Overview and Health Effects

Food Industry Processes

This article is adapted from the 3rd edition “Encyclopaedia of Occupational Health” articles “Food industries”, by M Malagié; “Frozen food industry”, by G. Jenson; and “Canning and food preserving”, by J.C. Graham, which were revised by Donald L. Smith.

The term food industries covers a series of industrial activities directed at the processing, conversion, preparation, preservation and packaging of foodstuffs (see table 1). The raw materials used are generally of vegetable or animal origin and produced by agriculture, farming, breeding and fishing. This article provides an overview of the complex of food industries. Other articles in this chapter and Encyclopaedia deal with particular food industry sectors and particular hazards.

Table 1. The food industries, their raw materials and processes

|

Industry |

Materials processed |

Storage requirements |

Processing techniques |

Preserving techniques |

Packaging of finished products |

|

Meat processing and preserving |

Beef, lamb, pork, poultry |

Cold stores |

Slaughtering, cutting up, boning, comminuting, cooking |

Salting, smoking, refrigeration, deep-freezing, sterilization |

Loose or in cans, cardboard |

|

Fish processing |

All types of fish |

Cold stores or salted loose or in barrels |

Heading, gutting, filleting, cooking |

Deep-freezing, drying, smoking, sterilization |

Loose in refrigerated containers or in cans |

|

Fruit and vegetable preserving |

Fresh fruit and vegetables |

Processed immediately; fruits may be stabilized with sulphur dioxide |

Blanching or cooking, grinding, vacuum- concentration of juices |

Sterilization, pasteurization, drying, dehydration, lyophilization (freeze drying) |

Bags, cans or glass or plastic bottles |

|

Milling |

Grains |

Silos may be fumigated in storage |

Grinding, sifting, milling, rolling |

Drying cooking or baking |

Silos (conveyed pneumatically), sacks or bags to other processes, or boxed for retail trade |

|

Baking |

Flour and other dry goods, water, oils |

Silos, super sacks and bags |

Kneading, fermentation, laminating surface treatments of seasoning |

Baking, cutting surface treatments and packaging |

Packaged for wholesale trades, restaurants and retail markets |

|

Biscuit making |

Flour, cream, butter, sugar, fruit and seasoning |

Silos, super sacks and bags |

Mixing, kneading, laminating moulding |

Baking, cutting surface treatments and packaging |

Bags, boxes for institutional and retail trades |

|

Pasta manufacture |

Flour, eggs |

Silos |

Kneading, grinding, cutting, extrusion or moulding |

Drying |

Bags, packets |

|

Sugar processing and refining |

Sugar beet, sugar cane |

Silos |

Crushing, maceration, vacuum concentration, centrifuging, drying |

Vacuum cooking |

Bags, packets |

|

Chocolate making and confectionery |

Cocoa bean sugar, fats |

Silos, sacks, conditioned chambers |

Roasting, grinding, mixing, conching, moulding |

– |

Packets |

|

Brewing |

Barley, hops |

Silos, tanks, conditioned cellars |

Grain milling, malting, brewing, filter pressing, fermentation |

Pasteurization |

Bottles, cans, barrels |

|

Distilling and manufacture of other beverages |

Fruit, grain, carbonated water |

Silos, tanks, vats |

Distillation, blending, aeration |

Pasteurization |

Barrels, bottles, cans |

|

Milk and milk products processing |

Milk, sugar, other constituents |

Immediate processing; subsequently in ripening vats, conditioned vats, cold store |

Skimming, churning (butter), coagulation (cheese), ripening |

Pasteurization, sterilization or concentration, desiccation |

Bottles, plastic wrapping, boxes (cheese) or unpacked |

|

Processing of oils and fats |

Groundnuts, olives, dates, other fruit and grain, animal or vegetable fats |

Silos, tanks, cold stores |

Milling, solvent or steam extraction, filter pressing |

Pasteurization where necessary |

Bottles, packets, cans |

The food industry today has become highly diversified, with manufacturing ranging from small, traditional, family-run activities that are highly labour intensive, to large, capital-intensive and highly mechanized industrial processes. Many food industries depend almost entirely on local agriculture or fishing. In the past, this meant seasonal production and hiring of seasonal workers. Improvements in food processing and preservation technologies have taken some of the pressure off workers to process food quickly to prevent spoilage. This has resulted in a decrease in seasonal employment fluctuations. However, certain industries still have seasonal activities, such as fresh fruit and vegetable processing and increases in production of baked goods, chocolate and so forth for holiday seasons. Seasonal workers are often women and foreign workers.

The world’s food product output has been increasing. World exports of food products in 1989 totalled US$290 billion, a 30% increase over 1981. Industrialized market economy countries had a 67% share of this export. Much of this increase can be attributed to an increased demand for processed food and drink, especially in developing countries where the market has not yet been saturated.

This increase in output of food and drink products, however, has not resulted in increased employment because of intensified competition, which has resulted in decreased employment in many food industries, especially in industrialized countries. This is due to increased productivity and mechanization in many of these industries.

Demographic pressure, uneven distribution of agricultural resources and the need to insure preservation of food products to facilitate their better distribution explain the rapid technical evolution in the food industries. Constant economic and marketing pressures drive the industry to provide new and different products for market, while other operations may make the same product in the same way for decades. Even highly industrialized facilities often resort to seemingly archaic techniques when starting new products or processes. In practice, to satisfy population requirements, there is a need not only for a sufficient quantity of foodstuffs, which presupposes an increase of production, but also strict control of sanitation to obtain the quality essential to maintain the health of the community. Only modernization of techniques justified by production volumes in a stable production environment will eliminate manual handling hazards. In spite of the extreme diversity of the food industries, the preparation processes can be divided into handling and storage of raw materials, extraction, processing, preservation and packaging.

Handling and Storage

Manipulation of the raw materials, the ingredients during processing and the finished products is varied and diverse. The current trend is to minimize manual handling by mechanization, through “continuous processing” and automation. Mechanical handling may involve: self-propelled in-plant transport with or without palletization or super or bulk sacks (often containing several thousand pounds of dry powder material); conveyor belts (e.g., with beets, grain and fruit); bucket elevators (e.g., with grain and fish); spiral conveyors (e.g., with confectionery and flour); air fluming (e.g., for unloading grain, sugar or nuts and for transport of flours).

Storage of raw materials is most important in a seasonal industry (e.g., sugar refining, brewing, grain processing and canning). It is usually done in silos, tanks, cellars, bins or cold stores. Storage of the finished products varies according to their nature (liquid or solid), the method of preserving and the method of packaging (loose, in sack or super sack, in bundles, boxes or bottles); and the respective premises must be planned to suit the conditions of handling and preserving (traffic aisles, ease of access, temperature and humidity suited to product, cold-storage installations). Commodities may be held in oxygen-deficient atmospheres or under fumigation while in storage or just before shipment.

Extraction

To extract a specific food product from fruit, cereals or liquids, any of the following methods may be used: crushing, pounding or grinding, extraction by heat (direct or indirect), extraction by solvents, drying and filtration.

Crushing, pounding and grinding are usually preparatory operations—for example, the crushing of cocoa beans and the slicing of sugar beet. In other cases it may be the actual extraction process, as in flour milling.

Heat can be used directly as a means of preparation by extraction, as in roasting (e.g., cocoa, coffee and chicory); in manufacturing it is usually used directly or indirectly in the form of steam (e.g., extraction of edible oils or extraction of sweet juice from thin slices of beet in the sugar industry).

Oils can be extracted equally well by combining and mixing the crushed fruit with solvents that are later eliminated by filtering and reheating. The separation of liquid products is carried out by centrifuging (turbines in a sugar refinery) or by filtering through filter presses in breweries and in oil and fat production.

Production Processes

Operations in processing food products are extremely varied and can be described only after individual study of each industry, but the following general procedures are used: fermentation, cooking, dehydration and distillation.

