Cement

Cement is a hydraulic bonding agent used in building construction and civil engineering. It is a fine powder obtained by grinding the clinker of a clay and limestone mixture calcined at high temperatures. When water is added to cement it becomes a slurry that gradually hardens to a stone-like consistency. It can be mixed with sand and gravel (coarse aggregates) to form mortar and concrete.

There are two types of cement: natural and artificial. The natural cements are obtained from natural materials having a cement-like structure and require only calcining and grinding to yield hydraulic cement powder. Artificial cements are available in large and increasing numbers. Each type has a different composition and mechanical structure and has specific merits and uses. Artificial cements may be classified as portland cement (named after the town of Portland in the United Kingdom) and aluminous cement.

Production

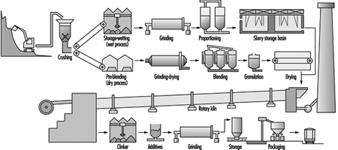

The portland process, which accounts for by far the largest part of world cement production, is illustrated in figure 1. It comprises two stages: clinker manufacture and clinker grinding. The raw materials used for clinker manufacture are calcareous materials such as limestone and argillaceous materials such as clay. The raw materials are blended and ground either dry (dry process) or in water (wet process). The pulverised mixture is calcined either in vertical or rotary-inclined kilns at a temperature ranging from 1,400 to 1,450°C. On leaving the kiln, the clinker is cooled rapidly to prevent the conversion of tricalcium silicate, the main ingredient of portland cement, into bicalcium silicate and calcium oxide.

Figure 1. The manufacture of cement

The lumps of cooled clinker are often mixed with gypsum and various other additives which control the setting time and other properties of the mixture in use. In this way it is possible to obtain a wide range of different cements such as normal portland cement, rapid-setting cement, hydraulic cement, metallurgical cement, trass cement, hydrophobic cement, maritime cement, cements for oil and gas wells, cements for highways or dams, expansive cement, magnesium cement and so on. Finally, the clinker is ground in a mill, screened and stored in silos ready for packaging and shipping. The chemical composition of normal portland cement is:

- calcium oxide (CaO): 60 to 70%

- silicon dioxide (SiO2) (including about 5% free SiO2): 19 to 24%

- aluminium trioxide (Al3O3): 4 to 7%

- ferric oxide (Fe2O3): 2 to 6%

- magnesium oxide (MgO): less than 5%

Aluminous cement produces mortar or concrete with high initial strength. It is made from a mixture of limestone and clay with a high aluminium oxide content (without extenders) which is calcined at about 1,400°C. The chemical composition of aluminous cement is approximately:

- aluminium oxide (Al2O3): 50%

- calcium oxide (CaO): 40%

- ferric oxide (Fe2O3): 6%

- silicon dioxide (SiO2): 4%

Fuel shortages lead to the increased production of natural cements, especially those using tuff (volcanic ash). If necessary, this is calcined at 1,200°C, instead of 1,400 to 1,450°C as required for portland. The tuff may contain 70 to 80% amorphous free silica and 5 to 10% quartz. With calcination the amorphous silica is partially transformed to tridimite and crystobalite.

Uses

Cement is used as a binding agent in mortar and concrete —a mixture of cement, gravel and sand. By varying the processing method or by including additives, different types of concrete may be obtained using a single type of cement (e.g., normal, clay, bituminous, asphalt tar, rapid-setting, foamed, waterproof, microporous, reinforced, stressed, centrifuged concrete and so on).

Hazards

In the quarries from which the clay, limestone and gypsum for cement are extracted, workers are exposed to the hazards of climatic conditions, dusts produced during drilling and crushing, explosions and falls of rock and earth. Road transport accidents occur during haulage to the cement works.

