Human factors are a major component of the causes of accidents in the workplace. Estimates of the actual extent of the involvement vary markedly, but a study in the early 1980s of the causes of all work-related fatalities occurring in Australia over three years revealed that behavioural factors were involved in more than 90% of fatal accidents. In view of data like these, it is important to have an understanding of the role of human factors in accidents. Traditional models of accident causation placed superficial emphasis on human factors. Where human factors were included, they were depicted as linked to error occurring in the immediate sequence of events leading to the accident. A better understanding of how, why and when human factors become involved in accidents enhances our ability to make predictions about the role of human factors and helps to prevent accidents. A number of models have been put forward that attempt to describe the part that human factors play in accidents.

Accident Causation Models

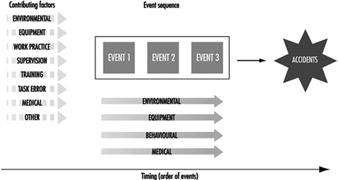

Recent models have extended the role of human factors beyond the immediate causal events leading to the accident. Models now tend to include additional factors in the wider circumstances of the accident. Figure 1 shows details of such an approach: For example, human factors, such as work practices and supervision, can be included both as error in the event sequence leading immediately to the accident and as pre-existing human factors contributing to the accident event sequence. The two main components (contributing factors and event sequences) of this human factors model should be envisaged as occurring on a notional time line on which the order—contributing factors followed by a sequence of errors—is fixed, but the time base on which they occur is not. Both of these components are essential parts of accident causation.

Figure 1. Model of accident causation

The Nature of Error

An essential component of accident prevention, therefore, is gaining an understanding of the nature, timing and causes of error. One of the important and unique characteristics of error, distinguishing it from other factors involved in accidents, is that error is a normal part of behaviour. Error plays a fundamental role in learning new skills and behaviours and in maintaining those behaviours. Through testing the boundaries of interactions with the environment, and consequently making errors, humans learn just what the boundaries are. This is essential not only for learning a new skill but also for updating and maintaining ones they have already learned. The degree to which humans test the boundaries of their skills is related to the level of risk that they are prepared to accept.

It seems that errors are a constant feature of all behaviour. Studies show also that they occur in the causes of approximately two-thirds of work-related fatal accidents. It is essential therefore to develop some ideas about the form they are likely to take, and when and why they might occur. While there are many aspects of human error that are not yet understood, our current level of understanding allows some predictions to be made about error types. Knowledge of these types of error will, it is to be hoped, guide our efforts to prevent error or at least to modify the adverse consequences of error.

One of the most important features of the nature of error is that it is not a unitary phenomenon. Even though traditional accident analysis often treats error as if it were a singular entity which cannot be dissected further, there are a number of ways that errors can occur. Errors differ depending on the information-processing function being challenged. For example, errors can take the form of false sensations due to poor or degraded stimulation of the sensory organs, attentional failures due to the demands of prolonged or very complex stimulation from the environment, various types of memory lapses, errors of judgement and reasoning errors. All of these types of errors are distinguishable in terms of the context or task characteristics in which they occur. They signify breakdown in different information-processing functions and consequently would require different approaches to overcoming each of them.

Different types of error can also be distinguished with respect to skilled and unskilled behaviour. Training is often said to be a solution to problems of human error since skilled behaviour means that the required sequence of actions can be performed without conscious, constant attention and feedback, requiring only intermittent conscious checking to ensure that the behaviour is on track. The advantages of skilled behaviour are that once triggered, it requires little effort from the operator. It allows other activities to be undertaken at the same time (for instance, one can drive an automobile and talk at the same time) and allows the operator to plan for future aspects of the task. Furthermore, skilled behaviour is usually predictable. Unfortunately, while greater skill reduces the likelihood of many types of error, it increases the likelihood of others. Errors during skilled behaviour occur as absent-minded or unintended actions or lapses and are distinct from the mistakes which occur during unskilled behaviour. Skill-based errors tend to be associated with switching in the nature of attentional control of the task. They can occur during the conscious checking mode or they may be due to conclusion of similar patterns of skilled behaviour.

A second characteristic of errors is that they are not novel or random. Error forms are limited. They take similar forms in all types of functions. For example, “place losing” errors occur in speech and perceptual tasks as well as in knowledge-related or problem-solving tasks. Similarly, the timing and location of error in the accident causation sequence does not appear to be random. An important characteristic of information processing is that it is expressed in the same way regardless of the setting. This means that the error forms that occur in everyday life in the kitchen, for example, occur in the same manner in the most high-risk industries. The consequences of these errors, however, are very different and are determined by the setting in which the error occurs, rather than by the nature of the error itself.

