such as drop-forge hammering shops, rooms housing air compressors, ultrasonic welding processes, and so forth. The main purposes of noise measurement in occupational settings are to (1) identify overexposed workers and quantify their exposures and (2) assess the need both for engineering noise control and the other types of control that are indicated. Other uses of noise measurement are to evaluate the effectiveness of particular noise controls and to determine the background levels in audiometric rooms.

Measuring Instruments

Instruments for noise measurement include sound level meters, noise dosimeters and auxiliary equipment. The basic instrument is the sound level meter, an electronic instrument consisting of a microphone, an amplifier, various filters, a squaring device, an exponential averager and a read-out calibrated in decibels (dB). Sound level meters are categorized by their precision, ranging from the most precise (type 0) to the least (type 3). Type 0 is usually used in the laboratory, type 1 is used for other precision sound level measurements, type 2 is the general purpose meter, and type 3, the survey meter, is not recommended for industrial use. Figure 1 and figure 2, illustrate a sound level meter.

Figure 1. Sound level meter—calibration check. Courtesy of Larson Davis

Figure 2. Sound level meter with wind screen. Courtesy of Larson Davis

Specifications for sound level meters may be found in national and international standards, such as the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). The IEC publications IEC 651 (1979) and IEC 804 (1985) pertain to sound level meters of types 0, 1, and 2, with frequency weightings A, B, and C, and “slow,” “fast” and “impulse” time constants. ANSI S1.4-1983, as amended by ANSI S1.4A-1985, also provides specifications for sound level meters.

To facilitate more detailed acoustical analysis, full octave-band and 1/3 octave-band filter sets may be attached to or included in modern sound level meters. Nowadays, sound level meters are becoming increasingly small and easy to use, while at the same time their measurement possibilities are expanding.

For measuring non-steady noise exposures, such as those that occur in intermittent or impulse noise environments, an integrating sound level meter is most convenient to use. These meters can simultaneously measure the equivalent, peak and maximum sound levels, and calculate, log and store several values automatically. The noise dose meter or “dosimeter” is a form of integrating sound level meter that can be worn in the shirt pocket or attached to the worker’s clothing. Data from the noise dosimeter may be computerized and printed out.

It is important to make sure that noise measuring instruments are always properly calibrated. This means checking the instrument’s calibration acoustically before and after each day’s use, as well as making electronic assessments at appropriate intervals.

Measurement Methods

The noise measurement methods to be used depend on the measurement objectives, namely, to assess the following:

- the risk of hearing impairment

- the need for and appropriate types of engineering controls

- the “noise load” for compatibility with the type of job to be performed

- the background level necessary for communication and safety.

International standard ISO 2204 gives three types of method for noise measurement: (1) the survey method, (2) the engineering method and (3) the precision method.

The survey method

This method requires the least amount of time and equipment. Noise levels of a working zone are measured with a sound level meter using a limited number of measuring points. Although there is no detailed analysis of the acoustic environment, time factors should be noted, such as whether the noise is constant or intermittent and how long the workers are exposed. The A-weighting network is usually used in the survey method, but when there is a predominant low-frequency component, the C-weighting network or the linear response may be appropriate.

The engineering method

With this method, A-weighted sound level measurements or those using other weighting networks are supplemented with measurements using full octave or 1/3 octave-band filters. The number of measuring points and the frequency ranges are selected according to the measurement objectives. Temporal factors should again be recorded. This method is useful for assessing interference with speech communication by calculating speech interference levels (SILs), as well as for engineering noise abatement programmes and for estimating the auditory and non-auditory effects of noise.

The precision method

This method is required for complex situations, where the most thorough description of the noise problem is needed. Overall measurements of sound level are supplemented with full octave or 1/3 octave-band measurements and time histories are recorded for appropriate time intervals according to the duration and fluctuations of the noise. For example, it may be necessary to measure peak sound levels of impulses using an instrument’s “peak hold” setting, or to measure levels of infrasound or ultrasound, requiring special frequency measuring capabilities, microphone directivity, and so forth.

Those who use the precision method should make sure that the instrument’s dynamic range is sufficiently great to prevent “overshoot” when measuring impulses and that the frequency response should be broad enough if infrasound or ultrasound is to be measured. The instrument should be capable of making measurements of frequencies as low as 2 Hz for infrasound and up to at least 16 kHz for ultrasound, with microphones that are sufficiently small.

The following “common sense” steps may be useful for the novice noise measurer:

- Listen for the main characteristics of the noise to be measured (temporal qualities, such as steady-state, intermittent or impulse qualities; frequency characteristics, such as those of wide-band noise, predominant tones, infrasound, ultrasound, etc.). Note the most prominent characteristics.

- Choose the most suitable instrumentation (type of sound level meter, noise dosimeter, filters, tape recorder, etc.).

- Check the instrument’s calibration and performance (batteries, calibration data, microphone corrections, etc.).

- Make notes or a sketch (if using a system) of the instrumentation, including model and serial numbers.

- Make a sketch of the noise environment to be measured, including major noise sources and the size and important characteristics of the room or outdoor setting.