Fermentation, obtained usually by addition of a micro-organism to the previously prepared product, is practiced in bakeries, breweries, the wine and spirits industry and the cheese products industry. (See also the chapter Beverage industry.)

Cooking occurs in many manufacturing operations: canning and preserving of meat, fish, vegetables and fruits; ready-to-serve meat-processing plants (e.g., chicken nuggets); in bakeries, biscuit making, breweries; and so on. In other cases, cooking is done in a vacuum-sealed container and produces a concentration of the product (e.g., sugar refining and tomato-paste production).

Besides the drying of products by the sun, as with many tropical fruits, dehydration can be carried out in hot air (fixed dryers or drying tunnels), by contact (on a drying drum heated by steam, such as in the instant-coffee industry and the tea industry), vacuum drying (often combined with filtering) and lyophilization (freeze drying), where the product is first frozen solid and then dried by vacuum in a heated chamber.

Distillation is used in the making of spirits. The fermented liquid, treated to separate grain or fruit, is vaporized in a still; the condensed vapour is then collected as liquid ethyl alcohol.

Preservation Processes

It is important to prevent any deterioration of food products, as much for the quality of the products as for the more serious risk of contamination or threat to the consumers’ health.

There are six basic methods of food preservation:

- radiation sterilization

- antibiotic sterilization

- chemical action

- dehydration

- refrigeration.

Briefly, the first three methods destroy microbial life; the latter merely inhibit growth. Raw ingredients such as fish and meat, fruit or vegetables are taken fresh and preserved by one of the above methods, or a mixture of different foods are processed to form a product or dish, which is then preserved. Such products include soups, meat dishes and puddings.

Food preservation goes back to the last Ice Age, about 15,000 BC, when Cro-Magnon humans discovered for the first time a way of preserving food by smoking it. The evidence for this lies in the caves at Les Eyzies in the Dordogne in France, where this way of life is well portrayed in carvings, engravings and paintings. From then to the present day, although many methods have been used and still are, heat remains one of the principal cornerstones of food preservation.

High-temperature processes can destroy bacteria, depending on the cooking temperature and duration. Sterilization (mainly used in canneries) involves submitting the already canned product to the action of steam, generally in a closed container such as an autoclave or continuous cooker. Pasteurization—the term is particularly reserved for liquids such as fruit juice, beer, milk or cream—is carried out at a lower temperature and for a short time. Smoking is carried out mainly on fish, ham and bacon, assuring dehydration and giving a distinctive flavor.

Ionizing radiation sterilization is used heavily on spices in some countries to reduce wastage and spoilage. “Radiation pasteurization” using much lower doses enables the refrigerated shelf life of many foods to be considerably extended. However, sterilizing canned foods with radiation requires such high dosage that unacceptable flavours and odours result.

Ionizing radiation has two other well recognized uses in the food industry—the screening of food packs for foreign matter and monitoring to detect underfilling.

Microwave sterilization is another type of electromagnetic emission that is currently finding use in the food industry. It is used for rapidly thawing raw frozen ingredients before further processing, as well as for heating frozen cooked foods in 2 to 3 minutes. Such a method, with its low moisture content loss, preserves the appearance and flavour of the food.

Drying is a common preservation process. Sun drying is the oldest and most widely used method of food preservation. Today foodstuffs may be dried in air, superheated steam, in vacuum, in inert gas and by direct application of heat. Many types of dryers exist, the particular type being dependent on the nature of the material, the desired form of finished product and so on. Dehydration is a process in which heat is transferred into the water in the food, which is vapourized. The water vapour is then removed.

Low-temperature processes involve storage in a cold store (the temperature determined by the nature of the products), freezing and deep-freezing, which allows foodstuffs to be preserved in their naturally fresh state, by various methods of slow or rapid freezing.

With freeze drying, the material to be dried is frozen and placed in a sealed chamber. The chamber pressure is reduced and maintained at a value below 1 mm Hg. Heat is applied to the material, the surface ice heats up and the resultant water vapour is drawn off by the vacuum system. As the ice boundary recedes into the material, the ice sublimes in situ and the water percolates to the surface through the pore structure of the material.

Intermediate-moisture foods are foodstuffs that contain relatively large amounts of water (5 to 30%) and yet do not support microbial growth. The technology, which is difficult, is a spin-off from space travel. Open-shelf stability is achieved by suitable control of acidity, redox potential, humectants and preservatives. Most developments to date have been in foods for pet animals.

Whatever the preservation process, the food to be preserved has first to be prepared. Meat preservation involves a butchery department; fish needs cleaning and gutting, filleting, curing and so on. Before fruit and vegetables can be preserved they have to be washed, cleaned, blanched, perhaps graded, peeled, stalked, shelled and stoned. Many of the ingredients have to be chopped, sliced, minced or pressed.

Packaging

There are many methods of packaging food, including canning, aseptic packaging and frozen packaging.

Canning

The conventional method of canning is based on the original work of Appert in France, for which in 1810 the French government awarded him a prize of 12,000 francs. He preserved food in glass containers. In Dartford, England, in 1812, Donkin and Hall set up the first cannery using tinned iron containers.

Today the world uses several million tonnes of tinplate annually for the canning industry, and a substantial amount of preserved food is packed into glass jars. The process of canning consists of taking cleaned food, raw or partly cooked but not intentionally sterilized, and packing it into a can that is sealed with a lid. The can is then heated, usually by steam under pressure, to a certain temperature for a period of time to allow penetration of the heat to the centre of the can, destroying the microbial life. The can is then cooled in air or chlorinated water, after which it is labelled and packed.

Changes in processing have occurred over the years. Continuous sterilizers cause less damage to cans by impact and allow cooling and drying in a closed atmosphere. Foods can also be heat preserved in retortable pouches. These are bags of small cross-sectional area made from laminates of aluminium and heat-sealable plastics. The process is the same as for conventional canning, but better taste properties are claimed for the products because sterilization times can be reduced. Very careful control of the retorting process is essential to avoid damage to the heat seals with subsequent bacterial spoilage.

Aseptic packaging

There have been recent developments in the aseptic packaging of food. The process is fundamentally different from conventional canning. In the aseptic method the food container and closure are sterilized separately, and the filling and closing are done in a sterile atmosphere. Product quality is optimal because heat treatment of the foodstuff can be controlled precisely and is independent of the size or material of the container. Of concern is employee exposure to the sterilizing agents. It is likely that the method will become more widely used because overall it should result in energy savings. To date most progress has been made with liquids and purées sterilized by the so-called HTST process, in which the product is heated to a high temperature for a few seconds. Developments on particulate foodstuffs will follow. One likely benefit in food factories will be the reduction of noise if rigid metallic containers are replaced. Such containers may also cause problems by contaminating preserved food with lead and tin. These are minimized by new-type two-piece containers drawn from lacquered tinplate and three-piece containers with welded instead of soldered side seams.

Frozen packaging

The frozen food industry utilizes all methods of deep-freezing fresh food at temperatures below their freezing point, thus forming ice crystals in the watery tissues. The food may be frozen raw or partially cooked (e.g., animal carcasses or made-up meat dishes, fish or fish products, vegetables, fruits, poultry, eggs, ready-made meals, bread and cakes). Frozen perishable products can be transported over long distances and stored for processing and/or sale when demand arises, and seasonal products can be available at all times.

Food for freezing must be in prime condition and prepared under strict hygienic control. Packaging materials should be vapour- and aroma-proof and resistant to low temperatures. The quality of the product depends on the rate of freezing: if too slow, the structure of the food may be damaged by large ice crystals and enzymatic and microbiological properties destroyed. Small items, such as shrimps and peas, can be frozen quickly, which makes for an improvement in quality.