Models of Human Error

In the categorization of error and the development of models of human error, it is important to take all aspects of error into account to the extent possible. The resulting categorization, however, needs to be usable in practice. This is possibly the biggest constraint. What can be done in developing a theory of accident causation can be very difficult to apply in practice. In attempting to analyse the causes of an accident, or to predict the role of human factors in a process, it is not possible to understand all aspects of human information processing which contributed or might contribute. It may never be possible, for example, to know the role of intention before an accident occurred. Even afterwards, the very fact that the accident had occurred can change a person’s recall of the events surrounding it. The error categorizations that have been most successful to date therefore focus on the nature of the behaviour that was performed at the time the error occurred. This allows error analysis to be relatively objective and as reproducible as possible.

These categorizations of error distinguish between those occurring during skilled behaviour (slips, lapses or unintended acts) and those occurring during unskilled or problem-solving behaviour (mistakes).

Slips or skill-based errors are defined as unintended errors occurring when the behaviour is a highly practised routine or automatic in nature.

Mistakes have been further categorized into two types:

- rule-based errors, which occur when the behaviour requires the application of rules

- knowledge-based errors, which occur during problem solving when the person has no skill or rule to apply.

This means that knowledge-based errors occur through lack of expertise, rule-based errors through the failure to apply the expertise appropriately, and skill-based errors through a disruption of the execution of the programme of actions, usually due to changes in attentional level (Rasmussen 1982).

Application of these categories in a population study of work-related fatal accidents showed that they could be used reliably. The results showed that skill-based errors occurred most frequently overall and that occurrences of the three error types were distributed differently across the event sequence. Skill-based errors, for example, occurred most commonly as the last event immediately before the accident (79% of fatalities). Since, at this point, there is little time for recovery, their consequences may be more severe. Mistakes, on the other hand, appear to be distributed earlier in the accident sequence.

Human Factors in the Wider Circumstances of Accidents

Elaboration of the involvement of human factors other than human error in the circumstances immediately surrounding the accident represents a major advance in understanding accident genesis. While there is no question that error is present in most accident sequences, human factors are also involved in a broader sense, taking the form, for example, of standard operating work procedures and the influences that determine the nature and acceptability of work procedures, including the earliest decisions of management. Clearly, flawed work procedures and decisions are related to error since they involve errors of judgement and reasoning. However, flawed work procedures are distinguished by the characteristic that the errors of judgement and reasoning have been permitted to become standard ways of operating, since, having no immediate consequences, they do not make their presence urgently felt. They are, nevertheless, recognizable as unsafe work systems with fundamental vulnerabilities that provide the circumstances which may later, unintentionally, interact with human action and lead directly to accidents.

In this context, the term human factors covers a wide range of elements involved in the interaction between individuals and their working environment. Some of these are direct and observable aspects of the ways in which work systems function that do not have immediate adverse consequences. Design, use and maintenance of equipment, the provision, use and maintenance of personal protective and other safety equipment and standard operating procedures originating from management or workers, or both, are all examples of such ongoing practices.

These observable aspects of human factors in system functioning are to a large extent manifestations of the overall organizational setting, a human element even more removed from direct involvement in accidents. Characteristics of organizations have been collectively termed organizational culture or climate. These terms have been used to refer to the set of goals and beliefs an individual holds and the impact of the organization’s goals and beliefs on those of the individual. Ultimately, the collective or norm values, reflecting the characteristics of the organization, are likely to be influential determinants of attitude and motivation for safe behaviour at all levels. The level of risk tolerated in a work setting, for example, is determined by such values. Thus, the culture of any organization, clearly reflected in its work system and the standard operating procedures of its workers, is a crucial aspect of the role of human factors in accident causation.

The conventional view of accidents as a number of things suddenly going wrong at the time and the place of the accident, concentrates attention on the overt measurable event at the time of the accident. In fact, errors occur in a context which itself may allow the unsafe act or error to have its consequences. In order to reveal accident causes that originate in pre-existing conditions in work systems, we need to take into account all of the various ways in which the human element can contribute to accidents.This is perhaps the most important consequence of taking a broad view of the role of human factors in accident causation. Flawed decisions and practices in work systems, while not having an immediate impact, act to create the setting conducive to operator error—or to the error’s having consequences—at the time of the accident.

