Ideally, the most effective means of noise control is to prevent the source of noise from entering into the plant environment in the first place—by establishing an effective “Buy Quiet” programme to furnish the workplace with equipment engineered for low noise output. To carry out such a programme, a clear, well-written statement of specifications for limiting noise characteristics of new plant equipment, facilities and processes must be designed to take the hazard of noise into account. A good programme builds in monitoring and maintenance as well.

Once equipment is installed and excess noise identified through sound level measurements, the problem of controlling noise becomes more complicated. However, there are engineering controls available which can be retrofitted to existing equipment. In addition, there is usually more than one noise control option for each problem. Therefore, it becomes important for the individual managing the noise control programme to determine the most feasible and economical means available for noise reduction in each given situation.

Controlling Noise in Factory and Product Design

The use of written specifications to define the requirements for equipment, its installation, and acceptance are standard practice in today’s environment. One of the foremost opportunities in the area of noise control available to the factory designer is to influence the selection, purchase and layout of new equipment. When properly written and administered, implementation of a “Buy Quiet” programme through purchase specifications can prove to be an effective means of controlling noise.

The most proactive approach towards controlling noise in the facility design and equipment procurement stage exists in Europe. In 1985, the twelve member states of the European Community (EC)—now the European Union (EU)— adopted “New Approach” Directives designed to address a broad class of equipment or machinery, rather than individual standards for each type of equipment. By the end of 1994 there had been three “New Approach” Directives issued that contain requirements on noise. These Directives are:

- Directive 89/392/EEC, with two amendments 91/368/EEC and 93/44/EEC

- Directive 89/106/EEC

- Directive 89/686/EEC, with one amendment 93/95/EEC.

The first item listed above (89/392/EEC) is commonly called the Machinery Directive. This Directive compels equipment manufacturers to include noise control as an essential part of machine safety. The basic aim of these measures is that for machinery or equipment to be sold within the EU, it must satisfy the essential requirements regarding noise. As a result, there has been a major emphasis on the design of low-noise equipment since the late 1980s by manufacturers interested in marketing within the EU.

For companies outside the EU attempting to implement a voluntary “Buy Quiet” programme, the degree of success achieved is largely dependent upon the timing and commitment of the entire management hierarchy. The first step in the programme is to establish acceptable noise criteria for construction of a new plant, expansion of an existing facility and purchase of new equipment. For the programme to be effective, the specified noise limits must be viewed by both the purchaser and vendor as an absolute requirement. When a product does not meet other equipment design parameters, such as size, flow rate, pressure, allowable temperature rise, and so forth, it is deemed unacceptable by company management. This is the same commitment that must be followed regarding noise levels in order to achieve a successful “Buy Quiet” programme.

As regards the timing aspect mentioned above, the earlier in the design process that consideration is given to the noise aspects of a project or equipment purchase, the greater the probability of success. In many situations, the factory designer or equipment buyer will have a choice of equipment types. Knowledge of the noise characteristics of the various alternatives will allow him or her to specify the quieter ones.

Besides selection of the equipment, early involvement in the design of the equipment layout within the plant is essential. Relocating equipment on paper during the design phase of a project is clearly much easier than physically moving the equipment later, especially once the equipment is in operation. A simple rule to follow is to keep machines, processes and work areas of approximately equal noise level together; and separate particularly noisy and particularly quiet areas by buffer zones having intermediate noise levels.

Validation of noise criteria as an absolute requirement requires a cooperative effort between company personnel from departments such as engineering, legal, purchasing, industrial hygiene and environment. For example, the industrial hygiene, safety, and/or personnel departments may determine the desired noise levels for equipment, as well as conduct sound surveys to qualify equipment. Next, company engineers may write the purchase specification, as well as select quiet types of equipment. The purchasing agent will most likely administer the contract and rely upon the law department representatives for assistance with enforcement. Involvement from all these parties should begin with the inception of the project and continue through funding requests, planning, design, bidding, installation and commissioning.

Even the most thorough and concise specification document is of little value unless the onus of compliance is placed on the supplier or manufacturer. Clear contract language must be used to define the means of determining compliance. Company procedures designed to enact guarantees should be consulted and followed. It may be desirable to include penalty clauses for non-compliance. Foremost in one’s enforcement strategy is the purchaser’s commitment to seeing that the requirements are met. Compromise on the noise criteria in exchange for cost, delivery date, performance, or other concessions should be the exception and not the rule.

