Myers, Melvin L.

Address: National Institute for Occupational Safety & Health, CDC, Office of Extramural Coordination & Special Projects, 1293 Berkeley Road, Avondale Estates, GA 30002-1517

Country: United States

Phone: 1 (404) 288-7085

Fax: 1 (404) 639-2196

E-mail: mlm2@cdc.gov

Past position(s): Special Assistant to the Director, National Institute for Occupational Safety and Health; Director, Office of Program Planning and Evaluation, National Institute for Occupational; Safety and Health; Technical Assistant to the Deputy Assistant Director, Office of Research and Development, Environmental Protection Agency

Education: BS, 1967, University of Idaho; MPA, 1977, Indiana University

Areas of interest: Safety and health in agriculture; safety and health in construction work; occupational and environmental health policy; history of occupational safety and health

General Profile

The printing, commercial photography and reproduction industries are important worldwide in terms of their economic significance. The printing industry is very diverse in technologies and in size of enterprises. However, regardless of size as measured by production volume, the different printing technologies described in this chapter are the most common. In terms of production volume, there are a limited number of large-scale operations, but many small ones. From the economic perspective, the printing industry is one of the largest industries and generates annual revenues of at least US$500 billion worldwide. Similarly, the commercial photography industry is diverse, with a limited number of large-volume and many small-volume operations. Photofinishing volume is about equally divided between the large and small-volume operations. The commercial photographic market generates annual revenues of approximately US$60 billion worldwide, with photofinishing operations comprising approximately 40% of this total. The reproduction industry, which consists of smaller-volume operations with combined annual revenues of about US$27 billion, generates close to 2 trillion copies annually. In addition, reproduction and duplication services on an even smaller scale are provided onsite at most organizations and companies.

Health, environmental and safety issues in these industries are evolving in response to substitutions with potentially less hazardous materials, new industrial hygiene control strategies, and the advent of new technologies, such as the introduction of digital technologies, electronic imaging and computers. Many historically important health and safety issues (e.g., solvents in the printing industry or formaldehyde as a stabilizer in photoprocessing solutions) will not be issues in the future due to material substitution or other risk management strategies. Nevertheless, new health, environmental and safety issues will arise that will have to be addressed by health and safety professionals. This suggests the continued importance of health and environmental monitoring as part of an effective risk management strategy in the printing, commercial photography and reproduction industries.

Beekeeping, Insect Raising and Silk Production

Some information on the silk industry was adapted from the article by J. Kubota in the 3rd edition of this Encyclopaedia.

More than a million species of insects exist in the world, and the global mass of insects exceeds the total mass of all other terrestrial animals. Insects such as crickets, grasshoppers, locusts, termites, beetle larvae, wasps, bees and moth caterpillars are among about 500 species that form part of the regular diet of people around the world. Usually humans hunt or gather insects for food rather than intentionally rearing and harvesting them.

In addition to food, humans use insects as sources of pollination, biological controls of pests and fibre. Different uses depend on the four stages of the insect’s life cycle, which consist of egg, larva, pupa and adult. Examples of commercial uses of insects include beekeeping (nearly 1 billion tonnes of honey produced annually and pollination of fruit and seed crops), insect rearing (more than 500 species in culture, including those used for insect biological control), shellac production (36,000 tonnes annually) and silk production (180,000 tonnes annually).

Beekeeping

Beekeepers raise the honey-bee in apiaries, a collection of hives that house bee colonies. The honey-bee is a source of flower pollination, honey and wax. Bees are important pollinators, making more than 46,430 foraging trips per bee for each kilogram of honey that they produce. During each foraging trip, the honey-bee will visit 500 flowers within a 25-minute period. The honey-bee’s source of honey is flower nectar. The bee uses the enzyme invertase to convert sucrose in the nectar into glucose and fructose and, with water evaporation, honey is produced. In addition, bumble-bees and cutter bees are grown for pollinating, respectively, tomato plants and alfalfa.

The honey-bee colony collects around a single queen bee, and they will colonize in boxes—artificial hives. Beekeepers establish an infant colony of about 10,000 bees in the bottom box of the hive, called a brood chamber. Each chamber contains ten panels with cells that are used for either storing honey or laying eggs. The queen lays about 1,500 eggs per day. The beekeeper then adds a food chamber super (a box placed on top of the brood box), which becomes the storage chamber for honey, on which the bees will survive through the winter. The colony continues to multiply, becoming mature at about 60,000 bees. The beekeeper adds a queen excluder (a flat panel that the larger queen cannot enter) on top of the food super to prevent the queen from laying eggs in additional shallow supers that will be stacked on top of the excluder. These additional supers are designed for harvesting only honey without the eggs.

The beekeeper moves the hives to where flowers are budding. A honey-bee colony can forage over an area of 48 hectares, and 1 hectare can support about two hives. The honey is harvested during the summer from the shallow supers, which can be stacked seven high as the colony grows and the bees fill the panels with honey. The supers with honey-laden panels are transported to the honey “house” for extraction. A sharp, warm knife, called an uncapping knife, is used to remove the wax caps that the bees have placed over the honeycombs within the panels. The honey is then extracted from the panels with a centrifugal force machine. The honey is collected and bottled for sale (Vivian 1986).

At the end of the season, the beekeeper winterizes the hives, wrapping them in tar paper to protect the colonies from the winter wind and to absorb the solar heat. The beekeeper also provides the bees with medicated sugar syrup for their winter consumption. In the spring, the hives are opened to begin production as mature honeybee colonies. If the colony becomes crowded, the colony will create another queen through special feeding, and the old queen will swarm with about half of the colony to find another accommodation. The beekeeper may capture the swarm and treat it as an infant colony.

Beekeepers are exposed to two related hazards from honey-bee stings. One hazard is sting envenomation. The other is venom hypersensitivity reaction and possible anaphylactic shock. Males at 40 years of age and older are at highest risk of fatal reactions. About 2% of the general population is thought to be allergic to venom, but systemic reactions in beekeepers and their immediate family members are estimated at 8.9%. The reaction incidence varies inversely to the numbers of stings received. Anaphylactic reactions to bumble-bee venom are rare except among bumble bee keepers, and their risk is greater if they have been sensitized to honey bee venom.

If a honey-bee stings the beekeeper, the stinger should be removed, and the sting site should be washed. Ice or a paste of baking soda and water should be applied to the site of envenomation. The victim should be watched for signs of systemic reaction, which can be a medical emergency. For anaphylactic reactions, epinephrine is administered subcutaneously at the first sign of symptoms. To assure safe beekeeping, the beekeeper should use smoke at the beehive to neutralize the bees’ protective behaviour and should wear a protective hood and veil, thin gloves and log sleeves or coveralls. Bees are attracted to sweat for the moisture, so beekeepers should not wear watch bands or belts where sweat collects. In extracting the honey, the beekeeper should keep his or her thumb and fingers clear of the cutting motion of the uncapping knife.

Mass Insect Raising

More than 500 species of arthropods are reared in the laboratory, including ants, beetles, mites, flies, moths, spiders and ticks. An important use of these arthropods is as biological controls for other animal species. For example, 2,000 years ago, markets in China sold nests of weaver ants to place in citrus orchards to prey on crop pests. Today, more than 5,000 species of insects have been identified worldwide as possible biological controls for crop pests, and 300 are successfully used regularly in 60 countries. Disease vectors have also become targets for biological control. As an example, the carnivorous mosquito from Southeast Asia, Toxorhynchites spp., also called the “tox” mosquito, has a larva that feeds on the larvae of the tiger mosquito, Aedesspp., which transmits diseases such as dengue fever to humans (O’Toole 1995).

Mass rearing facilities have been developed to raise sterile insects as a non-chemical pest-suppression tool. One such facility in Egypt rears a billion fruit flies (about 7 tonnes) each week. This rearing industry has two major cycles. One is the feed conversion or larval incubation cycle, and the other is the propagation or egg-production cycle. The sterile insect technique was first used to eliminate the screw worm, which preyed on cattle. Sterilization is accomplished by irradiating the pupae just prior to adult emergence from the cocoon with either x rays or gamma rays. This technique takes mass quantities of reared, sterile insects and releases them into infested areas where the sterile males mate with the wild, fertile females. Breaking the insect’s life cycle has dramatically reduced the fertility rate of these pests. This technique is used on screw worms, gypsy moths, boll weevils and fruit flies (Kok, Lomaliza and Shivhara 1988).

