An Integrated Approach in the Design of Workstations

In ergonomics, the design of workstations is a critical task. There is general agreement that in any work setting, whether blue-collar or white-collar, a well-designed workstation furthers not only the health and well-being of the workers, but also productivity and the quality of the products. Conversely, the poorly designed workstation is likely to cause or contribute to the development of health complaints or chronic occupational diseases, as well as to problems with keeping product quality and productivity at a prescribed level.

To every ergonomist, the above statement may seem trivial. It is also recognized by every ergonomist that working life worldwide is full of not only ergonomic shortcomings, but blatant violations of basic ergonomic principles. It is clearly evident that there is a widespread unawareness with respect to the importance of workstation design among those responsible: production engineers, supervisors and managers.

It is noteworthy that there is an international trend with respect to industrial work which would seem to underline the importance of ergonomic factors: the increasing demand for improved product quality, flexibility and product delivery precision. These demands are not compatible with a conservative view regarding the design of work and workplaces.

Although in the present context it is the physical factors of workplace design that are of chief concern, it should be borne in mind that the physical design of the workstation cannot in practice be separated from the organization of work. This principle will be made evident in the design process described in what follows. The quality of the end result of the process relies on three supports: ergonomic knowledge, integration with productivity and quality demands, and participation. The process of implementation of a new workstation must cater to this integration, and it is the main focus of this article.

Design considerations

Workstations are meant for work. It must be recognized that the point of departure in the workstation design process is that a certain production goal has to be achieved. The designer—often a production engineer or other person at middle-management level—develops internally a vision of the workplace, and starts to implement that vision through his or her planning media. The process is iterative: from a crude first attempt, the solutions become gradually more and more refined. It is essential that ergonomic aspects be taken into account in each iteration as the work progresses.

It should be noted that ergonomic design of workstations is closely related to ergonomic assessment of workstations. In fact, the structure to be followed here applies equally to the cases where the workstation already exists or when it is in a planning stage.

In the design process, there is a need for a structure which ensures that all relevant aspects be considered. The traditional way to handle this is to use checklists containing a series of those variables which should be taken into account. However, general purpose checklists tend to be voluminous and difficult to use, since in a particular design situation only a fraction of the checklist may be relevant. Furthermore, in a practical design situation, some variables stand out as being more important than others. A methodology to consider these factors jointly in a design situation is required. Such a methodology will be proposed in this article.

Recommendations for workstation design must be based on a relevant set of demands. It should be noted that it is in general not enough to take into account threshold limit values for individual variables. A recognized combined goal of productivity and conservation of health makes it necessary to be more ambitious than in a traditional design situation. In particular, the question of musculoskeletal complaints is a major aspect in many industrial situations, although this category of problems is by no means limited to the industrial environment.

A Workstation Design Process

Steps in the process

In the workstation design and implementation process, there is always an initial need to inform users and to organize the project so as to allow for full user participation and in order to increase the chance of full employee acceptance of the final result. A treatment of this goal is not within the scope of the present treatise, which concentrates on the problem of arriving at an optimal solution for the physical design of the workstation, but the design process nonetheless allows the integration of such a goal. In this process, the following steps should always be considered:

- collection of user-specified demands

- prioritizing of demands

- transfer of demands into (a) technical specifications and (b) specifications in user terms

- iterative development of the workstation’s physical layout

- physical implementation

- trial period of production

- full production

- evaluation and identification of rest problems.

The focus here is on steps one through five. Many times, only a subset of all these steps is actually included in the design of workstations. There may be various reasons for this. If the workstation is a standard design, such as in some VDU working situations, some steps may duly be excluded. However, in most cases the exclusion of some of the steps listed would lead to a workstation of lower quality than what can be considered acceptable. This can be the case when economic or time constraints are too severe, or when there is sheer neglect due to lack of knowledge or insight at management level.

Collection of user-specified demands

It is essential to identify the user of the workplace as any member of the production organization who may be able to contribute qualified views on its design. Users may include, for instance, the workers, the supervisors, the production planners and production engineers, as well as the safety steward. Experience shows clearly that these actors all have their unique knowledge which should be made use of in the process.