Within the United States, ANSI has published the standard ANSI S12.16: Guidelines for the Specification of Noise of New Machinery (1992). This standard is a useful guide for writing an internal company noise specification. In addition, this standard provides direction for obtaining sound level data from equipment manufacturers. Once obtained from the manufacturer, the data may then be used by plant designers in planning equipment layouts. Because of the various types of distinctive equipment and tools for which this standard has been prepared, there is no single survey protocol appropriate for the measurement of sound level data. As a result, this standard contains reference information on the appropriate sound measurement procedure for testing a variety of stationary equipment. These survey procedures were prepared by the appropriate trade or professional organization in the United States responsible for a particular type or class of equipment.

Retrofitting Existing Equipment

Before one can decide what needs to be done, it becomes necessary to identify the root cause of noise. Towards this end, it is useful to have an understanding as to how noise is generated. Noise is created for the most part by mechanical impacts, high-velocity air flow, high-velocity fluid flow, vibrating surface areas of a machine, and quite often by the product being manufactured. As regards the lattermost item, it is often the case in manufacturing and process industries such as metal fabrication, glass manufacturing, food processing, mining, and so forth, that the interaction between the product and machines imparts the energy that creates the noise.

Source identification

One of the most challenging aspects of noise control is identification of the actual source. In a typical industrial setting there are usually multiple machines operating simultaneously, which makes it difficult to identify the root cause of noise. This is especially true when a standard sound level meter (SLM) is used to evaluate the acoustical environment. The SLM typically provides a sound pressure level (SPL) at a specific location, which is most likely the result of more than one noise source. Therefore, it becomes incumbent upon the surveyor to employ a systematic approach that will help separate out the individual sources and their relative contribution to the overall SPL. The following survey techniques may be used to help with identifying the origin or source of noise:

- Measure the frequency spectrum and graph the data.

- Measure the sound level, in dBA, as a function of time.

- Compare frequency data from similar equipment or production lines.

- Isolate components with temporary controls, or by turning on and off individual items whenever possible.

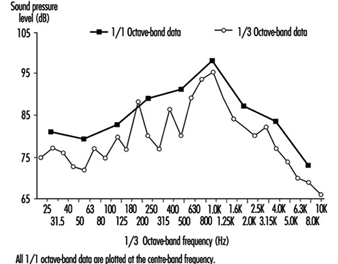

One of the most effective methods for locating the source of the noise is to measure its frequency spectrum. Once the data are measured, it is very useful to graph the results so that one can visually observe the characteristics of the source. For most noise abatement problems, the measurements can be accomplished with either full (1/1) or one-third (1/3) octave-band filters used with the SLM. The advantage of 1/3 octave-band measurement is that it provides more detailed information about what is emanating from a piece of equipment. Figure 1 exhibits a comparison between 1/1 and 1/3 octave-band measurements conducted near a nine-piston pump. As depicted in this figure, the 1/3 octave-band data clearly identifies the pumping frequency and many of its harmonics. If one used only 1/1, or full octave-band data, as depicted by the solid line and plotted at each centre-band frequency in figure 1, it becomes more difficult to diagnose what is occurring within the pump. With 1/1 octave-band data there are a total of nine data points between 25 Hertz (Hz) and 10,000 Hz, as shown in this figure. However, there are a total of 27 data points in this frequency range with the use of 1/3 octave-band measurements. Clearly, 1/3 octave-band data will provide more useful data towards identifying the root cause of a noise. This information is critical if the objective is to control noise at the source. If the only interest is to treat the path along which sound waves are transmitted, then 1/1 octave-band data will be sufficient for purposes of selecting acoustically appropriate products or materials.

