Rice

Rice is the staple food for Asian people; it is prepared by cooking or ground as flour for bread making, thus helping to feed the rest of the world population. Various kinds of rice are produced to suit the taste of the consumers. Rice cultivation is done either in marshy, lowland areas with plenty of water or in plateau or hilly regions where natural rainfall provides adequate amounts of water.

Cultivation Process

Rice can be cultivated either by hand or by partial or full mechanization, according to the technological development of the country and the need for productivity. Whatever kind of operation is done, the following step-by-step processes are necessary.

- Ploughing. The land is ploughed in three stages to eliminate lumps and to make soil as soft and muddy as possible. Buffalo, oxen or cows usually pull the ploughs, though the use of mechanical equipment is increasing.

- Weeding is carried out three times by irrigating the land for 5 days at a time and then letting it dry for 5 days. At the end of each cycle, the land is beaten with a heavy wooden tool to kill off young weeds so they may be used as natural fertilizer.

- Preparation of seedlings. The seeds are soaked in a large water-filled jar with appropriate concentrations of salt added to make the healthy seeds sink. These healthy seeds are then thoroughly washed, soaked overnight, wrapped in a thick cloth or sack for 2 nights to germinate, sown in the area prepared for them and left to grow for approximately 30 days.

- Transplantation. The young plants, in bunches of 3 to 5, are thrust into the mud in rows and grown for 10 days. After about a total of 45 days, the plant is fully grown and begins to bear seeds.

- Harvesting. When the plant is about 100 days old, it is usually reaped by hand (see figure 1); sickles or similar tools are used for cutting the bearing grains off.

- Drying is done in the open air in the sun, to make the moisture content fall below 15%.

- Threshing separates the grain, with its husk or glume, from the stalk. Traditionally, buffaloes or oxen are used to slowly drag the threshing combs over the stalk to force out the grain. Many places use locally made machines for this.

- Storage. Grains and hays are stored in barns or silos.

Figure 1. Harvesting of rice plants by hand in China, 1992

Lenore Manderson

Hazards

Common and specific hazards are as follows:

- Poor housing, low sanitary standards, inadequate nourishment and the need to drink large quantities of water, which is not always pure, lead to general weakness and fatigue, possible sunstroke, intestinal troubles and diarrhoea.

- Most injuries caused by farm machinery occur when the workers are not familiar with the machines. Muscles, bones and joints are intensively used, both in dynamic and static loads, causing physical fatigue and resulting in the reduction of work capacity and an increase in traumatic injuries and accidents. Children and adolescents, as well as migrant workers, die from farm injuries each year.

- Chemical agents, such as fertilizers, strong weedkillers, pesticides and other extensively used substances, increase the hazards both for the workers and the animal or plant foods they consume (e.g., fish, field crabs, water plants, mushrooms, medicinal herbs, field rats or even contaminated water).

- Diseases (e.g., malaria, tetanus, hookworm, schistosomiasis, leptospirosis, hay fever, farmer’s lung, dermatitis, blepharitis, conjunctivitis, common cold and sunstroke) are very common, as are nutritional disorders (e.g., protein deficiency, toxins), alcoholism, heavy smoking and other addictive habits.

- The most common occupational diseases are skin diseases. These include: redness and blisters from prickly rice leaves; abrasions and skin injuries caused by prickly plants; calluses of the palms, hands, knees and elbows caused by bad posture and the use of hand tools; skin fungal infections (tinea) due to epidermophytes and Monilia (candida), which may be complicated by secondary sensitization, redness and blisters, frequently due to Staphylococcus bacteria; vesicular dermatitis (small blisters) on the feet sometimes attributed to Rhizopus parasiticus; itch commonly caused by the penetration of the skin by Ancylostoma (hookworms); schistosome dermatitis caused directly or indirectly by contact with water containing blood flukes from nonhuman hosts; and redness, blisters and oedema resulting from insect stings.

- Respiratory diseases due to organic and inorganic dusts and synthetic chemicals are common. Gram-negative bacterial endotoxin levels in air are high in some countries. Silage gas poisoning of high nitrate soils is also a health problem.

- Climatic agents such as heat, heavy rain, humidity, high wind, storms and lightning strike both workers and cattle.

- Psychological stress factors such as economic problems, sense of insecurity, lack of social standing, lack of educational opportunities, lack of prospects and risk of unexpected calamities are particularly common in the developing countries.

Safety and Health Measures

Working conditions should be improved and the health hazards reduced through increased mechanization. Ergonomic interventions to organize the work and working equipment, and systematic training of the body and its movements to ensure good working methods, are essential.

Necessary medical preventive methods should be strictly applied, including the introduction of first aid instruction, the provision of treatment facilities, health promotion campaigns and medical surveillance of workers.

Improvement of housing, sanitary standards, accessible potable water, nutritional environmental hygiene and economic stability are essential for the quality of life of rice field workers.

Applicable International Labour Organization (ILO) Conventions and Recommendations should be followed. These include:

- The Minimum Age (Agriculture) Convention, 1921 (No.10), provides that children under the age of 14 years may not be employed or work in any public or private agricultural undertakings, or in any branch thereof, when school is in session.

- The Night Work of Children and Young Persons (Agriculture) Recommendation, 1921 (No.14), requires that each Member State regulate the employment of children under the age of 14 years in agricultural tasks at night, leaving not less than 10 consecutive hours for them to rest. For young persons between the age of 14 and 18 years, the period of rest must consist of not less than 9 consecutive hours.

- The Plantations Convention, 1958 (No.110), provides that every recruited worker shall be medically examined. This Convention is obviously of great importance for workers of all ages.

- The Maximum Weight Convention, 1967 (No.127), identified optimum loads that can be handled by 90% of workers for all routine and repetitive manual-handling tasks.

Case Study: Agricultural Machinery

Adapted from 3rd edition, “Encyclopaedia of Occupational Health and Safety”.

Agricultural machinery is designed to till the soil and render it more suitable for crop growth, to sow seeds, to apply agricultural chemicals for improved plant growth and control of pests and diseases, and to harvest and store the mature crops. There is an extremely wide variety of agricultural machines, but all are essentially a combination of gears, shafts, chains, belts, knives, shakers and so on, assembled to perform a certain task. These parts are usually suspended in a frame which may be either stationary or, as is more often the case, mobile and designed to perform the desired operation while moving across a field. The major groups of agricultural machines are: soil tillage machines; planting machines; cultivating machines; forage harvesting machines; grain, fibre, vegetable, and fruit and nut harvesting machines; agricultural chemical applicators; transport and elevating machines; and sorting and packaging machines.

Soil tillage machines. These include ploughs, tillers, subsoilers, harrows, rollers, levellers, graders and so on. They are designed to turn, agitate, level and compact the soil to prepare it for planting. They may be small in size and require only a small power source (as in the case of a one-person roto-tiller for tilling a rice paddy), or they may be large and require a considerable power source (as in the case of a combined subsoiler, drill and harrow).

Planting machines. These include planters, drills, broadcast seeders and so on and are designed to take seeds from a hopper or bin and insert them in the soil at a predetermined depth and spacing or spread them uniformly over the ground. Planters may be of simple design and comprise a single-row seeding mechanism, or they may be highly complex (as is the case with the multi-row planter with attachments that simultaneously add fertilizer, pesticides and herbicides).

Cultivating machines. These include rotary hoes, cultivators, weeders (mechanical and flame) and so on. They are used to eradicate undesirable weeds or grasses which compete with the plant for soil moisture and make the harvest of the crop more difficult. They also improve the soil tillage so as to make it more absorptive of rain.

Forage harvesting machines. These include mowers, choppers, balers and so on and are designed to sever the stems of roughage crops from their roots and prepare them for storage or immediate use. The machines also vary in their complexity: the simple mower merely cuts the crop, whereas the chopper will not only separate the stalk from the root but will also chop the entire plant into small pieces and load it into a vehicle, which may be a towed wagon. Crimpers, which crush or break the stems of plants, are often used to expedite the field-drying process of fodder crops to prevent spoilage, especially of legumes that will be placed in dry storage or baled. Pelleting machines are used to compress fodder crops into compact cubes for mechanical feeding of livestock. Balers are used to compress fodder into square or round bales to facilitate storage and handling. Some bales are small enough (20 to 40 kg) to handle manually, while others may be so large (400 to 500 kg) as to require mechanical handling systems.

