Elevators

An elevator (lift) is a permanent lifting installation serving two or more defined landing levels, comprising an enclosed space, or car, whose dimensions and means of construction clearly permit the access of people, and which runs between rigid vertical guides. A lift, therefore, is a vehicle for raising and lowering people and/or goods from one floor to another floor within a building directly (single push-button control) or with intermediate stops (collective control).

A second category is the service lift (dumb waiter), a permanent lifting installation serving defined levels, but with a car that is too small to transport people. Service lifts transport foods and supplies in hotels and hospitals, books in libraries, mail in office buildings and so on. Generally, the floor area of such a car does not exceed 1 m2, its depth 1 m, and its height 1.20 m.

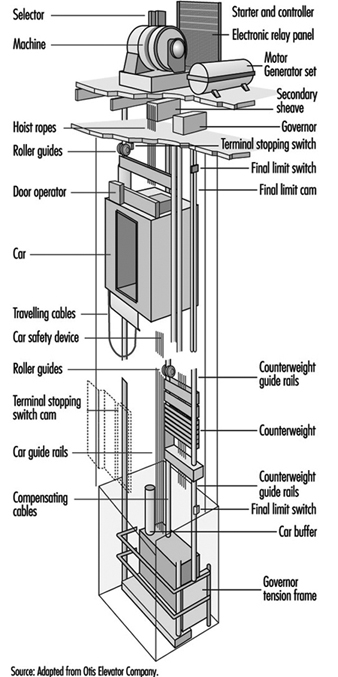

Elevators are driven directly by an electric motor (electric lifts; see figure 1) or indirectly, through the movement of a liquid under pressure generated by a pump driven by an electric motor (hydraulic lifts).

Figure 1. A cut-away view of an elevator installation showing the essential components

Electric lifts are almost exclusively driven by traction machines, geared or gearless, depending on car speed. The designation “traction” means that the power from an electric motor is transmitted to the multiple rope suspension of the car and a counterweight by friction between the specially shaped grooves of the driving or traction sheave of the machine and the ropes.

Hydraulic lifts have become widely used since the 1970s for the transport of goods and passengers, usually for a height not exceeding six floors. Hydraulic oil is used as pressure fluid. The direct-acting system with a ram supporting and moving the car is the simplest one.

Standardization

Technical Committee 178 of the ISO has drafted standards for: loads and speeds up to 2.50 m/s; car and hoistway dimensions to accommodate passengers and goods; bed and service lifts for residential buildings, offices, hotels, hospitals and nursing homes; control devices, signals and additional accessories; and selection and planning of lifts in residential buildings. Each building should be provided with at least one lift accessible to handicapped people in wheelchairs. The Association française de normalisation (AFNOR) is in charge of the Secretariat of this Technical Committee.

General safety requirements

Every industrialized country has a safety code drawn up and kept up to date by a national standards committee. Since this work was started in the 1920s, the various codes have gradually been made more similar, and differences now are generally not fundamental. Large manufacturing firms produce units that comply with the codes.

In the 1970s the ILO, in close cooperation with the International Committee for the Reglementation of Lifts (CIRA), published a code of practice for the construction and installation of lifts and service lifts and, a few years later, for escalators. These directives are intended as a guide for countries engaged in the drafting or modification of safety rules. A standardized set of safety rules for electric and hydraulic lifts, service lifts, escalators and passenger conveyors, the object being the elimination of technical barriers to trade among the member countries of the European Community, is also under the purview of the European Committee for Standardization (CEN). The American National Standards Institute (ANSI) has devised a safety code for lifts and escalators.

Safety rules are aimed at several types of possible accidents with lifts: shearing, crushing, falling, impact, trapping, fire, electric shock, damage to material, accidents due to wear, and accidents due to corrosion. People to be safeguarded are: users, maintenance and inspection personnel and people outside the hoistway and the machine room. Objects to be safeguarded are: loads in the car, components of the lift installation and the building.

Committees drawing up safety rules have to assume that all components are correctly designed, are of sound mechanical and electrical construction, are made of material of adequate strength and suitable quality and are free from defects. Potential imprudent acts of users have to be taken into account.

Shearing is prevented by providing adequate clearances between moving components and between moving and fixed parts. Crushing is prevented by providing sufficient headroom at the top of the hoistway between the roof of the car in its highest position and the top of the shaft and a clear space in the pit where someone can remain safely when the car is in its lowest position. These spaces are assured by buffers or stops.

Protection against falling down the hoistway is obtained by solid landing doors and an automatic cut off that prevents movement of the cab until the doors are fully closed and locked. Landing doors of the power-operated sliding type are preferred for passenger lifts.

Impact is limited by restraining the kinetic energy of closing power-operated doors; trapping of passengers in a stalled car is prevented by providing an emergency unlocking device on the doors and a means for specially trained personnel to open them and extricate the passengers.

