70. Livestock Rearing

Chapter Editor: Melvin L. Myers

Table of Contents

Tables and Figures

Livestock Rearing: Its Extent and Health Effects

Melvin L. Myers

Health Problems and Disease Patterns

Kendall Thu, Craig Zwerling and Kelley Donham

Case Study: Arthopod-related Occupational Health Problems

Donald Barnard

Forage Crops

Lorann Stallones

Livestock Confinement

Kelley Donham

Animal Husbandry

Dean T. Stueland and Paul D. Gunderson

Case Study: Animal Behaviour

David L. Hard

Manure and Waste Handling

William Popendorf

A Checklist for Livestock Rearing Safety Practice

Melvin L. Myers

Dairy

John May

Cattle, Sheep and Goats

Melvin L. Myers

Pigs

Melvin L. Myers

Poultry and Egg Production

Steven W. Lenhart

Case Study: Poultry Catching, Live Hauling and Processing

Tony Ashdown

Horses and Other Equines

Lynn Barroby

Case Study: Elephants

Melvin L. Myers

Draught Animals in Asia

D.D. Joshi

Bull Raising

David L. Hard

Pet, Furbearer and Laboratory Animal Production

Christian E. Newcomer

Fish Farming and Aquaculture

George A. Conway and Ray RaLonde

Beekeeping, Insect Raising and Silk Production

Melvin L. Myers and Donald Barnard

Tables

Click a link below to view table in article context.

1. Livestock uses

2. International livestock production (1,000 tonnes)

3. Annual US livestock faeces & urine production

4. Types of human health problems associated with livestock

5. Primary zoonoses by world region

6. Different occupations & health & safety

7. Potential arthropod hazards in the workplace

8. Normal & allergic reactions to insect sting

9. Compounds identified in swine confinement

10. Ambient levels of various gases in swine confinement

11. Respiratory diseases associated with swine production

12. Zoonotic diseases of livestock handlers

13. Physical properties of manure

14. Some important toxicologic benchmarks for hydrogen sulphide

15. Some safety procedures related to manure spreaders

16. Types of ruminants domesticated as livestock

17. Livestock rearing processes & potential hazards

18. Respiratory illnesses from exposures on livestock farms

19. Zoonoses associated with horses

20. Normal draught power of various animals

Figures

Point to a thumbnail to see figure caption, click to see the figure in article context.

Livestock Rearing: Its Extent and Health Effects

Overview

Humans depend upon animals for food and related by-products, work and a variety of other uses (see table 1). To meet these demands, they have domesticated or held in captivity species of mammals, birds, reptiles, fish and arthropods. These animals have become known as livestock, and rearing them has implications for occupational safety and health. This general profile of the industry includes its evolution and structure, the economic importance of different commodities of livestock, and regional characteristics of the industry and workforce. The articles in this chapter are organized by occupational processes, livestock sectors and consequences of livestock rearing.

Table 1. Livestock uses

|

Commodity |

Food |

By-products and other uses |

|

Dairy |

Fluid and dried milk, butter, cheese and curd, casein, evaporated milk, cream, yoghurt and other fermented milk, ice cream, whey |

Male calves and old cows sold into the cattle commodity market; milk as an industrial feedstock of carbohydrates (lactose as a diluent for drugs), proteins (used as a surfactant to stabilize food emulsions) and fats (lipids have potential uses as emulsifiers, surfactants and gels), offal |

|

Cattle, buffalo, sheep |

Meat (beef, mutton), edible tallow |

Hides and skins (leather, collagens for sausage casings, cosmetics, wound dressing, human tissue repair), offal, work (traction), wool, hair, dung (as fuel and fertilizer), bone meal, religious objects, pet food, tallow and grease (fatty acids, varnish, rubber goods, soaps, lamp oil, plastics, lubricants) fat, blood meal |

|

Poultry |

Meat, eggs, duck eggs (in India) |

Feathers and down, manure (as fertilizer), leather, fat, offal, flightless bird oil (carrier for dermal path pharmaceuticals), weed control (geese in mint fields) |

|

Pig |

Meat |

Hides and skins, hair, lard, manure, offal |

|

Fish (aquaculture) |

Meat |

Fishmeal, oil, shell, aquarium pets |

|

Horse, other equines |

Meat, blood, milk |

Recreation (riding, racing), work (riding, traction), glue, dog feed, hair |

|

Micro-livestock (rabbit, guinea pig), dog, cat |

Meat |

Pets, furs and skins, guard dogs, seeing-eye dogs, hunting dogs, experimentation, sheep herding (by the dog), rodent control (by the cat) |

|

Bulls |

Recreation (bull-fighting, rodeo riding), semen |

|

|

Insects and other invertebrates (e.g., |

Honey, 500 species (grubs, grasshoppers, ants, crickets, termites, locusts, beetle larvae, wasps and bees, moth caterpillars) are a regular diet among many non-western societies |

Beeswax, silk, predatory insects (>5,000 species are possible and 400 are known as controls for crop pests; the carnivorous “tox” mosquito |

Sources: DeFoliart 1992; Gillespie 1997; FAO 1995; O’Toole 1995; Tannahil 1973; USDA 1996a, 1996b.

Evolution and structure of the industry

Livestock evolved over the past 12,000 years through selection by human communities and adaptation to new environments. Historians believe that goat and sheep were the first species of animals domesticated for human use. Then, about 9,000 years ago, humans domesticated the pig. The cow was the last major food animal that humans domesticated, about 8,000 years ago in Turkey or Macedonia. It was probably only after cattle were domesticated that milk was discovered as a useful foodstuff. Goat, sheep, reindeer and camel milk were also used. People of the Indus valley domesticated the Indian jungle fowl primarily for its egg production, which became the world’s chicken, with its source of eggs and meat. People of Mexico had domesticated the turkey (Tannahill 1973).

Humans used several other mammalian and avian species for food, as well as amphibian and fish species and various arthropods. Insects have always provided an important source of protein, and today they are part of the human diet principally in the world’s non-western cultures (DeFoliart 1992). Honey from the honey bee was an early food; smoking bees from their nest to collect honey was known in Egypt as early as 5,000 years ago. Fishing is also an ancient occupation used to produce food, but because fishers are depleting wild fisheries, aquaculture has been the fastest growing contributor to fish production since the early 1980s, contributing about 14% to the total current production of fish (Platt 1995).

Humans also domesticated many mammals for use for draught, including the horse, donkey, elephant, dog, buffalo, camel and reindeer. The first animal used for draught, perhaps with the exception of the dog, was likely the goat, which could defoliate scrub for land cultivation through its browsing. Historians believe that Asians domesticated the Asian wolf, which was to become the dog, 13,000 years ago. The dog proved to be useful to the hunter for its speed, hearing and sense of smell, and the sheepdog aided in the early domestication of sheep (Tannahill 1973). The people of the steppe lands of Eurasia domesticated the horse about 4,000 years ago. Its use for work (traction) was stimulated by the invention of the horseshoe, collar harness and feeding of oats. Although draught is still important in much of the world, farmers displace draught animals with machines as farming and transportation becomes more mechanized. Some mammals, such as the cat, are used to control rodents (Caras 1996).

The structure of the current livestock industry can be defined by commodities, the animal products that enter the market. Table 2 shows a number of these commodities and the worldwide production or consumption of these products.

Table 2. International livestock production (1,000 tonnes)

|

Commodity |

1991 |

1992 |

1993 |

1994 |

1995 |

1996 |

|

Beef and veal carcasses |

46,344 |

45,396 |

44,361 |

45,572 |

46,772 |

47,404 |

|

Pork carcasses |

63,114 |

64,738 |

66,567 |

70,115 |

74,704 |

76,836 |

|

Lamb, mutton, goat carcasses |

6,385 |

6,245 |

6,238 |

6,281 |

6,490 |

6,956 |

|

Bovine hides and skins |

4,076 |

3,983 |

3,892 |

3,751 |

3,778 |

3,811 |

|

Tallow and grease |

6,538 |

6,677 |

7,511 |

7,572 |

7,723 |

7,995 |

|

Poultry meat |

35,639 |

37,527 |

39,710 |

43,207 |

44,450 |

47,149 |

|

Cow’s milk |

385,197 |

379,379 |

379,732 |

382,051 |

382,747 |

385,110 |

|

Shrimps |

815 |

884 |

N/A |

N/A |

N/A |

N/A |

|

Molluscs |

3,075 |

3,500 |

N/A |

N/A |

N/A |

N/A |

|

Salmonoids |

615 |

628 |

N/A |

N/A |

N/A |

N/A |

|

Freshwater fish |

7,271 |

7,981 |

N/A |

N/A |

N/A |

N/A |

|

Egg consumption (million pieces) |

529,080 |

541,369 |

567,469 |

617,591 |

616,998 |

622,655 |

Sources: FAO 1995; USDA 1996a, 1996b.