Figure 1. Comparison between 1/1 and 1/3 octave-band data

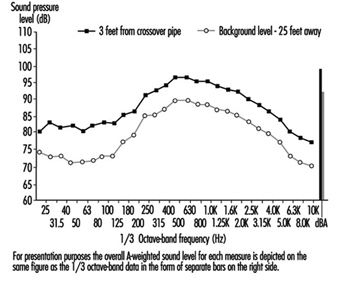

Figure 2 shows a comparison between the 1/3 octave-band spectrum measured 3 feet from the crossover pipe of a liquid chiller compressor and the background level measured approximately 25 feet away (please note the approximations given in the footnote). This position represents the general area where employees typically walk through this room. For the most part the compressor room is not routinely occupied by workers. The only exception exists when maintenance workers are repairing or overhauling other equipment in the room. Besides the compressor, there are several other large machines operating in this area. To assist with the identification of the primary noise sources, several frequency spectrums were measured near each of the equipment items. When each spectrum was compared to the data at the background position in the walkway, only the crossover pipe of the compressor unit exhibited a similar spectrum shape. Consequently, it may be concluded this is the primary noise source controlling the level measured at the employee walkway. So as depicted in figure 2, through the use of frequency data measured near the equipment and graphically comparing individual sources to the data recorded at employee workstations or other areas of interest, it is often possible to identify the dominant sources of noises clearly.

Figure 2. Comparison of crossover pipe versus background level

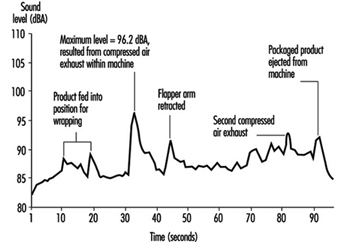

When the sound level fluctuates, as with cyclic equipment, it is useful to measure the overall A-weighted sound level versus time. With this procedure it is important to observe and document what events are occurring over time. Figure 3 exhibits the sound level measured at the operator’s workstation over one full machine cycle. The process depicted in figure 3 represents that of a product wrapping machine, which has a cycle time of approximately 95 seconds. As shown in the figure, the maximum noise level of 96.2 dBA occurs during the release of compressed air, 33 seconds into the machine cycle. The other important events are also labelled in the figure, which permits the identification of the source and relative contribution of each activity during the full wrapping cycle.

Figure 3. Workstation for packaging operator

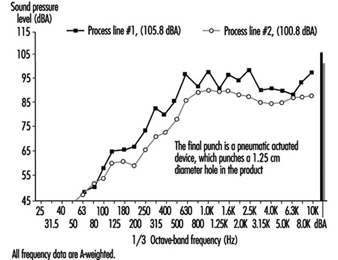

In industrial settings where there are multiple process lines with the same equipment, it is a worthwhile effort to compare the frequency data for similar equipment to one another. Figure 4 depicts this comparison for two similar process lines, both of which manufacture the same product and operate at the same speed. Part of the process involves the use of a pneumatically actuated device that punches a one-half inch hole in the product as a final phase in its production. Inspection of this figure clearly reveals that line #1 has an overall sound level 5 dBA higher than line #2. In addition, the spectrum depicted for line #1 contains a fundamental frequency and many harmonics that do not appear in the spectrum for line #2. Consequently, it is necessary to investigate the cause of these differences. Often significant differences will be an indication of the need for maintenance, such as was the situation for the final punch mechanism of line #2. However, this particular noise problem will require additional control measures since the overall level on line #1 is still relatively high. But the point of this survey technique is to identify the different noise problems that may exist between similar items of equipment and processes that may be easily remedied with effective maintenance or other adjustments.

Figure 4. Final punch operation for identical process lines

As mentioned above, an SLM typically provides an SPL that comprises acoustical energy from one or more noise sources. Under optimum measurement conditions, it would be best to measure each item of equipment with all other equipment turned off. Although this situation is ideal, it is rarely practical to shut down the plant to allow isolation of a particular source. In order to circumvent this limitation, it is often effective to use temporary control measures with certain noise sources that will provide some short-term noise reduction so as to allow measurement of another source. Some materials available that can provide a temporary reduction include plywood enclosures, acoustical blankets, silencers and barriers. Often, permanent application of these materials will create long-term problems such as heat build-up, interference with the operator’s access or product flow, or costly pressure drops associated with improperly selected silencers. However, for assisting with the isolation of individual components, these materials can be effective as a short-term control.

Another method available for isolating a particular machine or component is to turn different equipment on and off, or sections of a production line. To effectively conduct this type of diagnostic analysis the process must be capable of functioning with the selected item turned off. Next, for this procedure to be legitimate it is critical that the manufacturing process not be affected in any manner. If the process is affected, then it is entirely possible that the measurement will not be representative of the noise level under normal conditions. Finally, all valid data may then be ranked by magnitude of the overall dBA value to help prioritize equipment for engineering noise control.

