Production entails human activities that result in material, energy, information or other entities that are useful to individuals and to society; its development depends upon the collection, processing, dissemination and use of information. Work may be described as human activity directed to pre-set goals in the production process, with tools and equipment serving as the material instrumentality of such activity. But it should be borne in mind that in the work process the information that is continually received and organized affects and directs the process.

The work process itself contains information in the form of accumulated experience which is stored by the worker (as knowledge and skills); embodied, as it were, in tools, equipment, machinery and, in particular, by complex technological systems; and made explicit through the medium of information processing equipment. The work process is a concrete and dynamic way of using information to achieve certain set objectives. The safety components of this information are equally distributed among the various elements of work—the worker, the tools and equipment, the working environment and the objects of production; indeed, safety information should ideally be an integral part of the information needed for the production itself: instead of “how to produce something” it should be “how to safely (with lower risk) produce something”. Several experiments have demonstrated that information linking safety to production is not merely necessary but is increasingly being perceived as such.

Production entails not only the obvious technical creation of new output out of either natural raw materials or pre-existing man-made materials and goods, but also includes the modification and reorganization of information that pertains to the material production process and to the information cycle itself. The scope of the information element of a developing production process increases rapidly. Following the familiar practice of dividing the process of production into three parts, namely, energy production, materials production and information production, we may also divide its products into similar categories. However, these are usually of a mixed character. Energy is generally carried by matter, and information is either associated with matter—printed matter, for instance—or with energy, such as electrical charge or the optical and electronic impulses carried by fibre-optic lines. But, unlike material products, information does not necessarily lose its value when it undergoes reproductive processes. It is a product which can be reproduced in mass, yet its copies can be exactly as valid as the original.

Safety Information and Its Use in Production Systems

Safety information ranges over a great breadth of subjects and may assume a correspondingly great variety of forms. It can be classified as to whether it conveys statistical figures, descriptive information, reference data, original texts or quantitative or qualitative matter. It may be a statistical table setting forth a collection of quantitative data relating to accident incidence, or a chemical safety data sheet. It may be a computer-readable database, ready-to-use materials (including illustrations and drawings), model legislation and regulations, or the research results pertaining to a particular safety problem. Historically, most information needs were covered by conventional communication methods, oral and written, until the relatively recent advent of photography, radio communication, films, television and video productions. Although the methods of mass media were to facilitate electronic copying, they nevertheless lacked selectivity. Plainly, not all people need or are interested in the same type of safety information. Libraries and, in particular, specialized safety documentation centres provide a fairly comprehensive selection of documents which could provide specific details for each user of information, but their resources are not readily accessible in the form of copied matter. The latest methods of information collection, storage and retrieval, however, have solved this problem. Electronically managed information may contain the same amount of or more information than a full specialized library and it can be easily and quickly duplicated.

Safety professionals, namely, inspectors, industrial hygienists, safety engineers, safety representatives, managers, supervisors, researchers, and workers as well, will make use of information to the greatest desirable extent only if it is easily available. All that they need should be accessible right on their desks or bookshelves. Existing documentation could be converted into electronic form and organized in such a way that retrieval will be quick and reliable. These tasks are already being carried out and represent an enormous undertaking. First, selection is essential. Information should be assembled and provided on a priority basis and the retrieval process should be convenient and reliable. These goals require better organization of databases and more intelligent software and hardware.

Quantitative Safety Information

Information in factual, quantitative form is essentially expressed as numerical figures. Quantitative measures may record nominal values, such as a given number of accidents; ordinal values that define priorities; or ratios, such as may describe the frequency of accidents relative to their severity. The chief problem is to define criteria for the effectiveness of safety practices and to find the best ways to measure them (Tarrants 1980). Another problem is to design forms of information that are effective in setting forth the nature of (and the need for) safety measures and that, at the same time, are understandable to all concerned—workers, for example, or users of chemicals and chemical equipment. It has been shown that safety information will influence behaviour, but that the change in behaviour is influenced not only by the content of the information, but also by the form in which it is presented, for example, by its attractiveness and intelligibility. If risks are not effectively presented and correctly understood and recognized, one cannot expect rational and safe behaviour on the part either of workers, managers, designers, suppliers or others concerned with safety.