A typical sterile insect facility has an airlock system to restrict unwanted insect entry and fertile insect escape. Rearing tasks include mopping and sweeping, egg stacking, tray washing, diet preparation, inoculation (placing eggs into agar), pupae dyeing, emergence tending, packing, quarantining, irradiating, screening and weighing. In the pupae room, vermiculite is mixed with water and placed in trays. The trays are stacked, and the vermiculite dust is swept with a broom. The pupae are separated from the vermiculite with a sieve. The insect pupae chosen for the sterile insect technique are transported in trays stacked on racks to the irradiation chamber in a different area or facility, where they are irradiated and rendered sterile (Froehlich 1995; Kiefer 1996).

Insect workers, including silkworm workers, may have an allergic reaction to arthropod allergens (scales, hairs, other body parts). Initial symptoms are itchy eyes and irritation of the nose followed by intermittent episodes of wheezing, coughing and breathlessness. Subsequent asthma attacks are triggered by re-exposure to the allergen.

Entomologists and workers in sterile fly facilities are exposed to a variety of potentially hazardous, flammable agents. These agents include: in entomology laboratories, isopropyl alcohol, ethyl alcohol and xylene; in the diet preparation room, isopropyl alcohol is used in water solution to sterilize walls and ceilings with a sprayer. Vermiculite dust poses respiratory concerns. Some vermiculites are contaminated with asbestos. Air-handling units in these facilities emit noise that may be damaging to employee hearing. Proper exhaust ventilation and personal respiratory protection can be used in facilities to control exposure to airborne allergens and dusts. Non-dusty working materials should be used. Air conditioning and frequent changes of filters may help reduce airborne levels of spines and hairs. X rays or gamma rays (ionizing radiation) can damage genetic material. Protection is needed against x rays or gamma rays and their sources in the irradiation facilities (Froehlich 1995; Kiefer 1996).

Silkworm Raising

Vermiculture, the raising of worms, has a long history in some cultures. Worms, especially the meal worm (which is a larva rather than a true worm) from the darkling beetle, are raised by the billions as animal fodder for laboratory animals and pets. Worms are also used in composting operations (vermi-composting).

Sericulture is the term used for silkworm cocoon production, which includes silkworm feeding and cocoon formation. Cultivation of the silkworm and the silk moth caterpillar dates back to 3000 BC in China. Silkworm farmers have domesticated the silkworm moth; there are no remaining wild populations. Silkworms eat only white mulberry leaves. Fibre production thus has historically depended upon the leafing season of the mulberry tree. Artificial foods have been developed for the silkworm so that production can extend the year around. Silkworms are raised on trays sometimes mounted on racks. The worms take about 42 days of feeding at a constant temperature of 25 °C. Artificial heating may be required. Silk is a secretion from the silkworm’s mouth that solidifies upon contact with air. The silkworm secretes about 2 km of silk fibre to form a cocoon during the pupal stage (Johnson 1982). After the cocoon is formed, the silkworm farmer kills the pupa in a hot oven, and ships the cocoon to a factory. At the factory, silk is harvested from the cocoon and spun into thread and yarn.

Nine per cent of silkworm workers manifest asthma in response to silkworm moth scales, although most asthma in silkworm workers is attributed to inhalation of silkworm faeces. In addition, contact of the skin with silkworm caterpillar hairs may produce a primary irritant contact-dermatitis. Contact with raw silk may also produce allergic skin reactions. For silk moth production, hyposensitization therapy (for moth scales and faeces) provides improvement for 79.4% of recipients. Corticosteroids may reverse the effects of inhaled antigens. Skin lesions may respond to topical corticosteroid lotions and creams. Oral antihistamines relieve itching and burning. Carbon monoxide poisoning has been identified among some silkworm farmers in their homes, where they are maintaining warmth with charcoal fires as they raise the silkworms. Charcoal fires and kerosene heaters should be replaced with electric heaters to avoid carbon monoxide exposures.

Pigs

Pigs were primarily domesticated from two wild stocks—the European wild boar and the East Indian pig. The Chinese domesticated the pig as early as 4900 BC, and today more than 400 million pigs are reared in China out of 840 million worldwide (Caras 1996).

Pigs are reared primarily for food and have many distinguishing attributes. They grow fast and large, and the sows have large litters and short gestation periods of about 100 to 110 days. Pigs are omnivores and eat berries, carrion, insects and garbage, as well as the corn, silage and pasture of high-production enterprises. They convert 35% of their feed into meat and lard, which is more efficient than ruminant species such as cattle (Gillespie 1997).

Production Processes

Some pig holdings are small—for example, one or two animals, which can represent much of a family’s wealth (Scherf 1995). Large pig operations include two major processes (Gillespie 1997).

One process is pure-bred production, in which pig breeding stock are improved. Within the pure-bred operation, artificial insemination is prevalent. Pure-bred boars are typically used to breed sows in the other major process, commercial production. The commercial production process rears pigs for the slaughter market and typically follows one of two different types of operations. One operation is a two-stage system. The first stage is feeder pig production, which uses a herd of sows to farrow litters of 14 to 16 piglets per sow. The pigs are weaned, then sold to the next stage of the system, the buying and finishing enterprise, which feeds them for the slaughter market. The most common feeds are corn and soybean oil meal. The feed grains are typically ground.

The other and most common operation is the complete sow and litter system. This production operation rears a herd of breeding sows and farrowing pigs, caring for and feeding the farrowed pigs for the slaughter market.

Some sows give birth to a litter that may outnumber her teats. To feed the excess piglets, a practice is to spread piglets from large litters into other sows’ smaller litters. Pigs are born with needle teeth, which are typically clipped at the gum-line before the pig is two days old. Ears are notched for identification. Tail docking occurs when the pig is about 3 days old. Male pigs raised for the slaughter market are castrated before they are 3 weeks old.

Maintaining a healthy herd is the single most important management practice in pig production. Sanitation and the selection of healthy breeding stock are important. Vaccination, sulpha drugs and antibiotics are used to prevent many infectious diseases. Insecticides are used to control lice and mites. The large roundworm and other parasites of pigs are controlled through sanitation and drugs.

Facilities used for pig production include pasture systems, a combination of pasture and low-investment housing and high-investment total-confinement systems. The trend is toward more confinement housing because it produces faster growth than does pasture rearing. However, pasture is valuable in feeding the pig-breeding herd to prevent fattening the breeding herd; it may be used for all or part of the production operation with the use of portable housing and equipment.

Confinement buildings require ventilation to control temperature and moisture. Heat may be added in farrowing houses. Slotted floors are used in confinement houses as a labour-saving approach for handling manure. Fencing and handling feeding and watering equipment are needed for the pig production enterprise. Facilities are cleaned by power washing and disinfecting after all bedding, manure and feed are removed (Gillespie 1997).

Hazards

Injuries from pigs usually occur within or close to farm buildings. Dangerous environments include slippery floors, manure pits, automatic feeding equipment and confinement buildings. Confinement buildings have a manure storage pit that emits gases that, if not ventilated, can kill not only pigs, but workers as well.

Pig behaviour can pose hazards to workers. A sow will attack if her piglets are threatened. Pigs can bite, step on or knock people down. They tend to stay in or return to familiar areas. A pig will try to return to the herd when attempts are made to separate it. Pigs are likely to balk when moved from a dark area into a light area, such as out of a pig house into the daylight. At night, they will resist moving into dark areas (Gillespie 1997).

In a Canadian study of pig farmers, 71% reported chronic back problems. Risk factors include intervertebral disc loading associated with driving and sitting for long periods while operating heavy equipment. This study also identified lifting, bending, twisting, pushing and pulling as risk factors. In addition, more than 35% of these farmers reported chronic knee problems (Holness and Nethercott 1994).