Grain and fibre harvesting machines. These include reapers, binders, corn pickers, combines, threshers and so on. They are used to remove the ripe grain or fibre from the plant and place it in a bin or bag for transport to the storage area. Grain harvesting may involve the use of a number of machines, such as a reaper or binder to cut the standing grain, a wagon or truck to transport the crop to the threshing or separating machines and vehicles to transport the grain to a storage area. In other cases many of these functions may be performed by a single machine, the combine harvester (figure 1), which cuts the standing grain, separates it from the stalk, cleans it and collects it in a bin, all while moving through the field. Such machines will also load the grain into transport vehicles. Some machines such as cotton pickers and corn pickers may operate selectively and remove only the grain or fibre boll from the stem or stalk.

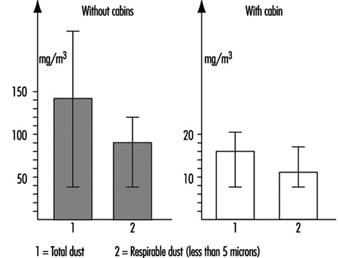

Figure 1. Combine for harvesting wheat without an enclosed cabin.

Vegetable harvesting machines. These include diggers and lifters, and are designed either to dig the crops from the earth and separate them from the soil or to lift or pull the plant free. The potato digger, for example, may form part of a potato combine comprising a sorting, grading device, polisher, bagger and elevator. At the other extreme is the simple two-wheeled, bladed sugar-beet lifter which is followed by hand labourers.

Fruit and nut harvesting machines. These machines are used to harvest berries, fruit and nuts. They may be as simple as a tractor-mounted, vibrating tree shaker which separates the ripe fruit from the tree. Or they may be as complex as the ones which harvest the fruit, catch the falling fruit, place it in a storage container and later transfer it to transport vehicles.

Transport and elevating machines. These also vary considerably in size and complexity ranging, for example, from a simple wagon comprising merely a platform on wheels to a self-loading and stacking transport unit. Inclined chain, flight or belt conveyors or other mechanical handling devices are used to move bulky material (hay, straw, ear corn and so on) from wagon to storage or from one location in a building to another. Screw conveyors are used to move granular material and grain from one level to another, and blowers or pneumatic conveyors are used to move light materials horizontally or vertically.

Agricultural chemical applicators. These are used to apply fertilizers to stimulate plant growth or herbicides and pesticides to control weeds and pests. The chemicals may be liquid, powdered or granular, and the applicator distributes them either by pressure through a nozzle or by centrifugal force. Applicators may be portable or vehicle-mounted; the use of aircraft for chemical application is growing rapidly.

Sorting and packaging machines. These machines are usually stationary. They may be as simple as a fanning mill, which grades and cleans grain merely by passing it over a series of screens, or as complex as a seed mill, which will not only grade and clean but also, for example, separate different types of seeds. Packaging machines usually form part of a sophisticated grading system. They are used primarily for fruit and vegetables and may wrap the produce in paper, bag it or insert it into a plastic container.

Power plants. Electric motors may be used to drive stationary equipment permanently located near a mains supply; however, since many agricultural machines are mobile and must operate in remote areas, they are usually powered by an integral petrol engine or by a separate engine such as that of a tractor. Power from a tractor may be transmitted to the machine via belt, chain, gear or shaft drives; most tractors are fitted with a power take-off coupling specially designed for this purpose.

Mechanization

The mechanization of agricultural work and work processes has relieved many workers throughout the world of onerous, back-breaking, monotonous labour. At the same time, the speed and power associated with mechanization contributes greatly toward serious traumatic injury. Throughout the world, countries that practise mechanized agriculture list tractors and field and farmstead machinery as leading agents of fatal and disabling injury in agricultural work. Power tools also contribute to the injury toll, though these injuries are usually less severe. Some machinery also presents environmental hazards such as noise and vibration.

Tractor hazards

Farm tractors have many characteristics that result in their being the most important piece of power equipment on the farm. Most tractors have rubber tyres, hydraulic systems, and power take-off (PTO), and utilize a combination of engine speeds and gear ratios. These characteristics combine to provide tractors with speed, power, flexibility and adaptability. The most serious hazards associated with tractor operation include overturns, runovers and PTO entanglement. Tractor overturns fatally injure far more victims than any other type of incident. Table 1 provides a listing of tractor hazards and how injuries occur.

Table 1. Common tractor hazards and how they occur

|

Hazard |

Type of incident |

How injury occurs |

|

Overturns |

Side rollovers |

Operating on slopes, turning corners too fast, rear wheel drops into a hole or off-road surface. |

|

Rear rollovers |

Hitching to a point other than the drawbar, rear wheels are stuck in mudhole or are frozen to the ground. |

|

|

Runovers |

Passenger (extra rider) falls off |

Most tractors are designed only for one operator; therefore, there is no safe location for an extra person on a tractor. |

|

Operator falls off |

Knocked off by low-hanging tree limb, bounced out of seat by traversing rough ground. |

|

|

Operator is run over while standing on the ground |

Jump starting tractor with tractor inadvertently in gear. Tractor rolls while mounting/dismounting. Tractor rolls during hitching/unhitching of equipment. |

|

|

Bystander or on-ground helper is run over |

Bystander incidents often involve small children the operator does not see. On-ground helper incidents are similar to operator-on-the-ground incidents. |

|

|

Power take-off (PTO) |

Entanglement with PTO stub shaft |

Master shield is missing and PTO is left engaged while tractor is running. Operator may be mounting/dismounting from rear of tractor. |

|

Slips and falls |

Mounting/dismounting from tractor |

Wet and/or muddy feet, first/last step is high off the ground, difficult to reach handholds, hurrying, facing wrong way when dismounting. |

|

Noise-induced hearing loss |

Operating tractor |

The tractor muffler may be missing, damaged, or is a non-recommended replacement; tractor engine is not maintained properly; metal weather cab redirects sound back to the operator. Damaging noise level may come from a combination of tractor and attached machine. (Older tractors generally produce louder sounds than newer tractors.) |

Overturns

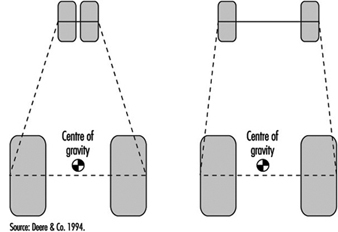

The central concept in tractor stability/instability is centre of gravity (CG). A tractor’s CG is the point on the tractor where all parts balance one another. For example, when a two-wheel-drive tractor is sitting with all wheels on level ground, the CG is typically about 25.4 cm above and 0.6 m in front of the rear axle and in the centre of the tractor body. For four-wheel-drive and centre-articulated tractors, the CG is located slightly more forward. For a tractor to stay upright, its CG must stay within the tractor’s stability baseline. Stability baselines are essentially imaginary lines drawn between points where tractor tires contact the ground (see figure 1). A tractor’s CG as such does not move, but its relationship with stability baselines may change. This most often occurs as the tractor moves out of a perfectly level position, such as onto a slope. A changing relationship between CG and stability baseline means the tractor is moving toward an unstable position. If the CG-stability baseline relationship changes significantly (e.g., the tractor CG moves beyond the stability baseline), the tractor rolls over. If equipment such as a front-end loader, a round bale lifting fork or a chemical side-saddle tank is mounted on the tractor, the additional weight shifts the CG toward that piece of equipment. As mounted equipment is raised, the CG is raised.

Figure 1. The stability baseline of a tricycle tractor and a wide front-end tractor, respectively

Other factors important to tractor stability/instability include centrifugal force (CF), rear-axle torque (RAT) and drawbar leverage (DBL). Each of these factors works through the CG. Centrifugal force is the outward force nature exerts on objects that move in a circular fashion. Centrifugal force increases both as the turning angle of the tractor becomes sharper (decreases) and as the speed of the tractor increases during a turn. The CF increase is directly proportional to the turning angle of the tractor. For every degree the tractor is turned tighter, there is an equal amount of increased CF. The relationship between CF and tractor speed, however, is not directly proportional. Finding the increase in CF from turning a tractor at a higher speed (assuming the turning radius stays the same) calls for squaring the difference between the two tractor speeds.