During cement processing, the main hazard is dust. In the past, dust levels ranging from 26 to 114 mg/m3 have been recorded in quarries and cement works. In individual processes the following dust levels were reported: clay extraction—41.4 mg/m3; raw materials crushing and milling—79.8 mg/m3; sieving— 384 mg/m3; clinker grinding—140 mg/m3; cement packing— 256.6 mg/m3; and loading, etc.—179 mg/m3. In modern factories using the wet process, 15 to 20 mg dust/m3 air are occasionally the upper short-time values. The air pollution in the neighbourhood of cement factories is around 5 to 10% of the old values, thanks in particular to the widespread use of electrostatic filters. The free silica content of the dust usually varies between the level in raw material (clay may contain fine particulate quartz, and sand may be added) and that of the clinker or the cement, from which all the free silica will normally have been eliminated.

Other hazards encountered in cement works include high ambient temperatures, especially near furnace doors and on furnace platforms, radiant heat and high noise levels (120 dB) in the vicinity of the ball mills. Carbon monoxide concentrations ranging from trace quantities up to 50 ppm have been found near limestone kilns.

Other hazardous conditions encountered in cement industry workers include diseases of the respiratory system, digestive disorders, skin diseases, rheumatic and nervous conditions and hearing and visual disorders.

Respiratory tract diseases

Respiratory tract disorders are the most important group of occupational diseases in the cement industry and are the result of inhalation of airborne dust and the effects of macroclimatic and microclimatic conditions in the workplace environment. Chronic bronchitis, often associated with emphysema, has been reported as the most frequent respiratory disease.

Normal portland cement does not cause silicosis because of the absence of free silica. However, workers engaged in cement production may be exposed to raw materials which present great variations in free silica content. Acid-resistant cements used for refractory plates, bricks and dust contain high amounts of free silica, and exposure to them involves a definite risk of silicosis.

Cement pneumoconiosis has been described as a benign pinhead or reticular pneumoconiosis, which may appear after prolonged exposure, and presents a very slow progression. However, a few cases of severe pneumoconiosis have also been observed, most likely following exposure to materials other than clay and portland cement.

Some cements also contain varying amounts of diatomaceous earth and tuff. It is reported that when heated, diatomaceous earth becomes more toxic due to the transformation of the amorphous silica into cristobalite, a crystalline substance even more pathogenic than quartz. Concomitant tuberculosis may complicate the course of the cement pneumoconiosis.

Digestive disorders

Attention has been drawn to the apparently high incidence of gastroduodenal ulcers in the cement industry. Examination of 269 cement plant workers revealed 13 cases of gastroduodenal ulcer (4.8%). Subsequently, gastric ulcers were induced in both guinea pigs and a dog fed on cement dust. However, a study at a cement works showed a sickness absence rate of 1.48 to 2.69% due to gastroduodenal ulcers. Since ulcers may pass through an acute phase several times a year, these figures are not excessive when compared with those for other occupations.

Skin diseases

Skin diseases are widely reported in the literature and have been said to account for about 25% and more of all the occupational skin diseases. Various forms have been observed, including inclusions in the skin, periungal erosions, diffuse eczematous lesions and cutaneous infections (furuncles, abscesses and panaritiums). However, these are more frequent among cement users (e.g., bricklayers and masons) than among cement manufacturing plant workers.

As early as 1947 it was suggested that cement eczema might be due to the presence in the cement of hexavalent chromium (detected by the chromium solution test). The chromium salts probably enter the dermal papillae, combine with proteins and produce a sensitization of an allergic nature. Since the raw materials used for cement manufacture do not usually contain chromium, the following have been listed as the possible sources of the chromium in cement: volcanic rock, the abrasion of the refractory lining of the kiln, the steel balls used in the grinding mills and the different tools used for crushing and grinding the raw materials and the clinker. Sensitization to chromium may be the leading cause of nickel and cobalt sensitivity. The high alkalinity of cement is considered an important factor in cement dermatoses.

Rheumatic and nervous disorders

The wide variations in macroclimatic and microclimatic conditions encountered in the cement industry have been associated with the appearance of various disorders of the locomotor system (e.g., arthritis, rheumatism, spondylitis and various muscular pains) and the peripheral nervous system (e.g., back pain, neuralgia and radiculitis of the sciatic nerves).