Three types of air exposures pose hazards on pig farms:

- dust from feed, animal hair and faecal matter

- pesticides used on pigs and other chemicals, such as disinfectants

- ammonia, hydrogen sulphide, methane and carbon monoxide from manure storage pits.

Fires in buildings are another potential hazard, as is electricity.

Some zoonotic infections and parasites can be transmitted from the pig to the worker. Common zoonoses associated with pigs include brucellosis and leptospirosis (swineherd’s disease).

Preventive Action

Several safety recommendations have evolved for the safe handling of pigs (Gillespie 1997):

- Working with small pigs in the same pen as the sow should be avoided.

- A hurdle or solid panel should be used when handling pigs to avoid bites and being knocked over.

- A pig can be moved backwards by placing a basket over its head.

- Children should be kept out of pig pens and not allowed to reach through fences to pet pigs.

- Because of their herding instincts, it is easier to separate a group of pigs from a herd than a single animal.

- Pigs can be moved from dark to light areas with the use of artificial light. When pigs are moved at night, such as through chutes or alleys, a light should be placed at the destination.

- Loading chutes should be level or at not more than a 25-degree angle.

Musculoskeletal injury risk can be decreased by reducing exposure to repetitive trauma (by taking frequent breaks or by varying the kinds of tasks), improving posture, reducing the weight lifted (use co-worker or mechanical assistance) and avoiding rapid, jerking movements.

Dust control techniques include lowering stock density to reduce dust concentration. In addition, automatic feed delivery systems should be enclosed to contain dust. Water misting can be used, but it is ineffective in freezing weather and can contribute to the survival of bioaerosols and increase endotoxin levels. Filters and scrubbers in the air handling system show promise in cleaning dust particles from recirculated air. Respirators are another way to control dust exposures (Feddes and Barber 1994).

Vent pipes should be installed in manure pits to prevent dangerous gases from recirculating into the farm buildings. Electrical power should be maintained to vent fans at the pits. Workers should be trained in the safe use of pesticides and other chemicals, such as disinfectants, used in pig production.

Cleanliness, vaccination, quarantine of sick animals and avoiding exposures are ways to control zoonoses. When treating sick pigs, wear rubber gloves. A person who becomes sick after working with sick pigs should contact a physician (Gillespie 1997).

Cattle, sheep and goats

Material on hair-cutting and shearing was written with the assistance of J.F. Copplestone’s article on the subject in the 3rd edition of this Encyclopaedia.

Several animals convert high-fibre feeds, called roughage (over 18% fibre), into edible food that is consumed by humans. This ability comes from their four-stomach digestion system, which includes their largest stomach, the rumen (for which they gain the designation ruminants) (Gillespie 1997). Table 1 shows the various types of ruminant livestock that have been domesticated and their uses.

Table 1. Types of ruminants domesticated as livestock

|

Ruminant type |

Uses |

|

Cattle |

Meat, milk, draught |

|

Sheep |

Meat, wool |

|

Goats |

Meat, milk, mohair |

|

Camelids (llama, alpaca, dromedary and bactrian camels) |

Meat, milk, hair, draught |

|

Buffalo (water buffalo) |

Meat, draught |

|

Bison |

Meat |

|

Yaks |

Meat, milk, wool |

|

Reindeer |

Meat, milk, draught |

Production Processes

Processes for rearing ruminants vary from intensive, high-production operations such as raising beef cattle on large, 2,000-km2 ranches in Texas to communal grazing such as the nomadic herders of Kenya and the United Republic of Tanzania. Some farmers use their cattle as oxen for traction power in farm tasks such as ploughing. In humid areas, water buffalo serve the same purpose (Ker 1995). The trend is toward high-production, intensive systems (Gillespie 1997).

High-volume, intensive beef production depends on various interdependent operations. One is the cow-calf system, which involves keeping a herd of cows. The cows are bred by bulls or artificial insemination annually to produce calves, and, after weaning, the calves are sold to cattle feeders to raise for slaughter. Male calves are castrated for the slaughter market; a castrated calf is called a steer. Pure-bred breeders maintain the herds of breeding stock, including bulls, which are very dangerous animals.

Sheep are produced in either range or farm flocks. In range production, flocks of 1,000 to 1,500 ewes are common. In farm flocks, production is usually small and typically a secondary enterprise. Sheep are raised for their wool or as feeder lambs for the slaughter market. Lambs are docked, and most male lambs are castrated. Some enterprises specialize in raising rams for pure-bred breeding.

Goats are raised through either range or small-farm production for their mohair, milk and meat. Pure-bred breeders are small operations that raise rams for breeding does. Specific breeds exist for each of these products. The goats are dehorned, and most males are castrated. Goats browse on shoots, twigs and leaves of brush plants, and thus they may also be used to control brush on a ranch or farm.

Other major processes involved in rearing cattle, sheep and goats include feeding, disease and parasite control, hair clipping and fleece shearing. The milking process and livestock waste disposal are addressed in other articles in this chapter.

Cattle, sheep and goats are fed in several ways, including grazing or feeding hay and silage. Grazing is the least expensive way to deliver forage to animals. Animals typically graze on pastures, wild lands or crop residues, such as corn stalks, which remain in the field after crop harvests. Hay is harvested from the field and typically stored loose or in stacked bales. The feeding operation includes moving the hay from the stack to the open field or into mangers to feed the animals. Some crops such as corn are harvested and converted into silage. Silage is typically moved mechanically into mangers for feeding.

The control of diseases and parasites in cattle, sheep and goats is an integral part of the livestock-rearing process and requires animal contact. Routine visits to the herd by a veterinarian are an important part of this process, as is observing vital signs. Timely vaccination against diseases and quarantining diseased animals are also important.

External parasites include flies, lice, mange, mites and ticks. Chemicals are one control against these parasites. Pesticides are applied by spraying or through insecticide-impregnated ear tags. The heel fly lays eggs on the hair of cattle, and its larva, the cattle grub, burrows into the skin. A control for this grub is systemic pesticides (spread throughout the body through spray, dips or as a feed additive). Internal parasites, including roundworms or flatworms, are controlled with drugs, antibiotics or drenches (oral administration of a liquid medication). Sanitation is also a strategy for the control of infectious diseases and parasite infestations (Gillespie 1997).

The removal of hair from live animals helps to maintain their cleanliness or comfort and to prepare them for exhibitions. Hair may be sheared from live animals as a product, such as the fleece from sheep or mohair from goats. The sheep shearer catches the animal in a pen and drags it to a stand where it is laid on its back for the shearing operation. It is pinned by the shearer’s legs. Hair cutters and sheep shearers use a hand-operated scissors or motorized shears to clip the hair. The motorized shears are typically powered by electricity. Prior to shearing and also as part of gestation management, sheep are tagged and crutched (i.e., hair encrusted with faeces is removed). The cut fleece is manually trimmed according to the quality and staple of the hair. It is then compressed into packs for transportation using a hand-operated screw or hydraulic ram.

Facilities used for raising cattle, sheep and goats are generally considered to be either confined or unconfined. Confined facilities include confinement houses, feedlots, barns, corrals (holding, sorting and crowding pens), fences and working and loading chutes. Unconfined facilities refer to pasture or range operations. Feeding facilities include storage facilities (vertical and horizontal silos), feed grinding and mixing equipment, haystacks, conveying equipment (including augers and elevators), feed bunks, water fountains and mineral and salt feeders. In addition, sun protection may be provided by sheds, trees or overhead lattice work. Other facilities include back rubbers for parasite control, creep-feeders (allows feeder calves or lambs to feed without adults feeding), self-feeders, calf shelters, cattle-guard gates and cattle treatment stalls. Fencing may be used around pastures, and these include barbed wire and electric fences. Woven wire may be required to contain goats. Free-ranging animals would require herding to control their movement; goats may be tethered, but require shade. Dipping tanks are used for parasite control in large sheep flocks (Gillespie 1997).

