A lamp is an energy converter. Although it may carry out secondary functions, its prime purpose is the transformation of electrical energy into visible electromagnetic radiation. There are many ways to create light. The standard method for creating general lighting is the conversion of electrical energy into light.

Types of Light

Incandescence

When solids and liquids are heated, they emit visible radiation at temperatures above 1,000 K; this is known as incandescence.

Such heating is the basis of light generation in filament lamps: an electrical current passes through a thin tungsten wire, whose temperature rises to around 2,500 to 3,200 K, depending upon the type of lamp and its application.

There is a limit to this method, which is described by Planck’s Law for the performance of a black body radiator, according to which the spectral distribution of energy radiated increases with temperature. At about 3,600 K and above, there is a marked gain in emission of visible radiation, and the wavelength of maximum power shifts into the visible band. This temperature is close to the melting point of tungsten, which is used for the filament, so the practical temperature limit is around 2,700 K, above which filament evaporation becomes excessive. One result of these spectral shifts is that a large part of the radiation emitted is not given off as light but as heat in the infrared region. Filament lamps can thus be effective heating devices and are used in lamps designed for print drying, food preparation and animal rearing.

Electric discharge

Electrical discharge is a technique used in modern light sources for commerce and industry because of the more efficient production of light. Some lamp types combine the electrical discharge with photoluminescence.

An electric current passed through a gas will excite the atoms and molecules to emit radiation of a spectrum which is characteristic of the elements present. Two metals are commonly used, sodium and mercury, because their characteristics give useful radiations within the visible spectrum. Neither metal emits a continuous spectrum, and discharge lamps have selective spectra. Their colour rendering will never be identical to continuous spectra. Discharge lamps are often classed as high pressure or low pressure, although these terms are only relative, and a high-pressure sodium lamp operates at below one atmosphere.

Types of Luminescence

Photoluminescence occurs when radiation is absorbed by a solid and is then re-emitted at a different wavelength. When the re-emitted radiation is within the visible spectrum the process is called fluorescence or phosphorescence.

Electroluminescence occurs when light is generated by an electric current passed through certain solids, such as phosphor materials. It is used for self-illuminated signs and instrument panels but has not proved to be a practical light source for the lighting of buildings or exteriors.

Evolution of Electric Lamps

Although technological progress has enabled different lamps to be produced, the main factors influencing their development have been external market forces. For example, the production of filament lamps in use at the start of this century was possible only after the availability of good vacuum pumps and the drawing of tungsten wire. However, it was the large-scale generation and distribution of electricity to meet the demand for electric lighting that determined market growth. Electric lighting offered many advantages over gas- or oil-generated light, such as steady light that requires infrequent maintenance as well as the increased safety of having no exposed flame, and no local by-products of combustion.

During the period of recovery after the Second World War, the emphasis was on productivity. The fluorescent tubular lamp became the dominant light source because it made possible the shadow-free and comparatively heat-free lighting of factories and offices, allowing maximum use of the space. The light output and wattage requirements for a typical 1,500 mm fluorescent tubular lamp is given in table 1.

Table 1. Improved light output and wattage requirements of some typical 1,500 mm fluorescent tube lamps

|

Rating (W) |

Diameter (mm) |

Gas fill |

Light output (lumens) |

|

80 |

38 |

argon |

4,800 |

|

65 |

38 |

argon |

4,900 |

|

58 |

25 |

krypton |

5,100 |

|

50 |

25 |

argon |

5,100 |

By the 1970s oil prices rose and energy costs became a significant part of operating costs. Fluorescent lamps that produce the same amount of light with less electrical consumption were demanded by the market. Lamp design was refined in several ways. As the century closes there is a growing awareness of global environment issues. Better use of declining raw materials, recycling or safe disposal of products and the continuing concern over energy consumption (particularly energy generated from fossil fuels) are impacting on current lamp designs.

Performance Criteria

Performance criteria vary by application. In general, there is no particular hierarchy of importance of these criteria.

Light output: The lumen output of a lamp will determine its suitability in relation to the scale of the installation and the quantity of illumination required.

Colour appearance and colour rendering: Separate scales and numerical values apply to colour appearance and colour rendering. It is important to remember that the figures provide guidance only, and some are only approximations. Whenever possible, assessments of suitability should be made with actual lamps and with the colours or materials that apply to the situation.

