The moral imperative of an enterprise to actively seek to reduce damages, pain and suffering in the workplace will be tempered by the ability of the organization to sustain such an effort. Most human activities have risk attached to them, and risks in the workplace vary widely, from those much lower than those associated with normal, non-occupational activities, to very significantly more hazardous ones. An essential part of an organization is its willingness to accept the risks of business which have the potential for producing financial losses and are based on the pain and suffering of employees that result from accidents. A successful safety programme is intended to control a portion of these losses by reducing the risks, particularly where such risks arise from unsafe conditions or unsafe acts. The safety programme, therefore, is simply another subsystem of management. Like other management programmes, the safety programme consists of complementary strategies, procedures and standards. Similarly, the measure of a safety programme is performance—that is, how well it reduces accidents and the consequent losses.

A safe workplace depends on the control of hazards and unsafe behaviours, and control such as this is the primary function of management. A safety programme should produce complementary benefits: a reduction in damages and pain and suffering in the workforce (from both acute and chronic injuries and illnesses) and a resultant reduction in the financial burden to the organization due to such accidents. To achieve such benefits, a successful safety programme will follow the general approach of all management tools by establishing goals, monitoring performance and correcting deviations. This approach will be applied to a rather wide range of organizational activities, including organizational design, the production processes and the behaviour of the workers.

Safety in the Enterprise

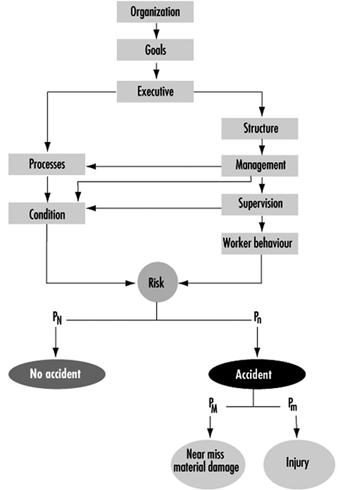

A safe workplace is the end product of a complex and interactive process, and each process is a characteristic of an individual organization. A typical process is described in figure 1. The successful programme will need to address the various aspects of such a system.

Figure 1. The management process and occupational safety

Safety is often seen as a worker/workplace issue, but figure 1 indicates the pivotal role of management in safety as it responds to the overall goals of the organization. This can be seen from management’s clear responsibility for the selection of the industrial processes utilized, the control of supervision, working conditions, and the attitudes and procedures of the worker, all of which are factors that establish the extent of a risk in a particular workplace. Usually there is a large probability that no accident will occur, and a small probability that there will be an accident leading to either material damage or injury to a worker. A safety programme is concerned with reducing that risk and also minimizing injuries that occur.

Understanding the Accident Process

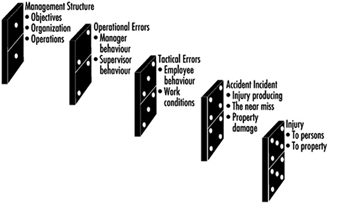

There are several competing theories of accident causation, but the model first proposed by Frank Bird (1974) is particularly valuable, as it provides a ready analogy which is compatible with many management practices. Bird likened the process that leads to injury or damage to a row of dominoes, standing on edge (see figure 2). When any domino falls, it can disturb the others and a sequence is actuated which eventually leads to the fall of the final piece, corresponding to the occurrence of an injury. This analogy implies that if any one of the dominoes is removed from the sequence, or is robust enough to withstand the previous impact, then the chain of events will be broken and the ultimate event of injury or damage will not occur.

Figure 2. The Bird domino theory as modified by E. Adams

Despite more recent models, this approach is still valuable, for it clearly identifies the concept of interventions in the accident process and the role of the effective safety programme in introducing them to inhibit the process and prevent injury.