The various methods of freezing include: air freezing, blast freezing, fluid-bed freezing, fluid freezing, contact freezing, liqui-freezing and dehydro-freezing.

Air freezing in its simplest form involves placing food in trays on shelves in a cold store at approximately –30 ºC for a time varying from a few hours to 3 days, depending on size. Blast freezing, a more complicated technique, uses a rapidly circulating stream of cold air, sometimes combined with cold spirals, which removes heat by means of radiation. Temperatures range between –40 and –50 ºC, and the maximum air speed is 5 m/s. Blast freezing may be carried out in tunnel freezers, often equipped with conveyors to carry the food through to cold-storage rooms. When the freezer is adjacent to the cold store, the tunnel is often closed with an air curtain instead of doors.

Fluid-bed freezing is used for chopped or sliced vegetables, peas and so on, which are placed on a perforated belt through which a stream of air is blown. Each item is coated with ice and thus retains its shape and separateness. The frozen vegetables may be stored in large containers and repackaged when needed in small units. In fluid freezing (one of the oldest known methods) the food, usually fish, is immersed in a strong solution of brine. Salt may penetrate unwrapped goods and even wrappings, affecting the flavour and hastening rancidity. This method had declined in use but is now gaining ground again as more effective plastic wrapping materials are developed. Poultry is frozen by a combination of the fluid- and air-freezing methods. Each bird, packed in polyethylene or similar material, is first sprayed or immersed in a fluid to freeze its outer layer; the inside is afterwards frozen in a blast freezer.

Contact freezing is the common method for foodstuffs packed in cartons, which are placed between hollow shelves through which a cooling fluid is circulated; the shelves are pressed flat against the cartons, usually by hydraulic pressure.

In liqui-freezing, the product is placed on a conveyor belt which is passed through a tank of liquid nitrogen (or occasionally liquid carbon dioxide) or through a tunnel where liquid nitrogen is sprayed. Freezing occurs at a temperature as low as –196 ºC, and not every type of product or wrapping can withstand this cold. Dehydro-freezing, which removes some of the water before freezing, is used for certain vegetables and fruits. A considerable reduction of weight is achieved, involving lower transport, storage and wrapping costs.

During cold storage, the product must be kept at a temperature of –25 to –30 ºC, and good air circulation must be maintained. Transport of frozen goods has to be in refrigerated wagons, lorries, ships and so on, and during loading and unloading, the goods must be exposed to as little heat as possible. Usually, firms producing frozen food also prepare the raw material, but sometimes this treatment is carried out in separate establishments. In beef and poultry operations, carbon dioxide is often used to cool and preserve product during shipping.

Hazards and Their Prevention

Injury hazards

The most common causes of injuries in the food industry are hand tools, especially knives; operation of machinery; collisions with moving or stationary objects; falls or slips; and burns.

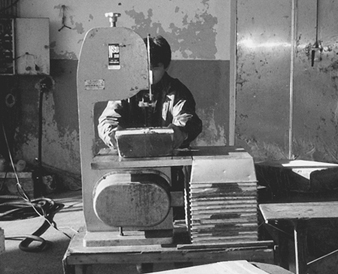

Injuries caused by knives in meat and fish preparation can be minimized by design and maintenance, adequate work areas, selection of the right knife for the job, provision of tough protective gloves and aprons and correct training of workers on both the sharpening and the use of the knife. Mechanical cutting devices also pose a hazard, and good maintenance and adequate training of workers is critical to prevent injuries (see figure 1).

Figure 1. Carving frozen whale meat on a band saw without adequate machine guarding and electrical precautions, Japan, 1989

L. Manderson

Although accidents involving transmission machinery are relatively infrequent, they are likely to be serious. Risks related to machines and handling systems must be studied individually in each industry. Handling problems can be addressed by close examination of injury history for each particular process and by use of appropriate personal protection, such as foot and leg protection, hand and arm protection and eye and face protection. Risks from machinery can be prevented by secure machinery guarding. Mechanical handling equipment, especially conveyors, is widely employed, and particular attention should be paid to in-running nips on such equipment. Filling and closing machines should be totally enclosed except for the intake and discharge openings. The intakes of conveyor belts and drums, as well as pulleys and gearing, should be securely protected. To prevent cuts in canning, for example, effective arrangements for clearing up sharp tin or broken glass are required. Serious injury due to the inadvertent start-up of transmission machinery during cleaning or maintenance can be avoided by strict lockout/tagout procedures.

Falling accidents are most often caused by:

- The state of the floor. Accidents are possible when floors are uneven, wet or made slippery by the type of surface; by products; by fatty, oily or dusty waste; or, in cold rooms, from humid air condensing on the floors. Anti-slip floors help to prevent slips. Finding the proper surface and cleaning regimen, along with good housekeeping and proper footwear, will help prevent many falls. Curbs around machines containing water will prevent water flowing onto the floor. Good drainage should be provided to remove rapidly any accumulating liquids or spillage that occurs.

- Uncovered pits or drainage channels. Maintenance of covers or barricading of the hazard is necessary.

- Work at heights. Provision of safe means of access to equipment and storage areas, sound ladders and fall protection (including body harnesses and lifelines) can prevent many hazards.

- Steam or dust. Operations that generate steam or dust may not only make the floor slippery but also prevent good visibility.

- Insufficient or inconsistent lighting. Illumination needs to be bright enough for employees to be able to observe the process. The perception of inadequate lighting occurs when warehouses appear dark compared to production areas and people’s eyes do not adjust when moving from one light level to the other.

Burns and scalds from hot liquors and cooking equipment are common; similar injuries arise from steam and hot water used in equipment cleaning. Even more serious accidents can occur due to explosion of boilers or autoclaves due to lack of regular examination, poor employee training, poor procedures or poor maintenance. All steam equipment needs regular and careful maintenance to prevent major explosion or minor leaks.

Electrical installations, especially in wet or damp places, require proper grounding and good maintenance to control the common hazard of electrical shock. In addition to proper grounds, outlets protected with ground fault interrupters (GFIs) are effective in protecting from electrical shock. Proper electrical classification for hazardous environments is critical. Often flavours, extracts and dusty flammable powders such as grain dust, corn starch or sugar (thought of as foodstuffs rather than hazardous chemicals) may require classified electrical equipment to eliminate ignition during process upsets or excursions. Fires may also occur if welding is done around explosive/combustible organic dusts in grain elevators and mills. Explosions may also occur in gas or oil-fired ovens or cooking processes if they are not installed, operated or maintained correctly; provided with the essential safety devices; or if proper safety procedures are not followed (especially in open flame operations).

Strict product sanitation control is vital at all stages of food processing, including in slaughterhouses. Personal and industrial hygiene practices are most important in guarding against infection or contamination of the products. The premises and equipment should be designed to encourage personal hygiene through good, conveniently situated and sanitary washing facilities, showerbaths when necessary, provision and laundering of suitable protective clothing and provision of barrier creams and lotions, where appropriate.

Strict equipment sanitation is also vital to all stages of food processing. During the regular operation of most facilities, safety standards are effective to control equipment hazards. During the sanitation cycle, equipment must be opened up, guards removed and interlock systems disabled. A frustration is that the equipment is designed to run, but clean-up is often an afterthought. A disproportional share of the most serious injuries happen during this part of the process. Injuries are commonly caused by exposure to in-running nip points, hot water, chemicals and acid or base splashes, or by cleaning moving equipment. Dangerous high-pressure hoses which carry hot water also pose a hazard. Lack of equipment-specific procedures, lack of training and the low experience level of the typical new employee pressed into a cleaning job can add to the problem. The hazard is increased when equipment to be cleaned is located in areas that are not easily accessible. An effective lockout/tagout programme is essential. Current best practice to help control the problem is designing of clean-in-place facilities. Some equipment is designed to be self-cleaning by use of high-pressure spray balls and self-scrubbing systems, but too often manual labour is required to address trouble spots. In the meat and poultry industries, for example, all cleaning is manual.