Hazards

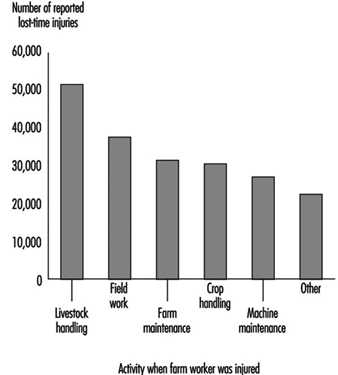

Table 2 shows several other processes of cattle, sheep and goat handling, with associated hazardous exposures. In a survey of farm workers in the United States (Meyers 1997), handling livestock represented 26% of lost-time injuries. This percentage was higher than any other farm activity, as shown in figure 1. These figures would be expected to be representative of the injury rate in other industrialized countries. In countries where draught animals are common, injury rates would be expected to be higher. Injuries from cattle usually occur in farm buildings or in the vicinity of buildings. Cattle inflict injuries when they kick or step on people or crush them against a hard surface such as the side of a pen. People may also be injured by falling when working with cattle, sheep and goats. Bulls inflict the most serious injuries. Most of the people injured are family members rather than hired workers. Fatigue can reduce judgement, and thus increase the chance of injury (Fretz 1989).

Table 2. Livestock rearing processes and potential hazards

|

Process |

Potential hazardous exposures |

|

Breeding, artificial inseminating |

Violent acts by bulls, rams or bucks; slips and falls; |

|

Feeding |

Organic dust; silo gas; machines; lifting; electricity |

|

Calving, lambing, kidding |

Lifting and pulling; animal behaviour |

|

Castrating, docking |

Animal behaviour; lifting; cuts from knives |

|

Dehorning |

Animal behaviour; cuts from trimmers; caustic |

|

Branding and marking |

Burns; animal behaviour |

|

Vaccinating |

Animal behaviour; needle sticks |

|

Spraying and dusting/drenching, worming |

Organophosphates |

|

Foot/hoof trimming |

Animal behaviour; awkward postures; tool-related |

|

Shearing, tagging and crutching, washing and clipping |

Awkward postures and lifting; animal behaviour; |

|

Loading and unloading |

Animal behaviour |

|

Manure handling |

Manure gases; slips and falls; lifting; machines |

Sources: Deere & Co. 1994; Fretz 1989; Gillespie 1997; NIOSH 1994.

Figure 1. Estimates of lost-time injury frequency by farm activity in the United States, 1993

Livestock exhibit behaviours that can lead to injuries of workers. The herding instinct is strong among animals such as cattle or sheep, and imposed limits such as isolation or overcrowding can lead to unusual behavioural patterns. Reflexive response is a common defensive behaviour among animals, and it can be predicted. Territorialism is another behaviour that is predictable. A reflexive escape struggle is apparent when an animal is removed from its normal quarters and placed in a confined environment. Animals that are restrained by chutes for loading for transportation will exhibit agitated reflex response behaviour.

Dangerous environments are numerous in cattle, sheep and goat production facilities. These include slippery floors, manure pits, corrals, dusty feed areas, silos, mechanized feeding equipment and animal confinement buildings. Confinement buildings may have manure storage pits, which can emit lethal gases (Gillespie 1997).

Heat exhaustion and stroke are potential hazards. Heavy physical labour, stress and strain, heat, high humidity and dehydration from lack of drinking water all contribute to these hazards.

Livestock handlers are at risk for developing respiratory illness from exposure to inhaled dusts. A common illness is organic dust toxic syndrome. This syndrome may follow exposures to heavy concentrations of organic dusts contaminated with micro-organisms. About 30 to 40% of workers who are exposed to organic dusts will develop this syndrome, which includes the conditions shown in table 3; this table also shows other respiratory conditions (NIOSH 1994).

Table 3. Respiratory illnesses from exposures on livestock farms

|

Organic dust toxic syndrome conditions |

|

Precipitin-negative farmer’s lung disease |

|

Pulmonary mycotoxicosis |

|

Silo unloader’s syndrome |

|

Grain fever in grain elevator workers |

|

Other important respiratory illnesses |

|

“Silo fillers’ disease” (acute toxic inflammation of the lung) |

|

“Farmer’s lung disease” (hypersensitivity pneumonitis) |

|

Bronchitis |

|

Asphyxiation (suffocation) |

|

Toxic gas inhalation (for example, manure pits) |

Hair cutters and sheep shearers face several hazards. Cuts and abrasions may result during the shearing operation. Animal hoofs and horns also present potential hazards. Slips and falls are an ever-present hazard while handling the animals. Power for the shears is sometimes transferred by belts, and guards must be maintained. Electrical hazards are also present. Shearers also face postural hazards, particularly to the back, as a result of catching and tipping the sheep. Constraining the animal between the shearer’s legs tends to strain the back, and torsional movements are common while shearing. Manual shearing usually results in tenosynovitis.

The control of insects on cattle, sheep and goats with pesticide spray or powder can expose workers to the pesticide. Sheep dips submerge the animal in a pesticide bath, and handling the animal or contact with the bath solution or contaminated wool can also expose workers to the pesticide (Gillespie 1997).

Common zoonoses include rabies, brucellosis, bovine tuberculosis, trichinosis, salmonella, leptospirosis, ringworm, tapeworm, orf virus disease, Q fever and spotted fever. Diseases that may be contracted while working with hair and fleece include tetanus, salmonellosis from tagging and crutching, leptospirosis, anthrax and parasitic diseases.

Animal faeces and urine also provide a mechanism for infection of workers. Cattle are a reservoir for cryptosporidosis, a disease that can be transmitted from cattle to humans through the faecal-oral route. Calves with diarrhoea (scours) may harbour this disease. Schistosomiasis, an infection by blood flukes, is found in cattle, water buffalo and other animals in several parts of the world; its life cycle goes from eggs excreted in urine and faeces, developing into larvae, which enter snails, then to free-swimming cercariae that attach to and penetrate human skin. Penetration can occur while workers are wading in water.

Some zoonoses are arthropod-borne viral diseases. The primary vectors for these diseases are mosquitoes, ticks and sandflies. These diseases include arboviral encephalitides transmitted by ticks and milk from sheep, babesiosis transmitted by ticks from cattle and Crimean-Congo haemorrhagic fever (Central Asian haemorrhagic fever) transmitted by mosquitoes and ticks from cattle, sheep and goats (as amplifying hosts) during epizootics (Benenson 1990; Mullan and Murthy 1991).

Preventive Action

The principal occupational hazards that occur in rearing ruminants include injuries, respiratory problems and zoonotic diseases. (See “A checklist for livestock rearing safety practices”.)

Stair steps should be maintained in good condition, and floors must be even to reduce fall hazards. Guards on belts, mechanical screws, compression rams and shear sharpening equipment should be maintained. Wiring should be maintained in good condition to prevent electrical shock. Ventilation should be assured wherever internal combustion engines are used in barns.

Training and experience in properly handling animals helps to prevent injuries related to the animals’ behaviour. Safe livestock handling requires understanding of both innate and acquired components of animal behaviour. Facilities should be designed so workers do not have to enter small or enclosed areas with animals. Lighting should be diffuse, since animals may become confused and balk around bright lights. Sudden noises or movements may startle cattle, causing them to crowd a person against hard surfaces. Even clothing hanging on fences flapping in the wind can startle cattle. They should be approached from the front so as not to surprise them. Avoid use of contrasting patterns in cattle facilities, because cattle will slow or stop when they see these patterns. Shadows across the floor should be avoided because cattle may refuse to cross over them (Gillespie 1997).

Risks of organic dust exposure can be minimized in several ways. Workers should be aware of the health effects of breathing organic dust and inform their physician about recent dust exposures when seeking help for respiratory illness. Minimizing spoilage of feed can minimize potential fungal spore exposures. To avoid such hazards, workers should use mechanized equipment to move decaying materials. Farm operators should use local exhaust ventilation and wet methods of dust suppression to minimize exposure. Appropriate respirators should be worn when organic dust exposure cannot be avoided (NIOSH 1994).

Preventing zoonoses depends upon maintaining clean livestock facilities, vaccinating the animals, quarantine of sick animals and avoiding exposure to sick animals. Rubber gloves should be worn when treating sick animals to avoid exposures through any cuts in the hands. Workers who become sick after contact with a sick animal should seek medical help (Gillespie 1997).

