Hearing Protectors

No one knows when people first discovered that covering the ears with the flats of the hands or plugging up the ear canals with one’s fingers was effective in reducing the level of unwanted sound—noise—but the basic technique has been in use for generations as the last line of defence against loud sound. Unfortunately, this level of technology precludes the use of most others. Hearing protectors, an obvious solution to the problem, are a form of noise control in that they block the path of the noise from the source to the ear. They come in various forms, as depicted in figure 1.

Figure 1. Examples of different types of hearing protectors

An earplug is a device worn in the external ear canal. Premolded earplugs are available in one or more standard sizes intended to fit into the ear canals of most people. A formable, user-molded earplug is made of a pliable material that is shaped by the wearer to fit into the ear canal to form an acoustic seal. A custom-molded earplug is individually made to fit the particular ear of the wearer. Earplugs can be made from vinyl, silicone, elastomer formulations, cotton and wax, spun glass wool, and slow-recovery closed-cell foam.

A semi-insert earplug, also called an ear-canal cap, is worn against the opening of the external ear canal: the effect is similar to plugging one’s ear canal with a fingertip. Semi-insert devices are manufactured in one size and are designed to fit most ears. This sort of device is held in place by a lightweight headband with mild tension.

An earmuff is a device composed of a headband and two circumaural cups that are usually made of plastic. The headband may be made of metal or plastic. The circumaural ear cup completely encloses the outer ear and seals against the side of the head with a cushion. The cushion may be made of foam or it may be filled with fluid. Most earmuffs have a lining inside the ear cup to absorb the sound that is transmitted through the shell of the ear cup in order to improve the attenuation above approximately 2,000 Hz. Some earmuffs are designed so that the headband may be worn over the head, behind the neck or under the chin, although the amount of protection they afford may be different for each headband position. Other earmuffs are designed to fit on “hard hats.” These may offer less protection because the hard-hat attachment makes it more difficult to adjust the earmuff and they do not fit as wide a range of head sizes as do those with headbands.

In the United States there are 53 manufacturers and distributors of hearing protectors who, as of July 1994, sold 86 models of earplugs, 138 models of earmuffs, and 17 models of semi-insert hearing protectors. In spite of the diversity of hearing protectors, foam earplugs designed for one-time use account for more than half of the hearing protectors in use in the United States.

Last line of defence

The most effective way to avoid noise-induced hearing loss is to stay out of hazardous noise areas. In many work settings it is possible to redesign the manufacturing process so that operators work in enclosed, sound-attenuating control rooms. The noise is reduced in these control rooms to the point where it is not hazardous and where speech communication is not impaired. The next most effective way to avoid noise-induced hearing loss is to reduce the noise at the source so that it is no longer hazardous. This is often done by designing quiet equipment or retrofitting noise control devices to existing equipment.

When it is not possible to avoid the noise or to reduce the noise at the source, hearing protection becomes the last resort. As the last line of defence, having no backup, its effectiveness can often be abridged.

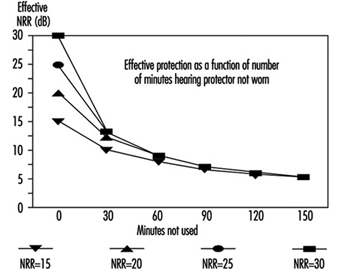

One of the ways to diminish the effectiveness of hearing protectors is to use them less than 100% of the time. Figure 2 shows what happens. Eventually, no matter how much protection is afforded by design, protection is reduced as percent of wearing time decreases. Wearers who remove an earplug or lift an earmuff to talk with fellow workers in noisy environments can severely reduce the amount of protection they receive.

Figure 2. Decrease in effective protection as time of non-use during an 8-hour day increases (based on 3-dB exchange rate)

The Rating Systems and How to Use Them

There are many ways to rate hearing protectors. The most common methods are the single-number systems such as the Noise Reduction Rating (NRR) (EPA 1979) used in the United States and the Single Number Rating (SNR), used in Europe (ISO 1994). Another European rating method is the HML (ISO 1994) that uses three numbers to rate protectors. Finally, there are methods based on the attenuation of the hearing protectors for each of the octave bands, called the long or octave-band method in the United States and the assumed protection value method in Europe (ISO 1994).