- Measure the noise and note down the level measured for each weighting network or for each frequency band. Also note the meter response (such as “slow,” “fast,” “impulse,” etc.), and note the extent to which the meter fluctuates (e.g., plus or minus 2 dB).

If measurements are made outdoors, pertinent meteorological data, such as wind, temperature and humidity should be noted if they are considered important. A windscreen should always be used for outdoor measurements, and even for some indoor measurements. The manufacturer’s instructions should always be followed to avoid the influence of factors such as wind, moisture, dust and electrical and magnetic fields, which may affect the readings.

Measuring procedures

There are two basic approaches to measuring noise in the workplace:

- The exposure of each worker, worker type or worker representative may be measured. The noise dosimeter is the preferable instrument for this purpose.

- Noise levels may be measured in various areas, creating a noise map for the determination of risk areas. In this case, a sound level meter would be used to take readings at regular points in a coordinate network.

Worker Exposure Evaluation

To assess the risk of hearing loss from specific noise exposures, the reader should consult the international standard, ISO 1999 (1990). The standard contains an example of this risk assessment in its Annex D.

Noise exposures should be measured in the vicinity of the worker’s ear and, in assessing the relative hazard of workers’ exposures, subtractions should not be made for the attenuation provided by hearing protection devices. The reason for this caveat is that there is considerable evidence that the attenuation provided by hearing protectors as they are worn on the job is often less than half the attenuation estimated by the manufacturer. The reason for this is that the manufacturer’s data are obtained under laboratory conditions and these devices are not usually fitted and worn so effectively in the field. At the moment, there is no international standard for estimating the attenuation of hearing protectors as they are worn in the field, but a good rule of thumb would be to divide the laboratory values in half.

In some circumstances, especially those involving difficult tasks or jobs requiring concentration, it may be important to minimize the stress or fatigue related to noise exposure by adopting noise control measures. This may be true even for moderate noise levels (below 85 dBA), when there is little risk of hearing impairment, but the noise is annoying or fatiguing. In such cases it may be useful to perform loudness assessments using ISO 532 (1975), Method for Calculating Loudness Level.

Interference with speech communication may be estimated according to ISO 2204 (1979) using the “articulation index”, or more simply by measuring the sound levels in the octave bands centred at 500, 1,000 and 2,000 Hz, resulting in the “speech interference level”.

Exposure criteria

The selection of noise exposure criteria depends on the goal to be attained, such as the prevention of hearing loss or the prevention of stress and fatigue. Maximum permissible exposures in terms of daily average noise levels vary among nations from 80, to 85, to 90 dBA, with trading parameters (exchange rates) of 3, 4, or 5 dBA. In some countries, such as Russia, permissible noise levels are set anywhere from 50 to 80 dBA, according to the type of job performed and taking into account the mental and physical work load. For example, the allowable levels for computer work or the performance of demanding clerical work are 50 to 60 dBA. (For more information on exposure criteria, see the article “Standards and regulations” in this chapter.)

Engineering Noise Control

Ideally, the most effective means of noise control is to prevent the source of noise from entering into the plant environment in the first place—by establishing an effective “Buy Quiet” programme to furnish the workplace with equipment engineered for low noise output. To carry out such a programme, a clear, well-written statement of specifications for limiting noise characteristics of new plant equipment, facilities and processes must be designed to take the hazard of noise into account. A good programme builds in monitoring and maintenance as well.

Once equipment is installed and excess noise identified through sound level measurements, the problem of controlling noise becomes more complicated. However, there are engineering controls available which can be retrofitted to existing equipment. In addition, there is usually more than one noise control option for each problem. Therefore, it becomes important for the individual managing the noise control programme to determine the most feasible and economical means available for noise reduction in each given situation.

Controlling Noise in Factory and Product Design

The use of written specifications to define the requirements for equipment, its installation, and acceptance are standard practice in today’s environment. One of the foremost opportunities in the area of noise control available to the factory designer is to influence the selection, purchase and layout of new equipment. When properly written and administered, implementation of a “Buy Quiet” programme through purchase specifications can prove to be an effective means of controlling noise.

The most proactive approach towards controlling noise in the facility design and equipment procurement stage exists in Europe. In 1985, the twelve member states of the European Community (EC)—now the European Union (EU)— adopted “New Approach” Directives designed to address a broad class of equipment or machinery, rather than individual standards for each type of equipment. By the end of 1994 there had been three “New Approach” Directives issued that contain requirements on noise. These Directives are:

- Directive 89/392/EEC, with two amendments 91/368/EEC and 93/44/EEC

- Directive 89/106/EEC

- Directive 89/686/EEC, with one amendment 93/95/EEC.

The first item listed above (89/392/EEC) is commonly called the Machinery Directive. This Directive compels equipment manufacturers to include noise control as an essential part of machine safety. The basic aim of these measures is that for machinery or equipment to be sold within the EU, it must satisfy the essential requirements regarding noise. As a result, there has been a major emphasis on the design of low-noise equipment since the late 1980s by manufacturers interested in marketing within the EU.