A Checklist for Livestock Rearing Safety Practices

Feeding

- Use proper ventilation in buildings and silos.

- Keep entrances to grain, feed and silage storage areas closed and locked.

- Post warning signs in feed and silage storage areas about the hazard of entrapment in flowing grain or feed.

- Maintain silo and bin ladders in good condition.

- Shield auger inlets to prevent contact with augers.

- Cover loading troughs on augers, elevators and conveyors with grating.

- Use caution when moving augers and elevators; check for overhead power lines.

- Assure that shields are in place for all feeding, grinding and other equipment.

- Be aware of health effects of breathing organic dust, and inform your doctor about recent dust exposure when seeking treatment for respiratory illness.

- Use automated or mechanized equipment to move decayed materials.

- Use source containment, local exhaust ventilation and wet methods to control organic dust.

- Use appropriate respiratory protection when dust exposure is unavoidable.

Handling

- Establish good sanitation, vaccination and inoculation programmes.

- When working with animals, plan an escape exit; have at least two ways out.

- Livestock handlers should have enough strength and experience for the job.

- Avoid working with animals when you are tired.

- Use caution when approaching animals so as not to startle them.

- Know the animals and be patient with them.

- Dehorn dangerous animals.

- Post warning signs where chemicals are stored; lock them in a room or cabinet.

- Mix all chemicals outside or in a well-ventilated area.

- Be careful when leading animals.

- Wear rubber gloves when treating sick animals.

- Vaccinate animals, and quarantine sick animals.

- Wash hands after contact with calves with diarrhoea (scours).

Containment and housing

- Make sure all pens, gates, loading chutes and fences are in good repair and strong enough to contain the animal.

- Do not allow tobacco smoking around farm buildings and fuel storage and refueling areas; post “no smoking” signs in these areas.

- Maintain fully charged ABC-type fire extinguishers in major farm buildings.

- Remove trash and debris around buildings to prevent fires and falls.

- Keep all buildings in good repair.

- Keep electrical wiring in good condition.

- Use adequate lighting in all buildings.

- Keep floors clean and free of broken concrete and slippery areas.

Waste disposal

- Correctly dispose of all chemical containers following directions on the label.

- Install vent pipes and exhaust fans in manure pits.

General Profile

In 1993, the worldwide production of electricity was 12.3 trillion kilowatt hours (United Nations 1995). (A kilowatt hour is the amount of electricity needed to light ten 100-watt bulbs for 1 hour.) One can judge the magnitude of this endeavour by considering data from the United States, which alone produced 25% of the total energy. The US electric utility industry, a mix of public and privately owned entities, generated 3.1 trillion kilowatt hours in 1993, using more than 10,000 generating units (US Department of Energy 1995). The portion of this industry that is owned by private investors employs 430,000 people in electric operations and maintenance, with revenues of US$200 billion annually.

Electricity is generated in plants which utilize fossil fuel (petroleum, natural gas or coal) or use nuclear energy or hydropower. In 1990, for example, 75% of France’s electrical power came from nuclear power stations. In 1993, 62% of the electricity generated worldwide came from fossil fuels, 19% from hydropower, and 18% from nuclear power. Other reusable sources of energy such as wind, solar, geothermal or biomass account for only a small proportion of world electric production. From generating stations, electricity is then transmitted over interconnected networks or grids to local distribution systems and on through to the consumer.

The workforce that makes all of this possible tends to be primarily male and to possess a high degree of technical skill and knowledge of “the system”. The tasks that these workers undertake are quite diverse, having elements in common with the construction, manufacturing, materials handling, transportation and communications industries. The next few articles describe some of these operations in detail. The articles on electric maintenance standards and environmental concerns also highlight major US government regulatory initiatives that affect the electric utility industry.

Aquatic Plants

Adapted from J.W.G. Lund’s article, “Algae”, “Encyclopaedia of Occupational Health and Safety,” 3rd edition.

Worldwide aquaculture production totalled 19.3 million tonnes in 1992, of which 5.4 million tonnes came from plants. In addition, much of the feed used on fish farms is water plants and algae, contributing to their growth as a part of aquaculture.

Water plants that are grown commercially include water spinach, watercress, water chestnuts, lotus stems and various seaweeds, which are grown as low-cost foods in Asia and Africa. Floating water plants that have commercial potential are duckweed and water hyacinth (FAO 1995).

Algae are a diverse group of organisms; if the cyanobacteria (blue-green algae) are included, they come in a range of sizes from bacteria (0.2 to 2 microns) to giant kelps (40 m). All algae are capable of photosynthesis and can liberate oxygen.

Algae are nearly all aquatic, but they may also live as a dual organism with fungi as lichens on drier rocks and on trees. Algae are found wherever there is moisture. Plant plankton consists almost exclusively of algae. Algae abound in lakes and rivers, and on the seashore. The slipperiness of stones and rocks, the slimes and discolourations of water usually are formed by aggregations of microscopic algae. They are found in hot springs, snowfields and Antarctic ice. On mountains they can form dark slippery streaks (Tintenstriche) that are dangerous to climbers.

There is no general agreement about algae classification, but they are commonly divided into 13 major groups whose members may differ markedly from one group to another in colour. The blue-green algae (Cyanophyta) are also considered by many microbiologists to be bacteria (Cyanobacteria) because they are procaryotes, which lack the membrane-bounded nuclei and other organelles of eukaryotic organisms. They are probably descendants of the earliest photosynthetic organisms, and their fossils have been found in rocks some 2 billion years old. Green algae (Chlorophyta), to which Chlorella belongs, has many of the characteristics of other green plants. Some are seaweeds, as are most of the red (Rhodophyta) and brown (Phaeophyta) algae. Chrysophyta, usually yellow or brownish in colour, include the diatoms, algae with walls made of polymerized silicon dioxide. Their fossil remains form industrially valuable deposits (Kieselguhr, diatomite, diatomaceous earth). Diatoms are the main basis of life in the oceans and contribute about 20 to 25% of the world’s plant production. Dinoflagellates (Dinophyta) are free-swimming algae especially common in the sea; some are toxic.

Uses

Water culture can vary greatly from the traditional 2-month to annual growing cycle of planting, then fertilizing and plant maintenance, followed by harvesting, processing, storage and sale. Sometimes the cycle is compressed to 1 day, such as in duckweed farming. Duckweed is the smallest flowering plant.

Some seaweeds are valuable commercially as sources of alginates, carrageenin and agar, which are used in industry and medicine (textiles, food additives, cosmetics, pharmaceuticals, emulsifiers and so on). Agar is the standard solid medium on which bacteria and other micro-organisms are cultivated. In the Far East, especially in Japan, a variety of seaweeds are used as human food. Seaweeds are good fertilizers, but their use is decreasing because of the labour costs and the availability of relatively cheap artificial fertilizers. Algae play an important part in tropical fish farms and in rice fields. The latter are commonly rich in Cyanophyta, some species of which can utilize nitrogen gas as their sole source of nitrogenous nutrient. As rice is the staple diet of the majority of the human race, the growth of algae in rice fields is under intensive study in countries such as India and Japan. Certain algae have been employed as a source of iodine and bromine.

The use of industrially cultivated microscopic algae has often been advocated for human food and has a potential for very high yields per unit area. However, the cost of dewatering has been a barrier.

Where there is a good climate and inexpensive land, algae can be used as part of the process of sewage purification and harvested as animal food. While a useful part of the living world of reservoirs, too much algae can seriously impede, or increase the cost of water supply. In swimming pools, algal poisons (algicides) can be used to control algal growth, but, apart from copper in low concentrations, such substances cannot be added to water or domestic supplies. Over-enrichment of water with nutrients, notably phosphorus, with consequent excessive growth of algae, is a major problem in some regions and has led to bans on the use of phosphorus-rich detergents. The best solution is to remove the excess phosphorus chemically in a sewage plant.