Economic importance

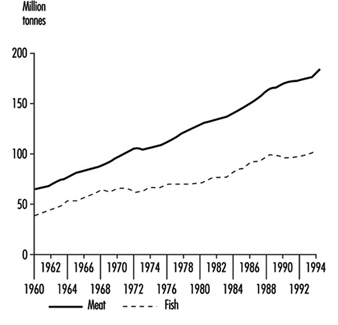

The world’s growing population and increased per capita consumption both increased the global demand for meat and fish, the results of which are shown in figure 1. Global meat production nearly trebled between 1960 and 1994. Over this period, per capita consumption increased from 21 to 33 kilograms per annum. Because of the limitations of available rangeland, beef production levelled off in 1990. As a result, animals that are more efficient in converting feed grain into meat, such as pigs and chickens, have gained a competitive advantage. Both pork and poultry have been increasing in dramatic contrast to beef production. Pork overtook beef in worldwide production in the late 1970s. Poultry may soon exceed beef production. Mutton production remains low and stagnant (USDA 1996a). Milk cows worldwide have been slowly decreasing while milk production has been increasing because of increasing production per cow (USDA 1996b).

Figure 1. World production of meat and fish

Aquaculture production increased at an annual rate of 9.1% from 1984 to 1992. Aquaculture animal production increased from 14 million tonnes worldwide in 1991 to 16 million tonnes in 1992, with Asia providing 84% of world production (Platt 1995). Insects are rich in vitamins, minerals and energy, and provide between 5% and 10% of the animal protein for many people. They also become a vital source of protein during times of famine (DeFoliart 1992).

Regional Characteristics of the Industry and Workforce

Separating the workforce engaged in livestock rearing from other agricultural activities is difficult. Pastoral activities, such as those in much of Africa, and heavy commodity-based operations, such as those in the United States, have differentiated more between livestock and crop raising. However, many agro-pastoral and agronomic enterprises integrate the two. In much of the world, draught animals are still used extensively in crop production. Moreover, livestock and poultry depend upon feed and forage generated from crop operations, and these operations are commonly integrated. The principal aquaculture species in the world is the plant-eating carp. Insect production is also tied directly to crop production. The silkworm feeds exclusively on mulberry leaves; honeybees depend upon flower nectar; plants depend upon them for pollination work; and humans harvest edible grubs from various crops. The 1994 world population totalled 5,623,500,000, and 2,735,021,000 people (49% of the population) were engaged in agriculture (see figure 2). The largest contribution to this workforce is in Asia, where 85% of the agricultural population rear draught animals. Regional characteristics related to livestock rearing follow.

Figure 2. Human population engaged in agriculture by world region, 1994.

Sub-Saharan Africa

Animal husbandry has been practised in sub-Saharan Africa for more than 5,000 years. Nomadic husbandry of the early livestock has evolved species that tolerate poor nutrition, infectious diseases and long migrations. About 65% of this region, much of it around desert areas, is suitable only for producing livestock. In 1994, 65% of the approximately 539 million people in sub-Saharan Africa depended upon agricultural income, down from 76% in 1975. Although its importance has grown since the mid-1980s, aquaculture has contributed little to the food supply for this region. Aquaculture in this region is based upon pond farming of tilapias, and export enterprises have attempted to culture marine shrimps. An export aquaculture industry in this region is expected to grow because Asian demand for fish is expected to increase, which will be fuelled by Asian investment and technology drawn to the region by a favourable climate and by African labour.

Asia and the Pacific

In Asia and the Pacific region, nearly 76% of the world’s agricultural population exists on 30% of the world’s arable land. About 85% of the farmers use cattle (bullocks) and buffaloes to cultivate and thresh crops.

Livestock rearing operations are mainly small-scale units in this region, but large commercial farms are establishing operations near urban centres. In rural areas, millions of people depend on livestock for meat, milk, eggs, hides and skins, draught power and wool. China exceeds the rest of the world with 400 million pigs; the remainder of the world has a total of 340 million pigs. India accounts for over one-fourth of the number of cattle and buffaloes worldwide, but because of religious policies that restrict cattle slaughter, India contributes less than 1% to the world’s beef supply. Milk production is a part of traditional agriculture in many countries of this region. Fish is a frequent ingredient in most people’s diet in this region. Asia contributes 84% of the world’s aquaculture production. At 6,856,000 tonnes, China alone produces nearly half of the world production,. Demand for fish is expected to increase rapidly, and aquaculture is expected to meet this demand.

Europe

In this region of 802 million people, 10.8% were engaged in agriculture in 1994, which has decreased significantly from 16.8% in 1975. Increased urbanization and mechanization have led to this decrease. Much of this arable land is in the moist, cool northern climates and is conducive to growing pastures for livestock. As a result, much of the livestock raising is located in the northern part of this region. Europe contributed 8.5% to the world’s production of aquaculture in 1992. Aquaculture has concentrated on relatively high-value species of finfish (288,500 tonnes) and shellfish (685,500 tonnes).

Latin America and the Caribbean

The Latin American and Caribbean region differs from other regions in many ways. Large tracts of land remain to be exploited, the region has large populations of domestic animals and much of the agriculture is operated as large operations. Livestock represents about one-third of the agricultural production, which makes up a significant part of the gross domestic product. Meat from beef cattle accounts for the largest share and makes up 20% of the world’s production. Most livestock species have been imported. Among those indigenous species that have been domesticated are guinea pigs, dogs, llamas, alpacas, Muscovy ducks, turkeys and black chickens. This region contributed only 2.3% to world aquaculture production in 1992.

Near East

Currently, 31% of the population of the Near East is engaged in agriculture. Because of the shortage of rainfall in this region, the only agricultural use for 62% of this land area is animal grazing. Most of the major livestock species were domesticated in this region (goats, sheep, pigs and cattle) at the confluence of the Tigris and Euphrates rivers. Later, in North Africa, water buffaloes, dromedary camels and asses were domesticated. Some livestock raising systems that existed in ancient times still exist today. These are subsistence systems in Arab tribal society, in which herds and flocks are moved seasonally over great distances in search of feed and water. Intensive farming systems are used in the more developed countries.

North America

Although agriculture is a major economic activity in Canada and the United States, the proportion of the population engaged in agriculture is less than 2.5%. Since the 1950s, agriculture has become more intensive, leading to fewer but larger farms. Livestock and livestock products make up a major proportion of the population’s diet, contributing 40% to the total food energy. The livestock industry in this region has been very dynamic. Introduced animals have been bred with indigenous animals to form new breeds. Consumer demand for leaner meats and eggs with less cholesterol is having an impact on breeding policy. Horses were used extensively at the turn of the nineteenth century, but they have declined in numbers because of mechanization. They are currently used in the race horse industry or for recreation. The United States has imported about 700 insect species to control more than 50 pests. Aquaculture in this region is growing, and accounted for 3.7% of the world’s aquaculture production in 1992 (FAO 1995; Scherf 1995).

Environmental and Public Health Issues

Occupational hazards of livestock rearing may lead to injuries, asthma or zoonotic infections. In addition, livestock rearing poses several environmental and public health issues. One issue is the effect of animal waste upon the environment. Other issues include the loss of biological diversity, risks associated with animal and product importation and food safety.

Water and air pollution

Animal wastes pose potential environmental consequences of water and air pollution. Based upon US annual discharge factors shown in table 3, major livestock breeds discharged a total of 14.3 billion tonnes of faeces and urine worldwide in 1994. Of this total, cattle (milk and beef) discharged 87%; pigs, 9%; and chickens and turkeys, 3% (Meadows 1995). Because of their high annual discharge factor of 9.76 tonnes of faeces and urine per animal, cattle contributed the most waste among these livestock types for all six United Nations Food and Agricultural Organization (FAO) regions of the world, ranging from 82% in both Europe and Asia to 96% in sub-Saharan Africa.