All of these methods use the real-ear attenuation at threshold values of the hearing protectors as determined in laboratories according to relevant standards. In the United States, attenuation testing is done in accordance with ANSI S3.19, Method for the Measurement of Real-Ear Protection of Hearing Protectors and Physical Attenuation of Earmuffs (ANSI 1974). Although this standard has been replaced by a newer one (ANSI 1984), the US Environmental Protection Agency (EPA) controls the NRR on hearing protector labels and requires the older standard to be used. In Europe attenuation testing is done in accordance with ISO 4869-1 (ISO 1990).

In general, the laboratory methods require that sound-field hearing thresholds be determined both with the protectors fitted and with the ears open. In the United States the hearing protector must be fitted by the experimenter, while in Europe the subject, assisted by the experimenter, performs this task. The difference between the protectors-fitted and ears-open sound field thresholds is the real-ear attenuation at threshold. Data are collected for a group of subjects, presently ten in the United States with three trials each and 16 in Europe with one trial each. The average attenuation and associated standard deviations are calculated for each octave band tested.

For purposes of discussion, the NRR method and the long method are described and illustrated in table 1.

Table 1. Example calculation of the Noise Reduction Rating (NRR) of a hearing protector

Procedure:

- Tabulate the sound pressure levels of pink noise, arbitrarily set for simplicity of computation to a level of 100 dB in each octave band.

- Tabulate the adjustments for the C-weighting scale at each octave-band centre frequency.

- Add lines 1 and 2 to obtain the C-weighted octave-band levels and logarithmically combine the C-weighted octave-band levels to determine the C-weighted sound pressure level.

- Tabulate the adjustments for the A-weighting scale at each octave-band centre frequency.

- Add line 1 and line 4 to obtain the A-weighted octave-band levels.

- Tabulate the attenuation provided by the device.

- Tabulate the standard deviations of attenuation (times 2) provided by the device.

- Subtract the values of the mean attenuations (step 6) and add the values of the standard deviations times 2 (step 7) to the A-weighted values (step 5) to obtain the estimated A-weighted octave-band sound levels under the device as it was fitted and tested in the laboratory. Combine the A-weighted octave-band levels logarithmically to obtain the A-weighted sound level effective when the device is worn.

- Subtract the A-weighted sound pressure level (step 8) and a 3-dB safety factor from the C-weighted sound pressure level (step 3) to obtain the NRR.

|

Steps |

Octave-band center frequency in Hz |

|||||||

|

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

dBX |

|

|

1. Assumed octave-band level of noise |

100.0 |

100.0 |

100.0 |

100.0 |

100.0 |

100.0 |

100.0 |

|

|

2. C-weighting correction |

–0.2 |

0.0 |

0.0 |

0.0 |

–0.2 |

–0.8 |

–3.0 |

|

|

3. C-weighted octave-band levels |

99.8 |

100.0 |

100.0 |

100.0 |

99.8 |

99.2 |

97.0 |

107.9 dBC |

|

4. A-weighting correction |

–16.1 |

–8.6 |

–3.2 |

0.0 |

+1.2 |

+1.0 |

–1.1 |

|

|

5. A-weighted octave-band levels |

83.9 |

91.4 |

96.8 |

100.0 |

101.2 |

101.0 |

98.9 |

|

|

6. Attenuation of hearing protector |

27.4 |

26.6 |

27.5 |

27.0 |

32.0 |

46.01 |

44.22 |

|

|

7. Standard deviation × 2 |

7.8 |

8.4 |

9.4 |

6.8 |

8.8 |

7.33 |

12.84 |

|

|

8. Estimated protected A-weighted octave band levels |

64.3 |

73.2 |

78.7 |

79.8 |

78.0 |

62.3 |

67.5 |

84.2 dBA |

|

9. NRR = 107.9 – 84.2 – 3 = 20.7 (Step 3 – Step 8 – 3 dB5 ) |

||||||||

1 Mean attenuation at 3000 and 4000 Hz.

2 Mean attenuation at 6000 and 8000 Hz.

3 Sum of standard deviations at 3000 and 4000 Hz.

4 Sum of standard deviations at 6000 and 8000 Hz.

5 The 3-dB correction factor is intended to account for spectrum uncertainty in that the noise in which the hearing protector is to be worn may deviate from the pink-noise spectrum used to calculate the NRR.

The NRR may be used to determine the protected noise level, that is, the effective A-weighted sound pressure level at the ear, by subtracting it from the C-weighted environmental noise level. Thus, if the C-weighted environmental noise level was 100 dBC and the NRR for the protector was 21 dB, the protected noise level would be 79 dBA (100–21 = 79). If only the A-weighted environmental noise level is known, a 7-dB correction is used (Franks, Themann and Sherris 1995). So, if the A-weighted noise level was 103 dBA, the protected noise level would be 89 dBA (103–[21-7] = 89).