Health hazards

Infections and infectious or parasitic diseases spread by animals or the waste products of animals used in manufacture are common occupational problems in the food industry. These zoonoses include anthrax, brucellosis, the leptospiroses, tularemia, bovine tuberculosis, glanders, erysipeloid, Q fever, foot-and-mouth disease, rabies and so on. Some food handlers may be subject to a wide variety of skin infections, including anthrax, actinomycosis and erysipeloid. Certain dried fruits are infested with mites; this can affect workers in sorting operations.

Apart from specific prophylactic vaccination against infectious diseases, proper gloves, good personal hygiene and the sanitary facilities to enable this (which are a prerequisite of any food industry as a protection to the product) are the most valuable preventive measures. Good washing facilities, including showers, and appropriate protective clothing are essential. Efficient medical care, especially for treatment of minor injuries, is an equally important requirement.

Contact dermatitis and allergies of the skin or respiratory system caused by organic products, animal or vegetable, are also common. Primary dermatitis can be caused by irritants such as acids, alkalis, detergents and water used in cleaning; friction from fruit picking and packing; and the handling of sugar, which is much used in food manufacture. Secondary sensitization results from the handling of many fruits and vegetables. Organic dusts from grain or flour can also cause respiratory diseases (e.g., “baker’s asthma”) and must be controlled. Too often the food industry considers the ingredients they use to be merely ingredients, rather than chemicals that can have health effects when employees are exposed to either industrial strengths or industrial quantities of “normal” household kitchen ingredients.

Cumulative trauma disorders

Many of the meat, poultry, fish and food processing plants involve highly repetitious and forceful work. The very nature of the products is such that manual labour often is needed to manipulate product when inspecting or loading fragile products into packaging or during the scale-up of a product before high-volume equipment is purchased or installed. Further, handling of boxes for shipping can cause back injuries. Three things to watch for are tasks involving extreme postures, high forces or high levels of repetition. Combinations of more than one factor make the problem more critical. Early detection and treatment of affected workers is desirable. Ergonomic redesign of equipment and other changes discussed in specific articles in this chapter will decrease the incidence of these hazards.

Refrigerants such as anhydrous ammonia, methyl chloride and other halogenated aliphatic hydrocarbons used in freezing and cold storage bring risks of poisoning and chemical burns. Emergency planning in addition to the normal fire planning is important. Training of workers in evacuation procedures is also necessary. Escape-type respiratory protection may be needed during evacuation from some areas of the facility. For some chemicals, sensors in the building are used to provide early warning to all employees through a central alarm system to signal the need to evacuate. Worker reactions to increases in ammonia levels must be taken seriously, and affected workers must be evacuated and treated. Ammonia leaks warrant strict attention and contiuous monitoring. Evacuation may be required if levels start to rise, before dangerous levels are reached. A central assembly point should be selected so that those who are evacuated are not in danger of being downwind of the refrigerant leak. Chemical protective clothing will be needed to aggressively approach the system leak to contain the release. Anhydrous ammonia and the less frequently used refrigerants, such as propane, butane, ethane and ethylene, are also flammable and explosive. Leaks from pipes are usually due to inadequate maintenance and can be prevented with adequate attention. Adequate measures should be taken for explosion prevention and firefighting.

Pesticides, fumigants and other hazardous materials must be kept under strict control and used only according to the manufacturer’s guidance. Organophosphate pesticides should only be used when accompanied with biological monitoring to assure the control of exposure.

The traditional tin/lead soldering of the side seam of a food can and the awareness of the problem of lead levels in food products have resulted in studies of environmental lead levels in can-making units and blood lead levels in workers. Evidence has shown both to be raised, but neither the environmental threshold limit value (TLV) nor the currently acceptable blood lead levels have ever been found to be exceeded. Thus, the results are consistent with a “low risk” lead process.

Carbon dioxide, used in cooling refrigerated products that are to be shipped, must also be kept under strict controls. Adequate ventilation must be provided over dry ice bins to prevent the gas from causing ill effects.

Exposure to cold can range from handling and storage of raw materials in winter or in processing and store rooms cooled with “still air”, to extremes of cold in air-blast refrigeration of raw materials, as in the ice cream and frozen foods industry. Cold-store workers may suffer impairment of health through exposure to cold if adequate protective clothing is not supplied. Exposure to cold is most critical for employees with sedentary jobs in very cold environments. Barriers should be used to deflect cold breezes from workers standing near fans used to circulate air. Job rotation to more active or warmer locations is advisable. In large tunnel freezing plants, it may be fatal for workers to stay in the rapidly moving stream of air, even if dressed in polar clothing. It is particularly important to prohibit entry into a tunnel freezer in operation and to make effective interlocking arrangements or use confined-space entry protocol to ensure that freezers cannot be started up while workers are still inside them. Warm lunchrooms and provision of hot drinks will mitigate the effects of cold work.

Heat, often combined with high humidity in cooking and sterilizing, can produce an equally intolerable physical environment, where heat stroke and heat exhaustion are an issue. These conditions are found especially in processing that entails evaporation of solutions, such as tomato paste production, often in countries where hot conditions already prevail. It is also prevalent on kill floors of slaughterhouses. Effective ventilation systems are essential, with special attention to condensation problems. Air conditioning may be necessary in some areas.

A serious health hazard in most modern plants, especially with canning, is exposure to noise. Putting additional high-speed machines in a limited space continues to drive noise levels up, despite best efforts to keep them below 85 dBA. The manufacture, conveying and filling of cans at speeds of up to 1,000 per minute leads to exposure of operators to a noise level of up to 100 dBA at frequencies ranging from 500 to 4,000 Hz, a dose equivalent of about 96 dBA, which if uncontrolled will lead in many cases to noise-induced deafness over a working lifetime. Certain engineering techniques can lead to some noise reduction; these include sound-absorbent mounting, magnetic elevators, nylon-coated cables and speed-matching in can conveyor systems. However, some radical change in the industry, such as the use of plastic containers, is the only hope for the future of producing a reasonably noise-free environment. At present, a hearing conservation programme based on audiometric examinations, hearing-protection equipment and education should be instituted. Noise refuges and personal ear protection should be provided.

Where ionizing radiation is used, the full precautions applicable to such work (e.g., radiation protection, hazard monitoring, health screening and periodic medical examinations) are necessary.

Medical supervision of workers is desirable; many food factories are small and membership in a group medical service may be the most effective way of securing this.

Health and safety committees that effectively involve the entire organization, including production operators, in the development of plant programmes is the key to a safe operation. Too often the food industry is not considered to be particularly hazardous, and a feeling of complacency develops. Often materials used are ones that people are familiar with and hence individuals may not understand the hazards that can arise when industrial strengths or quantities are employed. Plant employees who understand that safety rules and procedures are in place to protect their health and safety and not simply to meet government requirements are key to the development of a quality safety programme. Management must establish practices and policies that will allow employees to develop those beliefs.

Health Effects and Disease Patterns

Health effects found in food processing are similar to those found in other manufacturing operations. Respiratory disorders, skin diseases and contact allergies, hearing impairment and musculoskeletal disorders are among the most common occupational health problems in the food and beverage industry (Tomoda 1993; BLS 1991; Caisse nationale d’assurance maladie des travailleurs salariés 1990). Thermal extremes are also a concern. Table 1 shows rankings of the three most common occupational diseases in this industry in selected countries.