The collection of the user-specified demands should meet a number of criteria:

- Openness. There should be no filter applied in the initial stage of the process. All points of view should be noted without voiced criticism.

- Non-discrimination. Viewpoints from every category should be treated equally at this stage of the process. Special consideration should be given to the fact that some persons may be more outspoken than others, and that there is a risk that they may silence some of the other actors.

- Development through dialogue. There should be an opportunity to adjust and develop the demands through a dialogue between participants of different backgrounds. Prioritizing should be addressed as part of the process.

- Versatility. The process of collection of user-specified demands should be reasonably economical and not require the involvement of specialist consultants or extensive time demands on the part of the participants.

The above set of criteria may be met by using a methodology based on quality function deployment (QFD) according to Sullivan (1986). Here, the user demands may be collected in a session where a mixed group of actors (not more than eight to ten people) is present. All participants are given a pad of removable self-sticking notes. They are asked to write down all workplace demands which they find relevant, each one on a separate slip of paper. Aspects relating to work environment and safety, productivity and quality should be covered. This activity may continue for as long as found necessary, typically ten to fifteen minutes. After this session, one after the other of the participants is asked to read out his or her demands and to stick the notes on a board in the room where everyone in the group can see them. The demands are grouped into natural categories such as lighting, lifting aids, production equipment, reaching requirements and flexibility demands. After the completion of the round, the group is given the opportunity to discuss and to comment on the set of demands, one category at a time, with respect to relevance and priority.

The set of user-specified demands collected in a process such as the one described in the above forms one of the bases for the development of the demand specification. Additional information in the process may be produced by other categories of actors, for example, product designers, quality engineers, or economists; however, it is vital to realize the potential contribution that the users can make in this context.

Prioritizing and demand specification

With respect to the specification process, it is essential that the different types of demands be given consideration according to their respective importance; otherwise, all aspects that have been taken into account will have to be considered in parallel, which may tend to make the design situation complex and difficult to handle. This is why checklists, which need to be elaborate if they are to serve the purpose, tend to be difficult to manage in a particular design situation.

It may be difficult to devise a priority scheme which serves all types of workstations equally well. However, on the assumption that manual handling of materials, tools or products is an essential aspect of the work to be carried out in the workstation, there is a high probability that aspects associated with musculoskeletal load will be at the top of the priority list. The validity of this assumption may be checked in the user demand collection stage of the process. Relevant user demands may be, for instance, associated with muscular strain and fatigue, reaching, seeing, or ease of manipulation.

It is essential to realize that it may not be possible to transform all user-specified demands into technical demand specifications. Although such demands may relate to more subtle aspects such as comfort, they may nevertheless be of high relevance and should be considered in the process.

Musculoskeletal load variables

In line with the above reasoning, we shall here apply the view that there is a set of basic ergonomic variables relating to musculoskeletal load which need to be taken into account as a priority in the design process, in order to eliminate the risk of work-related musculosketal disorders (WRMDs). This type of disorder is a pain syndrome, localized in the musculoskeletal system, which develops over long periods of time as a result of repeated stresses on a particular body part (Putz-Anderson 1988). The essential variables are (e.g., Corlett 1988):

- muscular force demand

- working posture demand

- time demand.

With respect to muscular force, criteria setting may be based on a combination of biomechanical, physiological and psychological factors. This is a variable that is operationalized through measurement of output force demands, in terms of handled mass or required force for, say, the operation of handles. Also, peak loads in connection with highly dynamic work may have to be taken into account.

Working posture demands may be evaluated by mapping (a) situations where the joint structures are stretched beyond the natural range of movement, and (b) certain particularly awkward situations, such as kneeling, twisting, or stooped postures, or work with the hand held above shoulder level.

Time demands may be evaluated on the basis of mapping (a) short-cycle, repetitive work, and (b) static work. It should be noted that static work evaluation may not exclusively concern maintaining a working posture or producing a constant output force over lengthy periods of time; from the point of view of the stabilizing muscles, particularly in the shoulder joint, seemingly dynamic work may have a static character. It may thus be necessary to consider lengthy periods of joint mobilization.