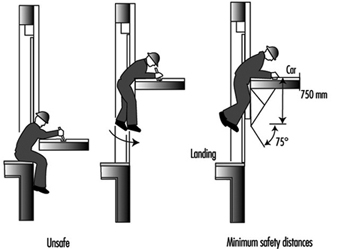

Overloading of a car is prevented by a strict ratio between the rated load and the net floor area of the car. Doors are required on all the cars passenger lifts to keep passengers from being trapped in the space between the car sill and the hoistway or the landing doors. Car sills must be fitted with a toe guard of a height of not less than 0.75 m to prevent accidents, as shown in figure 2. Cars have to be provided with safety gear capable of stopping and holding a fully loaded car in the event of overspeed or failure of the suspension. The gear is operated by an overspeed governor driven by the car by means of a rope (see figure 1). As passengers stand upright and move in a vertical direction, the retardation during the operation of the safety device should lie between 0.2 and 1.0 g (m/s2) to guard against injuries (g = standard acceleration of free fall).

Figure 2. Layout of the toe guard on the car sill to prevent trapping

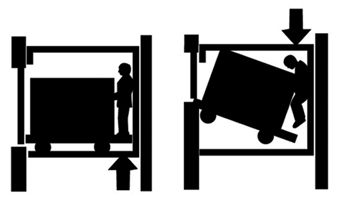

Depending on national legislation, lifts intended mainly for the transport of goods, vehicles and motor cars accompanied by authorized and instructed users may have one or two opposite car entrances not provided with car doors, under the condition that the rated speed does not exceed 0.63 m/s, the car depth is not less than 1.50 m and the wall of the hoistway facing the entrance, including the landing doors, is flush and smooth. On heavy-duty freight elevators (goods lifts), the landing doors are usually vertical bi-parting power-operated doors, which usually do not meet these conditions. In such a case, the required car door is a vertically sliding mesh gate. The clear width of the lift car and the landing doors must be the same to avoid damage to panels on the lift car by fork trucks or other vehicles entering or leaving the lift. The whole design of such a lift has to take account of the load, the weight of the handling equipment and the heavy forces involved in running, stopping and reversing these vehicles. The lift car guides require special reinforcement. When the transport of people is permitted, the number allowed should correspond to the maximum available area of the car floor. For example, the car floor area of a lift for a rated load of 2,500 kg should be 5 m2, corresponding to 33 persons. Loading and accompanying a load must be done with great care. Figure 3 shows a faulty situation.

Figure 3. Example of dangerous loading of a freight elevator (goods-lift).

Controls

All modern lifts are push-button and computer controlled, the car switch system operated by an attendant having been abandoned.

Single lifts and those grouped in two- to eight-car arrangements are usually equipped with collective controls which are interconnected in the case of multiple installations. The main feature of collective controls is that calls can be given at any moment, whether the car is moving or standstill and whether the landing doors are open or closed. Landing and car calls are collected and stored until answered. Regardless of the sequence in which they are received, calls are answered in the order that most efficiently operates the system.

Examinations and tests

Before a lift is put into service, it should be examined and tested by an organization approved by the public authorities to establish the lift’s conformity with the safety rules in the country where it has been installed. A technical dossier should be submitted to the inspector by the manufacturers. The elements to be examined and tested and the way the tests should be run are listed in the safety code. Specific tests by an approved laboratory are required for: locking devices, landing doors (possibly including fire tests), safety gear, overspeed governors and oil buffers. Certificates of the corresponding components used in the installation should be included in the register. After a lift is put into service, periodic safety examinations should be conducted, with the intervals depending on traffic volume. These tests are intended to ensure compliance with the code and the proper operation of all safety devices. Components that do not function in normal service, such as the safety gear and buffers, should be tested with a car empty and at reduced speed to prevent excessive wear and stresses that can impair the safety of a lift.

Maintenance and inspection

A lift and its components should be inspected and maintained in good and safe working order at regular intervals by competent technicians who have obtained skill and a thorough knowledge of the mechanical and electrical details of the lift and the safety rules under the guidance of a qualified instructor. Preferably the technician is employed by the supplier or erector of the lift. Normally a technician is responsible for a specific number of lifts. Maintenance involves routine servicing such as adjustment and cleaning, lubrication of moving parts, preventive servicing to anticipate possible problems, emergency visits in the case of breakdowns and major repairs, which are usually done after consultation with a supervisor. The overriding safety hazard, however, is fire. Because of the risk that a lit cigarette or other burning object might fall into the crack between the car sill and the hoistway and ignite lubricating grease in the hoistway or debris at the bottom, the hoistway should regularly be cleaned out. All systems should be at zero energy level before maintenance work is begun. In single-unit buildings, before any work is started, notices should be posted at each landing indicating that the lift is out of service.