Table 3. Annual US livestock faeces and urine production

|

Livestock type |

Population |

Waste (tonnes) |

Tonnes per animal |

|

Cattle (milk and beef) |

46,500,000 |

450,000,000 |

9.76 |

|

Pig |

60,000,000 |

91,000,000 |

1.51 |

|

Chicken and turkey |

7,500,000,000 |

270,000,000 |

0.04 |

Source: Meadows 1995.

In the United States, farmers who specialize in livestock rearing do not engage in crop farming, as had been the historical practice. As a result, livestock waste is no longer systematically applied to crop land as a fertilizer. Another problem with modern livestock raising is the high concentration of animals into small areas such as confinement buildings or feedlots. Large operations may confine 50,000 to 100,000 cattle, 10,000 pigs or 400,000 chickens to an area. In addition, these operations tend to cluster near the processing plants to shorten the transportation distance of the animals to the plants.

Several environmental problems result from concentrated operations. These problems include lagoon spills, chronic seepage and runoff and airborne health effects. Nitrate peculation into the groundwater and runoff from fields and feedlots are major contributors to water contamination. A greater use of feedlots leads to concentration of animal manure and a greater risk for contamination of groundwater. Waste from cattle and pig operations is typically collected in lagoons, which are large, shallow pits dug into the ground. Lagoon design depends upon the settling of solids to the bottom, where they anaerobically digest, and the excess liquids are controlled by spraying them onto nearby fields before they overflow (Meadows 1995).

Biodegrading livestock waste also emits odorous gases that contain as many as 60 compounds. These compounds include ammonia and amines, sulphides, volatile fatty acids, alcohols, aldehydes, mercaptans, esters and carbonyls (Sweeten 1995). When humans sense odours from concentrated livestock operations, they can experience nausea, headaches, breathing problems, sleep interruption, appetite loss and irritation of the eyes, ears and throat.

Less understood are the adverse effects of livestock waste upon global warming and atmospheric deposition. Its contribution to global warming is through the generation of the greenhouse gases, carbon dioxide and methane. Livestock manure may contribute to nitrogen depositions because of ammonia release from waste lagoons into the atmosphere. Atmospheric nitrogen re-enters the hydrologic cycle through rain and flows into streams, rivers, lakes and coastal waters. Nitrogen in water contributes to increased algae blooms that reduce the oxygen available to fish.

Two modifications in livestock production offer solutions to some of the problems of pollution. These are less animal confinement and improved waste treatment systems.

Animal diversity

The potential for rapid loss of genes, species and habitats threatens the adaptability and traits of a variety of animals that are or could be useful. International efforts have stressed the need to preserve biological diversity at three levels: genetic, species and habitat. An example of declining genetic diversity is the limited number of sires used to breed artificially females of many livestock species (Scherf 1995).

With the decline of many livestock breeds, and thus the reduction of species diversity, dominant breeds have been increasing, with an emphasis on uniformity in higher production breeds. The problem of a lack of dairy cattle-breed diversity is particularly acute; with the exception of the high-producing Holstein, dairy populations are declining. Aquaculture has not reduced pressure on wild fish populations. For example, the use of fine nets for biomass fishing for shrimp food results in the collection of juveniles of valuable wild species, which adds to their depletion. Some species, such as groupers, milkfish and eels, cannot be bred in captivity, so their juveniles are caught in the wild and raised on fish farms, further reducing the stock of wild populations.

An example of a loss of habitat diversity is the impact of feed for fish farms on wild populations. Fish feed used in coastal areas affects wild populations of shrimp and fish by destroying their natural habitat such as mangroves. In addition, fish faeces and feed can accumulate on the bottom and kill the benthic communities that filter the water (Safina 1995).

Animal species that survive in abundance are those used as a means to human ends, but a social dilemma emerges from an animal rights movement that espouses that animals, especially warm-blooded animals, are not to be used as a means to human ends. Preceding the animal rights movement, an animal welfare movement started before the mid-1970s. Animal welfare proponents advocate the humane treatment of animals that are used for research, food, clothing, sport or companionship. Since the mid-1970s, the animal rights advocates assert that sentient animals have a right not to be used for research. It appears highly unlikely that the human use of animals will be abolished. It is also likely that animal welfare will continue as a popular movement (NIH 1988).

Animal and animal product importation

The history of livestock rearing is closely linked to the history of livestock importation into new areas of the world. Diseases spread with the spread of imported livestock and their products. Animals may carry disease that can infect other animals or humans, and countries have established quarantine services to control the spread of these zoonotic diseases. Among these diseases are scrapie, brucellosis, Q-fever and anthrax. Livestock and food inspection and quarantines have emerged as methods to control disease importation (MacDiarmid 1993).

Public concern about the potential infection of humans with the rare Creutzfeldt-Jakob disease (CJD) emerged among beef-importing nations in 1996. Eating beef infected with bovine spongiform encephalopathy (BSE), popularly known as mad cow disease, is suspected of leading to CJD infection. Although unproven, public perceptions include the proposition that the disease may have entered cattle from feed containing bone meal and offal from sheep afflicted with the similar disease, scrapie. All three diseases, in humans, cattle and sheep, exhibit common symptoms of sponge-like brain lesions. The diseases are fatal, their causes are unknown, and there are no tests to detect them. Britons launched a pre-emptive slaughter of one-third of their cattle population in 1996 to control BSE and restore consumer confidence in the safety of their beef exports (Aldhous 1996).

The importation of African bees into Brazil has also emerged into a public health issue. In the United States, subspecies of European bees produce honey and beeswax and pollinate crops. They rarely swarm aggressively, which aids safe beekeeping. The African subspecies has migrated from Brazil into Central America, Mexico and the Southeastern United States. This bee is aggressive and will swarm in defence of its colony. It has interbred with the European subspecies, which results in an Africanized bee that is more aggressive. The public health threat is multiple stings when the Africanized bee swarms and severe toxic reactions in humans.

Two controls currently exist for the Africanized bee. One is that they are not hardy in northern climates and may be restricted to warmer temperate climates like the Southern United States. The other control is routinely to replace the queen bee in hives with queen bees of the European subspecies, although this does not control wild colonies (Schumacher and Egen 1995).

Food safety

Many human food-borne illnesses result from pathogenic bacteria of animal origin. Examples include listeria and salmonellae found in dairy products and salmonellae and campylobacter found in meat and poultry. The Centers for Disease Control and Prevention estimates that 53% of all food-borne illness outbreaks in the United States were caused by bacterial contamination of animal products. They estimate that 33 million food-borne illnesses occur each year, from which 9,000 deaths result.

The subtherapeutic feeding of antibiotics and antibiotic treatment of diseased animals are current animal health practices. The potential diminished effectiveness of antibiotics for disease therapy is a rising concern because of the frequent development of antibiotic resistance of zoonotic pathogens. Many antibiotics added to animal feed are also used in human medicine, and antibiotic-resistant bacteria could develop and cause infections in animals and humans.

Drug residues in food that result from medication of livestock also present risks. Residues of antibiotics used in livestock or added to feed have been found in food-producing animals including dairy cows. Among these drugs are chloramphenicol and sulphamethazine. Alternatives to the prophylactic feeding use of antibiotics to maintain animal health include the modification of production systems. These modifications include reduced animal confinement, improved ventilation and improved waste treatment systems.

Diet has been associated with chronic diseases. Evidence of an association between fat consumption and heart disease has stimulated efforts to produce animal products with less fat content. These efforts include animal breeding, feeding intact rather than castrated males and genetic engineering. Hormones are also seen as a method for decreasing fat content in meat. Porcine growth hormones increase growth rate, feed efficiency and the ratio of muscle to fat. The growing popularity of low-fat, low-cholesterol species such as ostriches is another solution (NRC 1989).

