The purpose of this article is to provide a guide for calculating the magnitude of the accident problem; it is not a description of the magnitude itself. In dealing with occupational accidents, the magnitude of the problem can be estimated in different ways, depending on one’s need to estimate how big the problem has been or how big it will be in the future. (Some people may say that this distinction is an unnecessary one, since knowledge of the current extent of the problem will serve to indicate what is to be expected in the future.) The magnitude of the problem as well as its types differs from country to country, from industry to industry and from workplace to workplace.

An accident may be described as a result of a chain of events in which something has gone wrong, resulting in an undesired conclusion. It has been shown that human intervention may prevent the injury or damage to which such a chain of events would otherwise lead. However, given the fact of human intervention, the potential exists for far more dangerous possible chains of events than those actually leading to injury or damage. These possibilities must be considered in assessing the full extent of workplace risk. Assuming that events that might lead to injury or damage occur because of factors in the workplace, one is led to conclude that the magnitude of the problem has to be determined on the basis of the existence and frequency of such factors.

When dealing with accidents in the workplace, one can estimate the magnitude of the problem retrospectively by comparing the number of accidents (incidence rate) with the severity of the accidents (lost work days). However, if one wants to estimate the magnitude of the problem prospectively, it is done by evaluating the presence of risk factors in the workplace—that is, factors that might lead to accidents.

A sufficiently complete and accurate view of the state of affairs with respect to workplace accidents can be gained by means of a comprehensive reporting and record-keeping system. Analyses of well-prepared accident reports can give a picture of the basic relationships essential to understanding the causes of the accidents. In order to estimate the magnitude of the problem in detail, a determination of risk factors is essential. Knowledge of the relevant risk factors can be obtained by analysing the detailed information provided with each accident record as to where workers and operators were located when the accident occurred, what they were doing or handling, by what means, what damages or injuries occurred and other particulars surrounding the accident.

Risk

Risk measurement must be made on the basis of information regarding the number and seriousness of injuries that have occurred in the past, yielding a retrospective measurement. The risk of injury to individuals may be described by two types of data:

- Measurement of risk provides a calculated frequency of injuries and a measurement of the seriousness of the injury. This could be described as the number of lost work day cases (or fatalities) per number of workers (e.g., in Denmark, the risk of dying in an occupational accident is 3 fatalities per 100,000 employees).

- Type of risk or element of danger assessment provides not only an indication of the exposure sources and other harmful factors which may cause an accident, but also an indication of the circumstances leading to injury or damage. Work performed at a height, for example, will involve a risk of falling, with serious injury as a possible result. Similarly, work with cutting tools involves a risk of cuts from contact with sharp components, and work with noisy machines for a long period of time may result in hearing damage.

There exists a good deal of common-sense knowledge on many types of risks. For example, if you work at a height, you may fall; if it is slippery underfoot, then you may slip; and if there are sharp objects nearby, you may cut yourself. Many types of risk, not apparent to common sense, may be overlooked. With regard to these, the worker must be informed of the risk (e.g., that noise causes hearing damage, that some solvents cause brain damage and that certain chemicals cause acute poisoning by inhalation). Our knowledge of types of risk, from the most to the least conspicuous, whether gained through everyday experience or through research efforts, is based on past events. However, it is one thing to know what has happened, and another to assess what will happen in the future. It should be noted that the very knowledge of the exposure sources and other potentially harmful factors which may cause damage or injury in connection with tasks of various sorts, as well as knowledge of the factors that can either heighten or reduce those risk factors that influence risk measurement, can provide a basis for recognition of the risk.

Factors Determining Risk

The factors which are of greatest relevance in determining risk are:

- factors which determine the presence or absence (or potential) of risks of any sort

- factors which either increase or minimize the probability of these risks resulting in accidents or injuries

- factors affecting the seriousness of accidents associated with these risks.