Lamp life: Most lamps will require replacement several times during the life of the lighting installation, and designers should minimize the inconvenience to the occupants of odd failures and maintenance. Lamps are used in a wide variety of applications. The anticipated average life is often a compromise between cost and performance. For example, the lamp for a slide projector will have a life of a few hundred hours because the maximum light output is important to the quality of the image. By contrast, some roadway lighting lamps may be changed every two years, and this represents some 8,000 burning hours.

Further, lamp life is affected by operating conditions, and thus there is no simple figure that will apply in all conditions. Also, the effective lamp life may be determined by different failure modes. Physical failure such as filament or lamp rupture may be preceded by reduction in light output or changes in colour appearance. Lamp life is affected by external environmental conditions such as temperature, vibration, frequency of starting, supply voltage fluctuations, orientation and so on.

It should be noted that the average life quoted for a lamp type is the time for 50% failures from a batch of test lamps. This definition of life is not likely to be applicable to many commercial or industrial installations; thus practical lamp life is usually less than published values, which should be used for comparison only.

Efficiency: As a general rule the efficiency of a given type of lamp improves as the power rating increases, because most lamps have some fixed loss. However, different types of lamps have marked variation in efficiency. Lamps of the highest efficiency should be used, provided that the criteria of size, colour and lifetime are also met. Energy savings should not be at the expense of the visual comfort or the performance ability of the occupants. Some typical efficacies are given in table 2.

Table 2. Typical lamp efficacies

|

Lamp efficacies |

|

|

100 W filament lamp |

14 lumens/watt |

|

58 W fluorescent tube |

89 lumens/watt |

|

400 W high-pressure sodium |

125 lumens/watt |

|

131 W low-pressure sodium |

198 lumens/watt |

Main lamp types

Over the years, several nomenclature systems have been developed by national and international standards and registers.

In 1993, the International Electrotechnical Commission (IEC) published a new International Lamp Coding System (ILCOS) intended to replace existing national and regional coding systems. A list of some ILCOS short form codes for various lamps is given in table 3.

Table 3. International Lamp Coding System (ILCOS) short form coding system for some lamp types

|

Type (code) |

Common ratings (watts) |

Colour rendering |

Colour temperature (K) |

Life (hours) |

|

Compact fluorescent lamps (FS) |

5–55 |

good |

2,700–5,000 |

5,000–10,000 |

|

High-pressure mercury lamps (QE) |

80–750 |

fair |

3,300–3,800 |

20,000 |

|

High-pressure sodium lamps (S-) |

50–1,000 |

poor to good |

2,000–2,500 |

6,000–24,000 |

|

Incandescent lamps (I) |

5–500 |

good |

2,700 |

1,000–3,000 |

|

Induction lamps (XF) |

23–85 |

good |

3,000–4,000 |

10,000–60,000 |

|

Low-pressure sodium lamps (LS) |

26–180 |

monochromatic yellow colour |

1,800 |

16,000 |

|

Low-voltage tungsten halogen lamps (HS) |

12–100 |

good |

3,000 |

2,000–5,000 |

|

Metal halide lamps (M-) |

35–2,000 |

good to excellent |

3,000–5,000 |

6,000–20,000 |

|

Tubular fluorescent lamps (FD) |

4–100 |

fair to good |

2,700–6,500 |

10,000–15,000 |

|

Tungsten halogen lamps (HS) |

100–2,000 |

good |

3,000 |

2,000–4,000 |

Incandescent lamps

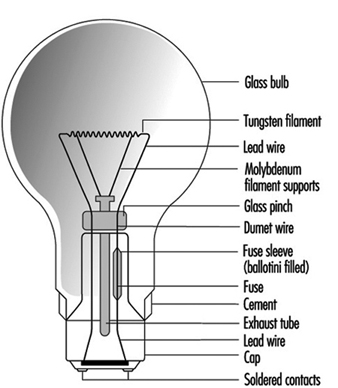

These lamps use a tungsten filament in an inert gas or vacuum with a glass envelope. The inert gas suppresses tungsten evaporation and lessens the envelope blackening. There is a large variety of lamp shapes, which are largely decorative in appearance. The construction of a typical General Lighting Service (GLS) lamp is given in figure 1.

Figure 1. Construction of a GLS lamp

Incandescent lamps are also available with a wide range of colours and finishes. The ILCOS codes and some typical shapes include those shown in table 4.