Health Problems and Disease Patterns

The domestication of animals occurred independently in a number of areas of the Old and New World over 10,000 years ago. Until domestication, hunting and gathering was the predominant subsistence pattern. The transformation to human control over animal and plant production and reproduction processes resulted in revolutionary changes in the structure of human societies and their relationships to the environment. The change to agriculture marked an increase in labour intensity and work time spent in food procurement-related activities. Small nuclear families, adapted to nomadic hunting and gathering groups, were transformed into large, extended, sedentary social units suited to labour-intensive domesticated food production.

The domestication of animals increased human susceptibility to animal-related injuries and diseases. Larger non-nomadic populations quartered in close proximity to animals provided greater opportunity for transmission of disease between animals and humans. The development of larger herds of more intensely handled livestock also increased the likelihood of injuries. Throughout the world, differing forms of animal agriculture are associated with varying risks for injury and disease. For example, the 50 million inhabitants who practice swidden (cut and burn) agriculture in equatorial regions face different problems from the 35 million pastoral nomads across Scandinavia and through central Asia or the 48 million food producers who practise an industrialized form of agriculture.

In this article, we provide an overview of selected injury patterns, infectious diseases, respiratory diseases and skin diseases associated with livestock production. The treatment is topically and geographically uneven because most research has been conducted in industrialized countries, where intensive forms of livestock production are common.

Overview

Types of human health problems and disease patterns associated with livestock production can be grouped according to the type of contact between animals and people (see table 1). Contact can occur via direct physical interaction, or contact with an organic or inorganic agent. Health problems associated with all types of livestock production can be grouped into each of these areas.

Table 1. Types of human health problems associated with livestock production

Health problems from direct physical contact

Allergic contact dermatitis

Allergic rhinitis

Bites, kicks, crushing

Envenomation and possible hypersensitivity

Asthma

Scratches

Traumatic injury

Health problems from organic agents

Agrochemical poisoning

Antibiotic resistance

Chronic bronchitis

Contact dermatitis

Allergies from drug residue food exposures

Food-borne illnesses

“Farmer’s lung”

Hypersensitivity pneumonitis

Mucous membrane irritation

Occupational asthma

Organic dust toxic syndrome (ODTS)

Allergies from pharmaceutical exposures

Zoonotic diseases

Health problems from physical agents

Hearing loss

Machinery-related trauma

Methane emission and greenhouse effect

Musculoskeletal disorders

Stress

Direct human contact with livestock ranges from the brute force of large animals such as the Chinese buffalo to the undetected skin contact by microscopic hairs of the Japanese oriental tussock moth. A corresponding range of health problems can result, from the temporary irritant to the debilitating physical blow. Notable problems include traumatic injuries from handling large livestock, venom hypersensitivity or toxicosis from venomous arthropod bites and stings, and contact and allergic contact skin dermatitis.

A number of organic agents utilize various pathways from livestock to humans, resulting in a range of health problems. Among the most globally important are zoonotic diseases. Over 150 zoonotic diseases have been identified worldwide, with approximately 40 significant for human health (Donham 1985). The importance of zoonotic diseases depends on regional factors such as agricultural practices, environment and a region’s social and economic status. The health consequences of zoonotic diseases range from the relatively benign flu-like symptoms of brucellosis to debilitating tuberculosis or potentially lethal strains of Escherichia coli or rabies.

Other organic agents include those associated with respiratory disease. Intensive livestock production systems in confined buildings create enclosed environments where dust, including microbes and their by-products, becomes concentrated and aerosolized along with gases that are in turned breathed by people. Approximately 33% of swine confinement workers in the United States suffer from organic dust toxic syndrome (ODTS) (Thorne et al. 1996).

Comparable problems exist in dairy barns, where dust containing endotoxin and/or other biologically active agents in the environment contributes to bronchitis, occupational asthma and inflammation of the mucous membrane. While these problems are most notable in developed countries where industrialized agriculture is widespread, the increasing export of confined livestock production technologies to developing areas such as Southeast Asia and Central America increases the risks for workers there.

Health problems from physical agents typically involve tools or machinery either directly or indirectly involved with livestock production in the agricultural work environment. Tractors are the leading cause of farm fatalities in developed countries. In addition, elevated rates of hearing loss associated with machinery and confined livestock production noises, and musculoskeletal disorders from repetitive motions, are also consequences of industrialized forms of animal agriculture. Agricultural industrialization, characterized by the use of capital-intensive technologies which interface between humans and the physical environment to produce food, is behind the growth of physical agents as significant livestock-related health factors.

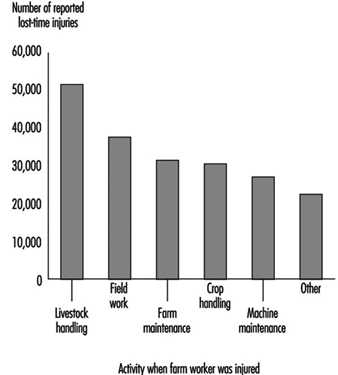

Injuries

Direct contact with livestock is a leading cause of injuries in many industrialized regions of the world. In the United States, the national Traumatic Injury Surveillance of Farmers (NIOSH 1993) indicates that livestock is the primary source of injury, with cattle, swine and sheep constituting 18% of all agricultural injuries and accounting for the highest rate of lost workdays. This is consistent with a 1980-81 survey conducted by the US National Safety Council (National Safety Council 1982).

Regional US studies consistently show livestock as a leading cause of injury in agricultural work. Early work on hospital visits by farmers in New York from 1929 to 1948 revealed livestock accounting for 17% of farm-related injuries, second only to machinery (Calandruccio and Powers 1949). Such trends continue, as research indicates livestock account for at least one-third of agricultural injuries among Vermont dairy farmers (Waller 1992), 19% of injuries among a random sample of Alabama farmers (Zhou and Roseman 1995), and 24% of injuries among Iowa farmers (Iowa Department of Public Health 1995). One of the few studies to analyse risk factors for livestock-specific injuries indicates such injuries may be related to the organization of production and specific features of the livestock rearing environment (Layde et al. 1996).

Evidence from other industrialized agricultural areas of the world reveals similar patterns. Research from Australia indicates that livestock workers have the second-highest occupational fatal injury rates in the country (Erlich et al. 1993). A study of accident records and emergency department visits of British farmers in West Wales (Cameron and Bishop 1992) reveals livestock were the leading source of injuries, accounting for 35% of farm-related accidents. In Denmark, a study of 257 hospital-treated agricultural injuries revealed livestock as the second-leading cause of injuries, accounting for 36% of injuries treated (Carstensen, Lauritsen and Rasmussen 1995). Surveillance research is necessary to address the lack of systematic data on livestock-related injury rates in developing areas of the world.

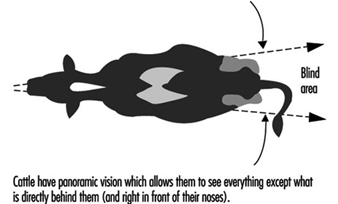

Prevention of livestock-related injuries involves understanding animal behaviour and respecting dangers by acting appropriately and using appropriate control technologies. Understanding animal habits related to feeding behaviours and environmental fluctuations, social relationships such as animals isolated from their herd, nurturing and protective instincts of female animals and the variable territorial nature and feeding patterns of livestock are critical in reducing the risk of injury. Prevention of injury also depends on using and maintaining livestock control equipment such as fences, pens, stalls and cages. Children are at particular risk and should be supervised in designated play areas well away from livestock holding areas.

Infectious Diseases

Zoonotic diseases can be classified according to their modes of transmission, which are in turn linked to forms of agriculture, human social organization and the ecosystem. The four general routes of transmission are:

- direct single vertebrate host

- cyclical multiple vertebrate host

- combination vertebrate-invertebrate host

- inanimate intermediary host.

Zoonotic diseases can be generally characterized as follows: they are non-fatal, infrequently diagnosed and sporadic rather than epidemic; they mimic other diseases; and humans are typically the dead-end hosts. Primary zoonotic diseases by region are listed in table 2.