Quantitative risk data are not, in general, well understood. There is broad public confusion about which are the greater hazards and which the lesser, because there exists no uniform measure of risk. One of the reasons for this state of affairs is that the public media do not emphasize continually occurring problems, even the more serious ones, but tend to highlight relatively rare and striking “shocking” news.

Another factor limiting the effectiveness of safety education is that processing complex quantitative risk information may exceed the cognitive abilities of individuals to the extent that they rely on heuristics, unsystematically absorbing the lessons of experience, to make safety-related tasks manageable. In general, low risks are overestimated and high risks underestimated (Viscusi 1987). This bias may be understood if we consider that without any information, all risks would be considered as equal. Every piece of information obtained through experience will then encourage a skewed risk perception, with the more frequent but less harmful incidents receiving more attention (and more cautiously avoided) than the rarer but graver accidents.

Qualitative Safety Information

While quantitative safety information, with its sharp focus on particular hazards, is needed to concentrate our efforts on essential safety problems, we need qualitative information, conveying its fund of relevant expertise, in order to find practical solutions (Takala 1992). By its nature this sort of information cannot be precise and quantitative but is heterogeneous and descriptive. It comprises such diverse sources as legal information, training materials, audiovisuals, labels, signs and symbols, chemical and technical safety data sheets, standards, codes of practices, textbooks, scientific periodical articles, dissertation theses, posters, newsletters and even leaflets. The variety of materials makes it quite difficult to classify and subsequently retrieve these materials when needed. But it can be done and has indeed been successfully carried out: the preparation of company-, branch-, industry- and even nation-wide hazard profiles represents a practical example of the provision of qualitative information in a systematic way that at the same time attaches quantitative measures to the relative importance of the problems in question.

Another key issue is that of intelligibility. Comprehension requires that information be presented in a way that will be understood by the end user. The improper use of language, whether that of everyday speech or special technical terminology (including jargon), can create perhaps the greatest barrier to the global dissemination of safety information. Texts must be conscientiously and deliberately framed so as to make a strongly positive appeal to their intended audience.

It would be desirable to establish a comprehensive knowledge base of all accumulated safety and health information, accessible to users through interfaces tailored specially to each user group. Ideally, such interfaces would translate the desired elements of this information, without redundancy, into a format understood by the user, whether it should involve natural language, specified terminology (or absence of it), images, illustrations, drawings or sound, and would be adapted to the needs and abilities of the end user.

Impact, Presentation and Types of Safety Information

Company-level safety information and the information cycle

Studies of safety information systems within companies suggest that information flow within enterprises follows a cyclical pattern:

data collection →

data analysis and storage →

distribution of safety information →

developing preventive measures →

production of goods and materials (risks and accidents) →

data collection, etc.

The main methods used to collect data are accident investigations, safety inspections by enterprise personnel and the reporting of near-accidents. These methods concentrate on safety problems and do not pay much attention to health and industrial hygiene problems. They do not provide information on experience accumulated outside the enterprise either. It is essential to share such experience from elsewhere, since accidents are rare events and it is not likely that a sufficient number of similar incidents, especially major accidents (e.g., the disasters at Bhopal, Flixborough, Seveso and Mexico City), will occur in any one enterprise, or even in any one country, to serve as a basis for effective preventive efforts. They might, however, re-occur somewhere in the world (ILO 1988).

Safety-related activities that industry may undertake can assume a variety of forms. Information campaigns aimed at improving safety information dissemination may include safety slogans, development of a housekeeping index, positive reinforcement and training programmes for workers (Saarela 1991). In some countries, occupational health services have been established to involve health personnel in the company’s work of accident prevention. These services must have the capability to collect workplace information—to carry out job load and hazard analyses, for instance—in order to perform their everyday tasks. Further, many companies have established computerized systems for the recording and reporting of accidents. Similar systems, adapted to record accidents at workplaces according to a standard format required by workmen’s compensation bodies, have been established in several countries.

National and global safety information and theinformation cycle

Just as the safety information cycle exists within a company, there is a similar information cycle on a national, and international, level. The flow of safety information from nation to nation may be understood as a circle representing various phases in the movement of information where safety information may be either needed, processed or disseminated.