Duckweed and a water hyacinth are potential livestock feeds, compost input or fuel. Aquatic plants are also used as feed for noncarnivorous fish. Fish farms produce three primary commodities: finfish, shrimp and mollusc. Of the finfish portion, 85% are made up of noncarnivorous species, primarily the carp. Both the shrimp and mollusc depend upon algae (FAO 1995).

Hazards

Abundant growths of freshwater algae often contain potentially toxic blue-green algae. Such “water blooms” are unlikely to harm humans because the water is so unpleasant to drink that swallowing a large and hence dangerous amount of algae is unlikely. On the other hand, cattle may be killed, especially in hot, dry areas where no other source of water may be available to them. Paralytic shellfish poisoning is caused by algae (dinoflagellates) on which the shellfish feed and whose powerful toxin they concentrate in their bodies with no apparent harm to themselves. Humans, as well as marine animals, can be harmed or killed by the toxin.

Prymnesium (Chrysophyta) is very toxic to fish and flourishes in weakly or moderately saline water. It presented a major threat to fish farming in Israel until research provided a practical method of detecting the presence of the toxin before it reached lethal proportions. A colourless member of the green algae (Prototheca) infects humans and other mammals from time to time.

There have been a few reports of algae causing skin irritations. Oscillatoria nigroviridis are known to cause dermatitis. In freshwater, Anaebaena, Lyngbya majuscula and Schizothrix can cause contact dermatitis. Red algae are known to cause breathing distress. Diatoms contain silica, so they could pose a silicosis hazard as a dust. Drowning is a hazard when working in deeper water while cultivating and harvesting water plants and algae. The use of algicides also poses hazards, and precautions provided on the pesticide label should be followed.

Bamboo and Cane

Adapted from Y.C. Ko’s article, “Bamboo and cane”, “Encyclopaedia of Occupational Health and Safety”, 3rd edition.

Bamboo, which is a subfamily of the grasses, exists as more than a thousand different species, but only a few species are cultivated in commercial plantations or nurseries. Bamboos are tree-like or shrubby grasses with woody stems, called culms. They range from small plants with centimetre-thick culms to giant subtropical species up to 30 m tall and 30 cm in diameter. Some bamboos grow at a prodigious rate, up to 16 cm in height per day. Bamboos rarely flower (and when they do, it may be at intervals of 120 years), but they can be cultivated by planting their stalks. Most bamboos came from Asia, where they grow wild in tropical and subtropical areas. Some species have been exported to temperate climates, where they require irrigation and special care during the winter.

Some bamboo species are used as vegetables and may be pickled or preserved. Bamboo has been used as an oral medicine against poisoning since it contains silicic acid which absorbs poison in the stomach. (Silicic acid is now produced synthetically.)

The wood-like properties of bamboo culms have led to their use for many other purposes. Bamboo is used in building houses, with the culms as uprights and the walls and roofs made from split stems or lattice work. Bamboo is also used for making boats and boat masts, rafts, fences, furniture, containers and handicraft products, including umbrellas and walking sticks. Other uses abound: water pipes, wheelbarrow axles, flutes, fishing rods, scaffolding, roller-blinds, ropes, rakes, brooms and weapons such as bows and arrows. In addition, bamboo pulp has been used to make high-quality paper. It is also grown in nurseries and used in gardens as ornamentals, wind breaks and hedges (Recht and Wetterwald 1992).

Cane is sometimes confused with bamboo, but is botanically different and comes from varieties of the rattan palm. Rattan palms grow freely in tropical and subtropical areas, particularly in Southeast Asia. Cane is used to make furniture (especially chairs), baskets, containers and other handicraft products. It is very popular due to its appearance and elasticity. It is frequently necessary to split the stems when cane is used in manufacturing.

Cultivation Processes

The processes for cultivating bamboo include propagation, planting, watering and feeding, pruning and harvesting. Bamboos are propagated in two ways: by planting seeds or by using sections of the rhizome (the underground stem). Some plantations depend upon natural reseeding. Since some bamboos flower infrequently and seeds remain viable only for a couple of weeks, most propagation is accomplished by dividing a large plant that includes the rhizome with culms. Spades, knives, axes or saws are used to divide the plant.

Growers plant bamboo in groves, and planting and replanting bamboo involves digging a hole, placing the plant into the hole and backfilling soil around its rhizomes and roots. About 10 years is required to establish a healthy grove of bamboo. Although not a concern in its native habitat where it rains often, irrigation is necessary when bamboos are grown in drier areas. Bamboo requires a lot of fertilizer, particularly nitrogen. Both animal dung and commercial fertilizer are used. Silica (SiO2) is as important for bamboos as is nitrogen. In natural growth, bamboo gains enough silica naturally by recycling it from shed leaves. In commercial nurseries, shed leaves are left around the bamboo and silica-rich clay minerals such as Bentonite may be added. Bamboos are pruned of old and dead culms to provide room for new growth. In Asian groves, dead culms may be split in the fields to hasten their decay and add to the soil’s humus.

Bamboo is harvested either as a food or for its wood or pulp. Bamboo shoots are harvested for food. They are dug from the soil and cut with a knife or chopped with an axe. The bamboo culms are harvested when they are 3 to 5 years old. Harvesting is timed for when the culms are neither too soft nor too hard. Bamboo culms are harvested for their wood. They are cut or chopped with a knife or an axe, and the cut bamboo may be heated to bend it or split with a knife and mallet, depending upon its end use.

Rattan palm cane is usually harvested from wild trees often in uncultivated mountainous areas. The stems of the plants are cut near the roots, dragged out from thickets and sun-dried. The leaves and the bark are then removed, and the stems are sent for processing.

Hazards and Their Prevention

Venomous snakes present a hazard in plantation groves. Stumbling over bamboo stumps may cause falls, and cuts can lead to tetanus infection. Bird and chicken droppings in bamboo groves can be contaminated with Histoplasma capsulatum (Storch et al. 1980). Working with bamboo culms can lead to knife cuts, particularly when splitting the culms. Sharp edges and the ends of bamboos can cause cuts or punctures. Hyperkeratosis of the palms and fingers has been observed in workers who make bamboo containers. Pesticide exposures are also possible. First aid and medical treatment is required to deal with snake bites. Vaccine and booster vaccine should be used to prevent tetanus.

All cutting knives and saws should be maintained and used with care. Where bird droppings are present, work should be conducted during wet conditions to prevent dust exposure, or respiratory protection should be used.

In harvesting palm cane, workers are exposed to the dangers of remote forests, including snakes and venomous insects. The bark of the tree has thorns that may tear the skin, and workers are exposed to cuts from knives. Gloves should be worn when the stems are handled. Cuts are also a risk during manufacture, and hyperkeratosis of the palms and fingers may often occur among workers, probably because of the friction of the material.

Tropical Tree and Palm Crops

Some text was revised from the articles “Date palms”, by D. Abed; “Raffia” and “Sisal”, by E. Arreguin Velez; “Copra”, by A.P. Bulengo; “Kapok”, by U. Egtasaeng; “Coconut cultivation”, by L.V.R. Fernando; “Bananas”, by Y. Ko; “Coir”, by P.V.C. Pinnagoda; and “Oil palms”, by G.O. Sofoluwe from the 3rd edition of this “Encyclopaedia”.

Although archaeological evidence is inconclusive, tropical forest trees transplanted to the village may have been the first domesticated agricultural crops. More than 200 fruit tree species have been identified in the humid tropics. Several of these trees and palms, such as the banana and coconut, are cultivated in smallholdings, cooperatives or plantations. While the date palm is completely domesticated, other species, such as the Brazil nut, are still harvested in the wild. More than 150 varieties of bananas and 2,500 palm species exist around the world, and they provide a broad range of products for human use. Sago palm wood feeds millions of people around the world. The coconut palm is used in more than 1,000 ways and the palmyra palm in more than 800 ways. About 400,000 people depend on the coconut for their entire livelihood. Several trees, fruits and palms of the tropical and semitropical zones of the world are listed in table 1, and table 2 shows selected commercial palms or palm types and their products.