Table 2. Primary zoonoses by world region

|

Common name |

Principal source |

Region |

|

Anthrax |

Mammals |

Eastern Mediterranean, West and Southeast Asia, Latin America |

|

Brucellosis |

Goats, sheep, cattle, swine |

Europe, Mediterranean area, United States |

|

Encephalitis, arthropod-borne |

Birds, sheep, rodents |

Africa, Australia, Central Europe, Far East, Latin America, Russia, United States |

|

Hydatidosis |

Dogs, ruminants, swine, wild carnivores |

Eastern Mediterranean, southern South America, South and East Africa, New Zealand, southern Australia, Siberia |

|

Leptospirosis |

Rodents, cattle, swine, wild carnivores, horses |

Worldwide, more prevalent in Caribbean |

|

Q fever |

Cattle, goats, sheep |

Worldwide |

|

Rabies |

Dogs, cats, wild carnivores, bats |

Worldwide |

|

Salmonellosis |

Birds, mammals |

Worldwide, most prevalent in regions with industrial agriculture and higher use of antibiotics |

|

Trichinosis |

Swine, wild carnivores, Arctic animals |

Argentina, Brazil, Central Europe, Chile North America, Spain |

|

Tuberculosis |

Cattle, dogs, goats |

Worldwide, most prevalent in developing countries |

Rates of zoonotic diseases among human populations are largely unknown owing to the lack of epidemiological data and to misdiagnoses. Even in industrialized countries such as the United States, zoonotic diseases such as leptospirosis are frequently mistaken for influenza. Symptoms are non-specific, making diagnosis difficult, a characteristic of many zoonoses.

Prevention of zoonotic diseases consists of a combination of disease eradication, animal vaccinations, human vaccinations, work environment sanitation, cleaning and protecting open wounds, appropriate food handling and preparation techniques (such as pasteurization of milk and thorough cooking of meat), use of personal protection equipment (such as boots in rice fields) and prudent use of antibiotics to reduce the growth of resistant strains. Control technologies and preventive behaviours should be conceptualized in terms of pathways, agents and hosts and specifically targeted to the four routes of transmission.

Respiratory Diseases

Given the variety and extent of exposures related to livestock production, respiratory diseases may be the major health problem. Studies in some sectors of livestock production in developed areas of the world reveal that 25% of livestock workers suffer from some form of respiratory disease (Thorne et al. 1996). The kinds of work most commonly associated with respiratory problems include grain production and handling and working in animal confinement units and dairy farming.

Agricultural respiratory diseases may result from exposures to a variety of dusts, gases, agricultural chemicals and infectious agents. Dust exposures may be divided into those primarily consisting of organic components and those consisting mainly of inorganic components. Field dust is the primary source of inorganic dust exposures. Organic dust is the major respiratory exposure to agricultural production workers. Disease results from periodic short-term exposures to agricultural organic dust containing large numbers of microbes.

ODTS is the acute flu-like illness seen following periodic short-term exposure to high concentrations of dust (Donham 1986). This syndrome has features very similar to those of acute farmer’s lung, but does not carry the risk of pulmonary impairment associated with farmer’s lung. Bronchitis affecting agricultural workers has both an acute and chronic form (Rylander 1994). Asthma, as defined by reversible airway obstruction associated with airway inflammation, can also be caused by agricultural exposures. In most cases this type of asthma is related to chronic inflammation of the airways rather than a specific allergy.

A second common exposure pattern is daily exposure to a lower level of organic dust. Typically, total dust levels are 2 to 9 mg/m3, microbe counts are at 103 to 105 organisms/m3 and endotoxin concentration is 50 to 900 EU/m3. Examples of such exposures include work in a swine confinement unit, a dairy barn or a poultry-growing facility. Usual symptoms seen with these exposures include those of acute and chronic bronchitis, an asthma-like syndrome and symptoms of mucous membrane irritation.

Gases play an important role in causing lung disorders in the agricultural setting. In swine confinement buildings and in poultry facilities, ammonia levels often contribute to respiratory problems. Exposure to the fertilizer anhydrous ammonia has both acute and long-term effects on the respiratory tract. Acute poisoning from hydrogen sulphide gas released from manure storage facilities in dairy barns and swine confinement units can cause fatalities. Inhalation of insecticidal fumigants can also lead to death.

Prevention of respiratory illnesses may be aided by controlling the source of dusts and other agents. In livestock buildings, this includes managing a correctly designed ventilation system and frequent cleaning to prevent build-up of dust. However, engineering controls alone are likely insufficient. Correct selection and use of a dust respirator is also needed. Alternatives to confinement operations can also be considered, including pasture-based and partially enclosed production arrangements, which can be as profitable as confined operations, particularly when occupational health costs are considered.

Skin Problems

Skin problems can be categorized as contact dermatitis, sun-related, infectious or insect-induced. Estimates indicate that agricultural workers are at highest occupational risk for certain dermatoses (Mathias 1989). While prevalence rates are lacking, particularly in developing regions, studies in the United States indicate that occupational skin disease may account for up to 70% of all occupational diseases among agricultural workers in certain regions (Hogan and Lane 1986).

There are three types of contact dermatoses: irritant dermatitis, allergic dermatitis and photocontact dermatitis. The most common form is irritant contact dermatitis, while allergic contact dermatitis is less common and photocontact reactions are rare (Zuehlke, Mutel and Donham 1980). Common sources of contact dermatitis on the farm include fertilizers, plants and pesticides. Of particular note is dermatitis from contact with livestock feed. Feeds containing additives such as antibiotics may result in allergic dermatitis.

Light-complexioned farmers in developing areas of the world are at particular risk for chronic sun-induced skin problems, including wrinkling, actinic keratoses (scaly non-cancerous lesions) and skin cancer. The two most common types of skin cancer are squamous and basal cell carcinomas. Epidemiological work in Canada indicates that farmers are at higher risk for squamous cell carcinoma than non-farmers (Hogan and Lane 1986). Squamous cell carcinomas often arise from actinic keratoses. Approximately 2 out of 100 squamous cell carcinomas metastasize, and they are most common on the lips. Basal cell carcinomas are more common and occur on the face and ears. While locally destructive, basal cell carcinomas rarely metastasize.

Infectious dermatoses most relevant for livestock workers are ringworm (dermatophytic fungi), orf (contagious ecthyma) and milker’s nodule. Ringworm infections are superficial skin infections that appear as red scaling lesions that result from contact with infected livestock, particularly dairy cattle. A study from India, where cattle generally roam free, revealed over 5% of rural inhabitants suffering from ringworm infections (Chaterjee et al. 1980). Orf, by contrast, is a pox virus usually contracted from infected sheep or goats. The result is typically lesions on the backs of hands or fingers which usually disappear with some scarring in about 6 weeks. Milker’s nodules result from infection with the pseudocowpox poxvirus, typically from contact with infected udders or teats of milk cows. These lesions appear similar to those of orf, though they are more often multiple.

Insect-induced dermatoses result primarily from bites and stings. Infections from mites that parasitize livestock or contaminate grains is particularly notable among livestock handlers. Chigger bites and scabies are typical skin problems from mites that result in various forms of reddened irritations that usually heal spontaneously. More serious are bites and stings from various insects such as bees, wasps, hornets or ants that result in anaphylactic reactions. Anaphylactic shock is a rare hypersensitivity reaction that occurs with an overproduction of chemicals emitted from white blood cells that result in constriction of the airways and can lead to cardiac arrest.

All of these skin problems are largely preventable. Contact dermatitis can be prevented by reducing exposures through use of protective clothing, gloves and appropriate personal hygiene. Additionally, insect-related problems can be prevented by wearing light-coloured and nonflowery clothing and by avoiding scented skin applications. The risk of skin cancer can be dramatically reduced by using appropriate clothing to minimize exposure, such as a wide-brimmed hat. Use of appropriate sunscreen lotions can also be helpful, but should not be relied upon.

Conclusion

The number of livestock worldwide has grown apace with the increase in human population. There are approximately 4 billion cattle, pigs, sheep, goats, horses, buffalo and camels in the world (Durning and Brough 1992). However, there is a notable lack of data on livestock-related human health problems in developing areas of the world such as China and India, where much of the livestock currently reside and where future growth is likely to occur. However, given the emergence of industrialized agriculture worldwide, it can be anticipated that many of the health problems documented in North American and European livestock production will likely accompany the emergence of industrialized livestock production elsewhere. It is also anticipated that health services in these areas will be inadequate to deal with the health and safety consequences of industrialized livestock production generally described here.