In order to assess the relative merits of various information systems, it is useful to discuss the dissemination of information in terms of the “information cycle”. The flow of safety information internationally is represented schematically in figure 1, based on Robert’s model (Robert 1983; Takala 1993). As a first step, safety information is identified or described by the author of a document, where the word “document” is used in its broadest sense, and may denote indifferently a scientific article, textbook, statistical report, piece of legislation, audiovisual training material, chemical safety data sheet or even a floppy disc or an entire database. Whatever its type, however, information may enter the cycle in either electronic or printed form.

Figure 1. The information cycle

MISSING

- Information is sent to a publisher or editor, who will evaluate its validity for publication. The publication of a document is, plainly, an important factor in its usefulness and general accessibility simply because unpublished materials are difficult to locate.

- Published documents can be used directly by a safety professional or they may target a non-professional end-user such as the worker at the workplace (for example, chemical safety data sheets).

- The document may then be sent to an information centre. In the case of documents that convey primary information (results of original research, for example), the centre will systematically collect, screen and select whatever useful information they may contain, thus carrying out the first rough reading of large volumes of documents. A regularly published or updated secondary publication, such as a periodical or database containing abstracts or reviews, may be published or made available by the information centre. This will draw attention on a continuous basis to significant developments in occupational safety and health.

- Such secondary publications or databases target mainly safety professionals. Examples of such secondary databases and publications are the CISDOC database and the Safety and Health at Work bulletin from the International Labour Organization, and the NIOSHTIC database from the National Institute for Occupational Safety and Health (NIOSH) in the United States. The interchange vehicle between a given institutional entity (e.g., a company) and the national or global information cycle is in all cases the user. The user is not necessarily an individual safety professional, but may also be the institution’s safety management system. A user of published material may furthermore communicate feedback directly to the author or publisher, a practice common for scientific publications.

- At this point in the information cycle, the published document may be modified as a result of “reality testing”, the stage at which the safety professional puts the information to actual use in order to reduce the number of accidents or work-related diseases, or to solve other problems at work.

- Experience contributes to better anticipation of health hazards and accidents.

- Experience may result in new research findings in the form of reports and documents which are sent to the publisher: thus the cycle is completed.

Applications of safety information

Information may be used for a number of purposes: training within and outside the company; design of machinery, processes, materials and methods; inspection and control operations. The varied character of such uses implies that the information must be prepared in a suitable form for each type of user. Users themselves modify and reprocess the information into new information products. For example, an inspectorate may draft new rules and regulations, machine manufacturers may set new guidelines in the light of their involvement in safety standardization activities, producers of chemicals may compile their own Material Safety Data Sheets and labels, and trainers may produce manuals, audiovisuals and handouts. Some information may be of a specific, ready-to-use type that offers direct solutions to individual safety and health problems, while other pieces of information may set forth improvements in the production process, such as a safer method, machine or material. Despite their variety, the common element among all of these information products is that in order to be useful, in the end they will have to be employed by a company safety management system. Resources involving processes, materials and methods must be selected, purchased, transported and installed; people to use them selected and trained; follow-up and supervision exercised; and outputs must be distributed with steady attention to a wide range of information needs.

Computerized Safety Information Systems

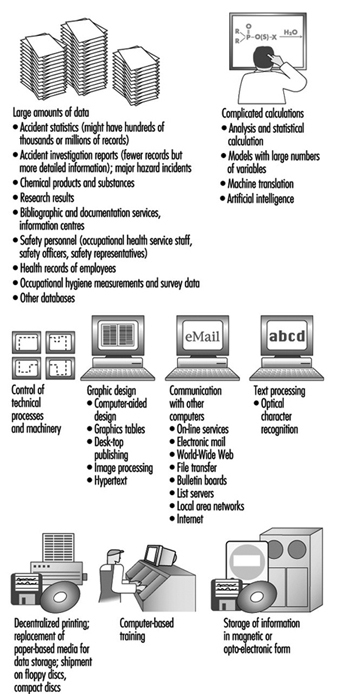

Computers are the latest link in the developmental process that ranges over all the information media, from spoken and written language to contemporary electronic systems. In fact, they may be able to do the work of all of the preceding types of information manipulation. Computers are particularly suitable for this purpose because of their ability to handle highly specific tasks involving large volumes of information. In the field of safety information, they may be especially useful for the types of need listed in figure 2.

Figure 2. Possible applications for computerized information