The long method requires that the octave-band environmental noise levels be known; there is no shortcut. Many modern sound level meters can simultaneously measure octave-band, C-weighted and A-weighted environmental noise levels. However, no dosimeters currently provide octave-band data. Calculation by the long method is described below and shown in table 2.

Table 2. Example of the long method for computing the A-weighted noise reduction for a hearing protector in a known environmental noise

Procedure:

- Tabulate the measured octave-band levels of the environmental noise.

- Tabulate the adjustments for A-weighting at each octave-band centre frequency.

- Add the results of steps 1 and 2 to obtain the A-weighted octave-band levels. Combine the A-weighted octave-band levels logarithmically to obtain the A-weighted environmental noise level.

- Tabulate the attenuation provided by the device for each octave band.

- Tabulate the standard deviations of attenuation (times 2) provided by the device for each octave band.

- Obtain the A-weighted octave-band levels under the protector by subtracting the mean attenuation (step 4) from the A-weighted octave-band levels (step 3), and adding the standard deviation of the attenuations times 2 (step 5). The A-weighted octave band levels are combined logarithmically to obtain the A-weighted sound level effective when the hearing protector is worn. The estimated A-weighted noise reduction in a given environment is calculated by subtracting the A-weighted sound level under the protector from the A-weighted environmental noise level (the result of step 3 minus that of step 6).

|

Steps |

Octave-band center frequency in Hz |

|||||||

|

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

dBA |

|

|

1. Measured octave-band levels of noise |

85.0 |

87.0 |

90.0 |

90.0 |

85.0 |

82.0 |

80.0 |

|

|

2. A-weighting correction |

–16.1 |

–8.6 |

–3.2 |

0.0 |

+1.2 |

+1.0 |

–1.1 |

|

|

3. A-weighted octave-band levels |

68.9 |

78.4 |

86.8 |

90.0 |

86.2 |

83.0 |

78.9 |

93.5 |

|

4. Attenuation of hearing protector |

27.4 |

26.6 |

27.5 |

27.0 |

32.0 |

46.01 |

44.22 |

|

|

5. Standard deviation × 2 |

7.8 |

8.4 |

9.4 |

6.8 |

8.8 |

7.33 |

12.84 |

|

|

6. Estimated protected |

49.3 |

60.2 |

68.7 |

69.8 |

63.0 |

44.3 |

47.5 |

73.0 |

1 Mean attenuation at 3000 and 4000 Hz.

2 Mean attenuation at 6000 and 8000 Hz.

3 Sum of standard deviations at 3000 and 4000 Hz.

4 Sum of standard deviations at 6000 and 8000 Hz.

The subtractive standard deviation corrections in the long method and in the NRR computations are intended to use the laboratory variability measurements to adjust the estimates of protection to correspond to values expected for most of the users (98% with a 2-standard-deviation correction or 84% if a 1-standard-deviation correction is used) who wear the hearing protector under conditions identical to those involved in the testing. The appropriateness of this adjustment is, of course, heavily dependent upon the validity of the laboratory-estimated standard deviations.

Comparison of the long method and the NRR

The long method and the NRR computations may be compared by subtracting the NRR (20.7) from the C-weighted sound pressure level for the spectrum in table 2 (95.2 dBC) to predict the effective level when the hearing protector is worn, namely 74.5 dBA. This compares favourably to the value of 73.0 dBA derived from the long method in table 2. Part of the disparity between the two estimates is due to the use of the approximate 3 dB spectral safety factor incorporated in line 9 of table 1. The spectral safety factor is intended to account for errors arising from the use of an assumed noise instead of an actual noise. Depending upon the slope of the spectrum and the shape of the attenuation curve of the hearing protector, the differences between the two methods may be greater than that shown in this example.

Reliability of test data

It is unfortunate that the attenuation values and their standard deviations as obtained in laboratories in the United States, and to a lesser extent in Europe, are not representative of those obtained by everyday wearers. Berger, Franks and Lindgren (1996) reviewed 22 real-world studies of hearing protectors and found that US laboratory values reported on the EPA-required label overestimated protection from 140 to almost 2000%. The overestimation was greatest for earplugs and least for earmuffs. Since 1987, the US Occupational Safety and Health Administration has recommended that the NRR be derated by 50% before calculations are made of noise levels under the hearing protector. In 1995, the US National Institute for Occupational Safety and Health (NIOSH) recommended that the NRR for earmuffs be derated by 25% that the NRR for formable earplugs be derated by 50% and that the NRR for premolded earplugs and semi inserts be derated by 70% before calculations of noise levels under the hearing protector are made (Rosenstock 1995).