Selecting the appropriate noise control options

Once the cause or source of noise is identified and it is known how it radiates to employee work areas, the next step is to decide what the available noise control options may be. The standard model used with respect to the control of almost any health hazard is to examine the various control options as they apply to the source, path and receiver. In some situations, control of one of these elements will be sufficient. However, under other circumstances it may be the case that treatment of more than one element is required to obtain an acceptable noise environment.

The first step in the noise control process should be to attempt some form of source treatment. In effect, source modification addresses the root cause of a noise problem, whereas control of the sound transmission path with barriers and enclosures only treats the symptoms of noise. In those situations where there are multiple sources within a machine and the objective is to treat the source, it will be necessary to address all noise-generating mechanisms on a component-by-component basis.

For excessive noise generated by mechanical impacts, the control options to investigate may include methods to reduce the driving force, reduce the distance between components, balance rotating equipment and install vibration isolation fittings. As regards noise arising from high-velocity air flow or fluid flow, the primary modification is to reduce the velocity of the medium, assuming this is a feasible option. Sometimes the velocity can be reduced by increasing the cross sectional area of the pipeline in question. Obstructions in the pipeline must be eliminated to allow for a streamlined flow, which in turn will reduce pressure variations and turbulence in the medium being transported. Finally, installation of a properly sized silencer or muffler can provide a significant reduction in the overall noise. The silencer manufacturer should be consulted for assistance with selection of the proper device, based on the operating parameters and constraints set forth by the purchaser.

When vibrating surface areas of a machine act as a sounding board for airborne noise, the control options include a reduction in the driving force associated with the noise, creation of smaller sections out of larger surface areas, perforation of the surface, increasing the substrate stiffness or mass, and application of damping material or vibration isolation fittings. As regards the use of vibration isolation and damping materials, the product manufacturer should be consulted for assistance with the selection of the appropriate materials and installation procedures. Finally, in many industries the actual product being manufactured will often be an efficient radiator of airborne sound. In these situations it is important to evaluate ways to tightly secure or better support the product during fabrication. Another noise control measure to investigate would be to reduce the impact force between the machine and product, between parts of the product itself, or between separate product items.

Often process or equipment redesign and source modification may prove to be infeasible. In addition, there may be situations when it is virtually impossible to identify the root cause of the noise. When any of these situations exist, the use of control measures for treatment of the sound transmission path would be an effective means for reducing the overall noise level. The two primary abatement measures for path treatments are acoustical enclosures and barriers.

The development of acoustical enclosures is well advanced in today’s marketplace. Both off-the-shelf and custom-made enclosures are available from several manufacturers. In order to procure the appropriate system it is necessary for the buyer to provide information as to the current overall noise level (and possibly frequency data), the dimensions of the equipment, the noise reduction goal, the need for product flow and employee access, and any other operating constraints. The vendor will then be able to use this information to select a stock item or fabricate a custom enclosure to satisfy the needs of the buyer.

In many situations it may be more economical to design and build an enclosure instead of purchasing a commercial system. In designing enclosures, many factors must be taken into consideration if the enclosure is to prove satisfactory from both an acoustical and a production point of view. Specific guidelines for enclosure design are as follows:

Enclosure dimensions. There is no critical guideline for the size or dimensions of an enclosure. The best rule to follow is the bigger the better. It is critical that sufficient clearance be provided to permit the equipment to perform all intended movement without contacting the enclosure.

Enclosure wall. The noise reduction provided by an enclosure is dependent upon the materials used in the construction of the walls and how tightly the enclosure is sealed. Selection of the appropriate materials for the enclosure wall should be determined using the following rules of thumb (Moreland 1979):

- for an enclosure, with no internal absorption:

TLreqd=NR+20 dBA

- with approximately 50% internal absorption:

TLreqd=NR+15 dBA

- with 100% internal absorption:

TLreqd=NR+10 dBA.

In these expressions TLreqd is the transmission loss required of the enclosure wall or panel, and NR is the noise reduction desired to meet the abatement goal.