Hearing and vision disorders

Moderate cochlear hypoacusia in workers in a cement mill has been reported. The main eye disease is conjunctivitis, which normally requires only ambulatory medical care.

Accidents

Accidents in quarries are due in most cases to falls of earth or rock, or they occur during transportation. In cement works the main types of accidental injuries are bruises, cuts and abrasions which occur during manual handling work.

Safety and health measures

A basic requirement in the prevention of dust hazards in the cement industry is a precise knowledge of the composition and, especially, of the free silica content of all the materials used. Knowledge of the exact composition of newly-developed types of cement is particularly important.

In quarries, excavators should be equipped with closed cabins and ventilation to ensure a pure air supply, and dust suppression measures should be implemented during drilling and crushing. The possibility of poisoning due to carbon monoxide and nitrous gases released during blasting may be countered by ensuring that workers are at a suitable distance during shotfiring and do not return to the blasting point until all fumes have cleared. Suitable protective clothing may be necessary to protect workers against inclement weather.

All dusty processes in cement works (grinding, sieving, transfer by conveyor belts) should be equipped with adequate ventilation systems, and conveyor belts carrying cement or raw materials should be enclosed, with special precautions being taken at conveyor transfer points. Good ventilation is also required on the clinker cooling platform, for clinker grinding and in cement packing plants.

The most difficult dust control problem is that of the clinker kiln stacks, which are usually fitted with electrostatic filters, preceded by bag or other filters. Electrostatic filters may be used also for the sieving and packing processes, where they must be combined with other methods for air pollution control. Ground clinker should be conveyed in enclosed screw conveyors.

Hot work points should be equipped with cold air showers, and adequate thermal screening should be provided. Repairs on clinker kilns should not be undertaken until the kiln has cooled adequately, and then only by young, healthy workers. These workers should be kept under medical supervision to check their cardiac, respiratory and sweat function and prevent the occurrence of thermal shock. Persons working in hot environments should be supplied with salted drinks when appropriate.

Skin disease prevention measures should include the provision of shower baths and barrier creams for use after showering. Desensitization treatment may be applied in cases of eczema: after removal from cement exposure for 3 to 6 months to allow healing, 2 drops of 1:10,000 aqueous potassium dichromate solution is applied to the skin for 5 minutes, 2 to 3 times per week. In the absence of local or general reaction, contact time is normally increased to 15 minutes, followed by an increase in the strength of the solution. This desensitization procedure can also be applied in cases of sensitivity to cobalt, nickel and manganese. It has been found that chrome dermatitis—and even chrome poisoning—may be prevented and treated with ascorbic acid. The mechanism for the inactivation of hexavalent chromium by ascorbic acid involves reduction to trivalent chromium, which has a low toxicity, and subsequent complex formation of the trivalent species.

Concrete and Reinforced Concrete Work

To produce concrete, aggregates, such as gravel and sand, are mixed with cement and water in motor-driven horizontal or vertical mixers of various capacities installed at the construction site, but sometimes it is more economical to have ready-mixed concrete delivered and discharged into a silo on the site. For this purpose concrete mixing stations are installed in the periphery of towns or near gravel pits. Special rotary-drum lorries are used to avoid separation of the mixed constituents of the concrete, which would lower the strength of concrete structures.

Tower cranes or hoists are used to transport the ready-mixed concrete from the mixer or silo to the framework. The size and height of certain structures may also require the use of concrete pumps for conveying and placing the ready-mixed concrete. There are pumps which lift the concrete to heights of up to 100 m. As their capacity is by far greater than that of cranes of hoists, they are used in particular for the construction of high piers, towers and silos with the aid of climbing formwork. Concrete pumps are generally mounted on lorries, and the rotary-drum lorries used for transporting ready-mixed concrete are now frequently equipped to deliver the concrete directly to the concrete pump without passing through a silo.