Table 1. Most common occupational diseases in the food and drink industries in selected countries

|

Country |

Year |

Occupational diseases |

|||

|

Most common |

Second most common |

Third most common |

Other |

||

|

Austria |

1989 |

Bronchitis, asthma |

Hearing impairment |

Skin diseases |

Infections transmitted by animals |

|

Belgium (food) |

1988 |

Diseases induced by inhalation of substances |

Diseases induced by physical agents |

Skin diseases |

Infections or parasites from animals |

|

Belgium (drink) |

1988 |

Diseases induced by physical agents |

Diseases induced by chemical agents |

Diseases induced by inhalation of substances |

– |

|

Colombia |

1989 |

Hearing impairment |

Respiratory disorders (asthma) |

Musculoskeletal disorders |

Skin diseases |

|

Czechoslovakia |

1988 |

Respiratory disorders |

Musculoskeletal disorders |

Digestive disorders |

Circulatory disorders, skin diseases |

|

Denmark |

1988 |

Physical coordination disorders |

Skin diseases |

Hearing impairment |

Infections, allergies |

|

France |

1988 |

Asthma and other respiratory disorders |

Strains in various parts of body (knees, elbows) |

Septicemia (blood poisoning) and other infections |

Hearing impairment |

|

Poland |

1989 |

Respiratory disorders |

Skin diseases |

Infections |

Hearing impairment |

|

Sweden |

1989 |

Musculoskeletal disorders |

Allergies (contact with chemical agents) |

Hearing impairment |

Infections |

|

United States |

1989 |

Disorders associated with repeated trauma |

Skin diseases |

Diseases due to physical agents |

Respiratory conditions associated with toxic agents |

Source: Tomoda 1993.

Respiratory System

Respiratory problems can largely be classified as rhinitis, which affects the nasal passages; broncho-constriction in the major airways; and pneumonitis, which consists of damage to the fine structures of the lung. Exposure to airborne dust from various foodstuffs, as well as chemicals, may lead to emphysema and asthma. A Finnish study found chronic rhinitis common among slaughterhouse and pre-cooked foods workers (30%), mill and bakery workers (26%) and food processing workers (23%). Also, food processing workers (14%) and slaughterhouse/pre-cooked foods workers (11%) suffered from chronic coughs. The causative agent is flour dust in bakery workers, while temperature variations and various kinds of dust (spices) are believed to cause disease in other branches.

Two studies in the former Yugoslavia found a much higher prevalence of chronic respiratory symptoms than in a control group. In a study of spice workers the most common complaint (57.6%) was dyspnea or breathing difficulty, followed by nasal catarrh (37.0%), sinusitis (27.2%), chronic cough (22.8%) and chronic phlegm and bronchitis (19.6%). A study of animal food processing workers found that in addition to the animal food processing ingredients, exposure included powdered coriander, garlic dust, cinnamon dust, red paprika dust and dust from other spices. Non-smokers studied showed a significantly higher prevalence of chronic phlegm and chest tightness. Smokers had a significantly higher prevalence of chronic coughs; chronic phlegm, chronic bronchitis and chest tightness were also observed. The frequency of acute respiratory symptoms associated with the working day was high for the exposed group, and respiratory ventilatory capacity of smokers was significantly lower than predicted. The study therefore concluded an association exists between exposure to animal food dust and the development of respiratory disorders.

Industrial injury compensation in the United Kingdom recognizes occupational asthma from the handling of enzymes, animals, grains and flour. Exposure to cinnamic aldehyde from tree bark and sulphur dioxide, a bleaching agent and fumigant, cause a high prevalence of asthma in cinnamon workers in Sri Lanka. Dust exposure is minimal for the workers who peel the bark, but workers in the local buyers’ stores are exposed to high levels of dust and sulphur dioxide. A study found 35 of 40 cinnamon workers complained of chronic coughs (37.5%) or suffered from asthma (22.5%). Other abnormalities included weight loss (65%), skin irritation (50%), hair loss (37.5%), eye irritation (22.5%) and rashes (12.5%). For workers who work under similar high concentrations of airborne dust of vegetable origin, asthma is highest in cinnamon workers (22.5%, compared with 6.4% in tea workers and 2.5% in kapok workers). Smoking is not believed to be directly related to the coughs, since similar symptoms occurred in 8 non-smoking women and 5 men who smoked about 7 cigarettes a day. Irritation of the respiratory mucosa by cinnamon dust causes the coughing.

Other studies examined the relationship between respiratory disorders and the allergens and antigens originating in foodstuffs, such as egg protein and seafood products. While no specific workplace dust could be linked to the various acute and chronic respiratory disorders among the exposed workers, the results of the studies indicate a strong association between the disorders and the work environment.

Use of microbiology has long been a part of food production. In general, most of the micro-organisms used in the food and drink industries are considered to be harmless. Wine, cheese, yogurt and sour dough all use a microbial process to yield a usable product. Production of proteins and enzymes increasingly use biotechnological techniques. Certain species of aspergillus and bacillus produce amylases that convert starches into sugar. Yeasts turn starch into acetone. Tricoderma and Penicillium produce cellulases that break down cellulose. As a result, spores of fungi and actinomycetes are widely found in food processing. Aspergillus and Penicillium are frequently present in the air in bakeries. Penicillium is also found in dairy and meat processing plants; during the maturation of cheeses and sausages, there can be abundant surface growth. Cleaning steps, prior to sale, disperse them into the air, and workers may develop allergic alveolitis. Occupational asthma cases have association with many of these organisms, while some are suspected of causing infection or carrying mycotoxins. The enzymes trypsin, chymotrypsin and protease are associated with hypersensitivity and respiratory disease, particularly among laboratory workers.

In addition to the airborne particulate originating from foodstuffs and microbial agents, inhalation of hazardous chemical substances used as reagents, refrigerants, fumigants and sanitizers may cause respiratory and other disorders. These substances are found in solid, liquid or gaseous form. Exposure at or above recognized limits often results in skin or eye irritation and respiratory disorders. Headaches, salivation, burning of the throat, perspiration, nausea and vomiting are symptoms of intoxication due to overexposure.

Ammonia is a colourless gas refrigerant, cleaning agent and fumigant for foodstuffs. Exposure to ammonia can result in corrosive burns or blistering of skin. Excessive and prolonged exposure can produce bronchitis and pneumonia.

Trichloroethylene, hexane, benzene, carbon monoxide (CO), carbon dioxide (CO2) and polyvinyl chloride (PVC) are frequently found in food and beverage plants. Trichloroethylene and hexane are used for olive oil extraction.

CO, a colourless, odourless gas, is difficult to detect. Exposure occurs in smokehouses that are poorly ventilated or while working in grain silos, wine fermentation cellars or where fish are stored. Dry-ice freezing or chilling, CO2-freeze tunnels and combustion processes expose workers to CO2. Intoxication symptoms of overexposure to CO and CO2 include headache, dizziness, drowsiness, nausea, vomiting and, in extreme cases, even death. CO also can aggravate heart and respiratory symptoms. The acceptable exposure limits, set by several governments, permit 100 times greater exposure to CO2 than CO to trigger the same response.

PVC is used for packaging and food-wrap materials. When PVC film is heated, thermal degradation products cause irritation to the eyes, nose and throat. Workers also report symptoms of wheezing, chest pains, breathing difficulties, nausea, muscle pains, chills and fever.

Hypochlorites, acids (phosphoric, nitric and sulphuric), caustics and quaternary ammonium compounds are frequently used in wet cleaning. Microbiology labs use mercury compounds and formaldehyde (gas and formalin solution). Disinfection in the lab uses phenolics, hypochlorites and glutaraldehyde. Irritation and corrosion to eyes, skin and lungs occur with excessive exposure and contact. Improper handling can release highly toxic substances, like chlorine and sulphur oxides.

The National Institute for Occupational Safety and Health (NIOSH) in the United States reported worker breathing difficulties during washing of poultry with super-chlorinated water. The symptoms included headaches, sore throat, tightness in the chest and difficulty breathing. Chloramine is the suspected agent. Chloromines can form when ammonia-treated water or amine-treated boiler water contacts hypochlorite solutions used in sanitation. Cities have added ammonia to water to prevent the formation of halomethanes. Air sample methods are not available for chloramines. Chlorine and ammonia levels are not predictive as indicators of exposure, as testing found their levels to be well below their limits.