The worldwide emergence of industrialized livestock production with its attendant human health consequences will accompany fundamental changes in the social, economic and political order comparable to those that followed from the domestication of animals over 10,000 years ago. Preventing human health problems will require broad understanding and appropriate engagement of these new forms of human adaptation and the place of livestock production within them.

Case Study: Arthropod-Related Occupational Health Problems

Arthropods comprise more than 1 million species of insects and thousands of species of ticks, mites, spiders, scorpions and centipedes. Bees, ants, wasps and scorpions sting and inject venom; mosquitoes and ticks suck blood and transmit diseases; and the scales and hairs from insect bodies can irritate the eyes and skin, as well as tissues in the nose, mouth and respiratory system. Most stings in humans are from social bees (bumble bees, honey bees). Other stings are from paper wasps, yellow jackets, hornets and ants.

Arthropods can be a health hazard in the workplace (see table 1), but in most cases, potential arthropod hazards are not unique to specific occupations. Rather, exposure to arthropods in the workplace depends on geographic location, local conditions and the time of year. Table 2 lists some of these hazards and their corresponding arthropod agents. For all arthropod hazards, the first line of defence is avoidance or exclusion of the offending agent. Venom immunotherapy may increase a person’s tolerance to arthropod venom and is accomplished by injecting increasing doses of venom over time. It is effective in 90 to 100% of venom hypersensitive individuals but involves an indefinite course of expensive injections. Table 3 lists normal and allergic reactions to insect stings.

Table 1. Different occupations and their potential for contact with arthropods that may adversely affect health and safety.

|

Occupation |

Arthropods |

|

Construction personnel, environmentalists, farmers, fishers, foresters, fish and wildlife workers, naturalists, transportation workers, park rangers, utility workers |

Ants, bees, biting flies, caterpillars, chiggers, centipedes, caddisflies, fly maggots, mayflies, scorpions, spiders, ticks, wasps |

|

Cosmetics manufacturers, dock workers, dye makers, factory workers, food processors, grainery workers, homemakers, millers, restaurant workers |

Ants; beetles; bean, grain and pea weevils; mites; scale insects; spiders |

|

Beekeepers |

Ants, bumble bees, honey bees, wasps |

|

Insect production workers, laboratory and field biologists, museum curators |

Over 500 species of arthropods are reared in the laboratory. Ants, beetles, mites, moths, spiders and ticks are especially important. |

|

Hospital and other health care workers, school administrators, teachers |

Ants, beetles, biting flies, caterpillars, cockroaches, mites |

|

Silk producers |

Silk worms |

Table 2. Potential arthropod hazards in the workplace and their causative agent(s)

|

Hazard |

Arthropod agents |

|

Bites, envenomation1 |

Ants, biting flies, centipedes, mites, spiders |

|

Sting envenomation, venom hypersensitivity2 |

Ants, bees, wasps, scorpions |

|

Tick toxicosis/paralysis |

Ticks |

|

Asthma |

Beetles, caddisflies, caterpillars, cockroaches, crickets, dust mites, fly maggots, grain mites, grain weevils, grasshoppers, honeybees, mayflies, moths, silk worms |

|

Contact dermatitis3 |

Blister beetles, caterpillars, cockroaches, dried fruit mites, dust mites, grain mites, straw itch mites, moths, silk worms, spiders |

1 Envenomation with poison from glands associated with mouthparts.

2 Envenomation with poison from glands not associated with mouthparts.

3 Includes primary irritant and allergic dermatitis.

Table 3. Normal and allergic reactions to insect sting

|

Type of response |

Reaction |

| I. Normal, non-allergic reactions at the time of the sting |

Pain, burning, itching, redness at the sting site, white area surrounding the sting site, swelling, tenderness |

| II. Normal, non-allergic reactions hours or days after sting |

Itching, residual redness, small brown or red damage spot at sting site, swelling at the sting site |

|

III. Large local reactions |

Massive swelling around the sting site extending over an area 10 cm or more and increasing in size for 24 to 72 hours, sometimes lasting up to a week or more |

|

IV. Cutaneous allergic reactions |

Hives anywhere on the skin, massive swelling remote from the sting site, generalized itching of the skin, generalized redness of the skin remote from the sting site |

|

V. Non life-threatening systemic |

Allergic rhinitis, minor respiratory symptoms, abdominal cramps |

|

VI. Life-threatening systemic allergic reactions |

Shock, unconsciousness, hypotension or fainting, difficulty in breathing, massive swelling in the throat. |

Source: Schmidt 1992.

Forage Crops

As populations tended to concentrate and the need for winter feeding in northern climates grew, the need to harvest, cure and feed hay to domestic animals emerged. Although pasture dates to the earliest domestication of animals, the first cultivated forage plant may have been alfalfa, with its recorded use dating back to 490 BC in Persia and Greece.

Livestock forage is a crucial input for livestock rearing. Forages are grown for their vegetation and not their grains or seeds. Stems, leaves and inflorescences (flower clusters) of some legumes (e.g., alfalfa and clover) and a variety of non-legume grasses are used for grazing or harvested and fed to livestock. When grain crops such as corn, sorghum or straw are harvested for their vegetation, they are considered forage crops.

Production Processes

The major categories of forage crops are pastures and open ranges, hay and silage. Forage crops can be harvested by livestock (in pastures) or by humans, either by hand or machinery. The crop can be used for farm feeding or for sale. In forage production, tractors are a source of traction and processing power, and, in dry areas, irrigation may be required.

Pasture is fed by allowing the livestock to graze or browse. The type of pasture crop, typically grass, varies in its production with the season of the year, and pastures are managed for spring, summer and fall grazing. Range management focuses on not overgrazing an area, which involves rotating livestock from one area to another. Crop residues may be part of the pasture diet for livestock.

Alfalfa, a popular hay crop, is not a good pasture crop because it causes bloating in ruminants, a condition of a gas build-up in the rumen (the first part of the cow’s stomach) that can kill a cow. In temperate climates, pastures are ineffective as a feed source in the winter, so stored feed is needed. Moreover, in large operations, harvested forage—hay and silage—is used because pasture is impractical for large concentrations of animals.

Hay is forage that is grown and dry-cured before storage and feeding. After the hay crop has grown, it is cut with a mowing machine or swather (a machine that combines the mowing and raking operations) and raked by a machine into a long row for drying (a windrow). During these two processes it is field cured for baling. Historically harvesting was done by pitchforking loose hay, which may still be used to feed the animals. Once cured, the hay is baled. The baling machine picks up the hay from the windrow, and compresses and wraps it into either a small square bale for manual handling, or large square or round bales for mechanical handling. The small bale may be kicked mechanically from the baler back into a trailer, or it may be picked up by hand and placed—a task called bucking—onto a trailer for transport to the storage area. The bales are stored in stacks, usually under a cover (barn, shed or plastic) to protect them from rain. Wet hay can easily spoil or spontaneously combust from the heat of the decaying process. Hay may be processed for commercial use into compressed pellets or cubes. A crop can be cut several times in a season, three times being typical. When it is fed, a bale is moved to the feeding trough, opened and placed into the trough where the animal can reach it. This part of the operation is typically manual.

Other forage that is harvested for livestock feeding is corn or sorghum for silage. The economic advantage is that corn has as much as 50% more energy when harvested as silage than grain. A machine is used to harvest most of the green plant. The crop is cut, crushed, chopped and ejected into a trailer. The material is then fed as green chop or stored in a silo, where it undergoes fermentation in the first 2 weeks. The fermentation establishes an environment that prevents spoilage. Over a year, the silo is emptied as the silage is fed to livestock. This feeding process is primarily mechanical.

Hazards and Their Prevention

The storage of animal feed presents health hazards for workers. Early in the storage process, nitrogen dioxide is produced and can cause serious respiratory damage and death (“silo filler’s disease”). Storage in enclosed environments, such as silos, can create this hazard, which can be avoided by not entering silos or enclosed storage spaces in the first few weeks after feed has been stored. Further problems can occur later if the alfalfa, hay, straw or other forage crop was wet when it was stored and there is a build-up of fungi and other microbial contaminants. This can result in acute respiratory illness (“silo unloader’s disease”, organic dust toxicity) and/or chronic respiratory diseases (“farmer’s lung”). The risk of acute and chronic respiratory diseases can be reduced through the use of appropriate respirators. There should also be appropriate confined space entry procedures.