Formwork

Formwork has followed the technical development rendered possible by the availability of larger tower cranes with longer arms and increased capacities, and it is no longer necessary to prepare shuttering in situ.

Prefabricated formwork up to 25 m2 in size is used in particular for making the vertical structures of large residential and industrial buildings, such as facades and dividing walls. These structural-steel formwork elements, which are prefabricated in the site shop or by the industry, are lined with sheet-metal or wooden panels. They are handled by crane and removed after the concrete has set. Depending on the type of building method, prefabricated formwork panels are either lowered to the ground for cleaning or taken to the next wall section ready for pouring.

So-called formwork tables are used to make horizontal structures (i.e., floor slabs for large buildings). These tables are composed of several structural-steel elements and can be assembled to form floors of different surfaces. The upper part of the table (i.e., the actual floor-slab form) is lowered by means of screw jacks or hydraulic jacks after the concrete has set. Special beak-like load-carrying devices have been devised to withdraw the tables, to lift them to the next floor and to insert them there.

Sliding or climbing formwork is used to build towers, silos, bridge piers and similar high structures. A single formwork element is prepared in situ for this purpose; its cross-section corresponds to that of the structure to be erected, and its height may vary between 2 and 4 m. The formwork surfaces in contact with the concrete are lined with steel sheets, and the entire element is linked to jacking devices. Vertical steel bars anchored in the concrete which is poured serve as jacking guides. The sliding form is jacked upwards as the concrete sets, and the reinforcement work and concrete placing continue without interruption. This means that work has to go on around the clock.

Climbing forms differ from sliding ones in that they are anchored in the concrete by means of screw sleeves. As soon as the poured concrete has set to the required strength, the anchor screws are undone, the form is lifted to the height of the next section to be poured, anchored and prepared for receiving the concrete.

So-called form cars are frequently used in civil engineering, in particular for making bridge deck slabs. Especially when long bridges or viaducts are built, a form car replaces the rather complex falsework. The deck forms corresponding to one length of bay are fitted to a structural-steel frame so that the various form elements can be jacked into position and be removed laterally or lowered after the concrete has set. When the bay is finished, the supporting frame is advanced by one bay length, the form elements are again jacked into position, and the next bay is poured

When a bridge is built using the so-called cantilever technique the form-supporting frame is much shorter than the one described above. It does not rest on the next pier but must be anchored to form a cantilever. This technique, which is generally used for very high bridges, often relies on two such frames which are advanced by stages from piers on both sides of the span.

Prestressed concrete is used particularly for bridges, but also in building especially designed structures. Strands of steel wire wrapped in steel-sheet or plastic sheathing are embedded in the concrete at the same time as the reinforcement. The ends of the strands or tendons are provided with head plates so that the prestressed concrete elements may be pretensioned with the aid of hydraulic jacks before the elements are loaded.

Prefabricated elements

Construction techniques for large residential buildings, bridges and tunnels have been rationalized even further by prefabricating elements such as floor slabs, walls, bridge beams and so on, in a special concrete factory or near the construction site. The prefabricated elements, which are assembled on the site, do away with the erection, displacement and dismantling of complex formwork and falsework, and a great deal of dangerous work at height can be avoided.

Reinforcement

Reinforcement is generally delivered to the site cut and bent according to bar and bending schedules. Only when prefabricating concrete elements on the site or in the factory are the reinforcement bars tied or welded to each other to form cages or mats which are inserted into the forms before the concrete is poured.

Prevention of accidents

Mechanization and rationalization have eliminated many traditional hazards on building sites, but have also created new dangers. For instance, fatalities due to falls from height have considerably diminished thanks to the use of form cars, form-supporting frames in bridge building and other techniques. This is due to the fact that the work platforms and walkways with their guard rails are assembled only once and displaced at the same time as the form car, whereas with traditional formwork the guard rails were often neglected. On the other hand, mechanical hazards are increasing and electrical hazards are particularly serious in wet environments. Health hazards arise from cement itself, from substances added for curing or waterproofing and from lubricants for formwork.