Fumigants prevent infestation during storage and transport of food raw materials. Some fumigants include anhydrous ammonia, phostoxin (phosphine) and methyl bromide. The short duration of this process makes respiratory protection the cost-effective strategy. Proper respiratory protection practices should be observed when handling these items until air measurements of the area are below applicable limits.

Employers should take steps to assess the level of toxic contamination at the workplace and ensure that exposure levels do not exceed limits found in safety and health codes. Contamination levels should be measured frequently, especially following changes in processing methods or the chemicals used.

Engineering controls to minimize the risk of intoxication or infection have two approaches. First, eliminate the use of such materials or substitute a less hazardous material. This may involve replacing a powdered substance with a liquid or slurry. Second, control the exposure through reducing the level of air contamination. Workplace designs include the following: total or partial enclosure of the process, suitable ventilation systems and restricted access (to reduce exposed population). An appropriate ventilation system is instrumental in preventing the dispersal of spores or aerosols throughout the workplace. Substitution of vacuum cleaning or wet cleaning for compressed-air blow-out of equipment is critical for dry materials that could become airborne during cleaning.

Administrative controls include worker rotation (to reduce exposure period) and off-shift/weekend hazardous task work (to reduce exposed population). Personal protective equipment (PPE) is the least favoured exposure control method due to high maintenance, availability issues in developing countries and the fact that the worker must remember to wear it.

PPE consists of splash goggles, face shields and respirators for workers mixing hazardous chemicals. Worker training on use and limitations, plus equipment fitting, must occur for the equipment to adequately serve its purpose. Different types of respirators (masks) are worn depending on the nature of the work and the level of the hazard. These respirators range from the simple half facepiece for dust and mist, through chemical air purifying of various facepiece types, up to self-contained breathing apparatus (SCBA). Proper selection (based on hazard, face-fit and maintenance) and training assure effectiveness of the respirator in reducing exposure and the incidence of respiratory disorders.

Skin

Skin problems found in the food and drink industries are skin disease (dermatitis) and contact allergies (e.g., eczema). Due to sanitation requirements, workers are constantly washing their hands with soap and using hand-dip stations that contain quaternary ammonium solutions. This constant wetting of the hands can reduce the lipid content of the skin and lead to dermatitis. Dermatitis is an inflammation of the skin as a result of contact-exposure to chemicals and food additives. Work with fats and oils can clog the pores of the skin and lead to acne-like symptoms. These primary irritants account for 80% of all occupational dermatitis seen.

There is growing concern that workers may become highly sensitized to microbial proteins and peptides generated by fermentation and extraction, which can lead to eczema and other allergies. An allergy is a hypersensitive response of any type that is greater than that which normally occurs in response to antigens (not-self) in the environment. Allergic contact dermatitis is rarely seen before the fifth or seventh day after exposure is initiated. Hypersensitivity occupational dermatitis is also reported for work with enzymes, such as trypsin, chymotrypsin and protease.

Chlorinated solvents (see “Respiratory system” section above) stimulate the epidermal cells to undertake peculiar growth patterns. This keratin stimulation may lead to tumour formation. Other chlorinated compounds found in soaps for antibacterial purposes can lead to photosensitivity dermatitis.

Reduction of exposure to causative agents is the principle preventive method for dermatitis and contact allergies. Adequately drying foodstuffs prior to storage and clean-condition storage can control airborne spores. PPE such as gloves, masks and uniforms keep workers from direct contact and minimize the risk of dermatitis and other allergies. Latex glove materials can cause allergic skin reactions and should be avoided. Proper application of barrier creams, where permitted, can also minimize contact with the skin irritant.

Infectious and parasitic diseases of animal origin are the occupational diseases most specific to the food and drink industries. The diseases are most common among meat-packing and dairy workers as a result of direct contact with infected animals. Agricultural workers and others are also at risk due to their contact with these animals. Prevention is particularly difficult since the animals may not give any overt signs of disease. Table 2 lists the types of infections reported.

Table 2. Types of infections reported in food and drink industries

|

Infections |

Exposure |

Symptoms |

|

Brucellosis (Brucella melitensis) |

Contact with infected cattle, goats and sheep (Northern and Central Europe and North America) |

Constant and recurring fever, headaches, weakness, joint pain, night sweats and loss of appetite; can also give rise to symptoms of arthritis, influenza, asthenia and spondylitis |

|

Erysipeloid |

Contact of open wounds with infected pigs and fish (Czechoslovakia) |

Localized redness, irritation, a burning sensation, pain in the infected area. It can spread to the bloodstream and lymph nodes. |

|

Leptospirosis |

Direct contact with infected animals or their urine |

Headaches, aching muscles, eye infections, fever, vomiting and chills; in more serious cases, kidney and liver damage, plus cardiovascular and neurological complications |

|

Epidermycosis |

Caused by a parasitic fungus on the skin of animals |

Erythema and blistering of skin |

|

Dematophytosis (ringworm) |

Fungal disease through contact with skin and hair of infected animals |

Localized hair loss and small crusts on the scalp |

|

Toxoplasmosis |

Contact with infected sheep, goats, cattle, pigs and poultry |

Acute stage: fever, muscle pain, sore throats, headaches, swollen lymph nodes and enlarged spleen. Chronic infection leads to development of cysts in the brain and muscle cells. Foetal transmission causes still- and premature births. Full-term babies can have brain and heart defects and may die. |

|

Papilloma viral lung cancers |

Regular contact with live animals or animal flesh coupled with exposure to polycyclic aromatic hydrocarbons and nitrites |

Lung cancers in butchers and slaughterhouse workers studied in England, Wales, Denmark and Sweden |

The fundamental principle for preventing the contraction and spread of infectious and parasitic skin diseases is personal hygiene. Clean washrooms, toilets and shower facilities should be provided. Uniforms, PPE and hand towels need to be washed and in some cases sterilized frequently. All wounds should be sterilized and dressed, regardless of how slight, and covered with protective gear until healed. Keeping the workplace clean and healthy is just as important. This includes the thorough washing of all equipment and surfaces that contact animal flesh after each workday, the control and extermination of rodents and the exclusion of dogs, cats and other animals from the workplace.

Vaccination of animals and inoculation of workers are measures many countries take to prevent infectious and parasitic diseases. Early detection and treatment of diseases with antibacterial/anti-parasitic drugs is essential to contain and even eradicate them. Workers should be examined as soon as any symptoms, such as recurring coughs, fever, headaches, sore throats and intestinal disorders, appear. In any case, workers should undergo medical examinations at established frequencies, including pre-placement/post-offer baseline exams. In some countries, authorities must be notified when examination detects work-related infection in the workers.

Noise and Hearing

Hearing impairment occurs as a result of continuous and prolonged exposure to noise above recognized threshold levels. This impairment is an incurable illness causing communication disorders and is stressful if the work demands concentration. As a result, psychological and physiological performance can deteriorate. There is also an association between high noise level exposure and abnormal blood pressure, heartbeat, respiration rate/volume, stomach and intestinal spasms and nervous disorders. Individual susceptibility, exposure duration and noise frequency plus intensity are factors that determine the exposure risk.

Safety and health codes vary from country to country, but worker exposure to noise is usually limited to 85 to 90 dBA for 8 continuous hours, followed by a 16-hour recovery time below 80 dBA. Ear protection should be made available at 85 dBA and is required for workers with a confirmed loss and for 8-hour exposures at or above 90 dBA. Annual audiometric testing is recommended, and in some countries required, for this exposed population. Noise measurements with a meter such as the American National Standards Institute (ANSI) Type II sound meter should be taken at least every 2 years. Readings should be repeated whenever equipment or process changes could increase the ambient noise levels.

