Forestry work is one of those occupations where personal protective equipment (PPE) is always needed. Mechanization has decreased the number of workers using hand-held chain-saws, but the remaining tasks are often in difficult places where the big machines cannot reach.

The efficiency and chain speed of the hand-held chain-saws have increased, while the protection given by protective clothing and footwear has decreased. The higher requirement for the protection has made the equipment heavy. Especially in summertime in Nordic countries, and all around the year in other countries, the protective devices add an extra load to the heavy work of forest workers. This article focuses on chain-saw operators, but protection is needed in most forestry work. Table 1 provides an overview of what should normally be required.

Table 1. Personal protective equipment appropriate for forestry operations.

| Operations | PPE1 |

| Planting Manual Mechanized | Safety boots or shoes Safety boots or shoes, close-fit clothing, ear muffs2 |

| Weeding/cleaning Smooth-edged tools Hand-saw Chain-saw | Safety boots or shoes, gloves, goggles Safety boots or shoes, gloves Safety boots or shoes,3 safety trousers, close-fit clothing, gloves,4 safety helmet, goggles, visor (mesh), ear muffs |

| Brush saw: with metal blade with nylon filament | Safety boots or shoes,3 safety trousers, close-fit clothing, gloves,4 safety helmet, goggles, visor (mesh), ear muffs Safety boots or shoes, safety trousers, gloves, goggles, ear muffs |

| Rotating knife/flail | Safety boots or shoes, close-fit clothing, gloves, ear muffs2 |

| Pesticide application | To comply with the specifications for the particular substance and application technique |

| Pruning5 Hand tools | Safety boots or shoes, gloves, safety helmet, 6 goggles, ear muffs |

| Felling7 Hand tools Chain-saw | Safety boots or shoes, close-fit clothing, gloves,8 safety helmet Safety boots or shoes, safety trousers, close-fit clothing, gloves,4 safety helment, visor (mesh), ear muffs |

| Mechanized | Safety boots or shoes, close-fit clothing, safety helmet, ear muffs |

| Debarking Manual Mechanized | Safety boots or shoes, gloves Safety boots or shoes, close-fit clothing, gloves, goggles, ear muffs2 |

| Splitting Manual Mechanized | Safety boots or shoes, gloves, goggles Safety boots or shoes, close-fit clothing, gloves, goggles, ear muffs |

| Extraction Manual, chute and animal Mechanized -skidder -forewarder -cable crane -heliocopter | Safety boots or shoes, gloves, safety helmet9 Safety boots or shoes, close-fit clothing, gloves,10 safety helmet, ear muffs2 Safety boots or shoes, close-fit clothing, safety helmet, ear muffs2 Safety boots or shoes, close-fit clothing, gloves,10 safety helmet, ear muffs2 Safety boots or shoes, close-fit clothing,11 gloves,10 safety helmet, goggles, ear muffs |

| Stacking/loading | Safety boots or shoes, close-fit clothing, gloves, safety helmet, ear muffs2 |

| Chipping | Safety boots or shoes, close-fit clothing, gloves, safety helmet, visor (mesh), ear muffs2 |

| Tree climbing: using a chain-saw not using a chain-saw | Safety boots or shoes,3 safety trousers, close-fit clothing, gloves,4 safety helmet,13 goggles, ear muffs Safety boots or shoes, safety helmet |

1 Safety boots or shoes should include integrated steel toes for medium or heavy loads. Safety trousers should incorporate clogging material; in hot climates/weather chain-saw leggings or chaps may be used. Safety trousers and chaps contain fibres that are inflammable and can melt; they should not be worn during firefighting. Ear plugs and ear valves are generally not suitable for forestry because of risk of infection.

2 When noise level at work position exceeds 85 dBA.

3 Chain-saw boots must have protective guarding at front vamp and instep.

4 Cut-resistant material must be incorporated.

5 If pruning involves tree climbing above 3 m, a fall-restricting device should be used. PPE must be used when falling branches are likely to cause injury.

6 When pruning to a height exceeding 2.5 m.

7 Felling includes debranching and crosscutting.

8 When using a hand-saw.

9 When extracting near unstable trees or branchwood.

10 Only if manipulating logs; gloves with heavy-duty palm if handling wire choker rope or tether line.

11 Highly visible colours should be used.

12 Helmet must have a chin strap.

13 Climbing helmets are preferable; if they are not available, safety helmets with chin straps may be used.

Source: ILO 1997.