RAT involves energy transfer between the tractor engine and the rear axle of a two-wheel-drive tractor. Engaging the clutch results in a twisting force, called torque, to the rear axle. This torque is then transferred to the tractor tyres. Under normal circumstances, the rear axle (and tyres) should rotate, and the tractor will move ahead. In lay terms, the rear axle is said to be rotating about the tractor chassis. If the rear axle should be unable to rotate, the tractor chassis rotates about the axle. This reverse rotation results in the front end of the tractor lifting off the ground until the tractor’s CG passes the rear stability baseline. At this point the tractor will continue rearward from its own weight until it crashes into the ground or another obstacle.

DBL is another principle of stability/instability related to rear overturns. When a two-wheel-drive tractor is pulling a load, its rear tyres push against the ground. Simultaneously, the load attached to the tractor is pulling back and down against the forward movement of the tractor. The load is pulling down because it is resting on the earth’s surface. This backward and downward pull results in the rear tyres becoming a pivot point, with the load acting as a force trying to tip the tractor rearward. An “angle of pull” is created between the ground’s surface and the point of attachment on the tractor. The heavier the load, and the higher the angle of pull, the more leverage the load has to tip the tractor rearward.

Runovers

There are three basic types of tractor runover incidents. One is when a passenger (extra rider) on the tractor falls off the tractor. A second is when the tractor operator falls off the tractor. The third type occurs when a person already on the ground is run over by the tractor. The person already on the ground may be a bystander (e.g., a non-working adult or a small child), a co-worker or the tractor operator. The tractor runover event often involves trailing machinery hitched to the tractor; it may be the trailing machinery that inflicts the injury. Extra rider injury incidents occur because there is no safe location for an extra person on a tractor, yet the practice of taking extra riders is common, as a means of saving time, for convenience, work assistance or baby-sitting. Whether an extra rider can be justified for any reason is strictly in the eye of the beholder. Safety experts and tractor manufacturers strongly recommend against an operator carrying an extra rider for any reason. This advice, however, conflicts with several factors that farmers must face daily. For instance, it is human nature to want to complete work tasks as easily and quickly as possible; different transportation may call for added expenditure of a meagre money supply; other baby-sitting options simply may not exist; and new tractor drivers must be taught how to operate tractors.

Persons already on the ground, usually tractor operators or children, are occasionally run over by tractors and their attached equipment. Tractor operators sometimes try to start their tractor from the ground, instead of from the operator’s seat. Most of these incidents occur with older tractors that will start with the tractor in gear, or on newer tractors where the starting interlocks built into the tractor have been by-passed. Small children, usually under the age of five, are sometimes run over by tractors and machinery that is moved around the farmstead. Often, the tractor operator is unaware that the child is even near the equipment. A loud noise, such as the start-up of a tractor, is often attractive to young children and may draw them near. And the practice of allowing extra riders may bring them running to the tractor.

Tractor safety rules include:

- The most important safety device for a tractor is a rollover protective structure (ROPS). This device, along with a properly buckled seat-belt, prevents an operator from being crushed by the tractor during a rollover.

- A ROPS enclosed cab provides even more protection, as cabs also provide protection from adverse weather elements and from falling off the tractor.

- A master shield over the PTO stub shaft protects against PTO entanglement.

- The one seat–one rider rule and other safe operating practices must be followed.

- Operator manuals must be read to learn how to safely operate the machine.

- Workers must be physically, psychologically and physiologically capable of operating a given machine.

Machinery Hazards

There are a multitude of machines used in mechanized agriculture. These machines are powered in many different ways including PTO shafts, hydraulic oil pressure, electrical power, engine power and ground traction. Many machines have several types of hazards. Table 2 gives machine hazards, descriptions of the hazards and examples of where the hazards occur on various machines.

Table 2. Common machinery hazards and where they occur

|

Hazards |

Sources |

Locations |

|

Pinch points |

Two machine parts moving together with at least one of them moving in a circle |

Where drive belts contact pulley wheels, drive chains contact gear sprockets, feed rolls mesh together |

|

Wrap points |

An exposed/unguarded rotating machine component |

Power take-off (PTO) drive shafts, beater bars on self-unloading ensilage wagons, blades of some manure spreaders |

|

Shear/cutting points |

The edges of two moving parts move across one another, or a single edge moves against a stationary edge or soft material |

Mowers and forage harvesters, small-grain combine heads, bedding choppers, grain augers |

|

Crush points |

Two moving objects moving toward each other, or one moving object moves toward a stationary object |

The front and rear tires/sections of articulating tractors, hitching machinery, a hand caught under a piece of hydraulically-controlled equipment |

|

Free-wheeling parts |

Machine parts that continue to move after power to the part has stopped, usually from the continuing rotation of knife or fan blades |

Forage harvesters, feed grinders, rotary mowers, ensilage blowers |

|

Thrown objects |

The chopping, grinding, cutting, and flinging motions of machines. Small objects such as rocks, metal, glass, sticks, and vegetation may be picked up and thrown with great force |

Rotary mowers, feed grinders, combines with straw choppers, and manure spreaders |

|

Stored energy |

Energy that is confined and released unintentionally or unexpectedly |

Machine springs, hydraulic systems, compressed air, electrical systems |

|

Burn points |

Skin burns from contacting hot parts of machines |

Hot mufflers, engine blocks, pipes, fluids (fuel, oils, chemicals) |

|

Pull-in points |

Occurs at the point where the machine takes the crop material in for further processing |

Corn pickers and combines, forage choppers, and hay balers |

|

Noise-induced hearing loss |

Operating machinery |

Tractors, field machinery, grain augers, dryers, silo blowers, bedding choppers, feed grinders. Damaging noise level may come from a combination of one or more machines. Older machines generally produce louder sounds than newer machines. |

Machinery power and speed

Though workers may understand that machinery is powerful and operates at very high speeds, most workers have not stopped to consider just how powerful machines are in comparison to their own power, nor do they fully comprehend how fast machines are. Machinery power varies considerably, but even small machines generate many times more horsepower than any person. A quick, pull-away action of a human arm normally generates less than 1 horsepower (hp), sometimes much less. A small 16-hp machine, such as a walk-behind mower, may have 20 to 40 times more power pulling a person into the machine than that person can generate pulling away. A medium-sized machine operated at 40 to 60 hp will have hundreds of times more power than a person.

This power and speed combination presents many potentially hazardous situations to workers. For example, the tractor’s PTO stub shaft transfers power between the tractor and PTO-powered machinery. Power transfer is accomplished by connecting a drive shaft from the machinery to the tractor’s PTO stub. The PTO stub and drive shaft rotate at 540 rpm (9 times/second) or 1,000 rpm (16.7 times/second) when operating at full recommended speed. Most incidents involving PTOs stem from clothing suddenly caught by an engaged but unguarded PTO stub or driveline. Even with a relatively quick reaction of 1 second (i.e., the worker tries to pull away from the shaft) and a shaft with a diameter of 76 mm operating only at half speed (e.g., at 270 rpm (one-half of 540), the victim’s clothing has already wrapped 1.1 m around the shaft. A faster-operating PTO and/or a slower reaction provides even less of an opportunity for the worker to avoid entanglement with the shaft.

When a machine is running at full recommended PTO speed, crop material moves into the machine intake or processing area at approximately 3.7 m/s. If a worker is holding onto crop material as it begins entry into the machine, he or she is usually unable to let go quickly enough to release the material before being pulled into the machine. In 0.3 second, the worker will be pulled 1.1 m into the machine. This situation most often happens when crop material plugs the intake point of the machine and the worker attempts to unplug it with the PTO engaged.

Machinery safety

Machinery safety is largely a matter of keeping the guards and shields that came with the original in place and properly maintained. Warning decals should be used as a reminder to keep guards and shields in place. If guards or shields must be removed for maintenance, service or adjustment, they must be replaced immediately upon completion of the repair. Safe operating practices must be followed. For example, the tractor must be shut off and the PTO or block hydraulic systems disengaged before unplugging or servicing equipment. Operator manuals must be read and their safety instructions followed. Workers must be properly trained.