Table 4. Common colours and shapes of incandescent lamps, with their ILCOS codes

|

Colour/Shape |

Code |

|

Clear |

/C |

|

Frosted |

/F |

|

White |

/W |

|

Red |

/R |

|

Blue |

/B |

|

Green |

/G |

|

Yellow |

/Y |

|

Pear shaped (GLS) |

IA |

|

Candle |

IB |

|

Conical |

IC |

|

Globular |

IG |

|

Mushroom |

IM |

Incandescent lamps are still popular for domestic lighting because of their low cost and compact size. However, for commercial and industrial lighting the low efficacy generates very high operating costs, so discharge lamps are the normal choice. A 100 W lamp has a typical efficacy of 14 lumens/watt compared with 96 lumens/watt for a 36 W fluorescent lamp.

Incandescent lamps are simple to dim by reducing the supply voltage, and are still used where dimming is a desired control feature.

The tungsten filament is a compact light source, easily focused by reflectors or lenses. Incandescent lamps are useful for display lighting where directional control is needed.

Tungsten halogen lamps

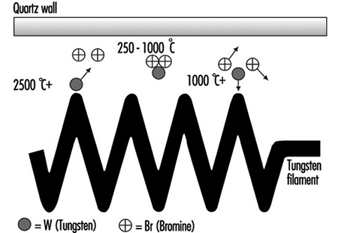

These are similar to incandescent lamps and produce light in the same manner from a tungsten filament. However the bulb contains halogen gas (bromine or iodine) which is active in controlling tungsten evaporation. See figure 2.

Figure 2. The halogen cycle

Fundamental to the halogen cycle is a minimum bulb wall temperature of 250 °C to ensure that the tungsten halide remains in a gaseous state and does not condense on the bulb wall. This temperature means bulbs made from quartz in place of glass. With quartz it is possible to reduce the bulb size.

Most tungsten halogen lamps have an improved life over incandescent equivalents and the filament is at a higher temperature, creating more light and whiter colour.

Tungsten halogen lamps have become popular where small size and high performance are the main requirement. Typical examples are stage lighting, including film and TV, where directional control and dimming are common requirements.

Low-voltage tungsten halogen lamps

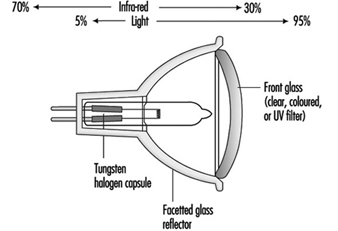

These were originally designed for slide and film projectors. At 12 V the filament for the same wattage as 230 V becomes smaller and thicker. This can be more efficiently focused, and the larger filament mass allows a higher operating temperature, increasing light output. The thick filament is more robust. These benefits were realized as being useful for the commercial display market, and even though it is necessary to have a step-down transformer, these lamps now dominate shop-window lighting. See figure 3.

Figure 3. Low-voltage dichroic reflector lamp

Although users of film projectors want as much light as possible, too much heat damages the transparency medium. A special type of reflector has been developed, which reflects only the visible radiation, allowing infrared radiation (heat) to pass through the back of lamp. This feature is now part of many low-voltage reflector lamps for display lighting as well as projector equipment.

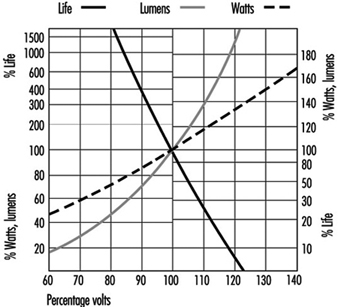

Voltage sensitivity: All filament lamps are sensitive to voltage variation, and light output and life are affected. The move to “harmonize” the supply voltage throughout Europe at 230 V is being achieved by widening the tolerances to which the generating authorities can operate. The move is towards ±10%, which is a voltage range of 207 to 253 V. Incandescent and tungsten halogen lamps cannot be operated sensibly over this range, so it will be necessary to match actual supply voltage to lamp ratings. See figure 4.

Figure 4. GLS filament lamps and supply voltage

Discharge lamps will also be affected by this wide voltage variation, so the correct specification of control gear becomes important.

Tubular fluorescent lamps

These are low pressure mercury lamps and are available as “hot cathode” and “cold cathode” versions. The former is the conventional fluorescent tube for offices and factories; “hot cathode” relates to the starting of the lamp by pre-heating the electrodes to create sufficient ionization of the gas and mercury vapour to establish the discharge.

Cold cathode lamps are mainly used for signage and advertising. See figure 5.

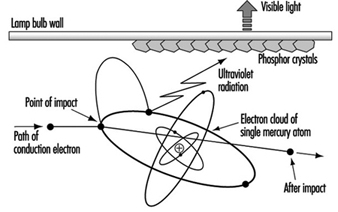

Figure 5. Principle of fluorescent lamp

Fluorescent lamps require external control gear for starting and to control the lamp current. In addition to the small amount of mercury vapour, there is a starting gas (argon or krypton).