Some important accident prevention measures to be taken for various operations are given below.

Concrete mixing

As concrete is nearly always mixed by machine, special attention should be paid to the design and layout of switchgear and feed-hopper skips. In particular, when concrete mixers are being cleaned, a switch may be unintentionally actuated, starting the drum or the skip and causing injury to the worker. Therefore, switches should be protected and also arranged in such a manner that no confusion is possible. If necessary, they should be interlocked or provided with a lock. The skips should be free from danger zones for the mixer attendant and workers moving on passageways near it. It must also be ensured that workers cleaning the pits beneath feed-hopper skips are not injured by the accidental lowering of the hopper.

Silos for aggregates, especially sand, present a hazard of fatal accidents. For example, workers entering a silo without a standby person and without a safety harness and lifeline may fall and be buried in the loose material. Silos should therefore be equipped with vibrators and platforms from which sticking sand can be poked down, and corresponding warning notices should be displayed. No person should be allowed to enter the silo without another standing by.

Concrete handling and placing

The proper layout of concrete transfer points and their equipment with mirrors and bucket receiving cages obviates the danger of injuring a standby worker who otherwise has to reach out for the crane bucket and guide it to a proper position.

Transfer silos which are jacked up hydraulically must be secured so that they are not suddenly lowered if a pipeline breaks.

Work platforms fitted with guard rails must be provided when placing the concrete in the forms with the aid of buckets suspended from the crane hook or with a concrete pump. The crane operators must be trained for this type of work and must have normal vision. If large distances are covered, two-way telephone communication or walkie-talkies have to be used.

When concrete pumps with pipelines and placer masts are used, special attention should be paid to the stability of the installation. Agitating lorries (cement mixers) with built-in concrete pumps must be equipped with interlocked switches which make it impossible to start the two operations simultaneously. The agitators must be guarded so that the operating personnel cannot come into contact with moving parts. The baskets for collecting the rubber ball which is pressed through the pipeline to clean it after the concrete has been poured, are now replaced by two elbows arranged in opposite directions. These elbows absorb almost all the pressure needed to push the ball through the placing line; they not only eliminate the whip effect at the line end, but also prevent the ball from being shot out of the line end.

When agitating lorries are used in combination with placing plant and lifting equipment, special attention has to be paid to overhead electric lines. Unless the overhead line can be displaced they must be insulated or guarded by protective scaffolds within the work range to exclude any accidental contact. It is important to contact the power supply station.

Formwork

Falls are common during the assembly of traditional formwork composed of square timber and boards because the necessary guard rails and toe boards are often neglected for work platforms which are only required for short periods. Nowadays, steel supporting structures are widely used to speed up formwork assembly, but here again the available guard rails and toe boards are frequently not installed on the pretext that they are needed for so short a time.

Plywood form panels, which are increasingly used, offer the advantage of being easy and quick to assemble. However, often after being used several times, they are frequently misappropriated as platforms for rapidly required scaffolds, and it is generally forgotten that the distances between the supporting transoms must be considerably reduced in comparison with normal scaffold planks. Accidents resulting from breakage of form panels misused as scaffold platforms are still rather frequent.

Two outstanding hazards must be borne in mind when using prefabricated form elements. These elements must be stored in such a manner that they cannot turn over. Since it is not always feasible to store form elements horizontally, they must be secured by stays. Form elements permanently equipped with platforms, guard rails and toeboards may be attached by slings to the crane hook as well as being assembled and dismantled on the structure under construction. They constitute a safe workplace for the personnel and do away with the provision of work platforms for placing the concrete. Fixed ladders may be added for safer access to platforms. Scaffold and work platforms with guard rails and toe boards permanently attached to the form element should be used in particular with sliding and climbing formwork.

Experience has shown that accidents due to falls are rare when work platforms do not have to be improvised and rapidly assembled. Unfortunately, form elements fitted with guard rails cannot be used everywhere, especially where small residential buildings are being erected.