Manual Operations in Farming

Agricultural methods and practices vary across national boundaries:

- industrial agriculture—industrialized countries of the West (temperate climate) and specialized sectors of the tropical countries

- green revolution agriculture—well endowed areas in the tropics, primarily irrigated plains and deltas of Asia, Latin America and North Africa

- resource-poor agriculture—hinterlands, dry lands, forests, mountains and hills, near deserts and swamps. About 1 billion people in Asia, 300 million in sub-Saharan Africa and 100 million in Latin America are dependent on this form of agriculture. Women comprise a large proportion of subsistence farmers—nearly 80% of the food for sub-Saharan Africa, 50 to 60% of Asia’s food, 46% of the Caribbean’s food, 31% of North Africa and the Middle East’s food and 30% of Latin America’s food is produced by women (Dankelman and Davidson 1988).

With distinct agro-climatic features, the farm crops are grouped as follows:

- Field crops (cereals, oilseeds, fibre, sugar and fodder crops) are rain-fed or cultivated through controlled irrigation.

- Upland and semi-upland cultivation (wheat, groundnuts, cotton and so on) are practised where irrigation or rain water is not abundantly available.

- Wetland cultivation (rice crops) is practised where the land is ploughed and puddled with 5 to 6 cm of standing water and seedlings are transplanted.

- Horticulture crops are fruit, vegetable and flower crops.

- Plantation or perennial crops include coconut, rubber, coffee, tea and so on.

- Pastures are anything nature grows without human intervention.

Farming Operations, Hand Tools and Machinery

Farming in the tropical countries is labour intensive. The ratio of rural population to arable land in Asia is twice as great as in Africa and three times that of Latin America. It is estimated that human effort provides more than 70% of the energy required for crop production tasks (FAO 1987). Improvement in the existing tools, equipment and methods of work has significant effects in minimizing human strain and fatigue and increasing farm productivity. For field crops, farm activities may be categorized based on the physiological demand of work with reference to an individual’s maximal working capacity (see table 1).

Table 1. Categorization of farm activities

|

Work severity |

Farm operations |

|||

|

Seed bed preparation |

Sowing |

Weeding and intercultivation |

Harvesting |

|

|

Light work |

Laddering (two workers) |

Broadcasting seeds/fertilizer, scaring birds, ridging |

Fertilizer broadcasting |

Grain cleaning, grading, spreading vegetables (squatting), pounding grain (helper), winnowing (sitting) |

|

Moderately heavy work |

Walking behind animal-drawn implement, levelling soil surface with wooden rake, laddering (one worker), digging soil with spade, bush cutting |

Manual uprooting of seedlings (squatting and bent posture), transplanting seedlings (bent posture), walking on a puddled field |

Manual weeding with sickle and hand hoe (squatting and bent posture), channel irrigation, knapsack spraying of pesticides, weeder operation in wet and dry soil |

Cutting crops, harvesting paddy, wheat (squatting and bent posture), plucking vegetables, manual winnowing (sitting and standing), cutting sugarcane, pedal-thresher helper, carrying load (20-35 kg) |

|

Heavy work |

Ploughing, water lifting (swing busket), hoeing dry soil, bund trimming wet soil, spade work, disc harrowing |

Weeder operation in dry soil |

Grain threshing by beating, pounding grain |

|

|

Extremely heavy work |

Bund trimming dry soil |

Germinating seeder operation in puddled field |

Pedal threshing, carrying load on head or yoke (60-80 kg) |

|

Source: Based on data from Nag, Sebastian and Marlankar 1980; Nag and Chatterjee 1981.

Seed-bed preparation

A suitable seed-bed is one that is mellow yet compact and free from vegetation that would interfere with seeding. Seed-bed preparation involves use of different types of hand tools, shallow chisel desi or a mould board plough pulled by draft animals (figure 1) or tractor implements for ploughing, harrowing and so on. About 0.4 hectare (ha) of land can be tilled by a bullock-drawn plough in a day, and a pair of bullocks can provide power to the extent of 1 horsepower (hp).

Figure 1. Bullock-drawn shallow chisel desi plough

In using animal-drawn equipment, the worker acts as a controller of animals and guides the implement with a handle. In most cases, the operator walks behind the implement or sits on the equipment (e.g., disc harrows and puddlers). The operation of animal-drawn implements involves considerable human energy expenditure. For a 15 cm plough, a person may walk about 67 km to cover a 1-hectare area. At a walking speed of 1.5 km/h, the human energy expenditure amounts to 21 kJ/min (about 5.6 × 104 kJ per ha). A handle on implements that is too long or too short results in physical discomfort. Gite (1991) and Gite and Yadav (1990) suggested that the optimum handle height of an implement may be adjusted between 64 and 84 cm (1.0 to 1.2 times the metacarpal III height of the operator).

Hand tools (spade, shovel, hoe and so on) are used for digging and loosening the soil. To minimize drudgery in shovelling work, Freivalds (1984) deduced the optimum rate of work (i.e., shovelling rate) (18 to 21 scoops/minute), shovel load (5 to 7 kg for 15 to 20 scoops/minute, and 8 kg for 6 to 8 scoops/minute), throw distance (1.2 m) and throw height (1 to 1.3 m). Recommendations also include a shovel lift angle of about 32°, a long tool handle, a large, square-pointed blade for shovelling, a round-pointed blade for digging and hollow back construction to reduce shovel weight.

Nag and Pradhan (1992) suggested low-lift and high-lift hoeing tasks (see figure 2), based on physiological and biomechanical studies. As a general guide, the method of work and the hoe design are the deciding factors in performance efficiency of hoeing tasks (Pradhan et al. 1986). The mode of striking the blade to the ground determines the angle at which it penetrates the soil. For low-lift work, the work output was optimized at 53 strokes/ minute, with a land area dug of 1.34 m2/minute, and a work-rest ratio of 10:7. For high-lift work, the optimal conditions were 21 strokes per minute and 0.33 m2/minute of land dug. The shape of the blade—rectangular, trapezoidal, triangular or circular—depends upon the purpose and preference of the local users. For different modes of hoeing, the recommended design dimensions are: weight 2 kg, angle between blade and handle 65 to 70° , handle length 70 to 75 cm, blade length 25 to 30 cm, blade width 22 to 24 cm and handle diameter 3 to 4 cm.

Figure 2. Hoeing tasks in bund trimming in paddy field

Pranab Kumar Nag

Sowing/planting and fertilizer application

The sowing of seeds and planting of seedlings involve the use of planters, seeders, drills and the manual broadcasting of seeds. About 8% of total person-hours are required for broadcasting of seeds and uprooting and transplanting of seedlings.

- In the broadcasting of seeds/fertilizer by hand, manually operated broadcasters allow uniform distribution with minimum drudgery.

- Seeding behind a plough consists of sowing of seeds in a furrow opened by a wooden plough.

- In drilling, seeds are placed in the soil by a seed drill or seed-cum-fertilizer drill. The push/pull force required for a worker to operate the drill (manual or animal-drawn units mounted on wheels) is an important design consideration.

- Dibbling is the placing of seeds by hand or with a small implement (a dibbler), at an average spacing of 15 x 15 cm or 25 x 25 cm. Abrasion of fingers and bodily discomfort due to bent and squat postures are common complaints.

- In planting, sugar cane sets are planted at 30 cm length in a furrow; potato seed tubers are planted flat and ridges are made.

- About 1/3 of the world’s rice is grown by the transplanting system. This is also done for tobacco and some vegetable crops. Usually, germinating seeds are broadcasted densely on a puddled field. The seedlings are uprooted and transplanted to a puddled field by hand or with manual or power-operated transplanters. The operator of a manually operated transplanter walks behind the unit to operate the handle mechanism to pick and transplant the seedlings.