The low pressure of mercury generates a discharge of pale blue light. The major part of the radiation is in the UV region at 254 nm, a characteristic radiation frequency for mercury. Inside of the tube wall is a thin phosphor coating, which absorbs the UV and radiates the energy as visible light. The colour quality of the light is determined by the phosphor coating. A range of phosphors are available of varying colour appearance and colour rendering.

During the 1950s phosphors available offered a choice of reasonable efficacy (60 lumens/watt) with light deficient in reds and blues, or improved colour rendering from “deluxe” phosphors of lower efficiency (40 lumens/watt).

By the 1970s new, narrow-band phosphors had been developed. These separately radiated red, blue and green light but, combined, produced white light. Adjusting the proportions gave a range of different colour appearances, all with similar excellent colour rendering. These tri-phosphors are more efficient than the earlier types and represent the best economic lighting solution, even though the lamps are more expensive. Improved efficacy reduces operating and installation costs.

The tri-phosphor principle has been extended by multi-phosphor lamps where critical colour rendering is necessary, such as for art galleries and industrial colour matching.

The modern narrow-band phosphors are more durable, have better lumen maintenance, and increase lamp life.

Compact fluorescent lamps

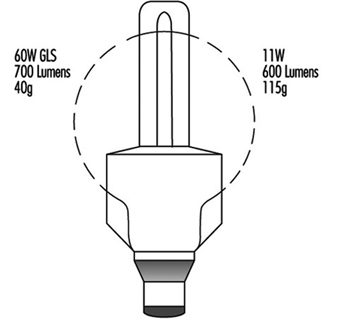

The fluorescent tube is not a practical replacement for the incandescent lamp because of its linear shape. Small, narrow-bore tubes can be configured to approximately the same size as the incandescent lamp, but this imposes a much higher electrical loading on the phosphor material. The use of tri-phosphors is essential to achieve acceptable lamp life. See figure 6.

Figure 6. Four-leg compact fluorescent

All compact fluorescent lamps use tri-phosphors, so, when they are used together with linear fluorescent lamps, the latter should also be tri-phosphor to ensure colour consistency.

Some compact lamps include the operating control gear to form retro-fit devices for incandescent lamps. The range is increasing and enables easy upgrading of existing installations to more energy-efficient lighting. These integral units are not suitable for dimming where that was part of the original controls.

High-frequency electronic control gear: If the normal supply frequency of 50 or 60 Hz is increased to 30 kHz, there is a 10% gain in efficacy of fluorescent tubes. Electronic circuits can operate individual lamps at such frequencies. The electronic circuit is designed to provide the same light output as wire-wound control gear, from reduced lamp power. This offers compatibility of lumen package with the advantage that reduced lamp loading will increase lamp life significantly. Electronic control gear is capable of operating over a range of supply voltages.

There is no common standard for electronic control gear, and lamp performance may differ from the published information issued by the lamp makers.

The use of high-frequency electronic gear removes the normal problem of flicker, to which some occupants may be sensitive.

Induction lamps

Lamps using the principle of induction have recently appeared on the market. They are low-pressure mercury lamps with tri-phosphor coating and as light producers are similar to fluorescent lamps. The energy is transferred to the lamp by high-frequency radiation, at approximately 2.5 MHz from an antenna positioned centrally within the lamp. There is no physical connection between the lamp bulb and the coil. Without electrodes or other wire connections the construction of the discharge vessel is simpler and more durable. Lamp life is mainly determined by the reliability of the electronic components and the lumen maintenance of the phosphor coating.

High-pressure mercury lamps

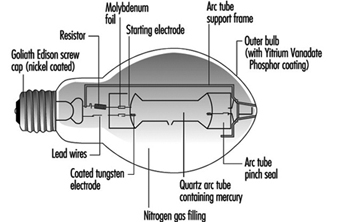

High-pressure discharges are more compact and have higher electrical loads; therefore, they require quartz arc tubes to withstand the pressure and temperature. The arc tube is contained in an outer glass envelope with a nitrogen or argon-nitrogen atmosphere to reduce oxidation and arcing. The bulb effectively filters the UV radiation from the arc tube. See figure 7.

Figure 7. Mercury lamp construction

At high pressure, the mercury discharge is mainly blue and green radiation. To improve the colour a phosphor coating of the outer bulb adds red light. There are deluxe versions with an increased red content, which give higher light output and improved colour rendering.