Traditionally, organizational aspects of accidents have been the most neglected aspect of accident analysis design and data collection. Because of their distant relationship in time from the occurrence of the accident, the causal link between accidents and organizational factors has often not been obvious. Recent conceptualizations have specifically structured analysis and data collection systems in such a way as to incorporate the organizational components of accidents. According to Feyer and Williamson (1991), who used one of the first systems designed to specifically include the organizational contribution to accidents, a considerable proportion of all occupational fatalities in Australia (42.0%) involved pre-existing and ongoing unsafe work practices as a causal factor. Waganaar, Hudson and Reason (1990), using a similar theoretical framework in which the organizational contribution to accidents was recognized, argued that organizational and managerial factors constitute latent failures in work systems that are analogous to resident pathogens in biological systems. Organizational flaws interact with triggering events and circumstances in the immediate circumstances surrounding accidents much as resident pathogens in the body combine with triggering agents such as toxic factors to bring about disease.

The central notion in these frameworks is that organizational and managerial flaws are present long before the onset of the accident sequence. That is, they are factors which have a latent or delayed-action effect. Thus, to understand how accidents occur, how people contribute to them and why they behave the way that they do, it is necessary to ensure that analysis does not begin and end with the circumstances that most directly and immediately lead to harm.

The Role of Human Factors in Accidents and Accident Prevention

In acknowledging the potential aetiological significance of the wider circumstances surrounding the accident, the model best describing accident causation has to take into account the relative timing of elements and how they relate to each other.

First, causal factors vary in terms of their causal importance, and also in terms of their temporal importance. Furthermore, these two dimensions can vary independently; that is, causes can be important because they occur very close in time to the accident and therefore they reveal something about the time of the accident, or they can be important because they are a prime cause underlying the accident, or both. By examining both the temporal and causal importance of factors involved in the wider circumstances as well as the immediate circumstances of the accident, analysis focuses on why the accident happened, rather than just describing how it happened.

Second, accidents are generally agreed to be multicausal. Human, technical and environmental components in the work system can interact in critical ways. Traditionally, accident analysis frameworks have been limited in terms of the range of categories defined. This, in turn, limits the nature of the information obtained and so limits the range of options highlighted for preventive action. When the wider circumstances of the accident are taken into consideration, the model has to deal with an even more extensive range of factors. Human factors are likely to interact with other human factors and also with non-human factors. The patterns of occurrences, co-occurrences and inter-relationships of the wide range of possible different elements within the causal network provides the most complete and therefore most informative picture of accident genesis.

Third, these two considerations, the nature of the event and the nature of its contribution to the accident, interact. Although multiple causes are always present, they are not equivalent in role. Accurate knowledge of the role of factors is the essential key to understanding why an accident happens and how to prevent it from recurring. For example, immediate environmental causes of accidents may have their impact because of earlier behavioural factors in the form of standard operating procedures. Similarly, pre-existing aspects of work systems may provide the context in which routine errors committed during skill-based behaviour can precipitate an accident with harmful consequences. Normally these routine errors would have benign consequences. Effective prevention would be best served if it were targeted towards the latent underlying causes, rather than the immediately precipitating factors. This level of understanding of the causal network and how it influences outcome is possible only if all types of factors are included for consideration, their relative timing is examined and their relative importance is determined.

Despite the potential for an almost infinite variety in the ways that human action can directly contribute to accidents, relatively few patterns of causal pathways account for the majority of accident causation. In particular, the range of underlying latent conditions which set the scene for later human and other factors to have their effect are limited predominantly to a small number of aspects of work systems. Feyer and Williamson (1991) reported that only four patterns of factors accounted for the causes of approximately two-thirds of all occupational fatalities in Australia over a 3-year period. Not surprisingly, almost all of these involved human factors at some point.

Summary

The nature of human involvement varies as to type and timing and as to its importance in terms of causing the accident (Williamson and Feyer 1990). Most commonly, human factors in the form of a limited range of pre-existing, flawed work systems create the underlying prime causes of the fatal accidents. These combine with later lapses during skilled performance or with hazards in environmental conditions to precipitate the accident. These patterns illustrate the layered role typical of the involvement of human factors in accident genesis. To be of use in preventive strategy formulation, however, the challenge is not to simply describe the various ways in which the human element is involved but rather to identify where and how it may be possible to intervene most effectively. This is possible only if the model used has the capacity to describe accurately and comprehensively the complex network of interrelated factors involved in accident causation, including the nature of the factors, their relative timing and their relative importance.