For preventive maintenance, careful visual inspection and checks of free movement, the condition of contacts and proper operation of the equipment are generally sufficient. The hoistway equipment is inspected from the top of the car. An inspection control is provided on the car roof comprising: a bi-stable switch to bring it into operation and to neutralize the normal control, including the operation of power-operated doors. Up and down constant pressure buttons allow movement of the car at reduced speed (not exceeding 0.63 m/s). The inspection operation must remain dependent on the safety devices (closed and locked doors and so on) and it should not be possible to overrun the limits of normal travel.

A stop switch on the inspection control station prevents unexpected movement of the car. The safest direction of travel is down. The technician must be in a safe position to observe the work environment when moving the car and possess the appropriate inspection devices. The technician must have a firm hold when the car is in motion. Before leaving, the technician must report to the person in charge of the lift.

Escalators

An escalator is a continuous moving, inclined stairway which conveys passengers upward and downward. Escalators are used in commercial buildings, department stores and railway and underground stations, to guide a stream of people in a confined route from one level to another.

General safety requirements

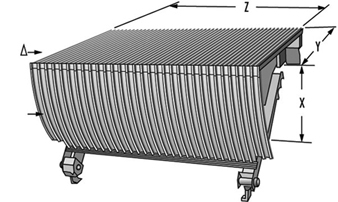

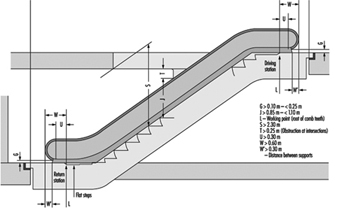

Escalators consist of a continuous chain of steps moved by a motor-driven machine by means of two roller chains, one at each side. The steps are guided by rollers on tracks which keep the step treads horizontal in the usable area. At the entrance and exit, guides ensure that over a distance of 0.80 to 1.10 m, depending on the speed and rise of the escalator, some steps form a horizontal flat surface. Step dimensions and construction are shown in figure 4. On the top of each balustrade, a handrail should be provided at a height of 0.85 to 1.10 m above the nose of the steps running parallel to the steps at substantially the same speed. The handrail at each extremity of the escalator, where the steps move horizontally, should extend at least 0.30 m beyond the landing plate and the newel including the handrail at least 0.60 m beyond (see figure 5). The handrail should enter the newel at a low point above the floor, and a guard should be installed with a safety switch to stop the escalator if fingers or hands are trapped at this point. Other risks of injury to users are formed by the clearances necessary between the side of the steps and the balustrades, between steps and combs and between treads and step risers, the latter more particularly in the upward direction at the curvature where a relative movement between consecutive steps occurs. The cleating and smoothness of the risers should prevent this risk.

Figure 4. Escalator step unit 1 (X: Height to next step (not greater than 0.24m); Y: Depth (at least 0.38m); Z: Width (between 0.58 and 1.10m); Δ: Grooved step tread; Φ: Cleated step riser)

Figure 5. Escalator step unit 2

People may ride with their shoes sliding against the balustrade, which can cause trapping at the points where the steps straighten out. Clearly legible signs and notices, preferably pictographs, should warn and instruct users. A sign should instruct adults to hold the hands of children, who may not be able to reach the handrail, and that children should stand at all times. Both ends of an escalator should be barricaded when it is out of service.

The incline of an escalator should not exceed 30°, though it may be increased to 35° if the vertical rise is 6 m or less and the speed along the incline is limited to 0.50 m/s. Machine rooms and driving and return stations should be easily accessible to specially-trained maintenance and inspection personnel only. These spaces can lie inside the truss or be separate. The clear height should be 1.80 m with covers, if any, opened and the space should be sufficient to ensure safe working conditions. The clear height above the steps at all points should be not less than 2.30 m.

The starting, stopping or reversal of movement of an escalator should be effected by authorized people only. If the country code permits operating a system that starts automatically when a passenger moves past an electric sensor, the escalator should be in operation before the user reaches the comb. Escalators should be equipped with an inspection control system for operation during maintenance and inspection.

Maintenance and inspection

Maintenance and inspection along the lines described above for lifts are usually required by authorities. A technical dossier should be available listing the main calculation data of the supporting structure, steps, step driving components, general data, layout drawings, schematic wiring diagrams and instructions. Before an escalator is put into service, it should be examined by a person or organization approved by the public authorities; subsequently periodic inspections at given intervals are needed.