For manual transplanting, the workers are required to be immersed knee deep in mud. The squatting posture used for planting on dry land, with one or two legs flexed at the knee, cannot be adopted in a watered field. About 85 person-hours are required to transplant seedlings for each hectare of land. The awkward posture and static load exert strain on the cardiovascular system and cause low-back pain (Nag and Dutt 1980). Manually operated seeders produce higher work output (i.e., a seeder is about eight times more efficient than transplanting by hand). However, maintaining the balance of the machine (see figure 3) in a puddled field requires about 2.5 times more energy than manual transplanting.

Figure 3. Operating an improved germinated seeder

Paranab Kumar Nag

Plant protection

Fertilizer, pesticide, herbicide and other chemical applicators are operated by pressure through nozzles or by centrifugal force. Large-scale spraying is based on the hydraulic nozzle spray atomizer, either manually operated or using tractor-mounted equipment. Knapsack sprayers are scaled-down models of vehicle-mounted sprayers (Bull 1982).

- A compression knapsack sprayer consists of a tank, a pump and a rod with nozzle and hose.

- A lever-operated knapsack sprayer (10 to 20 l) has an operating lever.

- A power knapsack sprayer consists of a chemical tank of about 10-litre capacity and an air-cooled engine of 1 to 3 hp. The sprayer and engine unit is mounted on a frame and carried on the operator’s back.

- A hand-operated bucket sprayer and foot-operated sprayer require two persons for operating the pump and spraying. A rocking sprayer is operated by the rocking (forward and backward) movement of the handle lever.

When carried on the shoulder for prolonged periods, the vibrations of knapsack sprayers/chemical applicators have detrimental effects on the human body. Spraying using a knapsack sprayer results in potential skin exposure (the legs experience 61% of the total contamination, the hands 33%, the torso 3%, the head 2%, and the arms 1%) (Bonsall 1985). Personal protective clothing (including gloves and boots) can reduce the dermal contamination of pesticides (Forget 1991, 1992). The work is quite strenuous, due to carrying of the load on the back as well as continuous operation of the sprayer handle (20 to 30 strokes/minute); in addition, there is the thermoregulatory load due to protective garments. The weight and height of the sprayer, shape of sprayer tank, mounting system and force required to operate the pump are important ergonomic aspects.

Irrigation

Irrigation is a prerequisite for intensive cropping in arid and semi-arid regions. Since time immemorial, various indigenous devices have been used for lifting water. Lifting water by different manual methods is physically strenuous. In spite of the availability of water pump sets (electrical or engine powered), manually operated devices are widely used (e.g., swing baskets, counterpoise water lifts, water wheels, chain and washer pumps, reciprocating pumps).

- A swing basket is used for lifting water from an irrigation channel (see figure 4). The capacity of the basket is about 4 to 6 l and the frequency of operation is about 15 to 20 swings/minute. Two operators work at right angles to the direction of basket motion. The work demands heavy physical activity, with adoption of awkward body movements and posture.

- A counterpoise water lift consists of a container attached to the end of a horizontal lever which is supported on a vertical pole. The worker exerts force on the counterweight to operate the device.

- Reciprocating pumps (piston-cylinder type hand pumps) are operated either by hand in reciprocating mode or by pedalling in rotary mode.

Figure 4. Lifting water from irrigation channel using a swing basket

Pranab Kumar Nag

Weeding and intercultivation

Undesirable plants and weeds cause losses by impairing crop yields and quality, harbouring plant pests and increasing irrigation cost. Reduction in yield varies from 10 to 60% depending upon the thickness of growth and the kind of weeds. About 15% of human labour is spent in removing weeds during the cultivating season. Women typically comprise a large portion of the workforce engaged in weeding. In a typical situation, a worker spends about 190 to 220 hours weeding one hectare of land by hand or hand hoe. Spades are also used for weeding and intercultivation.

Of several methods (e.g., mechanical, chemical, biological, cultural), mechanical weeding, either by pulling out the weeds by hand or with hand tools like the hand hoe and simple weeders, is useful in both dry and wet land (Nag and Dutt 1979; Gite and Yadav 1990). In dry land, the workers squat on the ground with one or two legs flexed at the knee and remove weeds using a sickle or hand hoe. In watered land, the workers adopt a bent forward stooping posture to remove weeds manually or with the help of weeders.

The physiological demand in using weeders (e.g., blade and rake, projection finger, double sweep type weeders) is relatively higher than in manual weeding. However, the efficiency of work in terms of area covered is significantly better with the weeders than with manual weeding. The energy demand in manual weeding jobs is only about 27% of one’s working capacity, whereas for different weeders, the energy demand goes up to 56%. However, the strain is relatively less in the case of wheel hoe-type weeders, with which it takes about 110 to 140 person-hours to cover one hectare. A wheel hoe-type weeder (push/pull) consists of one or two wheels, a blade, a frame and a handle. A force (push or pull) of about 5 to 20 kilograms of force (1 kgf = 9.81 Newtons) is required, with a frequency of about 20 to 40 strokes per minute. The technical specifications of the wheel hoe-type weeders, however, need to be standardized for better operation.

Harvesting

In rice and wheat crops, harvesting requires 8 to 10% of the total person-hours used in crop production. Despite rapid mechanization in harvesting, large-scale dependence on manual methods (see figure 5) will continue for years to come. Hand tools (sickle, scythe and so on) are used in manual harvesting. The scythe is commonly used in some parts of the world, because of its large area of coverage. However, it requires more energy than harvesting with a sickle.

Figure 5. Harvesting wheat crop using a sickle

Pranab Kumar Nag

The popularity of the sickle is due to its simplicity in construction and operation. A sickle is a curved blade, with a smooth or serrated edge, attached to a wooden handle. Sickle design varies from region to region, and there is a difference in cardiorespiratory load with different types of sickles. The output varies from 110 to 165 m2/hour, values corresponding to 90 and 60 person-hours per hectare of land. Awkward work postures may lead to long-term clinical complications relating to the back and to the joints of the limbs. Harvesting in a bent posture has the advantage of mobility on both dry and wet land, and it is about 16% faster than squatting; however, a bent posture is 18% more energy demanding than squatting (Nag et al. 1988).

Harvesting accidents, lacerations and incised wounds are common in paddy, wheat and cane sugar fields. The hand tools are primarily designed for right-handed persons, but are often used by left-handed users, who are unaware of the possible safety implications. The important factors in a sickle design are the blade geometry, blade serration, handle shape and size. Based on an ergonomics study, suggested design dimensions of a sickle are: weight, 200 g; total length, 33 cm; handle length, 11 cm; handle diameter, 3 cm; radius of blade curvature, 15 cm; blade concavity, 5 cm. For a serrated sickle: tooth pitch, 0.2 cm; tooth angle, 60°; and ratio of the length of cutting surface to chord length, 1.2. Since the workers perform activities under extreme climatic conditions, health and safety issues are critically important in tropical farming. The cardiorespiratory strain accumulates over long hours of work. Extreme climatic conditions and heat disorders place added stress on the worker and diminish working capacity.

Harvesting machines include mowers, choppers, balers and so on. Power-operated or animal-drawn reapers are also used for harvesting field crops. Combine harvesters (self-propelled or tractor operated) are useful where intensive cultivation is practised and the labour shortage is acute.

Harvesting of sorghum is done by cutting the ear-head and then cutting the plant, or vice versa. The cotton crop is collected in 3 to 5 pickings by hand as the ball matures. Harvesting of potatoes and sugar beets is done manually (see figure 6) or by using a blade harrow or digger, which may be animal or tractor powered. In the case of groundnuts, the vines are either pulled manually or removed using diggers, and the pods separated.

Figure 6. Manual harvesting of potatoes with a hand hoe

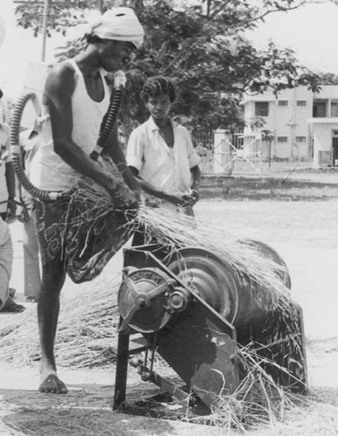

Threshing

Threshing includes separation of grains from the earheads. Age-old manual methods of threshing of grain from the paddy pinnacle are: rubbing the earheads with one’s feet, beating of the harvested crop on a plank, animal treading and so on. Threshing is classified as a moderately heavy task (Nag and Dutt 1980). In manual threshing by beating, (see figure 7) one separates about 1.6 to 1.8 kg of grain and 1.8 to 2.1 kg of straw per minute from medium sized paddy/wheat plants.