Ensuring that noise exposure levels are not hazardous is the primary strategy for noise controls. Good manufacturing practices (GMPs) dictate that control devices and their exposed surfaces be cleanable, do not harbour pests and have necessary approvals to contact food or be ancillary to food production. The methods adopted also depend on the availability of financial resources, equipment, materials and trained staff. One of the most important factors in noise reduction is the design of the workplace. Equipment should be designed for low noise and low vibration. Replacing metal parts with softer materials, like rubber, can reduce noise.

When new or replacement equipment is purchased a low-noise type should be selected. Silencers should be installed at air valves and exhaust pipes. Noise-producing machines and processes should be enclosed to reduce to a minimum the number of workers exposed to high noise levels. Where permitted, noise-proof partitions and noise-absorbing ceilings should be installed. Removal and cleaning of these partitions and ceiling tiles need to be included in the maintenance costs. The optimum solution is usually a combination of these measures, adapted to the needs of each workplace.

When engineering controls are not feasible or when it is impossible to reduce noise below harmful levels, PPE should be used to protect the ears. Protective equipment availability and worker awareness is important to prevent hearing impairment. In general, a selection of plugs and earmuffs will lead to greater acceptance and wearing.

Musculoskeletal System

Musculoskeletal disorders were also reported in the 1988–89 data (see table 1]). Data in the early 1990s noted more and more workers reporting occupational musculoskeletal disorders. Plant automation and work whose pacing is regulated by a machine or conveyor belt occurs today for more workers in the food industry than ever before. Tasks in automated plants tend to be monotonous, with workers performing the same movement all day long.

A Finnish study found that nearly 40% of survey participants reported performing repetitive work all day. Of those performing repetitive work, 60% used their hands, 37% used more than one part of the body and 3% used their feet. Workers in the following occupational groups perform repetitive work for two-thirds or more of their working hours: 70% of cleaners; 67% of slaughterhouse, pre-cooked food and packaging workers; 56% of warehouse and transport workers; and 54% of dairy workers.

Ergonomic stresses arise because most food products come from natural sources and are not uniform. Meat handling requires workers to handle carcasses of varying sizes. With the introduction of poultry sold in parts in the 1960s, more birds (40%, up from less than 20%) were cut into parts. Workers must make many cuts using sharp tools. Changes in US Department of Agriculture (USDA) inspection procedures now permit average line speeds to increase from 56 to 90 birds per minute. Packaging operations may involve repetitive hand and wrist motions to place finished items undamaged into trays or packs. This is especially true for new products, as the market may not justify high-volume operations. Special promotions, including recipes and coupons, may require that an item be manually inserted into the package. Ingredient packaging and workplace layout may require lifting beyond the action limits recommended by occupational health agencies.

Repetitive strain injuries (RSIs) include inflammation of the tendon (tendinitis) and inflammation of the tendon sheath (tenosynovitis). These are prevalent among workers whose jobs require repetitive hand movements, like meatpacking workers. Tasks that repeatedly combine the bending of the wrist with gripping, squeezing and twisting motion can cause carpal tunnel syndrome (CTS). CTS, characterized by a tingling sensation in the thumb and first three index fingers, is caused by inflammation in the wrist joint creating pressure on the nerve system in the wrist. Misdiagnosis of CTS as arthritis can result in permanent numbness and severe pain in the hands, elbows and shoulders.

Vibration disorders also accompany an increased level of mechanization. Food workers are no exception, although the problem may not be as serious as for certain other industries. Food workers using machines such as band saws, mixers and cutters are exposed to vibration. Cold temperatures also increase the probability of vibration disorders to the fingers of the hand. Five per cent of the participants in the Finnish study noted above were exposed to a fairly high level of vibration, while 9% were exposed to some level of vibration.

Excessive exposure to vibration leads, among other problems, to musculoskeletal disorders in the wrists, elbows and shoulders. The type and degree of disorder depend on the type of machine, how it is used and the level of oscillation involved. High levels of exposure can result in growth of a protuberance on the bone or the gradual destruction of the bone in the joint, resulting in severe pain and/or limited mobility.

Rotation of workers with a view to avoiding repetitive motions may reduce the risk by sharing the critical task across the team. Teamwork by task rotation or two-person handling of awkward/heavy ingredient bags can reduce the stress on a single worker in material handling. Tool maintenance, especially knife sharpening, also plays an important role. An ergonomic team of management and production workers can best address these issues as they arise.

Engineering controls focus on reduction or elimination of the 3 primary causes of musculoskeletal problems—force, position and repetition. The workplace should be analysed to identify needed changes, including workstation design (favouring adjustability), working methods, task automation/mechanical assists and ergonomically sound hand tools.

Adequate training should be provided to workers using knives on keeping the knife sharp to minimize force. Also, plants must provide adequate knife-sharpening facilities and avoid the cutting of frozen meat. Training encourages workers to understand the cause and prevention of musculoskeletal disorders. It reinforces the need to use correctly the tools and machines specified for the task. It should also encourage workers to report medical symptoms as soon as possible. Elimination of more invasive medical intervention by restriction of duties and other conservative care, is effective treatment of these disorders.

Heat and Cold

Thermal extremes exist in the food work area. People must work in freezers with temperatures of –18 °C or below. Freezer clothing helps insulate the worker from the cold, but warm break rooms with access to warm liquids must be provided. Meat-processing plants must be kept at 7 to 10 °C. This is below the comfort zone and workers may need to wear additional clothing layers.

Ovens and steam cookers have radiant and moist heat. Heat stress can occur during season changes and heat waves. Copious amounts of fluids and salting of foods may relieve the symptoms until the worker can acclimatize, usually after 5 to 10 days. Salt tablets are not recommended due to complications of hypertension or gastrointestinal upset.

Environmental Protection and Public Health Issues

Overview

The food industry is directly dependent on the natural environment for a supply of raw materials to produce contaminant-free products for human consumption. Due to the extensive processing of a great volume of materials, potential impact on the environment is considerable. This is also true of the beverage industry.

Environmental concern with respect to the food industry focuses more on organic pollutant loadings than on the impact of toxic substances. If pollutant loadings are inadequately prevented or controlled, they will strain community pollution control infrastructure or produce negative impacts on local ecosystems. Production techniques that control product losses serve the double function of improving yield and efficiency while at the same time reducing potential waste and pollution problems.

While the availability of potable water is essential, the food-processing industry also requires very large volumes of water for a wide variety of non-consumption uses, such as for initial cleaning of raw material, fluming, blanching, pasteurizing, cleaning of processing equipment and cooling of finished product. Water uses are identified by quality criteria for different applications, with the highest quality uses often requiring separate treatment to assure complete freedom from odour and taste and to ensure uniform conditions.

The processing of very large volumes of material introduces a potentially great solid waste problem in the production phase. Packaging waste has been the subject of increasing concern with regard to the post-consumer phase of a product’s life cycle. In certain branches of the food industry, processing activities are also associated with potential air emissions and odour control problems.

Despite considerable variation among specific industry sub-sectors, approaches to the prevention and control of pollution share many general characteristics.

Water Pollution Control

The food-processing industry has a raw waste effluent before treatment that is extremely high in soluble organic matter. Even small, seasonal plants are likely to have waste loads comparable to those of populations of 15,000 to 25,000, with large plants approximating the population-equivalent waste load of a quarter of a million people. If a stream or waterway receiving effluent is too small and organic waste too large in volume, the organic waste will utilize the dissolved oxygen in the process of being stabilized and will pollute or degrade the water body by reducing the dissolved oxygen value below that required by normal aquatic organisms. In most cases the waste from food-processing plants is amenable to biological treatment.