For companies outside the EU attempting to implement a voluntary “Buy Quiet” programme, the degree of success achieved is largely dependent upon the timing and commitment of the entire management hierarchy. The first step in the programme is to establish acceptable noise criteria for construction of a new plant, expansion of an existing facility and purchase of new equipment. For the programme to be effective, the specified noise limits must be viewed by both the purchaser and vendor as an absolute requirement. When a product does not meet other equipment design parameters, such as size, flow rate, pressure, allowable temperature rise, and so forth, it is deemed unacceptable by company management. This is the same commitment that must be followed regarding noise levels in order to achieve a successful “Buy Quiet” programme.

As regards the timing aspect mentioned above, the earlier in the design process that consideration is given to the noise aspects of a project or equipment purchase, the greater the probability of success. In many situations, the factory designer or equipment buyer will have a choice of equipment types. Knowledge of the noise characteristics of the various alternatives will allow him or her to specify the quieter ones.

Besides selection of the equipment, early involvement in the design of the equipment layout within the plant is essential. Relocating equipment on paper during the design phase of a project is clearly much easier than physically moving the equipment later, especially once the equipment is in operation. A simple rule to follow is to keep machines, processes and work areas of approximately equal noise level together; and separate particularly noisy and particularly quiet areas by buffer zones having intermediate noise levels.

Validation of noise criteria as an absolute requirement requires a cooperative effort between company personnel from departments such as engineering, legal, purchasing, industrial hygiene and environment. For example, the industrial hygiene, safety, and/or personnel departments may determine the desired noise levels for equipment, as well as conduct sound surveys to qualify equipment. Next, company engineers may write the purchase specification, as well as select quiet types of equipment. The purchasing agent will most likely administer the contract and rely upon the law department representatives for assistance with enforcement. Involvement from all these parties should begin with the inception of the project and continue through funding requests, planning, design, bidding, installation and commissioning.

Even the most thorough and concise specification document is of little value unless the onus of compliance is placed on the supplier or manufacturer. Clear contract language must be used to define the means of determining compliance. Company procedures designed to enact guarantees should be consulted and followed. It may be desirable to include penalty clauses for non-compliance. Foremost in one’s enforcement strategy is the purchaser’s commitment to seeing that the requirements are met. Compromise on the noise criteria in exchange for cost, delivery date, performance, or other concessions should be the exception and not the rule.

Within the United States, ANSI has published the standard ANSI S12.16: Guidelines for the Specification of Noise of New Machinery (1992). This standard is a useful guide for writing an internal company noise specification. In addition, this standard provides direction for obtaining sound level data from equipment manufacturers. Once obtained from the manufacturer, the data may then be used by plant designers in planning equipment layouts. Because of the various types of distinctive equipment and tools for which this standard has been prepared, there is no single survey protocol appropriate for the measurement of sound level data. As a result, this standard contains reference information on the appropriate sound measurement procedure for testing a variety of stationary equipment. These survey procedures were prepared by the appropriate trade or professional organization in the United States responsible for a particular type or class of equipment.

Retrofitting Existing Equipment

Before one can decide what needs to be done, it becomes necessary to identify the root cause of noise. Towards this end, it is useful to have an understanding as to how noise is generated. Noise is created for the most part by mechanical impacts, high-velocity air flow, high-velocity fluid flow, vibrating surface areas of a machine, and quite often by the product being manufactured. As regards the lattermost item, it is often the case in manufacturing and process industries such as metal fabrication, glass manufacturing, food processing, mining, and so forth, that the interaction between the product and machines imparts the energy that creates the noise.

Source identification

One of the most challenging aspects of noise control is identification of the actual source. In a typical industrial setting there are usually multiple machines operating simultaneously, which makes it difficult to identify the root cause of noise. This is especially true when a standard sound level meter (SLM) is used to evaluate the acoustical environment. The SLM typically provides a sound pressure level (SPL) at a specific location, which is most likely the result of more than one noise source. Therefore, it becomes incumbent upon the surveyor to employ a systematic approach that will help separate out the individual sources and their relative contribution to the overall SPL. The following survey techniques may be used to help with identifying the origin or source of noise:

- Measure the frequency spectrum and graph the data.

- Measure the sound level, in dBA, as a function of time.

- Compare frequency data from similar equipment or production lines.

- Isolate components with temporary controls, or by turning on and off individual items whenever possible.