To clarify the first point, it is necessary to identify the causes of the accident—namely, exposure sources and other harmful factors; the two latter points constitute the factors which influence the measurement of risk.

The primary factors in the working environment which are the direct causes of harm, either by way of occupational diseases or occupational accidents, are as follows:

Exposure sources and occupational disorders

The concept of injuries due to exposure sources is often linked to the concept of disease (or disorder) because a disease can be viewed as caused by exposure to one or several agents over a short (acute exposure) or long (chronic exposure) period of time. Chronic exposure agents are usually not directly harmful, but take effect rather after a relatively constant and extended period of exposure, whereas acute exposures are almost instantaneously harmful. The intensity, harmfulness and period of action is of importance to the development of the injury, which may often be a matter of a combination of the effects of several different agents. This fact makes it difficult to point out and determine the exposure sources because (among other reasons) monocausal correlations between specific disorders and specific exposure sources are almost never found.

Examples of exposure sources which may result in an injury in the form of a disease-like condition are:

- chemical exposures (solvents, cleaning agents, degreasing agents, etc.)

- physical exposures (noise, radiation, heat, cold, inadequate lighting, lack of oxygen, etc.)

- physiological exposures (heavy loads, bad work postures or repetitive work)

- biological exposures (viruses, bacteria, flour, animal blood or leather, etc.)

- psychological exposures (work in isolation, threat of violence, changing working hours, unusual job demands, etc.).

Harmful factors and occupational accidents

The concept of harmful factors (not including exposure sources) is linked to occupational accidents, because this is where damages occur and workers are exposed to the type of actions that cause instant injury. This type of action is easily identified because the damage or injury is recognized immediately when it occurs. The difficulty attached to this type of injury is the unexpected contact with the harmful factor.

Examples of harmful factors which may result in persons being injured by an accident are often linked to different energy forms, sources or activity, such as the following:

- energy that involves cutting, dividing or planing, usually in connection with such types of sharp objects as knives, saws and edged tools

- energy that involves pressing and compressing, usually in connection with different shaping means such as presses and clamping tools

- the conversion of kinetic energy into potential energy—for example, when something hits or falls against a worker

- the conversion of potential energy in a person into kinetic energy, such as occurs in falls from one level to another

- heat and cold, electricity, sound, light, radiation and vibration

- toxic and corrosive substances

- energy exposing the body to excessive stress in such actions, for example, as the moving of heavy loads or twisting of the body

- mental and psychological stresses such as the threat of violence.

Controlling Exposures

Exposure sources or other harmful factors are to a great extent governed by the nature of the processes, technologies, products and equipment to be found in the workplace, but may also be governed by the way in which the work is organized. From the point of view of measurable risk, it should be recognized that control of the probability of exposures and the seriousness of injuries to workers often depends on the following three factors:

- Elimination/substitution safety measures. Workplace hazards in the form of exposure sources or other harmful factors may be eliminated or mitigated by substitution (e.g., a less harmful chemical may replace a toxic chemical in a process). It should be noted that this is not totally possible, as exposure sources and other harmful factors will always be present in human surroundings (not least with respect to human working conditions).

- Technical safety measures. These measures, often called engineering controls, consist of separating persons from harmful factors by encapsulating the harmful elements, or installing barriers between workers and the factors which may cause injury. Examples of these measures include, but are not limited to, automation, remote control, use of ancillary equipment and machine protection (guarding).

- Organizational safety measures. Organizational safety measures, also known as administrative controls, include separating persons from harmful factors either by means of special working methods or by separation in time or space. Examples of these controls include, but are not limited to, reduced exposure time, preventive maintenance programmes, encapsulating the individual workers with personal protective equipment, and expedient organization of work.

Controlling Human Conduct

It is often not possible to isolate all hazards using the above control measures. It is commonly supposed that accident prevention analysis ends here because it is believed that the workers will then be able to take care of themselves by acting “according to the rules”. This means that safety and risk will at some point depend on factors which control human conduct—namely, whether the individual person has the knowledge, the skills, the opportunity and the will to act so as to ensure safety in the workplace. The following illustrates the role of these factors.