Moving Walkways (Passenger Conveyors)

A passenger conveyor, or power-driven continuous moving walkway, may be used for the conveyance of passengers between two points at the same or at different levels. Passenger conveyors are used to transport a great number of people in airports from the main station to the gates and back and in department stores and supermarkets. When the conveyors are horizontal, baby carriages, pushcarts and wheelchairs, luggage and food trolleys can be carried without risk, but on inclined conveyors these vehicles, if rather heavy, should be used only if they lock into place automatically. The ramp consists of metal pallets, similar to the step treads of escalators but longer, or rubber belt. The pallets must be grooved in the direction of travel, and combs should be placed at each end. The angle of inclination should not exceed 12° or more than 6° at the landings. The pallets and belt should move horizontally over a distance of not less than 0.40 m before entering the landing. The walkway runs between balustrades that are topped with a moving handrail that travels at substantially the same speed. The speed should not exceed 0.75 m/s unless the movement is horizontal, in which case 0.90 m/s is permitted provided the width does not exceed 1.10 m.

The safety requirements for passenger conveyors are generally similar to those for escalators and should be included in the same code.

Building Hoists

Building hoists are temporary installations used on construction sites for the transport of persons and materials. Each hoist is a guided car and should be operated by an attendant inside the car. In recent years, rack and pinion design has enabled the use of building hoists for efficient movement along radio towers or very tall smoke stacks for servicing. No one should ride a material hoist, except for inspection or maintenance.

The standards of safety vary considerably. In a few cases, these hoists are installed with the same standard of safety as permanent goods and passenger lifts in buildings, except that the hoistway is enclosed by strong wire mesh instead of solid materials to reduce the wind load. Strict regulations are needed although they need not be as strict as for passenger lifts; many countries have special regulations for these building hoists. However, in many cases the standard of safety is low, the construction poor, the hoists driven by a diesel engine winch and the car suspended by only a single steel wire rope. A building hoist should be driven by electric motors to ensure that the speed is kept within safe limits. The car should be enclosed and be provided with car entrance protections. Hoistway openings at the landings should be fitted with doors that are solid up to a height of 1 m from the floor, the upper part in wire mesh of maximum 10 x 10 mm aperture. Sills of landing doors and cars should have suitable toe guards. Cars should be provided with safety gear. One common type of accident results when workers travel on a platform hoist designed only for carrying goods, which do not have side walls or gates to keep the workers from striking a part of the scaffolding or from falling off the platform during the journey. A belt lift consists of steps on a moving vertical belt. A rider is at risk of being carried over the top, being unable to make an emergency stop, striking his or her head or shoulders on the edge of a floor opening, jumping on or off after the step has passed the floor level or being unable to reach the landing because of power failure or the belt’s stopping. Accordingly, such a lift should be used only by specially trained personnel employed by the building owner or a designee.

Fire Hazards

Generally, the hoistway for any lift extends over the full height of a building and interconnects the floors. A fire or the smoke from a fire breaking out in the lower part of a building may spread up the hoistway to other floors and, under certain circumstances, the well or hoistway may intensify a fire because of a chimney effect. Therefore, a hoistway should not form part of a building’s ventilation system. The hoistway should be totally enclosed by solid walls of non-combustible material that would not give off harmful fumes in case of a fire. A vent should be provided at the top of the lift hoistway or in the machine room above it to allow smoke to escape to open air.

Like the hoistway, the entrance doors should be fire resistant. Requirements are usually laid down in national building regulations and vary according to countries and conditions. Landing doors cannot be made smokeproof if they are to operate reliably.

No matter how tall the building, passengers should not use lifts in case of fire, because of the risks of the lift stopping at a floor in the fire zone and of passengers being trapped in the car in the event of failure of the electrical supply. In general, one lift that serves all floors is designated as a lift for firefighters that can be put at their disposal by means of a switch or special key on the main floor. The capacity, speed and car dimensions of the firefighters’ lift have to meet certain specifications. When firefighters use lifts, the normal operational controls are overridden.

The construction, maintenance and refinishing of elevator interiors, installation of carpeting and cleaning of the elevator (inside or out) may involve the use of volatile organic solvents, mastics or glues, which can present a risk to the central nervous system, as well as a fire hazard. Although these materials are used on other metal surfaces, including staircases and doors, the hazard is severe with elevators because of their small space, in which vapour concentrations can become excessive. The use of solvents on the outside of an elevator car can also be risky, again because of limited air flow, particularly in a blind hoistway, where venting may be impeded. (A blind hoistway is one without an exit door, usually extending for several floors between two destinations; where a group of elevators serves floors 20 and above, a blind hoistway would extend between floors 1 and 20.)

Lifts and Health

While lifts and hoists involve hazards, their use can also help reduce fatigue or serious muscle injury due to manual handling, and they can reduce labour costs, especially in building construction work in some developing countries. On some such sites where no lifts are used, workers have to carry heavy loads of bricks and other building materials up inclined runways numerous floors high in hot, humid weather.