The straw and hay used for bedding is usually dry and old, but may contain moulds and spores which can cause respiratory symptoms when dust is made airborne. Dust respirators can reduce exposure to this hazard.

Harvesting and baling equipment and bedding choppers are designed to chop, cut and mangle. They have been associated with traumatic injuries to farm workers. Many of these injuries occur when workers try to clear clogged parts while the equipment is still operating. The equipment should be turned off before clearing jams. If more than one person is working, then a lockout/tagout programme should be in effect. Another major source of injuries and fatalities is tractor overturns without proper roll-over protection for the driver (Deere & Co. 1994). More information on farm machinery hazards is also discussed elsewhere in this Encyclopaedia.

Where animals are used to plant, harvest and store feed, there is a possibility of animal-related injuries from kicks, bites, strains, sprains, crush injuries and lacerations. Correct animal handling techniques are the most likely means to reduce these injuries.

Manual handling of bales of hay and straw can result in ergonomic problems. Workers should be trained in correct lifting procedures, and mechanical equipment should be used where possible.

Forage and bedding are fire hazards. Wet hay, as mentioned previously, is a spontaneous combustion hazard. Dry hay, straw and so forth will burn easily, especially when loose. Even bailed forage is a major fuel source in a fire. Basic fire precautions should be instituted, such as no-smoking rules, elimination of spark sources and fire suppression measures.

Livestock Confinement

Global economic forces have contributed to the industrialization of agriculture (Donham and Thu 1995). In the developed countries, there are trends toward increased specialization, intensity and mechanization. Increased confinement production of livestock has been a result of these trends. Many developing countries have recognized the need to adopt confinement production in an attempt to transform their agriculture from a subsistence to a globally competitive enterprise. As more corporate organizations obtain ownership and control of the industry, fewer, but larger, farms with many employees replace the family farm.

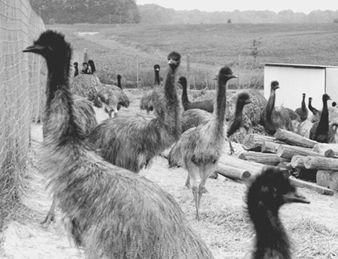

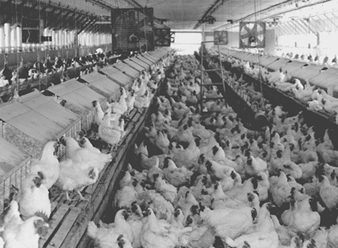

Conceptually, the confinement system applies principles of industrial mass production to livestock production. The concept of confinement production includes raising animals in high densities in structures that are isolated from the outside environment and equipped with mechanical or automated systems for ventilation, waste handling, feeding and watering (Donham, Rubino et al. 1977).

Several European countries have been using confinement systems since the early 1950s. Livestock confinement started to appear in the United States in the late 1950s. Poultry producers were first to use the system. By the early 1960s, the swine industry had also started to adopt this technique, followed more recently by dairy and beef producers.

Accompanying this industrialization, several worker health and social concerns have developed. In most Western countries, farms are getting fewer in number but larger in size. There are fewer family farms (combined labour and management) and more corporate structures (particularly in North America). The result is that there are more hired workers and relatively fewer family members working. Additionally, in North America, more workers are coming from minority and immigrant groups. Therefore, there is a risk of producing a new underclass of workers in some segments of the industry.

A whole new set of occupational hazardous exposures has arisen for the agricultural worker. These can be categorized under four main headings:

- toxic and asphyxiating gases

- bioactive aerosols of particulates

- infectious diseases

- noise.

Respiratory hazards are also a concern.

Toxic and Asphyxiating Gases

Several toxic and asphyxiating gases resulting from microbial degradation of animal wastes (urine and faeces) may be associated with livestock confinement. Wastes are most commonly stored in liquid form under the building, over a slatted floor or in a tank or lagoon outside the building. This manure storage system is usually anaerobic, leading to the formation of a number of toxic gases (see table 1) (Donham, Yeggy and Dauge 1988). See also the article “Manure and waste handling" in this chapter.

Table 1. Compounds identified in swine confinement building atmospheres

|

2-Propanol |

Ethanol |

Isopropyl propionate |

|

3-Pentanone |

Ethyl formate |

Isovaleric acid |

|

Acetaldehyde |

Ethylamine |

Methane |

|

Acetic acid |

Formaldehyde |

Methyl acetate |

|

Acetone |

Heptaldehyde |

Methylamine |

|

Ammonia |

Heterocylic nitrogen compound |

Methylmercaptan |

|

n-Butanol |

Hexanal |

Octaldehyde |

|

n-Butyl |

Hydrogen sulphide |

n-Propanol |

|

Butyric acid |

Indole |

Propionic acid |

|

Carbon dioxide |

Isobutanol |

Proponaldehyde |

|

Carbon monoxide |

Isobutyl acetate |

Propyl propionate |

|

Decaldehyde |

Isobutyraldehyde |

Skatole |

|

Diethyl sulphide |

Isobutyric acid |

Triethylamine |

|

Dimethyl sulphide |

Isopentanol |

Trimethylamine |

|

Disulphide |

Isopropyl acetate |

There are four common toxic or asphyxiating gases present in almost every operation where anaerobic digestion of wastes occurs: carbon dioxide (CO2), ammonia (NH3), hydrogen sulphide (H2S) and methane (CH4). A small amount of carbon monoxide (CO) may also be produced by the decomposing animal wastes, but its main source is heaters used to burn fossil fuels. Typical ambient levels of these gases (as well as particulates) in swine confinement buildings are shown in table 2. Also listed are maximum recommended exposures in swine buildings based on recent research (Donham and Reynolds 1995; Reynolds et al. 1996) and threshold limit values (TLVs) set by the American Conference of Governmental Industrial Hygienists (ACGIH 1994). These TLVs have been adopted as legal limits in many countries.

Table 2. Ambient levels of various gases in swine confinement buildings

|

Gas |

Range (ppm) |

Typical ambient concentrations (ppm) |

Recommended maximum exposure concentrations (ppm) |

Threshold limit values (ppm) |

|

CO |

0 to 200 |

42 |

50 |

50 |

|

CO2 |

1,000 to 10,000 |

8,000 |

1,500 |

5,000 |

|

NH3 |

5 to 200 |

81 |

7 |

25 |

|

H2S |

0 to 1,500 |

4 |

5 |

10 |

|

Total dust |

2 to 15 mg/m3 |

4 mg/m3 |

2.5 mg/m3 |

10 mg/m3 |

|

Respirable dust |

0.10 to 1.0 mg/m3 |

0.4 mg/m3 |

0.23 mg/m3 |

3 mg/m3 |

|

Endotoxin |

50 to 500 ng/m3 |

200 ng/m3 |

100 ng/m3 |

(none established) |

It can be seen that in many of the buildings, at least one gas, and often several, exceeds the exposure limits. It should be noted that simultaneous exposure to these toxic substances may be additive or synergistic—the TLV for the mixture may be exceeded even when individual TLVs are not exceeded. Concentrations are often higher in the winter than in the summer, because ventilation is reduced to conserve heat.

These gases have been implicated in several acute conditions in workers. H2S has been implicated in many sudden animal deaths and several human deaths (Donham and Knapp 1982). Most acute cases have occurred shortly after the manure pit has been agitated or emptied, which may result in a sudden release of a large volume of the acutely toxic H2S. In other fatal cases, manure pits had recently been emptied, and workers who entered the pit for inspection, repairs or to retrieve a dropped object collapsed without any forewarning. The available post-mortem results of these cases of acute poisoning revealed massive pulmonary oedema as the only notable finding. This lesion, combined with the history, is compatible with hydrogen sulphide intoxication. Rescue attempts by bystanders have often resulted in multiple fatalities. Confinement workers should therefore be informed of the risks involved and advised never to enter a manure storage facility without testing for the presence of toxic gases, being equipped with a respirator with its own oxygen supply, ensuring adequate ventilation and having at least two other workers stand by, attached by a rope to the worker who enters, so they can effect a rescue without endangering themselves. There should be a written confined-space programme.