Protection Mechanism and Efficiency of Personal Protective Devices

Protective clothing

Protective clothing against cuts protects by three different main mechanisms. In most cases the trousers and gloves contain a safety padding made of multilayer cloth having fibres with high tensile strength. When the moving chain touches the fibres, they are pulled out and will resist the movement of the chain. Second, these padding materials can go around the drive sprocket and the groove of the blade and increase the friction of the chain against the blade so much that the chain will stop. Third, the material can also be made such that the chain glides on the surface and cannot easily penetrate it.

Different work tasks require different protective coverage. For normal forest work the protective padding covers only the front part of the trousers and the back of safety gloves. Special tasks (e.g., gardening or tree surgery) often require a larger area of protective coverage. The protective paddings cover the legs totally, including the back side. If the saw is held above the head, protection of the upper body may be needed.

It must always be remembered that all PPE gives only limited protection, and correct and careful working methods must be used. The new hand-held chain-saws are so effective that the chain can easily go through the best protective material when the chain speed is high or the force of the chain against the protective material is great. Cut-proof protective paddings made of the best materials known at present would be so thick that they could not be used in heavy forest work. The compromise between protection efficiency and comfort is based on field experiments. It has been unavoidable that the protection level has been reduced to be able to increase the comfort of the clothing.

Protective footwear

Protective footwear made of rubber resists against cuts by the chain-saw quite well. The most frequent type of cut comes from contact of the chain with the toe area of the footwear. The safety footwear must have a cut-resistant lining on the front and metallic toe cups; this protects against these cuts very well. In higher temperatures the use of rubber boots is uncomfortable, and leather boots or ankle-high shoes should be used. These shoes too must be equipped with metallic toe cups. The protection is normally considerably lower than that of the rubber boots, and extra care should be taken when using leather boots or shoes. The working methods must be so planned that the possibility of chain contact with the feet is minimized.

Good fit and construction of the outer sole is essential to avoid slipping and falling accidents, which are very common. In areas where the ground may be covered by ice and snow or where workers walk on slippery logs, boots which can be equipped with spikes are preferred.

Protective helmet

Protective helmets provide protection against falling branches and trees. They also give protection against the chain-saw if a kick-back occurs. The helmet should be as light as possible to minimize neck strain. The headband must be correctly adjusted to make the helmet sit firmly on the head. The headbands of most helmets are so designed that vertical adjustment is possible as well. It is important to have the helmet sitting low on the brow so its weight does not cause too much discomfort when working in face-down posture. In cold weather it is necessary to use a textile or fur cap under the helmet. Special caps designed to be used with the helmet should be used. The cap can lower the protection efficiency of the helmet by wrong positioning of the helmet. The protection efficiency of hearing protectors can go to near zero when the cups of the hearing protectors are placed outside the cap. Forestry helmets have built-in devices to attach a visor and earmuffs for hearing protection. The cups of the hearing protectors should be placed directly against the head by insertion of the cups through slits in the cap.

In hot weather, helmets should have ventilation holes. The holes have to be part of the design of the helmet. Under no circumstances should holes be drilled into the helmet, as this may greatly reduce its strength.

Face and eye protection

The face protector or shield is normally attached to the helmet and is most commonly made of a mesh material. The plastic sheets easily get dirty after a relatively short working time. Cleaning is also difficult because the plastics resist solvents poorly. The mesh reduces the light coming to the eyes of the worker, and reflections on the surface of the threads can make seeing difficult. Sealed goggles worn under face protectors mist easily, and distortion of vision is often too high. Metal masks with a black coating and rectangular rather than round openings are preferable.

Hearing protectors

Hearing protectors are efficient only if the cups are placed firmly and tightly against the head. Therefore hearing protectors must be used carefully. Any space between the head and the sealing rings of the cups will decrease the efficiency markedly. For example, the side-arms of spectacles can cause this. The sealing ring shall be inspected often and must be changed when damaged.

Selection of Personal Protective Equipment

Before starting work in a new area, the possible risks should be evaluated. The working tools, methods, environment, the skills of the workers and so on should be evaluated, and all technical and organizational measures should be planned. If the risks cannot be eliminated by those methods, PPE can be used to improve the protection. PPE can never be used as the only preventive method. It must be seen as a complementary means only. The saw must have a chain brake, the worker must be trained and so on.