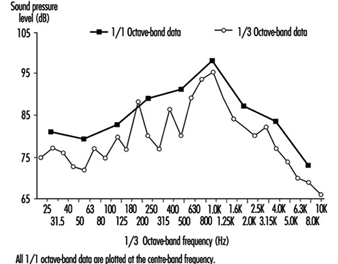

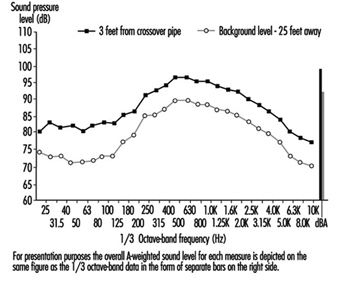

One of the most effective methods for locating the source of the noise is to measure its frequency spectrum. Once the data are measured, it is very useful to graph the results so that one can visually observe the characteristics of the source. For most noise abatement problems, the measurements can be accomplished with either full (1/1) or one-third (1/3) octave-band filters used with the SLM. The advantage of 1/3 octave-band measurement is that it provides more detailed information about what is emanating from a piece of equipment. Figure 1 exhibits a comparison between 1/1 and 1/3 octave-band measurements conducted near a nine-piston pump. As depicted in this figure, the 1/3 octave-band data clearly identifies the pumping frequency and many of its harmonics. If one used only 1/1, or full octave-band data, as depicted by the solid line and plotted at each centre-band frequency in figure 1, it becomes more difficult to diagnose what is occurring within the pump. With 1/1 octave-band data there are a total of nine data points between 25 Hertz (Hz) and 10,000 Hz, as shown in this figure. However, there are a total of 27 data points in this frequency range with the use of 1/3 octave-band measurements. Clearly, 1/3 octave-band data will provide more useful data towards identifying the root cause of a noise. This information is critical if the objective is to control noise at the source. If the only interest is to treat the path along which sound waves are transmitted, then 1/1 octave-band data will be sufficient for purposes of selecting acoustically appropriate products or materials.

Figure 1. Comparison between 1/1 and 1/3 octave-band data

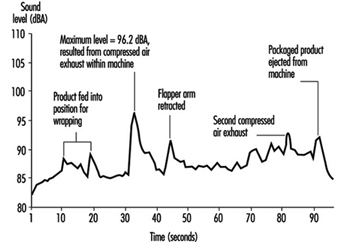

Figure 2 shows a comparison between the 1/3 octave-band spectrum measured 3 feet from the crossover pipe of a liquid chiller compressor and the background level measured approximately 25 feet away (please note the approximations given in the footnote). This position represents the general area where employees typically walk through this room. For the most part the compressor room is not routinely occupied by workers. The only exception exists when maintenance workers are repairing or overhauling other equipment in the room. Besides the compressor, there are several other large machines operating in this area. To assist with the identification of the primary noise sources, several frequency spectrums were measured near each of the equipment items. When each spectrum was compared to the data at the background position in the walkway, only the crossover pipe of the compressor unit exhibited a similar spectrum shape. Consequently, it may be concluded this is the primary noise source controlling the level measured at the employee walkway. So as depicted in figure 2, through the use of frequency data measured near the equipment and graphically comparing individual sources to the data recorded at employee workstations or other areas of interest, it is often possible to identify the dominant sources of noises clearly.

Figure 2. Comparison of crossover pipe versus background level

When the sound level fluctuates, as with cyclic equipment, it is useful to measure the overall A-weighted sound level versus time. With this procedure it is important to observe and document what events are occurring over time. Figure 3 exhibits the sound level measured at the operator’s workstation over one full machine cycle. The process depicted in figure 3 represents that of a product wrapping machine, which has a cycle time of approximately 95 seconds. As shown in the figure, the maximum noise level of 96.2 dBA occurs during the release of compressed air, 33 seconds into the machine cycle. The other important events are also labelled in the figure, which permits the identification of the source and relative contribution of each activity during the full wrapping cycle.

Figure 3. Workstation for packaging operator

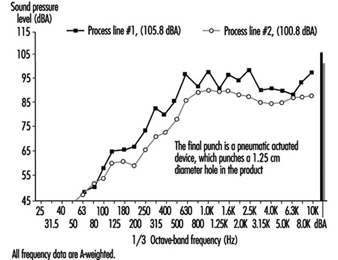

In industrial settings where there are multiple process lines with the same equipment, it is a worthwhile effort to compare the frequency data for similar equipment to one another. Figure 4 depicts this comparison for two similar process lines, both of which manufacture the same product and operate at the same speed. Part of the process involves the use of a pneumatically actuated device that punches a one-half inch hole in the product as a final phase in its production. Inspection of this figure clearly reveals that line #1 has an overall sound level 5 dBA higher than line #2. In addition, the spectrum depicted for line #1 contains a fundamental frequency and many harmonics that do not appear in the spectrum for line #2. Consequently, it is necessary to investigate the cause of these differences. Often significant differences will be an indication of the need for maintenance, such as was the situation for the final punch mechanism of line #2. However, this particular noise problem will require additional control measures since the overall level on line #1 is still relatively high. But the point of this survey technique is to identify the different noise problems that may exist between similar items of equipment and processes that may be easily remedied with effective maintenance or other adjustments.

Figure 4. Final punch operation for identical process lines

As mentioned above, an SLM typically provides an SPL that comprises acoustical energy from one or more noise sources. Under optimum measurement conditions, it would be best to measure each item of equipment with all other equipment turned off. Although this situation is ideal, it is rarely practical to shut down the plant to allow isolation of a particular source. In order to circumvent this limitation, it is often effective to use temporary control measures with certain noise sources that will provide some short-term noise reduction so as to allow measurement of another source. Some materials available that can provide a temporary reduction include plywood enclosures, acoustical blankets, silencers and barriers. Often, permanent application of these materials will create long-term problems such as heat build-up, interference with the operator’s access or product flow, or costly pressure drops associated with improperly selected silencers. However, for assisting with the isolation of individual components, these materials can be effective as a short-term control.