All high-pressure discharge lamps take time to reach full output. The initial discharge is via the conducting gas fill, and the metal evaporates as the lamp temperature increases.

At the stable pressure the lamp will not immediately restart without special control gear. There is a delay while the lamp cools sufficiently and the pressure reduces, so that the normal supply voltage or ignitor circuit is adequate to re-establish the arc.

Discharge lamps have a negative resistance characteristic, and so the external control gear is necessary to control the current. There are losses due to these control gear components so the user should consider total watts when considering operating costs and electrical installation. There is an exception for high-pressure mercury lamps, and one type contains a tungsten filament which both acts as the current limiting device and adds warm colours to the blue/green discharge. This enables the direct replacement of incandescent lamps.

Although mercury lamps have a long life of about 20,000 hours, the light output will fall to about 55% of the initial output at the end of this period, and therefore the economic life can be shorter.

Metal halide lamps

The colour and light output of mercury discharge lamps can be improved by adding different metals to the mercury arc. For each lamp the dose is small, and for accurate application it is more convenient to handle the metals in powder form as halides. This breaks down as the lamp warms up and releases the metal.

A metal halide lamp can use a number of different metals, each of which give off a specific characteristic colour. These include:

- dysprosium—broad blue-green

- indium—narrow blue

- lithium—narrow red

- scandium—broad blue-green

- sodium—narrow yellow

- thallium—narrow green

- tin—broad orange-red

There is no standard mixture of metals, so metal halide lamps from different manufacturers may not be compatible in appearance or operating performance. For lamps with the lower wattage ratings, 35 to 150 W, there is closer physical and electrical compatibility with a common standard.

Metal halide lamps require control gear, but the lack of compatibility means that it is necessary to match each combination of lamp and gear to ensure correct starting and running conditions.

Low-pressure sodium lamps

The arc tube is similar in size to the fluorescent tube but is made of special ply glass with an inner sodium resistant coating. The arc tube is formed in a narrow “U” shape and is contained in an outer vacuum jacket to ensure thermal stability. During starting, the lamps have a strong red glow from the neon gas fill.

The characteristic radiation from low-pressure sodium vapour is a monochromatic yellow. This is close to the peak sensitivity of the human eye, and low-pressure sodium lamps are the most efficient lamps available at nearly 200 lumens/watt. However the applications are limited to where colour discrimination is of no visual importance, such as trunk roads and underpasses, and residential streets.

In many situations these lamps are being replaced by high-pressure sodium lamps. Their smaller size offers better optical control, particularly for roadway lighting where there is growing concern over excessive sky glow.

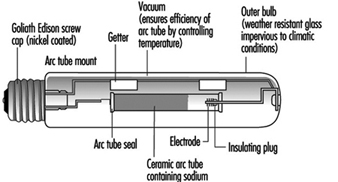

High-pressure sodium lamps

These lamps are similar to high-pressure mercury lamps but offer better efficacy (over 100 lumens/watt) and excellent lumen maintenance. The reactive nature of sodium requires the arc tube to be manufactured from translucent polycrystalline alumina, as glass or quartz are unsuitable. The outer glass bulb contains a vacuum to prevent arcing and oxidation. There is no UV radiation from the sodium discharge so phosphor coatings are of no value. Some bulbs are frosted or coated to diffuse the light source. See figure 8.

Figure 8. High-pressure sodium lamp construction

As the sodium pressure is increased, the radiation becomes a broad band around the yellow peak, and the appearance is golden white. However, as the pressure increases, the efficiency decreases. There are currently three separate types of high-pressure sodium lamps available, as shown in table 5.

Table 5. Types of high-pressure sodium lamp

|

Lamp type (code) |

Colour (K) |

Efficacy (lumens/watt) |

Life (hours) |

|

Standard |

2,000 |

110 |

24,000 |

|

Deluxe |

2,200 |

80 |

14,000 |

|

White (SON) |

2,500 |

50 |

Generally the standard lamps are used for exterior lighting, deluxe lamps for industrial interiors, and White SON for commercial/display applications.

Dimming of Discharge Lamps

The high-pressure lamps cannot be satisfactorily dimmed, as changing the lamp power changes the pressure and thus the fundamental characteristics of the lamp.

Fluorescent lamps can be dimmed using high-frequency supplies generated typically within the electronic control gear. The colour appearance remains very constant. In addition, the light output is approximately proportional to the lamp power, with consequent saving in electrical power when the light output is reduced. By integrating the light output from the lamp with the prevailing level of natural daylight, a near constant level of illuminance can be provided in an interior.