Seals. For maximum efficiency, all enclosure wall joints must be tight fitting. Openings around pipe penetrations, electrical wiring and so on, should be sealed with non-hardening mastic such as silicon caulk.

Internal absorption. To absorb and dissipate acoustical energy the internal surface area of the enclosure should be lined with acoustically absorptive material. The frequency spectrum of the source should be used to select the appropriate material. The manufacturer’s published absorption data provides the basis for matching the material to the source of noise. It is important to match the maximum absorption factors to those frequencies of the source that have the highest sound pressure levels. The product vendor or manufacturer can also assist with selection of the most effective material based on the frequency spectrum of the source.

Enclosure isolation. It is important that the enclosure structure be separated or isolated from the equipment in order to ensure that mechanical vibration is not transmitted to the enclosure itself. When parts of the machine, such as pipe penetrations, do come in contact with the enclosure, it is important to include vibration isolation fittings at the point of contact to short-circuit any potential transmission path. Finally, if the machine causes the floor to vibrate then the base of the enclosure should also be treated with vibration isolation material.

Providing for product flow. As with most production equipment, there will be a need to move product into and out of the enclosure. The use of acoustically lined channels or tunnels can permit product flow and yet provide acoustical absorption. To minimize the leakage of noise, it is recommended that all passageways be three times longer than the inside width of the largest dimension of the tunnel or channel opening.

Providing for worker access. Doors and windows may be installed to provide physical and visual access to the equipment. It is critical that all windows have at least the same transmission loss properties as the enclosure walls. Next, all access doors must tightly seal around all edges. To prevent operation of the equipment with the doors open, it is recommended that an interlocking system be included that permits operation only when the doors are fully closed.

Ventilation of enclosure. In many enclosure applications, there will be excessive heat build-up. To pass cooling air through the enclosure, a blower with a capacity of 650 to 750 cubic feet/metres should be installed on the outlet or discharge duct. Finally, the intake and discharge ducts should be lined with absorptive material.

Protection of absorptive material. To prevent the absorptive material from becoming contaminated, a splash barrier should be applied over the absorptive lining. This should be of a very light material, such as one-mil plastic film. The absorptive layer should be retained with expanded metal, perforated sheet metal or hardware cloth. The facing material should have at least 25% open area.

An alternative sound transmission path treatment is to use an acoustic barrier to block or shield the receiver (the worker at risk of the noise hazard) from the direct sound path. An acoustic barrier is a high transmission loss material, such as a solid partition or wall, inserted between the noise source and the receiver. By blocking the direct line-of-sight path to the source, the barrier causes the sound waves to reach the receiver by reflection off various surfaces in the room and by diffraction at the edges of the barrier. As a result, the overall noise level is reduced at the receiver’s location.

The effectiveness of a barrier is a function of its location relative to the noise source or receivers and of its overall dimensions. To maximize the potential noise reduction, the barrier should be located as closely as practical to either the source or receiver. Next, the barrier should be as tall and wide as possible. To block the sound path effectively, a high-density material, on the order of 4 to 6 lb/ft3, should be used. Finally, the barrier should not contain any openings or gaps, which can significantly reduce its effectiveness. If it is necessary to include a window for visual access to the equipment, then it is important that the window have a sound transmission rating at least equivalent to that of the barrier material itself.

The final option for reducing worker noise exposure is to treat the space or area where the employee works. This option is most practical for those job activities, such as product inspection or equipment monitoring stations, where employee movement is confined to a relatively small area. In these situations, an acoustical booth or shelter may be installed to isolate the employees and provide relief from excessive noise levels. Daily noise exposures will be reduced as long as a significant portion of the workshift is spent inside the shelter. To construct such a shelter, the previously described guidelines for enclosure design should be consulted.

In conclusion, implementation of an effective “Buy Quiet” programme should be the initial step in a total noise control process. This approach is designed to prevent the purchase or installation of any equipment that might present a noise problem. However, for those situations where excessive noise levels already exist, it is then necessary to evaluate the noise environment systematically in order to develop the most practical engineering control option for each individual noise source. In determining the relative priority and urgency of implementing noise control measures, employee exposures, occupancy of the space, and overall area noise levels should be considered. Obviously, an important aspect of the desired result is to obtain the maximum employee noise exposure reduction for the monetary funds invested and that the greatest degree of employee protection is secured at the same time.