The acceptability of a situation is of course based in practice on the demands on the part of the body that is under the highest strain.

It is important to note that these variables should not be considered one at a time but jointly. For instance, high force demands may be acceptable if they occur only occasionally; lifting the arm above shoulder level once in a while is not normally a risk factor. But combinations among such basic variables must be considered. This tends to make criteria setting difficult and involved.

In the Revised NIOSH equation for the design and evaluation of manual handling tasks (Waters et al. 1993), this problem is addressed by devising an equation for recommended weight limits which takes into account the following mediating factors: horizontal distance, vertical lifting height, lifting asymmetry, handle coupling and lifting frequency. In this way, the 23-kilogram acceptable load limit based on biomechanical, physiological and psychological criteria under ideal conditions, may be modified substantially upon taking into account the specifics of the working situation. The NIOSH equation provides a base for evaluation of work and workplaces involving lifting tasks. However, there are severe limitations as to the usability of the NIOSH equation: for instance, only two-handed lifts may be analysed; scientific evidence for analysis of one-handed lifts is still inconclusive. This illustrates the problem of applying scientific evidence exclusively as a basis for work and workplace design: in practice, scientific evidence must be merged with educated views of persons who have direct or indirect experience of the type of work considered.

The cube model

Ergonomic evaluation of workplaces, taking into account the complex set of variables which need to be considered, is to a large extent a communications problem. Based on the prioritizing discussion described above, a cube model for ergonomic evaluation of workplaces was developed (Kadefors 1993). Here the prime goal was to develop a didactic tool for communication purposes, based on the assumption that output force, posture and time measures in a great majority of situations constitute interrelated, prioritized basic variables.

For each one of the basic variables, it is recognized that the demands may be grouped with respect to severity. Here, it is proposed that such a grouping may be made in three classes: (1) low demands, (2) medium demands or (3) high demands. The demand levels may be set either by using whatever scientific evidence is available or by taking a consensus approach with a panel of users. These two alternatives are of course not mutually exclusive, and may well entail similar results, but probably with different degrees of generality.

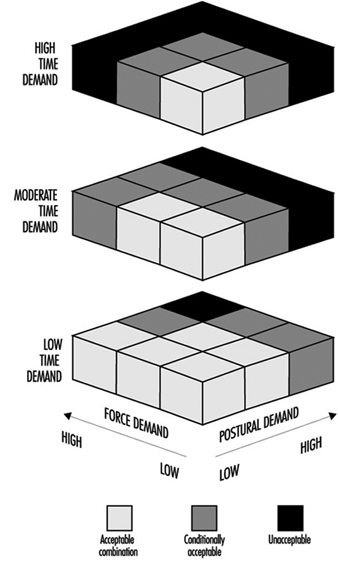

As noted above, combinations of the basic variables determine to a large extent the risk level with respect to the development of musculoskeletal complaints and cumulative trauma disorders. For instance, high time demands may render a working situation unacceptable in cases where there are also at least medium level demands with respect to force and posture. It is essential in the design and assessment of workplaces that the most important variables be considered jointly. Here a cube model for such evaluation purposes is proposed. The basic variables—force, posture and time—constitute the three axes of the cube. For each combination of demands a subcube may be defined; in all, the model incorporates 27 such subcubes (see figure 1).

Figure 1. The "cube model" for ergonomics assessment. Each cube represents a combination of demands relating to force, posture and time. Light: acceptable combination; gray: conditionally acceptable; black: unacceptable

An essential aspect of the model is the degree of acceptability of the demand combinations. In the model, a three-zone classification scheme is proposed for acceptability: (1) the situation is acceptable, (2) the situation is conditionally acceptable or (3) the situation is unacceptable. For didactic purposes, each subcube may be given a certain texture or colour (say, green-yellow-red). Again, the assessment may be user-based or based on scientific evidence. The conditionally acceptable (yellow) zone means that “there exists a risk of disease or injury that cannot be neglected, for the whole or a part of the operator population in question” (CEN 1994).

In order to develop this approach, it is useful to consider a case: the evaluation of load on the shoulder in moderately paced one-handed materials handling. This is a good example, since in this type of situation, it is normally the shoulder structures that are under the heaviest strain.