Organizational Goals

There is little disagreement among authors that the single most significant aspect of any safety programme is the visible continuous commitment of senior management. This commitment must be recognized and reflected by succeeding levels of management down through the supervisory ranks. Although executive management often believes its concern with safety is apparent to all in the enterprise, such clarity can be lost at the successive layers of management and supervision. In successful safety programmes, the executive management must demonstrate a clearly identified commitment to the concept that safety is a responsibility of all employees, from senior management to the temporary worker. Such a commitment should take the form of a brief written document, provided for everyone in the enterprise and utilized at the earliest possible stage for inducting new workers into the organization. Some organizations have recently extended this by introducing the concept that the commitment to a safe and healthy workplace for all its employees and customers is an explicit corporate value. Such corporations frequently express this point of view in written documents, together with more traditional corporate values, such as profitability, reliability, customer service and community commitment.

Clarity of communication is particularly important in large organizations, where the direct link between the owners of the enterprise and the workforce can easily be broken. One of the clearest ways to achieve this is by the development of a series of written policies and procedures, starting with senior management’s establishing objectives for the safety programme. These should be clear, concise, achievable, supportable and, above all, unambiguous. It is not sufficient for a manager to assume that everyone down the chain of command shares a similar background, understanding and perception of the safety programme. These aspects must be made perfectly explicit. Equally, in spelling out the terms of this written procedure, it is essential to have realistic goals.

Management Control

Developing effective safety programmes from this original commitment requires that the measurement of safety performance be an integral part of the annual performance review of all management and supervisory staff. In keeping with the philosophy that safety is only one measure, among many, of the manager’s control of the process, safety performance must be included along with output, cost per unit, and profitability of the department. Such a philosophy, insofar as accidents occur from a lack of control of the process, appears to be highly compatible with the contemporary emphasis on total quality management (TQM). Both procedures adopt the position that deviations from normal are minimized in order to provide more control in achieving the corporate objectives. Additionally, the TQM concept of year-by-year, incremental improvement, is particularly significant in the long-term management of safety programmes.

Training and Education

Training and education are major components of any safety programme. This begins with the dissemination from senior management not only of the programme’s objectives and goals, but also information on progress towards those goals, measured through record keeping and cost accounting. Education, by which is meant a more general understanding of the nature of a hazard and of approaches to risk reduction, appears to work well, particularly in circumstances where there is still doubt about individual risk factors. One example is the epidemic of upper extremity cumulative disorders in Australia, Europe and North America. These disorders have become more significant, especially given that broad agreement does not exist on criteria for control of these disorders. The cumulative nature of such disorders, however, makes control of this problem particularly amenable to education. An increased awareness of risks allows individual workers to avoid such conditions by recognizing their exposures and modifying them by changes to procedures. Similarly, an understanding of the mechanics of low-back stresses can prepare workers to avoid some potentially dangerous work practices and substitute safer methods of accomplishing tasks.

Training is as necessary for management and supervisors as it is for the workers, so that they develop an understanding of their responsibilities and duties and increase their awareness levels of hazard potential. Individual workers need to be provided with clear and unambiguous process-relevant procedures for safe working. They should have an understanding of the hazards involved in the particular operations, and the likely effects of exposures to both toxic and physical agents. Additionally, managers, supervisors and workers should be familiar with the procedures for minimizing losses once an accident has occurred.

Safe Behaviour

Philosophically, the twentieth century has seen several swings in which safety programmes have allocated varying amounts of responsibility for the behaviour of workers to the individual, the employer and society. However, it is clear that safe behaviour is an absolutely crucial part of the safety process. An example of the significance of such behaviour is the development of group ethics, or team norms, in which the assumption of a risk by an individual might be perceived negatively by other members of the group. The converse is true: the acceptance of dangerous practices can become accepted as “normal”. Such behaviours can be modified by specific procedures of training and reinforcement, as shown by the highly successful programmes that combated the spread of AIDS from careless needle use in the health care industry. The heightened emphasis by management, coupled with training and educational materials, fundamentally changed the procedures involved and reduced the incidence of this hazard.