Intra- and inter-laboratory variability

Another consideration, but of less impact than the real-world issues noted above, is within-laboratory validity and variability, as well as differences between facilities. Inter-laboratory variability can be substantial (Berger, Kerivan and Mintz 1982), affecting both the octave-band values and the computed NRRs, both in terms of absolute computations as well as rank ordering. Therefore, even rank ordering of hearing protectors based on attenuation values is best done at present only for data from a single laboratory.

Important Points for Selecting Protection

When a hearing protector is selected, there are several important points to be considered (Berger 1988). Foremost is that the protector will be adequate for the environmental noise in which it will be worn. The Hearing Conservation Amendment to the OSHA Noise Standard (1983) recommends that the noise level under the hearing protector be 85 dB or less. NIOSH has recommended that the noise level under the hearing protector be no higher than 82 dBA, so that risk of noise-induced hearing loss is minimal (Rosenstock 1995).

Second, the protector should not be overprotective. If the protected exposure level is more than 15 dB below the desired level, the hearing protector has too much attenuation and the wearer is considered to be overprotected, resulting in the wearer’s feeling isolated from the environment (BSI 1994). It may be difficult to hear speech and warning signals and wearers will temporarily either remove the protector when they need to communicate (as mentioned above) and verify warning signals or they will modify the protector to reduce its attenuation. In either case, the protection will usually be reduced to the point that hearing loss is no longer being prevented.

At present, accurate determination of protected noise levels is difficult since reported attenuations and standard deviations, along with their resultant NRRs, are inflated. However, using the derating factors recommended by the NIOSH should improve accuracy of such a determination in the short run.

Comfort is a critical issue. No hearing protector can be as comfortable as not wearing one at all. Covering or occluding the ears produces many unnatural sensations. These range from a change in the sound of one’s own voice due to the “occlusion effect” (see below), to a feeling of fullness of the ears or pressure on the head. Use of earmuffs or earplugs in hot environments may be uncomfortable because of the increase in perspiration. It will take time for wearers to get used to the sensations caused by hearing protectors and to some of the discomfort. However, when wearers experience such types of discomfort as headache from headband pressure or pain in the ear canals from earplug insertion, they should be fitted with alternative devices.

If earmuffs or reusable earplugs are used, a means to keep them clean should be provided. For earmuffs, wearers should have easy access to replaceable components such as ear cushions and ear cup liners. Wearers of disposable earplugs should have ready access to a fresh supply. If one intends to have earplugs reused, wearers should have access to earplug cleaning facilities. Wearers of custom-molded earplugs should have facilities to keep the earplugs clean and access to new earplugs when they have become damaged or worn out.

The average American worker is exposed to 2.7 occupational hazards each and every day (Luz et al. 1991). These hazards may require the use of other protective equipment such as “hard hats,” eye protection and respirators. It is important that any hearing protector selected be compatible with other safety equipment that is required. The NIOSH Compendium of Hearing Protective Devices (Franks, Themann and Sherris 1995) has tables that, among other things, list the compatibility of each hearing protector with other safety equipment.

The Occlusion Effect

The occlusion effect describes the increase in the efficiency with which bone-conducted sound is transmitted to the ear at frequencies below 2,000 Hz when the ear canal is sealed with a finger or an earplug, or is covered by an earmuff. The magnitude of the occlusion effect depends upon how the ear is occluded. The maximum occlusion effect occurs when the entrance to the ear canal is blocked. Earmuffs with large ear cups and earplugs that are deeply inserted cause less of an occlusion effect (Berger 1988). The occlusion effect often causes hearing protector wearers to object to wearing protection because they dislike the sound of their voices—louder, booming and muffled.

Communication Effects

Because of the occlusion effect that most hearing protectors cause, one’s own voice tends to sound louder—since the hearing protectors reduce the level of environmental noise, the voice sounds much louder than when the ears are open. To adjust for the increased loudness of one’s own speech, most wearers tend to lower their voice levels substantially, speaking more softly. Lowering the voice in a noisy environment where the listener is also wearing hearing protection contributes to the difficulty of communicating. Furthermore, even without an occlusion effect, most speakers raise their voice levels by only 5 to 6 dB for every 10 dB increase in environmental noise level (the Lombard effect). Thus, the combination of lowered voice level because of the use of hearing protection combined with inadequate elevation of voice level to make up for environmental noise has severe consequences on the ability of hearing-protector wearers to hear and understand each other in noise.