- Knowledge. Workers must first be aware of the types of risk, potential hazards and elements of danger that may be found in the workplace. This usually requires education, training and job experience. The risks also need to be identified, analysed, recorded and described in a readily understandable manner so that workers know when they are in a specific risk situation and what consequences are liable to follow from their actions.

- The opportunity to act. It must be possible for the workers to act safely. It is necessary for workers to be able to make use of the available technical and organizational—as well as physical and psychological—opportunities for action. Positive support of the safety programme must be forthcoming from management, supervisors and the surroundings, including concern about risk taking, designing and following working methods with safety in view, safe use of the proper tools, clearly defining tasks, establishing and following safe procedures, and providing clear instructions on how equipment and materials are to be safely handled.

- The will to act safely. Technical and organizational factors are important with respect to workers’ readiness to behave in ways that will ensure workplace safety, but social and cultural factors are at least equally important. Risks will arise if, for example, safe conduct is difficult or time-consuming, or if it is not desired by management or colleagues, or is not appreciated by them. Management must be clearly interested in safety, taking steps to prioritize it and displaying a positive attitude towards the need for safe conduct.

Information on the causes of accidents serves the following purposes:

- It can demonstrate where something is wrong and what needs to be changed.

- It indicates the types of harmful factors that cause accidents (or near accidents) and also describes the situations that result in damage and injuries.

- It identifies and describes the underlying circumstances that determine the presence of potential hazards and risky situations and that will result in optimum safety by their being altered or eliminated.

Information of a general sort can be obtained by a thorough analysis of the damage or injuries and the circumstances under which they occurred. Information obtained from other similar accidents may point out more general factors of importance, thus disclosing less immediately visible causal relationships. However, as very detailed and specific information can be obtained by analysing an individual accident, this information may help uncover the specific circumstances which should be addressed. Often, analysis of the individual accident will provide information which it is not possible to obtain from the general analysis, whereas the general analysis may point out factors which the specific analysis does not elucidate. Data from both of these kinds of analyses are important to help disclose obvious and direct causal relations at the individual level.

Analysis of Individual Accidents

Analysis of individual accidents has two primary purposes:

First, it can be used to determine the cause of an accident and the specific work factors that contributed to it. Following analysis, one can assess the extent to which the risk has been recognized. One may also decide upon technical and organizational safety measures and the degree to which more job experience might have diminished the risk. Furthermore, a clearer view is gained of the possible actions that might have been taken to avoid the risk, and the motivation that a worker must have to take these actions.

Second, one can gain knowledge which may be used for analyses of many similar accidents at both the enterprise level and at more comprehensive (e.g., organization-wide or national) levels. In this connection, it is important to assemble information such as the following:

- the identity of the workplace and the work itself (that is, information relating to the sector or the trade in which the workplace is positioned), and the work processes and the technology that characterize the work

- the nature and the seriousness of the accident

- factors causing the accident, such as exposure sources, the way in which the accident occurred and the specific working situation causing the accident

- general conditions at the workplace and the working situation (comprising the factors mentioned in the foregoing paragraph).

Types of Analyses

There are five primary types of analyses of accidents, each having a distinct purpose:

- Analyses and identification of where and which types of accidents occur. The goal is to determine the incidence of the injuries, as associated, for example, with sectors, trade groups, enterprises, work processes and types of technology.

- Analyses with respect to monitoring developments in the incidence of accidents. The purpose is to be warned of changes, both positive and negative. Measuring the effect of preventive initiatives may be the result of such analyses, and increases in new types of accidents within a specified area will constitute warning of new risk elements.

- Analyses to prioritize initiatives that call for high degrees of risk measurement, which in turn involve calculating the frequency and seriousness of accidents. The goal is to establish a basis for prioritization to determine where it is more important to carry out preventive measures than elsewhere.