With respect to the force variable, classification may be based in this case on handled mass. Here, low force demand is identified as levels below 10% of maximal voluntary lifting capacity (MVLC), which amounts to approximately 1.6 kg in an optimal working zone. High force demand requires more than 30% MVLC, approximately 4.8 kg. Medium force demand falls in between these limits. Low postural strain is when the upper arm is close to the thorax. High postural strain is when humeral abduction or flexion exceeds 45°. Medium postural strain is when the abduction/flexion angle is between 15° and 45°. Low time demand is when the handling occupies less than one hour per working day on and off, or continuously for less than 10 minutes per day. High time demand is when the handling takes place for more than four hours per working day, or continuously for more than 30 minutes (sustained or repetitively). Medium time demand is when the exposure falls between these limits.

In figure 1, degrees of acceptability have been assigned to combinations of demands. For instance, it is seen that high time demands may only be combined with combined low force and postural demands. Moving from unacceptable to acceptable may be undertaken by reducing demands in either dimension, but reduction in time demands is the most efficient way in many cases. In other words, in some cases workplace design should be altered, in other cases it may be more efficient to change the organization of work.

Using a consensus panel with a set of users for definition of demand levels and classification of degree of acceptability may enhance the workstation design process considerably, as considered below.

Additional variables

In addition to the basic variables considered above, a set of variables and factors characterizing the workplace from an ergonomics point of view has to be taken into account, depending upon the particular conditions of the situation to be analysed. They include:

- precautions to reduce risks for accidents

- specific environmental factors such as noise, lighting and ventilation

- exposure to climatic factors

- exposure to vibration (from hand-held tools or whole body)

- ease of meeting productivity and quality demands.

To a large extent these factors may be considered one at a time; hence the checklist approach may be useful. Grandjean (1988) in his textbook covers the essential aspects that usually need to be taken into account in this context. Konz (1990) in his guidelines provides for workstation organization and design a set of leading questions focusing on worker-machine interfacing in manufacturing systems.

In the design process followed here, the checklist should be read in conjunction with the user-specified demands.

A Workstation Design Example: Manual Welding

As an illustrative (hypothetical) example, the design process leading to implementation of a workstation for manual welding (Sundin et al. 1994) is described here. Welding is an activity frequently combining high demands for muscular force with high demands for manual precision. The work has a static character. The welder is often doing welding exclusively. The welding work environment is generally hostile, with a combination of exposure to high noise levels, welding smoke and optical radiation.

The task was to devise a workplace for manual MIG (metal inert gas) welding of medium size objects (up to 300 kg) in a workshop environment. The workstation had to be flexible since there was a variety of objects to be manufactured. There were high demands for productivity and quality.

A QFD process was carried out in order to provide a set of workstation demands in user terms. Welders, production engineers and product designers were involved. User demands, which are not listed here, covered a wide range of aspects including ergonomics, safety, productivity and quality.

Using the cube model approach, the panel identified, by consensus, limits between high, moderate and low load:

- Force variable. Less than 1 kg handled mass is termed a low load, whereas more than 3 kg is considered a high load.

- Postural strain variable. Working positions implying high strain are those involving elevated arms, twisted or deep forward-flexed positions, and kneeling positions, and also include situations where the wrist is held in extreme flexion/extension or deviation. Low strain occurs where the posture is straight upright standing or sitting and where hands are in optimal working zones.

- Time variable. Less than 10% of the working time devoted to welding is considered low demand, whereas more than 40% of total working time is termed high demand. Medium demands occur when the variable falls between the limits given above, or when the situation is unclear.

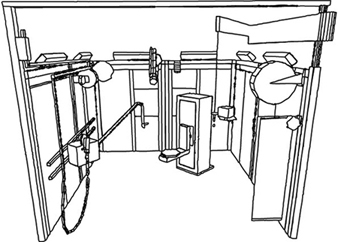

It was clear from assessment using the cube model (figure 1) that high time demands could not be accepted if there were concurrent high or moderate demands in terms of force and postural strain. In order to reduce these demands, mechanized object handling and tool suspension was deemed a necessity. There was consensus developed around this conclusion. Using a simple computer-aided design (CAD) program (ROOMER), an equipment library was created. Various workplace station layouts could be developed very easily and modified in close interaction with the users. This design approach has significant advantages compared with merely looking at plans. It gives the user an immediate vision of what the intended workplace may look like.