Table 1. Commercial tropical and subtropical trees, fruits and palms

|

Categories |

Species |

|

Tropical and semitropical fruits (excluding citrus) |

Figs, banana, jelly palm, loquat, papaya, guava, mango, kiwis, date, cherimoya, white sapota, durian, breadfruit, Surinam cherry, lychee, olive, carambola, carob, chocolate, loquat, avocado, sapodilla, japoticaba, pomegranate, pineapple |

|

Semitropical citrus fruits |

Orange, grapefruit, lime, lemon, tangerine, tangelos, calamondins, kumquats, citrons |

|

Tropical nut trees |

Cashew, Brazil, almond, pine, and macadamia nuts |

|

Oil crops |

Oil palm, olive, coconut |

|

Insect feed |

Mulberry leaf (silkworm feed), decaying sago palm pith (grub feed) |

|

Fibre crops |

Kapok, sisal, hemp, coir (coconut husk), raffia palm, piassaba palm, palmyra palm, fishtail palm |

|

Starch |

Sago palm |

|

Vanilla bean |

Vanilla orchid |

|

Groups |

Products |

Uses |

|

Coconut |

Nut meat Copra (desiccated meat) Nut water Nut shells Coir (husk) Leaves Wood Flower nectar inflorescence |

Food, copra, animal feed Food, oil, oilsoap, candle, cooking oil, margarine, cosmetics, detergent, pai, coconut milk, cream, jam Fuel, charcoal, bowls, scoops, cups Mats, string, potting soil mix, brush, rope, cordage Thatching, weaving Building Palm honey Palm sugar, alcohol, arrack (palm spirits) |

|

Date |

Fruit Sap |

Dry, sweet and fine dates Date sugar |

|

African oil |

Fruit (palm pulp oil; similar to olive oil) Seeds (palm kernel oil) |

Cosmetics, margarine, dressing, fuel, lubricants Soap, glycerine |

|

Palmyra |

Leaves Petioles and leaf sheaths Truck Fruit and seeds Sap, roots |

Paper, shelter, weaving, fans, buckets, caps Carpets, rope, twine, brooms, brushes Timber, sago, cabbage Food, fruit pulp, starch, buttons Sugar, wine, alcohol, vinegar, sura (raw sap drink) Food, diuretic |

|

Sago (trunk pith of various species) |

Starch Insect feed |

Meals, gruels, puddings, bread, flour Food (grubs feeding on decayed sago pith) |

|

Cabbage (various species) |

Apical bud (upper trunk) |

Salads, canned palm hearts or palmito |

|

Raffia |

Leaves |

Plaiting, baskets work, tying material |

|

Sugar (various species) |

Palm sap |

Palm sugar (gur, jaggery) |

|

Wax |

Leaves |

Candles, lipsticks, shoe polish, car polish, floor wax |

|

Rattan cane |

Stems |

Furniture |

|

Betel nut |

Fruit (nut) |

Stimulant (betel chewing) |

Processes

The agriculture of tropical tree and palm growing includes propagation, cultivation, harvesting and post-harvesting processes.

Propagation of tropical trees and palms can be sexual or asexual. Sexual techniques are needed to produce fruit; pollination is critical. The date palm is doecious, and pollen from the male palm must be dispersed upon the female flowers. Pollination is done either by hand or mechanically. The manual process involves the workers climbing the tree by gripping the truck or using tall ladders to hand pollinate the female trees by placing small male clusters in the center of each female cluster. The mechanical process uses a powerful sprayer to carry the pollen over the female clusters. In addition to use for generating products, sexual techniques are used to produce seed, which is planted and cultivated into new plants. An example of an asexual technique is cutting shoots from mature plants for replanting.

Cultivation can be manual or mechanized. Banana cultivation is typically manual, but in flat terrain, mechanization with large tractors is used. Mechanical shovels may be used to dig drainage ditches in banana fields. Fertilizer is added monthly to bananas, and pesticides are applied with boom sprayers or from the air. The plants are supported with bamboo poles against storm damage. A banana plant bears fruit after two years.

Harvesting relies largely on manual labour, though some machinery is also used. Harvesters cut the banana bunches, called hands, from the tree with a knife attached to a long pole. The bunch is dropped onto a worker’s shoulder and a second worker attaches a nylon cord to the bunch, which is then attached to an overhead cable that moves the bunch to a tractor and trailer for transport. Tapping the coconut inflorescence for the juice entails the taper walking from tree to tree on strands of rope high above the ground. Workers climb to the tree tops to pluck the nuts manually or cut the nuts with a knife attached to long bamboo poles. In the Southwest Pacific area the nuts are allowed to fall naturally; then they are gathered. The date ripens in the fall and two or three crops are gathered, requiring climbing the tree or a ladder to the date clusters. An old system of machete harvesting of fruit bunches has been replaced by the use of a hook and pole. However, the machete is still used in harvesting many crops (e.g., sisal leaves).

Post-harvest operations vary between tree and palm and by the expected product. After harvesting, banana workers—typically women and youth—wash the bananas, wrap them in polyethylene and pack them in corrugated cardboard boxes for shipping. Sisal leaves are dried, bound and transported to the factory. Kapok fruit is field dried, and the resulting brittle fruit is broken open with a hammer or pipe. Kapok fibers are then ginned in the field to remove seeds by shaking or stirring, packed in jute sacks, batted in sacks to soften the fibers and baled. After harvest, dates are hydrated and artificially ripened. They are exposed to hot air (100 to 110 °C) to glaze the skin and semi-pasteurize them and then packaged.

The dried meaty endosperm of the coconut is marketed as copra, and the prepared husk of the coconut is marketed as coir. The fibrous nut husks are stripped off by striking and levering them against spikes firmly fixed into the ground. The nut, stripped of the husk, is split in half with an axe and dried either in the sun, kilns or hot-air dryers. After drying, the meat is separated from the hard woody shell. Copra is used to produce coconut oil, oil extraction residue called copra cake or poonac and desiccated food. The coir is retted (partially rotted) by soaking in water for three to four weeks. Workers remove the retted coir from the pits in waist-deep water and send it for decortication, bleaching and processing.

Hazards and Their Prevention

Hazards in tropical fruit and palm crop production include injuries, natural exposures, pesticide exposures and respiratory and dermatitis problems. Working at high elevations is required for much work with many tropical trees and palms. The popular apple banana grows to 5 m, kapok to 15 m, coconut palms to 20 to 30 m, evergreen date palm to 30 m, and the oil palm, 12 m. Falls represent one of the most serious hazards in tropical tree cultivation, and so do falling objects. Safety harnesses and head protection should be used, and workers should be trained in their use. Using dwarf varieties of the palms may help eliminate the tree falls. Falls from the kapok tree because of branches breaking and minor hand injuries during shell cracking are also hazards.

Workers can be injured during the transport on trucks or tractor-drawn trailers. Workers climbing palms receive cuts and abrasions of the hands due to contact with sharp date palm spines and oil palm fruit as well as spiny sisal leaves. Sprains from falling in ditches and holes are a problem. Severe wounds from the machete may be inflicted. Workers, typically women, who lift packed boxes of bananas are exposed to heavy weights. Tractors should have safety cabs. Workers should be trained in the safe handling of agricultural implements, machinery guarding and safe tractor operation. Puncture-resistant gloves should be worn, and arm protection and hooks should be used in harvesting the oil palm fruit. Mechanization of weeding and cultivation reduces sprains from falls in ditches and holes. Safe and proper work practices should be used, such as proper lifting, getting help when lifting to reduce individual loads and taking breaks.

Natural hazards include snakes—a problem during forest clearing and in newly established plantations—and insects as well as diseases. Health problems include malaria, ancylostomiasis, anaemia and enteric diseases. The retting operation exposes workers to parasites and skin infections. Mosquito control, sanitation and safe drinking water are important.

Pesticide poisoning is a hazard in tropical tree production, and pesticides are used in significant quantities in fruit groves. However, palms have few problems with pests, and those that are a problem are unique to specific parts of the life cycle and thus can be identified for specific control. Integrated pest management and, when applying pesticides, following the manufacturer’s instructions are important protective measures.

Medical evaluations have identified cases of bronchial asthma among date workers probably from pollen exposure. Also reported among date workers are chronic dry eczema and “nail disease” (onychia). Respiratory protection should be provided during the pollination process, and workers should wear hand protection and frequently wash their hands to protect their skin when working with the trees and dates.