Another method available for isolating a particular machine or component is to turn different equipment on and off, or sections of a production line. To effectively conduct this type of diagnostic analysis the process must be capable of functioning with the selected item turned off. Next, for this procedure to be legitimate it is critical that the manufacturing process not be affected in any manner. If the process is affected, then it is entirely possible that the measurement will not be representative of the noise level under normal conditions. Finally, all valid data may then be ranked by magnitude of the overall dBA value to help prioritize equipment for engineering noise control.

Selecting the appropriate noise control options

Once the cause or source of noise is identified and it is known how it radiates to employee work areas, the next step is to decide what the available noise control options may be. The standard model used with respect to the control of almost any health hazard is to examine the various control options as they apply to the source, path and receiver. In some situations, control of one of these elements will be sufficient. However, under other circumstances it may be the case that treatment of more than one element is required to obtain an acceptable noise environment.

The first step in the noise control process should be to attempt some form of source treatment. In effect, source modification addresses the root cause of a noise problem, whereas control of the sound transmission path with barriers and enclosures only treats the symptoms of noise. In those situations where there are multiple sources within a machine and the objective is to treat the source, it will be necessary to address all noise-generating mechanisms on a component-by-component basis.

For excessive noise generated by mechanical impacts, the control options to investigate may include methods to reduce the driving force, reduce the distance between components, balance rotating equipment and install vibration isolation fittings. As regards noise arising from high-velocity air flow or fluid flow, the primary modification is to reduce the velocity of the medium, assuming this is a feasible option. Sometimes the velocity can be reduced by increasing the cross sectional area of the pipeline in question. Obstructions in the pipeline must be eliminated to allow for a streamlined flow, which in turn will reduce pressure variations and turbulence in the medium being transported. Finally, installation of a properly sized silencer or muffler can provide a significant reduction in the overall noise. The silencer manufacturer should be consulted for assistance with selection of the proper device, based on the operating parameters and constraints set forth by the purchaser.

When vibrating surface areas of a machine act as a sounding board for airborne noise, the control options include a reduction in the driving force associated with the noise, creation of smaller sections out of larger surface areas, perforation of the surface, increasing the substrate stiffness or mass, and application of damping material or vibration isolation fittings. As regards the use of vibration isolation and damping materials, the product manufacturer should be consulted for assistance with the selection of the appropriate materials and installation procedures. Finally, in many industries the actual product being manufactured will often be an efficient radiator of airborne sound. In these situations it is important to evaluate ways to tightly secure or better support the product during fabrication. Another noise control measure to investigate would be to reduce the impact force between the machine and product, between parts of the product itself, or between separate product items.

Often process or equipment redesign and source modification may prove to be infeasible. In addition, there may be situations when it is virtually impossible to identify the root cause of the noise. When any of these situations exist, the use of control measures for treatment of the sound transmission path would be an effective means for reducing the overall noise level. The two primary abatement measures for path treatments are acoustical enclosures and barriers.

The development of acoustical enclosures is well advanced in today’s marketplace. Both off-the-shelf and custom-made enclosures are available from several manufacturers. In order to procure the appropriate system it is necessary for the buyer to provide information as to the current overall noise level (and possibly frequency data), the dimensions of the equipment, the noise reduction goal, the need for product flow and employee access, and any other operating constraints. The vendor will then be able to use this information to select a stock item or fabricate a custom enclosure to satisfy the needs of the buyer.

In many situations it may be more economical to design and build an enclosure instead of purchasing a commercial system. In designing enclosures, many factors must be taken into consideration if the enclosure is to prove satisfactory from both an acoustical and a production point of view. Specific guidelines for enclosure design are as follows:

Enclosure dimensions. There is no critical guideline for the size or dimensions of an enclosure. The best rule to follow is the bigger the better. It is critical that sufficient clearance be provided to permit the equipment to perform all intended movement without contacting the enclosure.

Enclosure wall. The noise reduction provided by an enclosure is dependent upon the materials used in the construction of the walls and how tightly the enclosure is sealed. Selection of the appropriate materials for the enclosure wall should be determined using the following rules of thumb (Moreland 1979):

- for an enclosure, with no internal absorption:

TLreqd=NR+20 dBA

- with approximately 50% internal absorption:

TLreqd=NR+15 dBA

- with 100% internal absorption:

TLreqd=NR+10 dBA.

In these expressions TLreqd is the transmission loss required of the enclosure wall or panel, and NR is the noise reduction desired to meet the abatement goal.

Seals. For maximum efficiency, all enclosure wall joints must be tight fitting. Openings around pipe penetrations, electrical wiring and so on, should be sealed with non-hardening mastic such as silicon caulk.

Internal absorption. To absorb and dissipate acoustical energy the internal surface area of the enclosure should be lined with acoustically absorptive material. The frequency spectrum of the source should be used to select the appropriate material. The manufacturer’s published absorption data provides the basis for matching the material to the source of noise. It is important to match the maximum absorption factors to those frequencies of the source that have the highest sound pressure levels. The product vendor or manufacturer can also assist with selection of the most effective material based on the frequency spectrum of the source.