Figure 2. A CAD version of a workstation for manual welding, arrived at in the design process

Figure 2 shows the welding workstation arrived at using the CAD system. It is a workplace which reduces the force and posture demands, and which meets nearly all the residual user demands put forward.

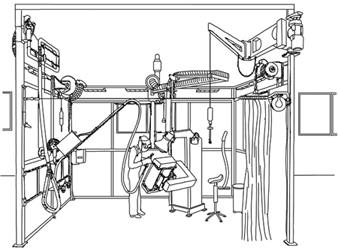

Figure 3. The welding workstation implemented

On the basis of the results of the first stages of the design process, a welding workplace (figure 3) was implemented. Assets of this workplace include:

- Work in the optimized zone is facilitated using a computerized handling device for welding objects. There is an overhead hoist for transportation purposes. As an alternative, a balanced lifting device is supplied for easy object handling.

- The welding gun and grinding machine are suspended, thus reducing force demands. They can be positioned anywhere around the welding object. A welding chair is supplied.

- All media come from above, which means that there are no cables on the floor.

- The workstation has lighting at three levels: general, workplace and process. The workplace lighting comes from ramps above the wall elements. The process lighting is integrated in the welding smoke ventilation arm.

- The workstation has ventilation at three levels: general displacement ventilation, workplace ventilation using a movable arm, and integrated ventilation in the MIG welding gun. The workplace ventilation is controlled from the welding gun.

- There are noise-absorbing wall elements on three sides of the workplace. A transparent welding curtain covers the fourth wall. This makes it possible for the welder to keep informed of what happens in the workshop environment.

In a real design situation, compromises of various kinds may have to be made, due to economic, space and other constraints. It should be noted, however, that licensed welders are hard to come by for the welding industry around the world, and they represent a considerable investment. Nearly no welders go into normal retirement as active welders. Keeping the skilled welder on the job is beneficial for all parties involved: welder, company and society. For instance, there are very good reasons why equipment for object handling and positioning should be an integral constituent of many welding workplaces.

Data for Workstation Design

In order to be able to design a workplace properly, extensive sets of basic information may be needed. Such information includes anthropometric data of user categories, lifting strength and other output force capacity data of male and female populations, specifications of what constitutes optimal working zones and so forth. In the present article, references to some key papers are given.

The most complete treatment of virtually all aspects of work and workstation design is probably still the textbook by Grandjean (1988). Information on a wide range of anthropometric aspects relevant to workstation design is presented by Pheasant (1986). Large amounts of biomechanical and anthropometric data are given by Chaffin and Andersson (1984). Konz (1990) has presented a practical guide to workstation design, including many useful rules of thumb. Evaluation criteria for the upper limb, particularly with reference to cumulative trauma disorders, have been presented by Putz-Anderson (1988). An assessment model for work with hand tools was given by Sperling et al. (1993). With respect to manual lifting, Waters and co-workers have developed the revised NIOSH equation, summarizing existing scientific knowledge on the subject (Waters et al. 1993). Specification of functional anthropometry and optimal working zones have been presented by, for example, Rebiffé, Zayana and Tarrière (1969) and Das and Grady (1983a, 1983b). Mital and Karwowski (1991) have edited a useful book reviewing various aspects relating in particular to the design of industrial workplaces.

The large amount of data needed to design workstations properly, taking all relevant aspects into account, will make necessary the use of modern information technology by production engineers and other responsible people. It is likely that various types of decision-support systems will be made available in the near future, for instance in the form of knowledge-based or expert systems. Reports on such developments have been given by, for example, DeGreve and Ayoub (1987), Laurig and Rombach (1989), and Pham and Onder (1992). However, it is an extremely difficult task to devise a system making it possible for the end-user to have easy access to all relevant data needed in a specific design situation.