- Analyses to determine how the accidents occurred and, especially, to establish both direct and underlying causes. This information is then applied to the selection, elaboration and implementation of concrete corrective action and preventive initiatives.

- Analyses for elucidation of special areas which have otherwise attracted attention (a sort of rediscovery or control analyses). Examples include analyses of incidences of a special injury risk or the discovery of a hitherto unrecognized risk identified in the course of examining an already known risk.

These types of analyses can be carried out at several different levels, ranging from the individual enterprise to the national level. Analyses at several levels will be necessary for preventive measures. Analyses involving general accident incident rates, monitoring, warning and prioritization will be carried out chiefly at higher levels, whereas analyses describing direct and underlying accident causes will be conducted at lower levels. The results of the analyses will accordingly be more specific at the individual level and more general at the higher level.

Phases of the Analysis

Irrespective of the level from which an analysis starts, it will usually have the following phases:

- identification of where the accidents occur at the general level selected

- specification of where the accidents occur at a more specific level within the general level

- determination of goals in view of the incidence (or frequency) and seriousness of the accidents

- description of exposure sources or other harmful factors—that is, the direct causes of damage and injury

- examination of the underlying causal relation and causal development.

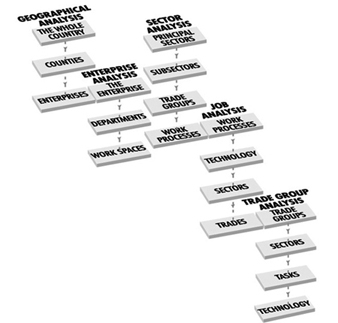

Examples of different levels of analysis are given in figure 1.

Figure 1. Different levels of accident analysis

Summary

Identification of accidents nationwide may provide knowledge of the sectors, trade groups, technologies and working processes within which damages and injuries occur. The goal is solely to identify where the accidents occurred. Measurement of accidents by frequency and seriousness partly establishes where something is wrong in particular and partly indicates where the risk has changed.

The type of workplace risk is established by descriptions of the types of accidents that take place and the way in which they arise within the individual workplace areas. In this way, knowledge is obtained of the exposure sources and other harmful factors present in the workplace in the event that preventive measures—attention to safety conditions, awareness of risk, providing opportunity for action and the appeal to the workers’ will—have proved insufficient to avert the accident.

Identification, measurement and description of accidents together provide the basis for what is to be done and who is to do it in order to reduce the risk. If, for example, specific exposure sources can be linked to specific technologies, it will help determine what special safety measures are necessary to control the risk. This information may also be used to influence manufacturers and suppliers associated with the technology in question. If it can be demonstrated that frequent and very serious accidents occur in connection with specific processes, the attempt may be made to adjust the nature of the equipment, machinery, operations or work procedures that are associated with these processes. Unfortunately, a typical feature of such initiatives and adjustments is that an almost unambiguous monocausal correlation between accidents and causes is required, and this is available for only a few cases.

Analyses of accidents within an enterprise may also be carried out from a general to a more specific level. However, the problem often is to assemble a sufficiently extensive database. If accident injury data covering a number of years are gathered at an enterprise (including information regarding minor injuries and near accidents), it will be possible to establish a useful database even at this level. The overall analysis of the enterprise will show whether there are special problems in specific sections of the enterprise, or in connection with specific tasks or with the use of specific types of technology. The detailed analysis will then show what is wrong and thus lead to an evaluation of preventive measures.

If workers’ conduct within a sector, trade group or enterprise, or the conduct of an individual is to be influenced, knowledge regarding many accidents is required in order to increase workers’ awareness. At the same time, information must be made available about the factors which increase the probability of accidents and about known possibilities of action that may minimize the risk of damage or injury. At this point, safety becomes a matter of motivating those responsible for people’s conduct at the level of a given sector, an industrial organization, a trade organization, the employer or the employee.