Enclosure isolation. It is important that the enclosure structure be separated or isolated from the equipment in order to ensure that mechanical vibration is not transmitted to the enclosure itself. When parts of the machine, such as pipe penetrations, do come in contact with the enclosure, it is important to include vibration isolation fittings at the point of contact to short-circuit any potential transmission path. Finally, if the machine causes the floor to vibrate then the base of the enclosure should also be treated with vibration isolation material.

Providing for product flow. As with most production equipment, there will be a need to move product into and out of the enclosure. The use of acoustically lined channels or tunnels can permit product flow and yet provide acoustical absorption. To minimize the leakage of noise, it is recommended that all passageways be three times longer than the inside width of the largest dimension of the tunnel or channel opening.

Providing for worker access. Doors and windows may be installed to provide physical and visual access to the equipment. It is critical that all windows have at least the same transmission loss properties as the enclosure walls. Next, all access doors must tightly seal around all edges. To prevent operation of the equipment with the doors open, it is recommended that an interlocking system be included that permits operation only when the doors are fully closed.

Ventilation of enclosure. In many enclosure applications, there will be excessive heat build-up. To pass cooling air through the enclosure, a blower with a capacity of 650 to 750 cubic feet/metres should be installed on the outlet or discharge duct. Finally, the intake and discharge ducts should be lined with absorptive material.

Protection of absorptive material. To prevent the absorptive material from becoming contaminated, a splash barrier should be applied over the absorptive lining. This should be of a very light material, such as one-mil plastic film. The absorptive layer should be retained with expanded metal, perforated sheet metal or hardware cloth. The facing material should have at least 25% open area.

An alternative sound transmission path treatment is to use an acoustic barrier to block or shield the receiver (the worker at risk of the noise hazard) from the direct sound path. An acoustic barrier is a high transmission loss material, such as a solid partition or wall, inserted between the noise source and the receiver. By blocking the direct line-of-sight path to the source, the barrier causes the sound waves to reach the receiver by reflection off various surfaces in the room and by diffraction at the edges of the barrier. As a result, the overall noise level is reduced at the receiver’s location.

The effectiveness of a barrier is a function of its location relative to the noise source or receivers and of its overall dimensions. To maximize the potential noise reduction, the barrier should be located as closely as practical to either the source or receiver. Next, the barrier should be as tall and wide as possible. To block the sound path effectively, a high-density material, on the order of 4 to 6 lb/ft3, should be used. Finally, the barrier should not contain any openings or gaps, which can significantly reduce its effectiveness. If it is necessary to include a window for visual access to the equipment, then it is important that the window have a sound transmission rating at least equivalent to that of the barrier material itself.

The final option for reducing worker noise exposure is to treat the space or area where the employee works. This option is most practical for those job activities, such as product inspection or equipment monitoring stations, where employee movement is confined to a relatively small area. In these situations, an acoustical booth or shelter may be installed to isolate the employees and provide relief from excessive noise levels. Daily noise exposures will be reduced as long as a significant portion of the workshift is spent inside the shelter. To construct such a shelter, the previously described guidelines for enclosure design should be consulted.

In conclusion, implementation of an effective “Buy Quiet” programme should be the initial step in a total noise control process. This approach is designed to prevent the purchase or installation of any equipment that might present a noise problem. However, for those situations where excessive noise levels already exist, it is then necessary to evaluate the noise environment systematically in order to develop the most practical engineering control option for each individual noise source. In determining the relative priority and urgency of implementing noise control measures, employee exposures, occupancy of the space, and overall area noise levels should be considered. Obviously, an important aspect of the desired result is to obtain the maximum employee noise exposure reduction for the monetary funds invested and that the greatest degree of employee protection is secured at the same time.

Hearing Conservation Programmes

The authors thank the North Carolina Department of Labor for permission to re-use materials developed during the writing of an NCDOL industry guide on hearing conservation.

The primary objective of occupational hearing conservation programmes (HCPs) is to prevent on-the-job noise-induced hearing loss due to hazardous workplace noise exposures (Royster and Royster 1989 and 1990). However, the person—who shall later be characterized as the “key individual”—who is responsible for making the HCP effective should use common sense to modify these practices to fit the local situation in order to achieve the desired goal: protection of workers from harmful occupational noise exposures. A secondary objective of these programmes should be to so educate and motivate individuals that they also elect to protect themselves from harmful non-occupational noise exposures and translate their knowledge about hearing conservation to their families and friends.

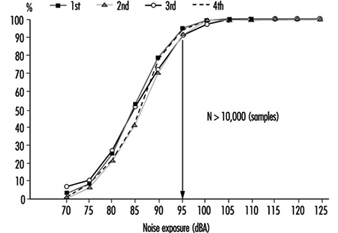

Figure 1 shows the distributions of over 10,000 noise exposure samples from four sources in two countries, including a variety of industrial, mining and military work environments. The samples are 8-hour time-weighted-average values based on exchange rates of 3, 4 and 5 dB. These data indicate that about 90% of daily equivalent noise exposures are 95 dBA or below, and only 10% exceed 95 dBA.

Figure 1. Estimated noise exposure hazard for different populations

The importance of the data in figure 1, assuming that they apply to most countries and populations, is simply that a vast majority of noise-exposed employees need to achieve only 10 dBA of protection from noise to eliminate the hazard. When hearing protection devices (HPDs) are worn to achieve this protection, those responsible for worker health must take the time to fit each individual with a device that is comfortable, practical for the environment, takes into account the individual’s auditory needs (ability to hear warning signals, speech, etc.), and provides an acoustic seal when worn day in and day out in real-world environments.