Urban Agriculture

Agriculture conducted in urban areas is a major contributor to food, fuel and fibre production in the world, and it exists largely for the daily needs of consumers within cities and towns. Urban agriculture uses and reuses natural resources and urban wastes to produce crops and livestock. Table 1 summarizes the variety of farming systems in urban areas. Urban agriculture is a source of income for an estimated 100 million people, and a source of food for 500 million. It is oriented to urban markets rather than national or global markets, and it consists of many small-scale farms and some large-scale agribusinesses. Urban farmers range from a household garden in 20 m2 or less, to a small-scale farmer making a living on 200 m2, to a large-scale operator who may rent 10 hectares in an industrial zone (UNDP 1996).

Table 1. Farming systems in urban areas

|

Farming systems |

Product |

Location or technique |

|

Aquaculture |

Fish and seafood, frogs, vegetables, seaweed and fodder |

Ponds, streams, cages, estuaries, sewage, lagoons, wetlands |

|

Horticulture |

Vegetables, fruit, herbs, beverages, compost |

Homesites, parks, rights-of-way, containers, rooftops, hydroponics, wetlands, greenhouses, shallow bed techniques, layered horticulture |

|

Floriculture |

Flowers, insecticides, house plants |

Ornamental horticulture, rooftops, containers, greenhouses, rights-of-way |

|

Husbandry |

Milk, eggs, meat, manure, hides, and fur |

Zero-grazing, rights-of-way, hillsides, cooperatives, pens, open spaces |

|

Agroforestry |

Fuel, fruits and nuts, compost, building material |

Street trees, homesites, steep slopes, vineyards, green belts, wetlands, orchards, forest parks, hedgerows |

|

Mycoculture |

Mushrooms, compost |

Sheds, cellers |

|

Vermaculture |

Compost, worms for animal and fish feed |

Sheds, trays |

|

Sericulture |

Silk |

Homesites, trays |

|

Apiculture |

Honey, pollination, wax |

Beehives, rights-of-way |

|

Landscape gardening, arboriculture |

Grounds design and upkeep, ornamentation, lawns, gardens |

Yards, parks, play fields, commercial frontage, road sides, lawn and garden equipment |

|

Beverage crops cultivation |

Grapes (wine), hibiscus, palm tea, coffee, sugar cane, qat (tea substitute), matte (herbed tea), banana (beer) |

Steep slopes, beverage processing |

Sources: UNDP 1996; Rowntree 1987.

Landscaping, an offshoot of architecture, has emerged as another urban agriculture endeavour. Landscape gardening is the tending of plants for their ornamental appearance in public parks and gardens, private yards and gardens, and industrial and commercial building plantings. Landscape gardening includes lawn care, planting annuals (bedding plants), and planting and caring for perennials, shrubs and trees. Related to landscape gardening is grounds keeping, in which playing fields, golf courses, municipal parks and so on are tended (Franck and Brownstone 1987).

Process Overview

Urban agriculture is seen as a method for establishing ecological sustainability for towns and cities in the future. Urban agriculture usually engages shorter-cycle, higher-value market crops and uses multi-cropping and integrated farming techniques located where space and water are scarce. It uses both vertical and horizontal space to its best advantage. The principal feature of urban farming is the reuse of waste. The processes are typical of agriculture with similar inputs and steps, but the design is to use both human and animal wastes as fertilizer and water sources for growing vegetation. In this near idealized model, external inputs still exist, however, such as pesticides (UNDP 1996).

In the special case of landscaping, appearance is the product. The care of lawns and ornamental trees, shrubs and flowers are the focus of the landscape operation. In general, the landscaper purchases planting stock from a nursery or a turf farm, plants the stock and cares for it routinely and frequently. It typically is labour and chemical intensive, and the use of hand and power tools and lawn and garden equipment is also common. Grass mowing is a routine chore in landscaping.

Hazards and Their Control

Urban agriculture is typically small scale, close to housing, exposed to urban pollutants, engaged in the reuse of waste and exposed to potential theft of products and related violence. The hazards related to various types of agriculture, pesticides and composting discussed elsewhere in this volume are similar (UNDP 1996).

In the developed countries, suburban farms and landscaping enterprises make use of lawn and garden equipment. This equipment includes small tractors (tractor attachments such as mowers, front-end loaders and blades) and utility haulers (similar to all-terrain vehicles). Other tractor attachments include tillers, carts, snow blowers and trimmers. These tractors all have engines, use fuel, have moving parts, carry an operator and are often used with towed or mounted equipment. They are substantially smaller than the typical agricultural tractor, but they can be overturned and cause serious injury. The fuel used on these tractors poses a fire hazard (Deere & Co. 1994).

Many of the tractor attachments have their own peculiar hazards. Children riding with adults have fallen from the tractor and been crushed under the wheels or chopped by mower blades. Mowers pose two types of hazards: one is potential contact with rotating blades and the other is being struck by objects thrown from the blades. Both front-end loaders and blades are operated hydraulically, and if left unattended and elevated, pose a hazard of falling onto anyone who gets a body part under the attachment. Utility haulers are inexpensive when compared to the cost of a small truck. They can turn over on steep terrain, especially when turning. They are dangerous when used on public roads because of the possibility of collision. (See table 2 for several safety tips for operating some types of lawn and garden equipment.)

Table 2. Safety advice for using mechanical lawn and garden equipment

Tractors (smaller than regular farm equipment)

Prevent rollovers:

- Do not drive where the tractor can tip or slip; avoid steep slopes; watch for rocks, holes

and similar hazards.

- Travel up and down slopes or hillsides; avoid travelling across steep slopes.

- Slow down and use care in turning to prevent tipping or losing steering and braking control.

- Stay within the tractor load limits; use ballast for stability; refer to the operator’s manual.

Never allow extra riders.

Maintain safety interlocks; they ensure that powered equipment is disengaged

when the operator is not seated or when starting the tractor.

Rotary lawn mowers (tractor mounted or walk-behind type)

Maintain safety interlocks.

Use proper blades and guards.

Keep all safety blades and guards in place and in good condition.

Wear substantial closed-toe shoes to prevent slipping and protect against injury.

Do not allow anyone to put their hands or feet near the mower deck or discharge chute

while the machine is running; stop the mower if children are nearby.

When leaving the machine, shut it down.

To prevent thrown object injuries:

- Clear the area to be mowed.

- Keep the mower deck guards, discharge chute, or bag in place.

- Stop the mower whenever someone comes near.

When working on mower (on push or walk-behind type mowers), disconnect the spark plug

to prevent engine starting.

Avoid fires by not spilling fuel on hot surfaces nor handling fuel near sparks or flames;

avoid the accumulation of fuel, oil and trash around hot surfaces.

Front-end loaders (attached to lawn and garden tractors)

Avoid overloading.

Back down ramps and steep inclines with the loader bucket lowered.

Watch the driving route rather than watching the bucket.

Operate the hydraulic loader controls only from the tractor seat.

Use the loader only for materials that it was designed to handle.

Lower the bucket to the ground when leaving the machine.

Utility haulers (similar to all-terrain vehicles but designed for off-the-road work)

Avoid rollovers:

- Practise driving on smooth terrain before driving on rough terrain.

- Do not speed; slow down before turning (especially on slopes).

- Reduce speed on slopes and rough terrain.

- Watch for holes, rocks and other hidden hazards.

Never allow extra riders.

Avoid tipping over by distributing the cargo box load so it is not too high or too far to rear.

Avoid an upset when raising the cargo box by staying clear of the edge of loading docks

or embankments.

When towing loads, place weight in the cargo box to assure traction.

Avoid driving on public roads.

Children should not operate these machines.

A helmet is recommended head protection.

Source: Adapted from Deere & Co. 1994.

" DISCLAIMER: The ILO does not take responsibility for content presented on this web portal that is presented in any language other than English, which is the language used for the initial production and peer-review of original content. Certain statistics have not been updated since the production of the 4th edition of the Encyclopaedia (1998)."