Figure 7. Threshing paddy pinnacle by beating

Pranab Kumar Nag

Mechanical threshers carry out threshing and winnowing operations simultaneously. The pedal thresher (oscillating or rotary mode) increases the output to 2.3 to 2.6 kg of grain (paddy/wheat) and 3.1 to 3.6 kg of straw per min. Pedal threshing (see figure 8) is a more strenuous activity than manual threshing by beating. The pedalling and holding of paddy plants on the rolling drum result in high muscular strains. Ergonomic improvements in the pedal thresher may allow a rhythmic pattern of leg work in alternate sitting and standing postures and minimize postural strains. The optimal momentum of the thresher may be reached at about 8 kg weight of the rolling drum.

Figure 8. A pedal thresher in operation

Pranab Krumar Nag

Power threshers are gradually being introduced in green revolution areas. Essentially they consist of a prime mover, a threshing unit, a winnowing unit, a feeding unit and a outlet for clean grain. Self-propelled combines are a combination of a harvester and a thresher unit for grain crops.

Fatal accidents have been reported in grain threshing using power threshers and fodder cutters. The incidence of moderate to severe thresher injuries was 13.1 per thousand threshers (Mohan and Patel 1992). Hands and feet can be injured by the rotor. The position of the feeding chute can result in awkward postures when feeding the crop into the thresher. The belt powering the thresher is also a common cause of injuries. With fodder cutters, the operators can sustain injury while feeding the fodder into the moving blades. Children sustain injury when playing with the machines.

The workers often stand on unstable platforms. In the event of a jerk or loss of balance, the torso weight pushes the hands into the threshing drum/fodder cutter. The thresher must be designed so that the feeding chute is at elbow level and the operators stand on a stable platform. The design of the fodder cutter may be improved for safety as follows (Mohan and Patel 1992):

- a warning roller placed on the chute before the feed rollers

- a locking pin to fix the flywheel when the cutter is not in use

- gear cover and blade guards to push limbs away and prevent clothes from getting entangled.

For threshing groundnuts, the traditional practice is to hold the plants by one hand and strike them against a rod or grill. For threshing maize, tubular maize shellers are used. The worker holds the equipment in his or her palm and inserts and rotates cobs through the equipment to separate the maize grains from the cobs. Output with this equipment is about 25 kg/hour. Hand-operated rotary type maize shellers have higher work output, about 50 to 120 kg/hour. The length of the handle, the force required to operate it and the speed of operation are the important considerations in hand-operated rotary maize shellers.

Winnowing

Winnowing is a process to separate grains from chaff by blowing air, using a hand fan or a pedal- or motor-driven fan. In manual methods (see figure 9), the whole content is thrown up in the air, and the grain and chaff get separated out by differential momentum. A mechanical winnower may, with considerable human exertion, be hand or pedal operated.

Figure 9. Manual winnowing

Pranab Kumar Nag

Other post-harvest operations include cleaning and grading of grains, shelling, decortication, hulling, peeling, slicing, fibre extraction and so on. Different types of manually operated equipment are used in post-harvest operations (e.g., potato peelers and slicers, coconut dehuskers). Decortication involves breaking of shells and removal of seeds (e.g., groundnuts, castor beans). A groundnut decorticator separates kernels from pods. Manual decortication has a very low output (about 2 kg of pod shelling per person-hour). Workers complain of bodily discomfort due to the continuous sitting or squatting posture. Oscillating or rotary-mode decorticators have an output of about 40 to 60 kg of pods per hour. Shelling and hulling refer to separation of seed coat or husk from the inner portion of the grain (e.g., paddy, soybean). Traditional rice hullers are manually (hand or foot) operated and are widely used in rural Asia. The maximum force which can be exerted by hand or foot determines the size and other characteristics of the device. Nowadays, motorized rice mills are used for hulling. In some grains, such as pigeonpea, the seed coat or husk is tightly attached. Removal of the husk in such cases is called dehusking.

For different hand tools and manually operated implements, the grip size and the force exerted on the handles are important considerations. In the case of shears, the force which can be applied by two hands is important. Although most injuries related to hand tools are classified as minor, their consequences are often painful and disabling because of delayed treatment. Design changes in hand tools should be limited to those that can be easily fabricated by village artisans. Safety aspects need to be given due consideration in powered equipment. Safety shoes and gloves available at present are far too expensive and are not suitable for farmers in the tropics.

Manual material-handling tasks

Most agricultural activities involve manual material-handling tasks (e.g., lifting, lowering, pulling, pushing and carrying of heavy loads), resulting in musculoskeletal strains, falls, spinal injuries and so on. The fall injury rate increases dramatically when the fall height is more than 2 m; impact forces are reduced manyfold if the victim falls on soft earth, hay or sand.

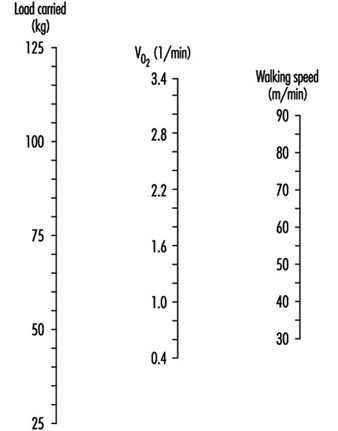

In rural areas, loads weighing 50 to 100 kg might be carried several miles on a daily basis (Sen and Nag 1975). In some countries, women and children have to fetch water in large quantities from a distance. These arduous tasks need to be minimized to the extent possible. Different methods of water carriage involve carrying on the head, on the hip, on the back and on the shoulder. These have been associated with a variety of biomechanical effects and spinal disorders (Dufaut 1988). Attempts have been made to improve shoulder load-carrying techniques, designs of wheelbarrows and so on. Load transportation using transverse yoke and head load are more efficient than the frontal yoke. The load optimization that can be carried by men may be obtained from the nomogram shown (figure 10). The nomogram is based on a multiple regression drawn between oxygen demand (the independent variable) and load carried and walking speed (the dependent variables). One may put a scale on the graph across the variables to identify the result. Two variables must be known to find the third. For example, with an oxygen demand of 1.4 l/min (approximate equivalent of 50% of one’s maximum working capacity) and walking speed of 30 m/min, the optimum load would be about 65 kg.

Figure 10. A nomogram to optimize load to be carried on head/yoke, with reference to walking speed and oxygen demand of work.

In view of the diversity of farm activities, certain organizational measures towards redesigning of tools and machinery, methods of work, installation of safety guards on machinery, optimization of human exposure to adverse work environment and so on may significantly improve conditions of work for farming populations (Christiani 1990). Extensive ergonomic research on farm methods and practices, tools and equipment may generate a great deal of knowledge for the betterment of health, safety and productivity of billions of agricultural workers. This being the world’s largest industry, the primitive image of the sector, particularly the resource-poor tropical agriculture, could be transformed as task-oriented. Thus rural workers can undergo systematic training on the hazards of jobs, and safe operational procedures can be developed.

Storing and Transportation Operations

Storing

The growing and gathering of crops and production of livestock has long been recognized as one of the world’s oldest and most important occupations. Farming and ranching today is as diverse as the many crops, fibres and livestock which are produced. At one extreme, the farming unit may consist of a single family that cultivates the soil and plants and harvests the crop, all by hand over a limited area. The opposite extreme includes large corporate farms spanning vast areas that are highly mechanized, using sophisticated machinery, equipment and facilities. The same is true for the storage of food and fibre. Storage of agricultural products may be as rudimentary as simple huts and hand-dug pits, and as complex as towering silos, bunkers, bins and refrigerated units.