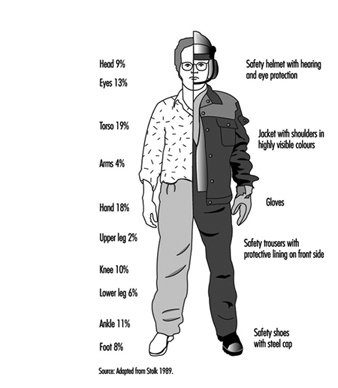

On the basis of this risk analysis, the requirements for personal protective devices must be defined. Environmental factors should be taken into account in order to minimize the load cased by the equipment. The hazard caused by the saw must be evaluated and the protection area and efficiency of clothing defined. If the workers are not professionals, the protection area and level should be higher, but this extra loading must be taken into account when the work periods are planned. After the requirements for PPE are defined according to the risks and tasks, the proper equipment is selected from among devices that have been approved. The workers should have the privilege of trying different models and sizes to select the one that best suits them. Improperly selected clothing can cause abnormal postures and movements, and thus can increase accident and health hazard risks. Figure 1 illustrates the selection of equipment.

Figure 1. Bodily location of injuries and personal protective equipment recommended for forest work, the Netherlands, 1989.

Determination of the Conditions of Use

All workers should be efficiently instructed and trained in the use of PPE. The protection mechanism must be described so that the workers themselves can inspect and evaluate the condition of the equipment daily. The consequences of non-use must be made clear. Proper cleaning and repair instructions must be given.

The protective equipment used in forestry work may constitute a relatively great extra burden to the worker. This must be taken into account when planning the working times and rest periods.

Often the use of PPE gives a false sense of safety. The supervisors must make sure that risk taking is not increasing and that the workers know well the limits of the protection efficiency.

Care and Maintenance

Improper methods used for maintenance and repair can destroy the protection efficiency of the equipment.

The shell of the helmet must be cleaned by weak detergent solutions. Resins cannot be removed efficiently without the use of solvents, but the use of solvents should be avoided because the shell can be damaged. The instructions of the manufacturer must be followed and the helmet discarded if it cannot be cleaned. Some materials are more resistant against the effects of solvents, and those should be selected for forest work use.

Also other environmental factors affect the materials used in a helmet. Plastic materials are sensitive to ultraviolet (UV) radiation of the sun, which makes the shell more rigid, especially at low temperatures; this ageing weakens the helmet, and it will not protect against impacts as planned. The ageing is difficult to see, but small hairline cracks and the loss of gloss can be signs of ageing. Also, when gently twisted, the shell may make cracking noises. The helmets should be carefully visually inspected at least every six months.

If the chain has been in contact with the trousers, the protection efficiency can be much reduced or disappear totally. If the safety padding fibres are drawn out, the trousers should be discarded and new ones should be used. If only the outer material is damaged it can be repaired carefully without making any stitches through the safety padding. The protection efficiency of safety trousers is commonly based on the strong fibres, and if those are fixed tightly during repair they will not provide protection as planned.

Washing must be done according to the instructions given by the manufacturer. It has been shown that wrong washing methods can destroy protection efficiency. The clothing of the forest worker is difficult to clean, and products should be selected which withstand the hard washing methods needed.

How the Approved Protective Equipment is Marked

The design and quality of manufacture of PPE must meet high standards. In the European Economic area, personal protective devices must be tested before they are placed on the market. The basic health and safety requirements for PPE are described in a directive. To clarify those requirements European harmonized standards have been drafted. The standards are voluntary, but devices designed to meet the requirements in the appropriate standards are deemed to meet the requirements of the directive. The International Standards Organization (ISO) and the European Committee for Standardization (CEN) are working on these standards together according to the Vienna Agreement. So there will be technically identical EN and ISO standards.

Accredited test stations are testing the devices and issuing a certificate if they meet the requirements. After that the manufacturer can mark the product with CE-marking, which shows that the conformity assessment has been carried out. In other countries the procedure is similar and the products are marked with the national approval mark.

An essential part of the product is the leaflet giving the user information about its proper use, the degree of protection it can provide and instructions for its cleaning, washing and repair.