The Operation of Hearing Protectors

Earmuffs

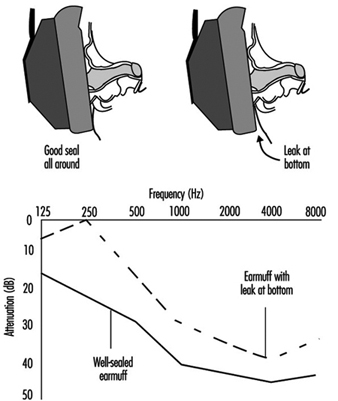

The basic function of earmuffs is to cover the outer ear with a cup that forms a noise-attenuating acoustic seal. The styles of the ear cup and the earmuff’s cushions as well as the tension provided by the headband determine, for the most part, how well the earmuff attenuates environmental noise. Figure 3 displays both an example of a well-fitted earmuff with a good seal all around the outer ear as well as an example of an earmuff with a leak underneath the cushion. The chart in figure 3 shows that while the tight-fitting earmuff has good attenuation at all frequencies, the one with a leak provides practically no low-frequency attenuation. Most earmuffs will provide attenuation approaching bone conduction, approximately 40 dB, for frequencies from 2,000 Hz and greater. The low-frequency attenuation properties of a tightly fitting earmuff are determined by design features and materials that include ear cup volume, the area of the ear cup opening, headband force and mass.

Figure 3. Well-fitted and poorly fitted earmuffs and their attenuation consequences

Earplugs

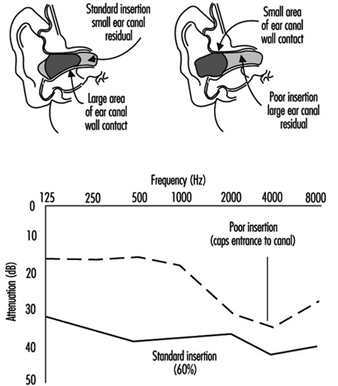

Figure 4 displays an example of a well-fitted, fully inserted foam earplug (about 60% of it extends into the ear canal) and an example of a poorly fitted, shallowly inserted foam earplug that just caps the ear canal entrance. The well-fitted earplug has good attenuation at all frequencies. The poorly fitted foam earplug has substantially less attenuation. The foam earplug, when fitted properly, can provide attenuation approaching bone conduction at many frequencies. In high-level noise, the differences in attenuation between a well-fitted and a poorly fitted foam earplug can be sufficient to either prevent or permit noise-induced hearing loss.

Figure 4. A well-fitted and a poorly fitted foam earplug and the attenuation consequences

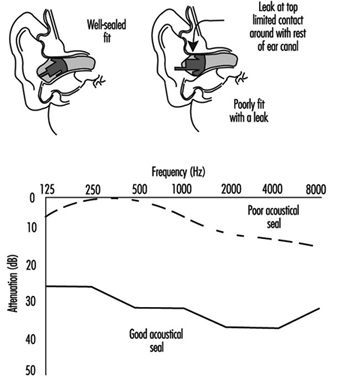

Figure 5 displays a well-fitted and poorly fitted premolded earplug. In general, premolded earplugs do not provide the same degree of attenuation as properly fitted foam earplugs or earmuffs. However, the well-fitted premolded earplug provides adequate attenuation for most industrial noises. The poorly fitted premolded earplug provides substantially less, and no attenuation at 250 and 500 Hz. It has been observed that for some wearers, there is actually gain at these frequencies, meaning that the protected noise level is actually higher than the environmental noise level, putting the wearer at more risk of developing noise-induced hearing loss than if the protector were not worn at all.

Figure 5. A well-fitted and a poorly fitted premolded earplug

Dual hearing protection

For some environmental noises, especially when daily equivalent exposures exceed about 105 dBA, a single hearing protector may be insufficient. In such situations wearers can use both earmuffs and earplugs in combination to achieve about 3 to 10 dB of extra protection, limited primarily by the bone conduction of the head of the wearer. Attenuation changes very little when different earmuffs are used with the same earplug, but changes greatly when different earplugs are used with the same earmuff. For dual protection, the choice of the earplug is critical for attenuation below 2,000 Hz, but at and above 2,000 Hz essentially all earmuff/earplug combinations provide attenuation approximately equal to the skull’s bone-conduction pathways.