This article presents a condensed set of good hearing conservation practices, as summarized in the checklist presented in figure 2.

Figure 2. Checklist of good HCP practices

Benefits of Hearing Conservation

Prevention of occupational hearing loss benefits the employee by preserving hearing abilities which are critical to good quality of life: interpersonal communication, enjoyment of music, detection of warning sounds, and many more. The HCP provides a health screening benefit, since non-occupational hearing losses and potentially treatable ear diseases are often detected through annual audiograms. Lowering noise exposure also reduces potential stress and fatigue related to noise.

The employer benefits directly by implementing an effective HCP which maintains employees’ good hearing, since workers will remain more productive and more versatile if their communication abilities are not impaired. Effective HCPs can reduce accident rates and promote work efficiency.

Phases of an HCP

Refer to the checklist in the figure 2 for details of each phase. Different personnel may be responsible for different phases, and these personnel comprise the HCP team.

Sound exposure surveys

Sound level meters or personal noise dosimeters are used to measure workplace sound levels and estimate workers’ noise exposures to determine if an HCP is needed; if so, the data so gathered will help establish appropriate HCP policies to protect employees (Royster, Berger and Royster 1986). Survey results identify which employees (by department or job) will be included in the HCP, which areas should be posted for required hearing protector use, and which hearing protection devices are adequate. Adequate samples of representative production conditions are needed to classify exposures into ranges (below 85 dBA, 85-89, 90-94, 95-99 dBA, etc.). The measurement of A-weighted sound levels during the general noise survey often identifies dominant noise sources in areas of the plant where follow-up engineering noise control studies may significantly reduce employee exposures.

Engineering and administrative noise controls

Noise controls may reduce employees’ noise exposures to a safe level, eliminating the need for a hearing conservation programme. Engineering controls (see “Engineering noise control” [NOI03AE] in this chapter) involve modifications of the noise source (such as fitting mufflers to air exhaust nozzles), the noise path (such as placing sound-blocking enclosures around equipment) or the receiver (such as constructing an enclosure around the employee’s workstation). Worker input is often needed in designing such modifications to ensure that they are practical and will not interfere with his or her tasks. Obviously, hazardous employee noise exposures should be reduced or eliminated by means of engineering noise controls whenever practical and feasible.

Administrative noise controls include replacement of old equipment with quieter new models, adherence to equipment maintenance programmes related to noise control, and changes in employee work schedules to reduce noise doses by limiting exposure time when practical and technically advisable. Planning and designing to achieve non-hazardous noise levels when new production facilities are brought on-line is an administrative control which can also eliminate the need for an HCP.

Education and motivation

HCP team members and employees will not actively participate in hearing conservation unless they understand its purpose, how they will benefit directly from the programme, and that compliance with the company’s safety and health requirements is a condition of employment. Without meaningful education to motivate individual actions, the HCP will fail (Royster and Royster 1986). Topics to be covered should include the following: the purpose and benefits of the HCP, sound survey methods and results, using and maintaining engineering noise control treatments to reduce exposures, hazardous off-the-job noise exposures, how noise damages hearing, consequences of hearing loss in daily life, selection and fitting of hearing protection devices and importance of consistent wear, how audiometric testing identifies hearing changes to indicate the need for greater protection and the employer’s HCP policies. Ideally, these topics can be explained to small groups of employees in safety meetings, given ample time for questions. In effective HCPs the educational phase is a continuous process—not just an annual presentation—as HCP personnel take daily opportunities to remind others about conserving their hearing.

Hearing protection

The employer provides hearing protection devices (earplugs, earmuffs, and semi-insert devices) for employees to wear as long as hazardous noise levels exist in the workplace. Because feasible engineering noise controls have not been developed for many types of industrial equipment, hearing protectors are the best current option for preventing noise-induced hearing loss in these situations. As indicated earlier, most noise-exposed workers need to achieve only 10 dB of attenuation to be adequately protected from noise. With the large selection of hearing protectors available today, adequate protection can be readily achieved (Royster 1985; Royster and Royster 1986) if devices are individually fitted to each employee to achieve an acoustic seal with acceptable comfort, and if the worker is taught how to wear the device correctly to maintain an acoustic seal, but consistently whenever a noise hazard exists.

Audiometric evaluations

Each exposed individual should receive a baseline hearing check followed by annual rechecks to monitor hearing status and detect any hearing change. An audiometer is used in a sound-attenuating booth to test the employee’s hearing thresholds at 0.5, 1, 2, 3, 4, 6 and 8 kHz. If the HCP is effective, employees’ audiometric results will not show significant changes associated with on-the-job noise-induced hearing damage. If suspicious hearing changes are found, the audiometric technician and the audiologist or physician who reviews the record can counsel the employee to wear HPDs more carefully, assess whether better-fitting HPDs are needed and motivate the individual to be more careful in protecting his or her hearing both on and off the job. Sometimes non-occupational causes of hearing change may be identified, such as gunfire or hobby noise exposure, or medical ear problems. Audiometric monitoring is useful only if quality control of testing procedures is maintained and if the results are used to trigger follow-up for individuals with significant hearing changes (Royster 1985).