Participation

Increasingly, societies are mandating worker participation in safety programmes. Although the validation of such participation tends to be somewhat variable, worker involvement can be valuable at several stages in the safety process. Undoubtedly the people who are exposed to the hazards are extremely valuable resources for identifying hazards, and frequently are aware of potential solutions for reducing them. When problems have been identified and solutions have been developed, implementation will be greatly facilitated if the workforce has been a partner in record keeping, identifying, developing and validating the proposed interventions. Finally, in terms of understanding management’s commitment and resource constraints, participation embodied in a safety programme is beneficial.

Incentives

Incentives have been widely promulgated in some countries for increasing safe behaviours. The evidence that these incentives work is far from convincing, although, as part of a comprehensive safety programme, they can be used to demonstrate management’s continuing concern with safety, and they can form a significant feedback of performance. Thus, those safety programmes in which a small financial award is mailed to a recipient are likely to be ineffective. The same award, made in public by senior management, and based on specific performance measures—for example, 2,500 hours of work without any accidents—is likely to form positive reinforcement. In practice, in many industries the reverse is true—there are considerable incentives that reward poor safety behaviours. For example, piece-rate payment systems clearly reward workers for cutting out any time-consuming elements in a work cycle, including any which may be related to safe working procedures. Enterprises using incentives are more likely to need engineering controls and active surveillance techniques if they are truly committed to protecting the health and safety of the workforce.

Measurement and Control

Information is the lifeblood of management, and record keeping is an essential part of management information. Without a good source of data, progress toward accident reduction will be unreliable, and management’s willingness to expend resources to reduce risks is likely to be impaired. In some countries, collection of such data is a legislative requirement, and clearly a successful safety programme must facilitate the gathering and collation of such data. Satisfaction of regulatory requirements may be necessary, but frequently is not sufficient for a successful safety programme. Local variations in such data requirements may occur—for example, between jurisdictions—with the result that the value of such data is obscured; this development is a particular problem in organizations with multiple locations located in different regional or national jurisdictions. Consequently, the standardization of, and approach to, data collection must be specifically established as part of the safety programme. Thus, each programme must first identify the information needed for compliance with regulations, but then determine the need for further collection and analysis necessary for accident reduction.

Costs of Accidents

An essential management aspect of the data system is the identification of the cost of losses. Loss source analysis—that is, the determination of the actual sources of losses—will include the measurement of the number of incidents, the severity of incidents and the direct costs of damages, injuries and illnesses. Such information is essential if management is to maintain its focus on the true problems in the workplace. In many countries, the compensation costs—whether borne directly by the employer, by a federation, or by a state organization—can be assumed to be proportional to the pain and suffering in the workplace. Thus, in identifying the source of loss, management is discharging its responsibility for providing safe working conditions for the workforce in a way that is highly compatible with the cost/benefit analysis approach used in other activities.

Direct costs are not the true financial costs from accidents and injuries borne by an enterprise. In many countries around the world, and with various degrees of rigour, attempts have been made to estimate indirect costs associated with accidents. These indirect costs include loss in supervisory time, loss of productive time during the accident investigation and cleanup, retraining of replacement workers, and the amount of overtime required to meet production schedules. These indirect costs have been found to exceed the direct costs substantially, often by factors estimated to be in a range of three to ten times those of the direct insurance losses.

Determining Costs

The measurement of losses normally involves passive surveillance, which requires that the preceding history be examined in terms of frequency and severity of accidents. Passive surveillance is not sufficient for certain situations, particularly those with very low probabilities of errors occurring, but large, uncontrolled potential damage in the case that they do occur. In such circumstances, particularly in complex process industries, it is necessary to perform an assessment of potential losses. It is clearly unacceptable that, simply because no process has yet claimed a victim, processes involving large amounts of energy or of toxic materials should not be analysed prior to such an accident. Thus, in some industries, it is wise to institute active surveillance, particularly where similar processes elsewhere have led to losses. Information from trade associations and from national and international labour and safety organizations is a valuable source that can be used to establish pre-incident estimates which are likely to be valid and valuable. Other techniques, including fault tree analysis and failure mode analysis, are discussed elsewhere in this Encyclopaedia. In circumstances such as those involving chemical exposures, active surveillance may include routine medical examinations of the worker. Such an approach is particularly significant where well-established limit values have been determined. This approach of estimating potential and actual losses highlights a feature that the successful safety programme should address, and that is the difference between day-to-day risk and the effect of a potential catastrophe.