Hazards and their prevention

Agricultural products such as grains, hays, fruit, nuts, vegetables and plant fibre are often stored for later human and livestock consumption or sale to the general populace or to manufacturers. The storage of agricultural products prior to shipment to market may occur in a variety of structures—pits, bunkers, bins, silos, refrigerated units, carts, wagons, barns and railroad cars, to mention a few. Despite the diversity of products being stored and of storage facilities, there are hazards which are common to the storage process:

Falls and falling objects

Falls may occur from heights or at the same level. In the case of bins, silos, barns and other storage structures, falls from heights most often occur from and in storage structures. Most often the cause is unguarded roofs, floor openings, stairways, lofts and shafts, and climbing ladders or standing on raised work areas such as an unprotected platform. Falls from height may also result from climbing on or off the transportation unit (e.g., wagons, carts and tractors). Falls from the same level occur from slippery surfaces, tripping over objects or being pushed by a moving object. Protection against falls includes such measures as:

- provision of safety belts, harnesses, lifelines and safety boots

- installation of guard rails, toeboards, cat-ladders or crawling boards on sloped roofs

- guarded floor openings, lofts and shafts

- use of the standard rise and run of stairways, provision of handrails on both sides, and application non-skid strips where necessary

- maintaining floors in good condition, free from uneven surfaces, holes and accumulations of waste or slippery substances

- provision of handholds on permanent ladders, guard platforms and landings

- maintaining extension or step ladders in good condition and training employees on their use.

Agricultural products may be stored loose in a facility or bundled, bagged, crated or bailed. Loose storage is often associated with grains such as wheat, corn or soybeans. Bundled, bagged, crated or bailed products include hay, straw, vegetables, grains and feeds. Falls of materials occur in all types of storage. Collapse of unsecured stacked foodstuffs, overhead materials and piles of goods are often causes of injury. Employees should be trained in the correct stacking of goods to prevent their collapse. Employers and managers must monitor the workplace for compliance.

Confined spaces

Agricultural products may be stored in two types of facilities—those that contain enough oxygen to sustain life, such as barns, open carts and wagons, and those that do not, such as some silos, tanks and refrigeration units. The latter are confined spaces, and should be treated with appropriate precautions. The oxygen level should be monitored prior to entry and a supplied air or self-contained breathing unit used if necessary; someone else should be on hand. Suffocation may also occur in either type of facility if the goods which it contains have the characteristics of a fluid. This is commonly associated with grains and similar foodstuffs. The worker dies as a result of drowning. In grain bins it is a common practice for an agricultural worker to enter the bin due to difficulties in loading or unloading, often caused by a condition of the grain resulting in bridging. Workers attempting to alleviate the situation by unbridging the grain may voluntarily walk on the bridged grain. They may fall in and be covered with the grain or be sucked under if the loading or unloading equipment is operational. Bridging also may occur to the sides of such structures, in which case a worker may enter to knock down the material sticking to the sides and become engulfed when the material fails. A lockout/tagout system and fall protection such as a safety belt and rope are essential if workers are to enter this type of structure. Children’s safety is of special concern. Often inquisitive, playful and wanting to do adult chores, they are attracted to such structures, and the results are all-too-often fatal.

Fruit and vegetables are often kept in cold storage prior to shipping to market. As indicated in the above paragraph, depending on the type of unit, cold storage may be considered a confined space and should be monitored for oxygen content. Other hazards include frostbite and cold-induced injury or death from body temperature loss following prolonged exposure to cold. Personal protective clothing should be worn appropriate to the temperature within the cold-storage unit.

Gases and poisons

Depending on the moisture content of the product when it is placed in storage and atmospheric and other conditions, feeds, grains and fibres may produce dangerous gases. Such gases include carbon monoxide (CO), carbon dioxide (CO2) and oxides of nitrogen (NOx), some of which may cause death in a matter of minutes. This is also especially important if the goods are stored in a facility in which nonlethal gases may be allowed to accumulate to dangerous levels, displacing oxygen. If the potential for gas production exists, then monitoring for gases should be done. In addition, foods and feeds may have been sprayed or treated with a pesticide during the growing period to kill weeds, insects or disease, or during the storage process to reduce spoilage or mould, spore or insect damage. This may add to the hazards of gas production, inhalation of dusts and handling of the product. Special care should be taken by workers to wear PPE depending on the nature and longevity of the treatment, the product used and the label directions.

Machine hazards

Storage facilities may contain a variety of machinery for conveying the product. These range from belt and roller conveyors to blowers, augers, slides and other such product-handling devices, each with its own power source. Hazards and suitable precautions include:

- Nip points formed by belts, pulleys and gears. Agricultural workers should be protected from nip and shear points by an appropriate guarding around the point of potential contact.

- Protruding belt fasteners, setscrews, keys, bolts and grooves. Protruding setscrews, keys or bolts on revolving shafts should be countersunk, encased or shrouded. Belt fasteners should be inspected and repaired.

- Shear points caused by flywheel arms, augers and their housing, pulley spokes, crank and lever mechanisms. These should be guarded or enclosed.

- Contact with moving transmission or electrical elements. These should be guarded or enclosed.

- Inadvertent starting of machinery or equipment. A system for locking out or tagging out equipment prior to maintenance or repair should be implemented and enforced.

- Loose clothing or hair getting wound on or caught by shafts. Clothing that is loose, frayed or that has hanging threads should never be worn. Other personal protective apparel and shoes appropriate to the job task should be worn.

- Excessive noise. Noise exposure should be monitored and administrative, engineering and/or personal protective controls should be taken if necessary.

Employees should be trained and aware of the hazards, basic safety rules and safe working methods.

Health outcomes

Agricultural workers who are involved in the handling of agricultural products for storage are at risk for respiratory disorders. Exposures to a variety of dusts, gases, chemicals, silica, fungal spores and endotoxins can result in damage to the lungs. Recent studies link lung disorders caused by these substances to workers who handle grain, cotton, flax, hemp, hay and tobacco. Therefore the populations at risk are worldwide. Agricultural lung disorders have many common names, some of which include: occupational asthma, farmer’s lung, green tobacco sickness, brown lung, organic dust toxic syndrome, silo filler’s or unloader’s disease, bronchitis and airway obstruction. Symptoms may first manifest themselves as being characteristic of influenza (chills, fever, coughing, headaches, myalgias and breathing difficulty). This is especially true for organic dusts. Prevention of lung dysfunction should include an assessment of the worker’s environment, health promotion programmes targeted at primary prevention and the use of personal protective respirators and other protective devices based on the environmental assessment.

Transportation Operations

Although it may seem simple, the transportation of goods to market is often as complex and hazardous as growing and storing the crop. The transportation of products to market is as diversified as the types of farming operations. Transportation may range from goods being carried by humans and livestock, to being transported by simple mechanical devices such as bicycles and animal-drawn carts, being hauled by complex mechanical equipment such as large carts and wagons pulled by tractors, to the use of commercial transportation systems, which include large trucks, buses, trains and airplanes. As the world’s population increases and urban areas grow, road travel of agricultural equipment and implements of husbandry has increased. In the US, according to the National Safety Council (NSC), 8,000 farm tractors and other agricultural vehicles were involved in highway accidents in 1992 (NSC 1993). Many farming operations are consolidating and expanding by acquiring or renting a number of smaller farms which are typically scattered and not adjoining. A 1991 study in Ohio showed that 79% of the farms surveyed operated in multiple locations (Bean and Lawrence 1992).

Hazards and their prevention

Although each of the modes of transportation mentioned above will have its own unique hazards, it is the intermix of civilian traffic with agricultural transport machinery and equipment that is of major concern. The increase in road travel of agricultural equipment has resulted in a greater number of collisions between motor vehicles and slower moving agricultural equipment. Farm equipment and implements of husbandry may be wider than the width of the road. Due to pressure of planting at the right time to assure a crop or harvesting and getting the crop to a market or storage location as quickly as possible, agricultural machinery must often travel on the roadways during periods of darkness, early morning or evening.

