Iron is most widely found in the crust of the earth, in the form of various minerals (oxides, hydrated ores, carbonates, sulphides, silicates and so on). Since prehistoric times, humans have learned to prepare and process these minerals by various washing, crushing and screening operations, by separating the gangue, calcining, sintering and pelletizing, in order to render the ores smeltable and to obtain iron and steel. In historic times, a prosperous iron industry developed in many countries, based on local supplies of ore and the proximity of forests to supply the charcoal for fuel. Early in the 18th century, the discovery that coke could be used in place of charcoal revolutionized the industry, making possible its rapid development as the base on which all other developments of the Industrial Revolution rested. Great advantages accrued to those countries where natural deposits of coal and iron ore lay close together.

Steel making was largely a development of the 19th century, with the invention of melting processes; the Bessemer (1855), the open hearth, usually fired by producer gas (1864); and the electric furnace (1900). Since the middle of the 20th century, oxygen conversion, pre-eminently the Linz-Donowitz (LD) process by oxygen lance, has made it possible to manufacture high quality steel with relatively low production costs.

Today, steel production is an index of national prosperity and the basis of mass production in many other industries such as shipbuilding, automobiles, construction, machinery, tools, and industrial and domestic equipment. The development of transport, in particular by sea, has made the international exchange of the raw materials required (iron ores, coal, fuel oil, scrap and additives) economically profitable. Therefore, the countries possessing iron ore deposits near coal fields are no longer privileged, and large smelting plants and steelworks have been built in the coastal regions of major industrialised countries and are supplied with raw materials from exporting countries which are able to meet the present-day requirements for high-grade materials.

During the past decades, so-called direct-reduction processes have been developed and have met with success. The iron ores, in particular high-grade or upgraded ores, are reduced to sponge iron by extracting the oxygen they contain, thus obtaining a ferrous material that replaces scrap.

Iron and Steel Production

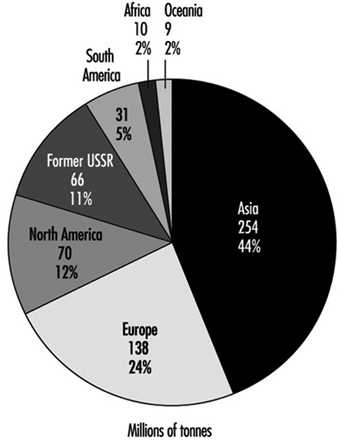

The world’s pig iron production was 578 million tonnes in 1995 (see figure 1).

Figure 1. World pig iron production in 1995, by regions

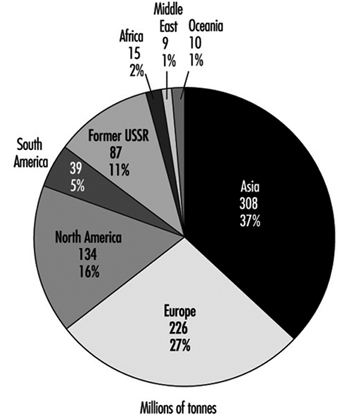

The world’s raw steel production was 828 million tonnes in 1995 (see figure 2).

Figure 2. World raw steel production in 1995, by regions

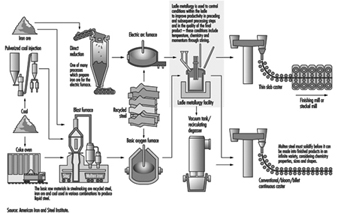

The steel industry has been undergoing a technological revolution, and the trend in building new production capacity has been towards the recycled steel-scrap-using electric arc furnace (EAF) by smaller mills (see figure 3). Although integrated steel works where steel is made from iron ore are operating at record levels of efficiency, EAF steel works with production capacities in the order of less than 1 million tonnes a year are becoming more common in the main steel-producing countries of the world.

Figure 3. Scrap charges or electric furnaces

Iron making

The overall flow line of iron and steel making is shown in figure 4.

Figure 4. Flow line of steel making

For iron making, the essential feature is the blast furnace, where iron ore is melted (reduced) to produce pig iron. The furnace is charged from the top with iron ore, coke and limestone; hot air, frequently enriched with oxygen, is blown in from the bottom; and the carbon monoxide produced from the coke transforms the iron ore into pig iron containing carbon. The limestone acts as a flux. At a temperature of 1,600°C (see figure 5) the pig iron melts and collects at the bottom of the furnace, and the limestone combines with the earth to form slag. The furnace is tapped (i.e., the pig iron is removed) periodically, and the pig iron may then be poured into pigs for later use (e.g., in foundries), or into ladles where it is transferred, still molten, to the steel-making plant.

Figure 5. Taking the temperature of molten metal in a blast furnace

Some large plants have coke ovens on the same site. The iron ores are generally subjected to special preparatory processes before being charged into the blast furnace (washing, reduction to ideal lump size by crushing and screening, separation of fine ore for sintering and pelletizing, mechanized sorting to separate the gangue, calcining, sintering and pelletizing). The slag that is removed from the furnace may be converted on the premises for other uses, in particular for making cement.

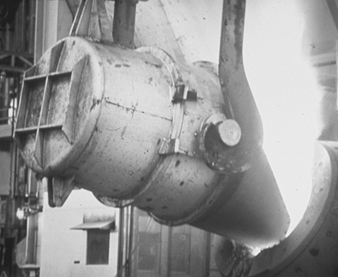

Figure 6. Hot metal charge for basic-oxygen furnace

Steel making

Pig iron contains large amounts of carbon as well as other impurities (mainly sulphur and phosphorus). It must, therefore, be refined. The carbon content must be reduced, the impurities oxidized and removed, and the iron converted into a highly elastic metal which can be forged and fabricated. This is the purpose of the steel-making operations. There are three types of steel-making furnaces: the open-hearth furnace, the basic-oxygen process converter (see figure 6) and the electric arc furnace (see figure 7). Open-hearth furnaces for the most part have been replaced by basic-oxygen converters (where steel is made by blowing air or oxygen into molten iron) and electric arc furnaces (where steel is made from scrap iron and sponge-iron pellets).