Information Feedback

The use of information feedback has been shown to be crucial in a wide range of organizational activities, including safety programmes. The calculation of both incidence rates and severity rates will form the basis for rational deployment of resources by the enterprise and for measuring the success of the programme. This information is as valuable to management for evaluating the safety function as it is to workers in the execution of the programme. However, the presentation of such data should reflect the end user: aggregated data will allow management comparison of operating units; department-specific data and visual aids (such as thermometer charts indicating the number of safe work days at the shop-floor level) can enhance understanding of, and buy-in from, the whole spectrum of employees.

Field Observation

The information system is an off-line component of a successful safety programme, which must be complemented by a hands-on approach to safety in the workplace. Such an approach would involve the walk-through, in which an informed and trained observer subjectively identifies hazards in the workplace. In addition to identifying hazards, the walk-through is particularly suitable for detecting issues of non-compliance with both corporate and legislative requirements. For example, the reduction of hazards by machine guarding is ineffective if many of the machines have had the guards removed—a typical finding of a walk-through. As the walk-through is an open-ended and adaptive procedure, it is also the easiest way to detect deficiencies in the training of the worker, and possibly those of the supervisor.

Effective safety programmes should utilize this technique on a regular but random basis. The walk-through, however, is not the only way of identifying hazards. The workers themselves can provide essential information. In many cases, they have experience of “near misses” that have never been reported, and are consequently in a good position to discuss these with the safety officer during the walk-through. Workers in general should be encouraged by supervision to report safety defects both actual and potential.

Accident Investigation

All accidents must be investigated by the responsible supervisor. Accidents such as those in the process industry often require investigation by a team of knowledgeable persons representing diverse interests, possibly including an outside expert. Successful programmes frequently involve workers in such accident investigations. This involvement brings benefits in terms of better understanding of the incident and of rapid dissemination of recommendations throughout the workforce. From figure 1, it is clear that, in this context, accidents are not only those events that conclude in an injury to a worker, but rather, events that encompass damage to equipment or materials or even significant events that result in neither (known as “near accidents”). The figure indicates that such incidents should be subject to management investigation and control even if, fortuitously, no worker is injured. Avoidance of similar incidents in the future will reduce the risk that they will result in injury. Accident investigations that seek to lay blame appear to be less successful than those seeking methods to determine cause. In an investigation that is seen to be an attempt to blame a worker, peer pressure and other psychosocial behaviours can severely degrade the quality of information collected.

The essentials of an accident report will include a formalized process, involving written descriptions of the events that occurred before, during and after the accident as well as an assessment of the factors that led to the accident. The report should end with a clear recommendation for action. The recommendation could range from immediate modification of the work process or, in the case of complex situations, to the need for further, professional investigation. Such reports should be signed by the responsible supervisor or the leader of the investigation team, and forwarded to an appropriate level of management. Management review and acceptance of the recommendations is an essential part of the accident reporting process. The signature of the manager should indicate his or her endorsement or rejection of the proposed changes to prevent future accidents, and rejections should be accompanied by an explanation. Accident investigations that do not lead to an individual responsibility for action for the recommendations are likely to be ineffective, and rapidly become viewed by all involved as irrelevant. A successful safety programme seeks to ensure that lessons learned from a particular incident are shared elsewhere within the organization.

Hazard Control

The best intervention as regards hazard control will always be the removal of the hazard by engineering design, substitution or modification. If the hazard is removed (or, at second best, shielded or guarded), then irrespective of the human variability arising from training, individual differences of strength, attention, fatigue or diurnal rhythm, the operator will be protected.