An in-depth study of all 50 states’ codes in the United States revealed that the lighting and marking requirements vary greatly from state to state. This diversity in requirements does not communicate a consistent message to motor vehicle drivers (Eicher 1993). Faster speeds of other vehicles combined with inadequate lighting or marking of agricultural equipment is often a deadly combination. A recent study in the United States found that the common accident types are rear end, sideswipe-meeting, sideswipe-passing, angle, head-on, backing and other. In 20% of the 803 two-vehicle crashes studied, the farm vehicle was struck from an angle. In 28% of the crashes, the farm vehicle was sideswiped (15% meeting and 13% passing). Twenty-two per cent of the accidents consisted of rear-end (15%), head-on (4%) and backing (3%) collisions. The remaining 25% were crashes which were caused by something other than a moving vehicle (i.e., a parked vehicle, pedestrian, animal and so on) (Glascock et al. 1993).

Livestock are used in many parts of the world as the “horsepower” to transport agricultural products. Although beasts of burden are generally reliable, most are colourblind, have territorial and maternal instincts, react independently and unexpectedly, and are of great strength. Such animals have caused vehicle crashes. Falls from agricultural machinery and implements of husbandry are common.

The following general safety principles apply to transportation operations:

- Local traffic rules, regulations or laws should be learned and obeyed.

- No riders or passengers other than those that are necessary to accomplish the transport and unloading duties should be permitted.

- Vehicles should stay as close to the shoulder of the road as road conditions will allow.

- Passing other vehicles (moving or parked) and pedestrians must be done with caution.

- Broken-down vehicles should be moved off the road if possible.

- All marking and lighting on machinery and equipment should be maintained and clean.

- Driving should never be done under the influence of alcohol or drugs.

Laws and regulations may dictate the state of acceptable lighting and marking. However, many such regulations only describe the minimal acceptable standards. Unless such regulations specifically prohibit retrofitting and adding additional lighting and marking, farmers should consider adding such devices. It is important that such lighting and marking devices be installed not only on self-propelled implements but also on pieces of equipment that they may be pulling or trailing.

Lights are especially critical for dusk, dawn and night-time movement of agricultural equipment. If the agricultural vehicle has a power source, consideration should be given to having, at a minimum: two headlights, two tail-lights, two turn signals and two brake lights.

Tail-lights, turn signals and brake lights may be incorporated into single units or can be attached as separate entities. Standards for such devices may be found through standard-setting organizations such as the American Society of Agricultural Engineers (ASAE), the American National Standards Institute (ANSI), the European Committee for Standardization (CEN) and the International Organization for Standardization (ISO).

If the agricultural vehicle does not have a power source, battery-powered lights, although not as effective, may be used. Many such lights are commercially available in a variety of types (flood, blinking, rotating and strobe) and sizes. If it is impossible to obtain these devices, then reflectors, flags and other alternative materials discussed below may be used.

Many new retroreflective fluorescent materials are available today to aid in marking agricultural vehicles for enhanced visibility. They are manufactured in patches or strips in a variety of colours. Local regulations should be consulted for acceptable colours or colour combinations.

Fluorescent materials provide excellent daytime visibility by relying on solar radiation for their light-emitting properties. A complex photochemical reaction takes place when the fluorescent pigments absorb non-visible solar radiation and re-emit the energy as a longer wavelength of light. In a sense, fluorescent materials appear to “glow” in the daytime and appear brighter than the conventional colours in the same light conditions. The primary disadvantage of fluorescent materials is their deterioration with prolonged exposure to solar radiation.

Reflection is an element of sight. Wavelengths of light strike an object and are either absorbed or bounced back in all directions (diffused reflection) or at an angle exactly opposite to the angle at which the light struck the object (specular reflection). Retroreflectivity is very similar to specular reflection; however, the light is reflected directly back toward the light source. There are three primary forms of retroreflective materials, each having a different degree of retroreflectivity based on how they were manufactured. They are presented here in increasing order of retroreflectivity: enclosed lens (often called engineering grade or Type ID), encapsulated lens (high intensity) and cube corner (diamond grade, prismatic, DOT C2 or Type IIIB). These retroreflective materials are excellent for night-time visual identification. These materials are also of great assistance in defining the extremities of agricultural implements. In this application, strips of retroreflective and fluorescent material across the width of the machinery, front and back, best communicate to drivers of other, nonagricultural vehicles the actual width of the equipment.

The distinctive red triangle with a yellow-orange centre is used in the United States, Canada and many other parts of the world to designate a class of vehicles as “slow moving”. This means the vehicle travels less than 40 km per hour on the roadway. Typically, other vehicles travel much faster, and the difference in speed may result in a misjudgement on the part of the faster vehicle driver, affecting the driver’s ability to stop in time to avoid an accident. This emblem or an acceptable substitute should always be used.

Health outcomes

Agricultural workers who are involved in the transportation of agricultural products may be at risk for respiratory disorders. Exposures to a variety of dusts, chemicals, silica, fungal spores and endotoxins may result in damage to the lungs. This is somewhat dependent on whether the transport vehicle has an enclosed cab and whether the operator engages in the loading and unloading process. If the transport vehicle has been used in the process of pesticide application, pesticides could be present and trapped inside the cab unless it has an air filtration system. Nevertheless, symptoms may first manifest themselves as being characteristic of influenza. This is especially true for organic dusts. Prevention of lung dysfunction should include an assessment of the worker’s environment, health promotion programmes targeted at primary prevention and the use of personal protective masks, respirators and other protective devices.

Harvesting Operations

The gathering in of agricultural crops upon maturity, or the practice of harvesting, signals the end of the production cycle prior to storage and processing. The size and quality of the crop removed from the field, orchard or vineyard represents the most significant measure of a farmer’s productivity and success. The value that has been placed on the outcome of the harvest is reflected in the terms used almost universally to measure and compare agricultural productivity, such as kilograms per hectare (kg/ha), bales per hectare, bushels per acre (bu/a) and tons per acre or hectare. From an agronomic perspective, it is actually the inputs that determine the yield; however, it is the harvest that becomes the primary determinant of whether or not there will be sufficient seed and resources to ensure the sustainability of the farm and those it supports. Because of the significance of harvest and all of its related activities, this part of the agricultural cycle has taken on an almost spiritual role in the lives of farmers throughout the world.

Few agricultural practices illustrate more clearly the scope and diversity of technology- and work-related hazards found in agricultural production than harvesting. Crop harvesting is carried out under a wide variety of conditions, over various types of terrain, utilizing machines from simple to complex that must handle a diversity of crops; it involves considerable physical effort from the farmer (Snyder and Bobick 1995). For these reasons, any attempt to briefly generalize the characteristics or nature of harvest practices and harvest-related hazards is extremely difficult. Small grains (rice, wheat, barley, oats and so on), for example, which dominate much of the planted cropland in the world, represent not only some of the most highly mechanized crops, but in large regions of Africa and Asia are harvested in a manner that would be familiar to farmers 2,500 years ago. The use of hand sickles to harvest a few stalks at a time, hard-packed clay threshing floors and simple threshing devices remain the primary tools of harvest for far too many producers.

The primary hazards associated with the more labour-intensive harvesting practices have changed little with time and are often overshadowed by the perceived increased risks associated with greater mechanization. Long hours of exposure to the elements, the physical demands resulting from lifting heavy loads, repetitive motion and awkward or stooped posture, along with natural hazards such as poisonous insects and snakes, have historically taken, and continue to take, a significant toll (see figure 1). Harvesting grain or sugar cane with a sickle or machete, picking fruit or vegetables by hand and manually removing peanuts from the vine are dirty, uncomfortable and exhausting tasks that in many communities frequently are completed by large numbers of children and women. One of the strongest motivating forces that has shaped modern harvesting practices has been the desire to remove the physical drudgery associated with manual harvesting.

Figure 1. Hand-harvesting millet

Even if the resources were available to mechanize harvesting and reduce its risks (and for many small farmers in many areas of the world, they are not), investments to improve the safety and health aspects of harvesting would likely have smaller returns than would comparable investments to improve housing, water quality or health care. This is especially true if farmers have access to large numbers of unemployed or underemployed workers. High levels of unemployment and limited job opportunities, for example, place large numbers of younger workers at risk of injury during harvest because they are cheaper to use than machines. Even in many countries with highly mechanized agricultural practices, child labour laws frequently exempt children involved in agricultural activities. For example, special provisions of the US Department of Labor child labour laws continue to exempt children under 16 during harvest and allow them to operate agricultural equipment under certain conditions (DOL 1968).