When the form elements are raised by crane from storage to the structure, lifting tackle of appropriate size and strength, such as slings and spreaders, must be used. If the angle between the sling legs is too large, the form elements must be handled with the aid of spreaders.

The workers cleaning the forms are exposed to a health hazard which is generally overlooked: the use of portable grinders to remove concrete residues adhering to the form surfaces. Dust measurements have shown that the grinding dust contains a high percentage of respirable fractions and silica. Therefore, dust control measures must be taken (e.g., portable grinders with exhaust devices linked to a filter unit or an enclosed form-board cleaning plant with exhaust ventilation.

Assembly of prefabricated elements

Special lifting equipment should be used in the manufacturing plant so that the elements can be moved and handled safely and without injury to the workers. Anchor bolts embedded in the concrete facilitate their handling not only in the factory but also on the assembly site. To avoid bending of the anchor bolts by oblique loads, large elements must be lifted with the aid of spreaders with short rope slings. If a load is applied to the bolts at an oblique angle, concrete may spill off and the bolts may be torn out. The use of inappropriate lifting tackle has caused serious accidents resulting from falling concrete elements.

Appropriate vehicles must be used for the road transport of prefabricated elements. They must be approximately secured against overturning or sliding—for example, when the driver has to brake the vehicle suddenly. Visibly displayed weight indications on the elements facilitate the task of the crane operator during loading, unloading and assembly on the site.

Lifting equipment on the site should be adequately chosen and operated. Tracks and roads must be kept in good condition in order to avoid overturning of loaded equipment during operation.

Work platforms protecting personnel against falls from height must be provided for the assembly of the elements. All possible means of collective protection, such as scaffolds, safety nets and overhead travelling cranes erected before completion of the building, should be taken into consideration before recourse is taken to reliance on PPE. It is, of course, possible to equip the workers with safety harnesses and lifelines, but experience has shown that there are workers who use this equipment only when they are under constant close supervision. Lifelines are indeed a hindrance when certain tasks are performed, and certain workers are proud of being capable of working at great heights without using any protection.

Before starting to design a prefabricated building, the architect, the manufacturer of the prefabricated elements and the building contractor should meet to discuss and study the course and safety of all operations. When it is known beforehand what types of handling and lifting equipment are available on the site, the concrete elements may be provided in the factory with fastening devices for guard rails and toe boards. The façade ends of floor elements, for instance, are then easily fitted with prefabricated guard rails and toe boards before the elements are lifted into place. The wall elements corresponding to the floor slab may thereafter be safely assembled because the workers are protected by guard rails.

For the erection of certain high industrial structures, mobile work platforms are lifted into position by crane and hung from suspension bolts embedded in the structure itself. In such cases it may be safer to transport the workers to the platform by crane (which should have high safety characteristics and be run by a qualified operator) than to use improvised scaffolds or ladders.

When post-tensioning concrete elements, attention should be paid to the design of the post-tensioning recesses, which should enable the tensioning jacks to be applied, operated and removed without any hazard for the personnel. Suspension hooks for tensioning jacks or openings for passing the crane rope must be provided for post-tensioning work beneath bridge decks or in box-type elements. This type of work, too, requires the provision of work platforms with guard rails and toe boards. The platform floor should be sufficiently low to allow for ample work space and safe handling of the jack. No person should be permitted at the rear of the tensioning jack because serious accidents may result from the high energy released in the breakage of an anchoring element or a steel tendon. The workers should also avoid being in front of the anchor plates as long as the mortar pressed into the tendon sheaths has not set. As the mortar pump is connected with hydraulic pipes to the jack, no person should be permitted in the area between pump and jack during tensioning. Continuous communication among the operators and with supervisors is also very important.

Training

Thorough training of plant operators in particular and all construction site personnel in general is becoming more and more important in view of increasing mechanization and the use of many types of machinery, plant and substances. Unskilled labourers or helpers should be employed in exceptional cases only, if the number of construction site accidents is to be reduced.