Unfortunately, in some cases, the costs of achieving this engineering design can reach or exceed the limits of economic liability. Certain processes are inherently much riskier than others, and feasible engineering designs are only partial solutions. Construction projects carried out at elevated sites, deep coal mining, steel production and over-the-road driving all require exposure of employees to higher than “normal” risks. In such cases, administrative control and personal protective devices may be necessary. Administrative control may involve specific training and procedures to reduce risks: consider, for example, the prohibition against individual workers entering confined spaces, or the provision of lockout systems designed to isolate dangerous equipment and processes from the operator during the work cycle. These procedures can be effective, but require continual maintenance. In particular, work practices tend to move away from compliance with the necessary administrative procedures. This trend must be halted by the implementation of procedures for training, and refresher training as well, for all workers and supervisors involved in the system.

The final component in hazard control is the use of personal protective devices, which include respirators, protective gloves, whole-body harnesses and hard hats, to mention just a few. In general, it can be seen that such devices are valuable when the hazards have not been entirely removed from the workplace, nor controlled by administrative procedures. They are intended to reduce the effect of such hazards on the worker, and typically are subject to concerns of improper use, design limitations, inadequate supervisor oversight, and failure of maintenance.

First Aid

Despite the best attempts to reduce hazards, the successful safety programme must address the post-accident scenario. The development of first aid and emergency medical treatment capabilities can provide major benefits for the safety programme. A protocol must be established for medical treatment following an accident. Selected workers must be familiarized with the written instructions for summoning medical assistance to the worksite. Such assistance should be prearranged, for a delay can seriously affect the condition of an injured worker. For accidents producing minor injuries, the inherent losses can be reduced by the provision of point-of-incident medical treatment. In-plant treatment for minor cuts and bruises, contusions and so on, can reduce operators’ time away from their tasks.

The first aid capability must include acceptable levels of supplies, but more important, adequate medical/first aid training. Such training can directly affect the probability of survival in case of a potentially mortal injury, and can reduce the actual severity of a range of less serious accidents. First aid action such as cardiopulmonary resuscitation, or the stabilization of haemorrhaging, can make the difference between life and death to patients in need of major emergency treatment. Frequently, the provision of immediate first aid at the accident site provides the opportunity for subsequent major surgical interventions. Such a capability is even more significant in nonurban enterprises, where medical treatment may be delayed by a matter of hours.

First aid can also facilitate the efficient return to work of a worker involved in a minor injury. Such in-house intervention has been shown to reduce the need for lengthy medical visits outside the enterprise, and thus prevents a loss of productivity. Perhaps even more significant is the reduced chance of the medicalization of the injury, which is seen as an emerging problem in several countries.

Catastrophe Planning

Routinely, at least annually, a safety programme should identify potential causes of catastrophe. In some circumstances—for example, with the storage of large amounts of flammable or hazardous materials—the focus of attention is not too difficult. In other circumstances, great ingenuity may be required to make meaningful suggestions to plan for such catastrophes. By definition, catastrophes are rare, and it is unlikely that a particular enterprise would have suffered a similar catastrophe earlier. Definition of medical management, communication flows and managerial control of the catastrophe situation should form part of the safety programme. It is clear that in many enterprises such annual plans would be rather minimal, but the very exercise of developing them can be valuable in increasing the management’s awareness of some of the risks that the business assumes.

Conclusion

The successful safety programme is not a book, or a binder of notes, but a conceptual plan to reduce the risks of injury as measured on the basis of both incidents and severity. Like all other processes in an enterprise, the safety process is the responsibility of management rather than that of a safety engineer or an individual worker. Management is responsible for setting the goals, providing resources, establishing means of measuring progress towards those goals and taking corrective action when this progress is unsatisfactory. In order to do this, information is the key requirement, followed in importance by communication of the objectives at all levels within the enterprise. At each level, from executive through management supervisor to the individual worker, contributions to safe working conditions can be made. But at the same time, organizational, procedural and behavioural inadequacies may regrettably prevent such contributions from occurring. The successful safety programme is one which recognizes and utilizes such factors in developing an integrated approach to reducing the pain and suffering in the workplace which arises from injuries and disease.