CO may also be present at acute toxic levels. Abortion problems in swine at an atmospheric concentration of 200 to 400 ppm and subacute symptoms in humans, such as chronic headache and nausea, have been documented in swine confinement systems. The possible effects on the human foetus should also be of concern. The primary source of CO is from improperly functioning hydrocarbon-burning heating units. Heavy accumulation of dust in swine confinement buildings makes it difficult to keep heaters in correct working order. Propane-fuelled radiant heaters are also a common source of lower levels of CO (e.g., 100 to 300 ppm). High-pressure washers powered by an internal combustion engine that may be run inside the building are another source; CO alarms should be installed.

Another acutely dangerous situation occurs when the ventilation system fails. Gas levels may then rapidly build up to critical levels. In this case the major problem is replacement of oxygen by other gases, primarily CO2 produced from the pit as well as from the respiratory activity of the animals in the building. Lethal conditions could be reached in as few as 7 hours. Regarding the health of the pigs, ventilation failure in warm weather may allow temperature and humidity to increase to lethal levels in 3 hours. Ventilation systems should be monitored.

A fourth potentially acute hazard arises from build-up of CH4, which is lighter than air and, when emitted from the manure pit, tends to accumulate in the upper portions of the building. There have been several instances of explosions occurring when the CH4 accumulation was ignited by a pilot light or a worker’s welding torch.

Bioactive Aerosols of Particulates

The sources of dust in confinement buildings are a combination of feed, dander and hair from the swine and dried faecal material (Donham and Scallon 1985). The particulates are about 24% protein and therefore have the potential not only for initiating an inflammatory response to foreign protein but also for initiating an adverse allergic reaction. The majority of particles are smaller than 5 microns, allowing them to be respired into the deep portions of the lungs, where they may produce a greater danger to health. The particulates are laden with microbes (104 to 107/m3 air). These microbes contribute several toxic/inflammatory substances including, among others, endotoxin (the most documented hazard), glucans, histamine and proteases. The recommended maximum concentrations for dusts are listed in table 2. Gases present within the building and bacteria in the atmosphere are adsorbed on the surface of the dust particles. Thus, the inhaled particles have the increased potentially hazardous effect of carrying irritating or toxic gases as well as potentially infectious bacteria into the lungs.

Infectious Diseases

Some 25 zoonotic diseases have been recognized as having occupational significance for agricultural workers. Many of these may be transmitted directly or indirectly from livestock. The crowded conditions prevailing in confinement systems offer a high potential for transmission of zoonotic diseases from livestock to humans. Swine confinement environment may offer a risk for transmission to workers of swine influenza, leptospirosis, Streptococcus suis and salmonella, for example. The poultry confinement environment may offer a risk for ornithosis, histoplasmosis, New Castle disease virus and salmonella. Bovine confinement could offer a risk for Q fever, Trichophyton verrucosum (animal ringworm) and leptospirosis.

Biologicals and antibiotics have also been recognized as potential health hazards. Injectable vaccines and various biologicals are commonly used in veterinary preventive medical programmes in animal confinement. Accidental inoculation of Brucella vaccines and Escherichia coli bacteria has been observed to cause illness in humans.

Antibiotics are commonly used both parenterally and incorporated in animal feed. Since it is recognized that feed is a common component of the dust present in animal confinement buildings, it is assumed that antibiotics are also present in the air. Thus, antibiotic hypersensitivity and antibiotic-resistant infections are potential hazards for the workers.

Noise

Noise levels of 103 dBA have been measured within animal confinement buildings; this is above the TLV, and offers a potential for noise-induced hearing loss (Donham, Yeggy and Dauge 1988).

Respiratory Symptoms of Livestock Confinement Workers

The general respiratory hazards within livestock confinement buildings are similar regardless of the species of livestock. However, swine confinements are associated with adverse health effects in a larger percentage of workers (25 to 70% of active workers), with more severe symptoms than those in poultry or cattle confinements (Rylander et al. 1989). The waste in poultry facilities is usually handled in solid form, and in this instance ammonia seems to be the primary gaseous problem; hydrogen sulphide is not present.

Subacute or chronic respiratory symptoms reported by confinement workers have been observed to be most frequently associated with swine confinement. Surveys of swine confinement workers have revealed that about 75% suffer from adverse acute upper respiratory symptoms. These symptoms can be broken down into three groups:

- acute or chronic inflammation of the respiratory airways (manifested as bronchitis)

- acquired occupational (non-allergic) constriction of the airways (asthma)

- delayed self-limited febrile illness with generalized symptoms (organic dust toxic syndrome (ODTS)).

Symptoms suggestive of chronic inflammation of the upper respiratory system are common; they are seen in about 70% of swine confinement workers. Most commonly, they include tightness of the chest, coughing, wheezing and excess sputum production.

In approximately 5% of workers, symptoms develop after working in the buildings for only a few weeks. The symptoms include chest tightness, wheezing and difficult breathing. Usually these workers are affected so severely that they are forced to seek employment elsewhere. Not enough is known to indicate whether this reaction is an allergic hypersensitivity or a non-allergic hypersensitivity to dust and gas. More typically, symptoms of bronchitis and asthma develop after 5 years of exposure.

Approximately 30% of workers occasionally experience episodes of delayed symptoms. Approximately 4 to 6 hours after working in the building they develop a flu-like illness manifested by fever, headache, malaise, general muscle aches and chest pain. They usually recover from these symptoms in 24 to 72 hours. This syndrome has been recognized as ODTS.

The potential for chronic lung damage certainly seems to be real for these workers. However, this has not been documented so far. It is recommended that certain procedures be followed to prevent chronic exposure as well as acute exposure to the hazardous materials in swine confinement buildings. Table 3 summarizes the medical conditions seen in swine confinement workers.

Table 3. Respiratory diseases associated with swine production

|

Upper airway disease |

Sinusitis |

|

Lower airway disease |

Occupational asthma |

|

Interstitial disease |

Alveolitis |

|

Generalized illness |

Organic dust toxic syndrome (ODTS) |

Sources: Donham, Zavala and Merchant 1984; Dosman et al. 1988; Haglind and Rylander 1987; Harries and Cromwell 1982; Heedrick et al. 1991; Holness et al. 1987; Iverson et al. 1988; Jones et al. 1984; Leistikow et al. 1989; Lenhart 1984; Rylander and Essle 1990; Rylander, Peterson and Donham 1990; Turner and Nichols 1995.

Worker Protection

Acute exposure to hydrogen sulphide. Care should always be taken to avoid exposure to H2S that may be given off when agitating an anaerobic liquid manure storage tank. If the storage is under the building, it is best to stay out of the building when the emptying procedure is going on and for several hours afterwards, until air sampling indicates it is safe. Ventilation should be at the maximum level during this time. A liquid manure storage facility should never be entered without the safety measures mentioned above being followed.

Particulate exposure. Simple management procedures, such as the use of automated feeding equipment designed to eliminate as much feed dust as possible should be used to control particulate exposure. Adding extra fat to feed, frequent power-washing of the building and installing slatted flooring that cleans well are all proven control measures. An oil-misting dust-control system is presently under study and may be available in the future. In addition to good engineering control, a good-quality dust mask should be worn.

Noise. Ear protectors should be provided and worn, particularly when working in the building in order to vaccinate the animals or for other management procedures. A hearing conservation programme should be instituted.

Animal Husbandry

Animal husbandry—the rearing and use of animals—involves a wide variety of activities, including breeding, feeding, moving animals from one location to another, basic care (e.g., hoof care, cleaning, vaccinations), care for injured animals (either by animal handlers or veterinarians) and activities associated with particular animals (e.g., milking of cows, shearing of sheep, working with draught animals).

Such handling of livestock is associated with a variety of injuries and illnesses among humans. These injuries and illnesses may be due to direct exposure or may be due to environmental contamination from animals. The risk of injury and illness is dependent largely on the type of livestock. The risk of injury also depends on the particulars of animal behaviour (see also the articles in this chapter on specific animals). In addition, persons associated with animal husbandry are often more likely to consume products from the animals. Finally, the specific exposures depend on methods of handling livestock, which have emerged from geographical and social factors that vary across human society.

Hazards and Precautions

Ergonomic Risks