Record Keeping

Requirements for the type of records to be kept and the duration for maintaining them vary among countries. In countries where litigation concerns and worker’s compensation are important issues, records should be maintained longer than required by occupational regulations since they are often useful for legal purposes. The goal of record keeping is to document how employees have been protected from noise (Royster and Royster 1989 and 1990). Especially important records include the sound survey procedures and findings, audiometric calibration and results, follow-up actions in response to employees’ hearing changes and documentation of hearing protector fitting and training. Records should include the names of the personnel who carried out the HCP tasks as well as the results.

Programme Evaluation

Characteristics of effective programmes

Successful HCPs share the following characteristics and promote a “safety culture” with respect to all safety programmes (safety eyeglasses, “hard hats”, safe lifting behaviour, etc.).

The “key individual”

The most important strategy for making the five phases of the HCP function together effectively is to unite them under the supervision of one individual of central importance (Royster and Royster 1989 and 1990). In smaller companies where one person may actually carry out all facets of the HCP, lack of coordination is not usually a problem. However, as the size of the organization increases, different types of staff become involved in the HCP: safety personnel, medical personnel, engineers, industrial hygienists, tool crib supervisors, production supervisors and others. With personnel from varying disciplines carrying out different aspects of the programme, it becomes very difficult to coordinate their efforts unless one “key individual” is able to oversee the entire HCP. The choice of who this person should be is critical to the success of the programme. One of the primary qualifications for the key individual is genuine interest in the company’s HCP.

The key individual is always approachable and is sincerely interested in comments or complaints that can help to improve the HCP. This individual does not take a remote attitude or stay in an office, running the HCP on paper by mandate, but spends time on the production floors or wherever workers are active in order to interact with them and observe how problems can be prevented or solved.

Active communications and roles

The primary HCP team members should meet together regularly to discuss the progress of the programme and ensure that all duties are being carried out. Once people with different tasks understand how their own roles contribute to the overall outcome of the programme, they will cooperate better to prevent hearing loss. The key individual can achieve this active communication and cooperation if management provides him or her with the authority to make HCP decisions and the resource allocations to act on decisions once they are made. The success of the HCP depends on everyone from the top boss to the most recently hired trainee; everyone has an important role. Management’s role is largely to support the HCP and enforce its policies as one facet of the company’s overall health and safety programme. For middle managers and supervisors the role is more direct: they help carry out the five phases. The role of employees is to participate actively in the programme and be aggressive in making suggestions to improve HCP operation. However, for employee participation to succeed, management and the HCP team must be receptive to comments and actually respond to employee input.

Hearing protectors—effective and enforced

The importance of hearing protection policies to HCP success is underscored by two desired characteristics of effective HCPs: strict enforcement of hearing protector utilization (there must be actual enforcement, not just a paper policy) and the availability of protectors which are potentially effective for use by the wearers in the work environment. Potentially effective devices are practical and comfortable enough for employees to wear consistently, and they provide adequate sound attenuation without impairing communication through overprotection.

Limited external influences on the HCP

If local HCP decisions are limited by policies mandated by corporate headquarters, the key individual may need top management’s assistance in obtaining exceptions to the corporate or external rules in order to meet local needs. The key individual also must keep strict control over any services provided by outside consultants, contractors or government officials (such as sound surveys or audiograms). When contractors are used, it is more difficult to integrate their services cohesively into the overall HCP, but it is critical to do so. If in-plant personnel do not follow through by using the information provided by the contractors, then the contracted elements of the programme lose effectiveness. Experience clearly indicates that it is very difficult to establish and maintain an effective HCP which depends predominantly on external contractors.

In contrast to the previous characteristics, the following is a listing of some common causes of HCP ineffectiveness.

- inadequate communication and coordination among HCP personnel

- insufficient or erroneous information used to make decisions

- inadequate training for hearing protector fitters and issuers

- inadequate or inappropriate selection of protectors in stock

- over-reliance on number ratings in choosing devices

- failure to fit and train each HPD wearer individually

- over-reliance on external sources (government or contractors) to provide HCP services

- failure to use audiometric monitoring results to educate and motivate employees

- failure to use audiometric data to evaluate HCP effectiveness.

Objective evaluation of the audiometric data

The audiometric data for the noise-exposed population provide evidence of whether the HCP is preventing occupational hearing loss. Over time, the rate of hearing change for noise-exposed employees should be no greater than that of matched controls without noisy jobs. To give an early indication of HCP effectiveness, procedures for audiometric database analysis have been developed using year-to-year variability in threshold values (Royster and Royster 1986; ANSI 1991).

Standards and Regulations

Terms

In the field of occupational noise, the terms regulation, standard, and legislation are often used interchangeably, even though technically they may have slightly different meanings. A standard is a codified set of rules or guidelines, much like a regulation, but it can be developed under the auspices of a consensus group, such as the International Organization for Standardization (ISO). Legislation consists of laws prescribed by legislating authorities or by local governing bodies.