The strength of wastewater varies considerably according to plant, specific process and raw product characteristics. From an economic point of view, it is normally less costly to treat a high-strength, low-volume waste than a large-volume, diluted waste. For this reason, effluent with a high biological oxygen demand (BOD), such as the blood of chickens or meat, should be kept out of poultry and meatpacking plant sewers to reduce pollution load, and retained in containers for separate disposal in a by-products or rendering plant.

Waste streams with extreme pH (acidity) values should be carefully considered because of their effect on biological treatment. The combination of acid and basic waste streams may result in neutralization, and, where possible, cooperation with adjacent industries may be very beneficial.

The liquid portion of food-processing waste is normally screened or separated after settling, as a preliminary step in any treatment process, so that these wastes can be disposed of as garbage or combined with other solids in a by-products recovery programme.

The treatment of wastewater can be accomplished by a variety of physical, chemical and biological methods. As secondary processes are more expensive, maximum use of primary treatment is critical in reducing loads. Primary treatment includes processes such as settling or plain sedimentation, filtration (single, dual and multi-media), flocculation, flotation, centrifugation ion exchange, reverse osmosis, carbon absorption and chemical precipitation. Settling facilities range from simple settling ponds to sophisticated clarifiers designed specifically for the particular waste stream characteristics.

The use of biological secondary treatment to follow primary treatment is frequently a necessity to reach wastewater effluent standards. As most food and beverage industry wastewaters contain mainly biodegradable organic pollutants, biological processes used as secondary treatment seek to reduce the BOD of the waste stream by mixing higher concentrations of organisms and oxygen in the waste stream to provide rapid oxidation and stabilization of the waste stream prior to their discharge back to the environment.

Techniques and combinations of techniques may be adapted to address specific waste situations. For example, for dairy wastes, anaerobic treatment to remove the major portion of the pollutant load, with aerobic post-treatment to further reduce the residual BOD and chemical oxygen demand (COD) down to low values and remove nutrients biologically, has proven to be effective. The biogas mixture of methane (CH4) and CO2 that is produced from anaerobic treatment can be captured and used as an alternative to fossil fuels or as a source for electrical power generation (typically 0.30 m3 biogas per kg of COD removed).

Other secondary methods that are widely used include the activated sludge process, aerobic trickling filters, spray irrigation and the use of a variety of ponds and lagoons. Odour nuisances have been associated with ponds of inadequate depth. Odours from anaerobic processes can be removed by the use of soil filters that can oxidize objectionable polar gases.

Air Pollution Control

Air pollution from the food industry generally revolves around the question of objectionable odours rather than toxic air emissions, with a few exceptions. For this reason, for example, many cities have regulated the location of slaughterhouses under their health codes. Isolation is one obvious way to reduce community complaints about odours. However, this does not remove the odour. Odour control measures such as absorbers or scrubbers may sometimes be necessary.

One major health concern in the food industries is leaks of ammonia gas from refrigeration units. Ammonia is a severe eye and respiratory irritant, and a major leak into the environment could require evacuation of local residents. A leak control plan and emergency procedures are necessary.

Food processes that use solvents (e.g., edible oil processing) may emit solvent vapours into the atmosphere. Closed systems and recycling of solvents is the best method of control. Industries such as sugar-cane refining, which use sulphuric acid and other acids, may release sulphur oxides and other contaminants into the atmosphere. Controls such as scrubbers should be used.

Solid Waste Management

Solid waste can be quite considerable. Tomato waste for canning, for example, may represent 15 to 30% of total quantity of product processed; with peas and corn, waste is in excess of 75%. By isolating solid wastes, the concentration of soluble organics in wastewater may be reduced and the drier solid wastes may be more easily used for by-product or feeding purposes and as fuel.

Utilization of process by-products in a manner that provides income will reduce the total cost of waste treatment and eventually the cost of the final product. Waste solids should be evaluated as sources of food for plants and animals. A growing emphasis has been devoted to the development of markets for by-products or for the compost produced by converting waste organic materials to an innocuous humus. Table 1 provides examples of uses for by-products from the food industry.

Table 1. Examples of uses for by-products from the food industry

|

Method |

Examples |

|

Anaerobic digestion |

Digestion by mixed bacteria population to yield methane and CO2 |

|

Animal feed |

Directly, after pressing or drying, as fodder ensiling or as supplement |

|

Composting |

Natural microbiological process in which organic components decompose under controlled aerobic conditions |

|

Edible fibre |

Method for utilizing organic solids by filtering and hydration |

|

Fermentation |

Combination of starch, sugar and alcohol-bearing substances |

|

Incineration |

Burning of biomass as fuel |

|

Pyrolysis |

Transformation of nut shells and fruit pits into charcoal briquets |

|

Soil amendment |

Fertilizing of soils with low nutrient and organic matter content |

Source: Adapted from Merlo and Rose 1992.

Water Reuse and Effluent Reduction

Extensive dependence on water by food-processing industries has encouraged the development of conservation and reuse programmes, especially in locations of water scarcity. Reuse of process water can provide substantial reductions in both water consumption and waste load, with reuse in many lower-quality applications not requiring biological treatment. However, any potential for anaerobic fermentation of organic solids must be avoided so that corrosive, odourous decomposition products do not affect equipment, work environment or product quality. Bacterial growth can be controlled by disinfection and by changing environmental factors such as pH and temperature.

Table 2 presents typical water reuse ratios. Factors such as the location of sprays, water temperature and pressure are key factors influencing the volume of water required for processing operations. For example, water used as a cooling medium to cool cans and for air conditioning may later be used for primary washing of vegetables and other products. The same water later may be used for fluming waste material, and finally a portion of it may be used to cool ashes in the powerhouse.

Table 2. Typical water reuse ratios for different industry sub-sectors

|

Sub-sectors |

Reuse ratios |

|

Beet sugar |

1.48 |

|

Cane sugar |

1.26 |

|

Corn and wheat milling |

1.22 |

|

Distilling |

1.51 |

|

Food processing |

1.19 |

|

Meat |

4.03 |

|

Poultry processing |

7.56 |

Water conservation techniques and waste prevention techniques include the use of high-pressure sprays for clean-up, elimination of excessive overflow from washing and soaking tanks, substitution of mechanical conveyors for water flumes, use of automatic shut-off valves on water hoses, separation of can cooling water from the composite waste flow and recirculation of can cooling water.

Pollution loads at processing plants can be reduced through modified processing methods. For example, most pollution load generated from fruit and vegetable processing originates in the peeling and blanching operations. By moving from conventional water or steam blanching to a hot gas blanching process, pollution loads can be reduced by as much as 99.9%. Similarly, dry caustic peeling can cut BOD by more than 90% in comparison to conventional peeling processes.

Energy Conservation

Energy needs have risen with the increased sophistication of the food industry. Energy is required for a wide a variety of equipment such as gas-fired ovens; dryers; steam boilers; electrical motors; refrigeration units; and heating, ventilation and air-conditioning systems.

As the cost of energy has risen, there has been a trend to install heat recovery equipment to conserve energy and to investigate the feasibility of alternative energy sources in various food-processing situations such as cheese processing, food dehydration and water heating. Energy conservation, waste minimization and water conservation are all mutually supportive strategies.

Consumer Health Issues

The increasing separation of the consumer from the food- production sector that has accompanied urbanization globally has resulted in a loss of the traditional means used by the consumer to ensure the quality and safety of food, making the consumer dependent on a functional and responsible food-processing industry. Increased dependence on food processing has created the possibility of exposure to pathogen-contaminated food from a single production facility. To provide protection from this threat, extensive regulatory structures have been established, especially in the industrialized countries, to protect public health and to regulate the use of additives and other chemicals. Harmonization of regulations and standards across borders is emerging as an issue to ensure the free flow of food among all the world’s countries.

Dairy industry wastewater treatment

The dairy industry is made up of a large number of relatively small plants supplying products such as milk, cheese, cottage cheese, sour cream, ice cream, whey solids and lactose.