Interference from glasses and head-worn personal protective equipment

Safety glasses, or other devices such as respirators that interfere with the earmuff’s circumaural seal, can degrade earmuff attenuation. For example, eye wear can reduce attenuation in individual octave bands by 3 to 7 dB.

Flat-response devices

A flat-attenuation earmuff or earplug is one that provides approximately equal attenuation for frequencies from 100 to 8,000 Hz. These devices maintain the same frequency response as the unoccluded ear, providing undistorted audition of signals (Berger 1991). A normal earmuff or earplug may sound as if the treble of the signal has been turned down, in addition to the overall lowering of the sound level. The flat-attenuation earmuff or earplug will sound as if only the volume has been reduced since its attenuation characteristics are “tuned” by the use of resonators, dampers and diaphragms. Flat-attenuation characteristics can be important for wearers having high-frequency hearing loss, for those for whom understanding speech while being protected is important, or for those for whom having high-quality sound is important, such as musicians. Flat attenuation devices are available as earmuffs and earplugs. One drawback of the flat-attenuation devices is that they don’t provide as much attenuation as conventional earmuffs and earplugs.

Passive amplitude-sensitive devices

A passive amplitude-sensitive hearing protector has no electronics and is designed to allow voice communications during quiet periods and provide little attenuation at low noise levels with protection increasing as the noise level increases. These devices contain orifices, valves, or diaphragms intended to produce this nonlinear attenuation, typically beginning once sound levels exceed 120 dB sound pressure levels (SPL). At sound levels below 120 dB SPL, orifice and valve-type devices typically act as vented earmolds, providing as much as 25 dB of attenuation at the higher frequencies, but very little attenuation at and below 1,000 Hz. Few occupational and recreational activities, other than shooting competitions (especially in outdoor environments), are appropriate if this type of hearing protector is expected to be truly effective in preventing noise-induced hearing loss.

Active amplitude-sensitive devices

An active amplitude-sensitive hearing protector has electronics and design goals similar to a passive amplitude-sensitive protector. These systems employ a microphone placed on the exterior of the ear cup or ported to the lateral surface of the earplug. The electronic circuit is designed to provide less and less amplification, or in some cases to completely shut down, as the environmental noise level increases. At the levels of normal conversational speech, these devices provide unity gain, (the loudness of speech is the same as if the protector wasn’t worn), or even a small amount of amplification. The goal is to keep the sound level under the earmuff or earplug to less than a 85 dBA diffuse-field equivalent. Some of the units built into earmuffs have a channel for each ear, thus allowing some level of localization to be maintained. Others have only one microphone. The fidelity (naturalness) of these systems varies among manufacturers. Because of the electronics package built into the ear cup which is necessary to have an active level-dependent system, these devices provide about four to six decibels less attenuation in their passive state, electronics turned off, than similar earmuffs without the electronics.

Active noise reduction

Active noise reduction, while an old concept, is a relatively new development for hearing protectors. Some units work by capturing the sound inside the ear cup, inverting its phase, and retransmitting the inverted noise into the ear cup to cancel the incoming sound. Other units work by capturing sound outside the ear cup, modifying its spectrum to account for the attenuation of the ear cup, and inserting the inverted noise into the ear cup, effectively using the electronics as a timing device so that the electrically inverted sound arrives in the ear cup at the same time as the noise transmitted through the ear cup. Active noise reduction is limited to the reduction of low-frequency noises below 1,000 Hz, with a maximum attenuation of 20 to 25 dB occurring at or below 300 Hz.

However, a portion of the attenuation provided by the active noise reduction system simply offsets the reduction in attenuation of the earmuffs that is caused by the inclusion in the ear cup of the very electronics which are required to effect the active noise reductions. At present these devices cost 10 to 50 times that of passive earmuffs or earplugs. If the electronics fail, the wearer may be inadequately protected and could experience more noise under the ear cup than if the electronics were simply shut off. As active noise cancellation devices become more popular, costs should diminish and their applicability may become more widespread.

The Best Hearing Protector

The best hearing protector is the one that the wearer will use willingly, 100% of the time. It is estimated that approximately 90% of noise-exposed workers in the manufacturing sector in the United States are exposed to noise levels of less than 95 dBA (Franks 1988). They need between 13 and 15 dB of attenuation to provide them with adequate protection. There are a wide array of hearing protectors that can provide sufficient attenuation. Finding the one that each worker will wear willingly 100% of the time is the challenge.