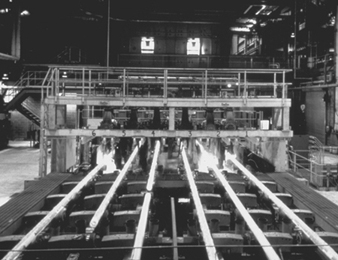

Figure 7. General view of electric furnace casting

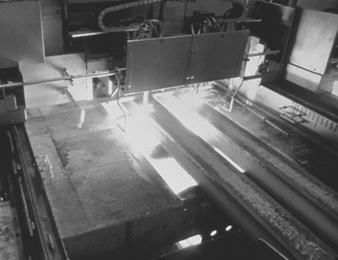

Special steels are alloys in which other metallic elements are incorporated to produce steels with special qualities and for special purposes, (e.g., chromium to prevent rusting, tungsten to give hardness and toughness at high temperatures, nickel to increase strength, ductility and corrosion resistance). These alloying constituents may be added either to the blast-furnace charge (see figure 8) or to the molten steel (in the furnace or ladle) (see figure 9). Molten metal from the steel-making process is poured into continuous-casting machines to form billets (see figure 10), blooms (see figure 11) or slabs. The molten metal can also be poured into moulds to form ingots. The majority of steel is produced by the casting method (see figure 12). The benefits of continuous casting are increased yield, higher quality, energy savings and a reduction in both capital and operating costs. Ingot-poured moulds are stored in soaking pits (i.e. underground ovens with doors), where ingots can be reheated before passing to the rolling mills or other subsequent processing (figure 4). Recently, companies have begun making steel with continuous casters. Rolling mills are discussed elsewhere in this chapter; foundries, forging and pressing are discussed in the chapter Metal processing and metal working industry.

Figure 8. Back of hot-metal charge

Figure 9. Continuous-casting ladle

Figure 10. Continuous-casting billet

Figure 11. Continuous-casting bloom

Figure 12. Control pulpit for continuous-casting process

Hazards

Accidents

In the iron and steel industry, large amounts of material are processed, transported and conveyed by massive equipment that dwarfs that of most industries. Steel works typically have sophisticated safety and health programmes to address hazards in an environment that can be unforgiving. An integrated approach combining good engineering and maintenance practices, safe job procedures, worker training and use of personal protective equipment (PPE) is usually required to control hazards.

Burns may occur at many points in the steel-making process: at the front of the furnace during tapping from molten metal or slag; from spills, spatters or eruptions of hot metal from ladles or vessels during processing, teeming (pouring) or transporting; and from contact with hot metal as it is being formed into a final product.

Water entrapped by molten metal or slag may generate explosive forces that launch hot metal or material over a wide area. Inserting a damp implement into molten metal may also cause violent eruptions.

Mechanical transport is essential in iron and steel manufacturing but exposes workers to potential struck-by and caught- between hazards. Overhead travelling cranes are found in almost all areas of steel works. Most large works also rely heavily on the use of fixed-rail equipment and large industrial tractors for transporting materials.

Safety programmes for crane use require training to ensure proper and safe operation of the crane and rigging of loads to prevent dropped loads; good communication and use of standard hand signals between crane drivers and slingers to prevent injuries from unexpected crane movement; inspection and maintenance programs for crane parts, lifting tackle, slings and hooks to prevent dropped loads; and safe means of access to cranes to avoid falls and accidents on crane transverse ways.

Safety programmes for railways also require good communication, especially during shifting and coupling of rail cars, to avoid catching people between rail car couplings.

Maintaining proper clearance for passage of large industrial tractors and other equipment and preventing unexpected start-up and movement are necessary to eliminate struck-by, struck-against and caught-between hazards to equipment operators, pedestrians and other vehicle operators. Programmes are also necessary for inspection and maintenance of equipment safety appliances and passageways.

Good housekeeping is a cornerstone of safety in iron and steel works. Floors and passageways can quickly become obstructed with material and implements that pose a tripping hazard. Large quantities of greases, oils and lubricants are used and if spilled can easily become a slipping hazard on walking or working surfaces.

Tools are subject to heavy wear and soon become compromised and perhaps dangerous to use. Although mechanization has greatly lessened the amount of manual handling in the industry, ergonomic strains still may occur on many occasions.

Sharp engines or burrs on steel products or metal bands pose laceration and puncture hazards to workers involved in finishing, shipping and scrap-handling operations. Cut-resistant gloves and wrist guards are often used to eliminate injuries.

Protective eye-wear programmes are particularly important in iron and steel works. Foreign-body eye hazards are prevalent in most areas, especially in raw material handling and steel finishing, where grinding, welding and burning are conducted.

Programmed maintenance is particularly important for accident prevention. Its purpose is to ensure the efficiency of the equipment and maintain fully operative guards, because failure may cause accidents. Adhering to safe operating practices and safety rules is also very important because of the complexity, size and speed of process equipment and machinery.

Carbon monoxide poisoning

Blast furnaces, converters and coke ovens produce large quantities of gases in the process of iron and steel manufacturing. After the dust has been removed, these gases are used as fuel sources in the various plants, and some are supplied to chemical plants for use as raw materials. They contain large amounts of carbon monoxide (blast-furnace gas, 22 to 30%; coke oven gas, 5 to 10%; converter gas, 68 to 70%).

Carbon monoxide sometimes emanates or leaks from the tops or bodies of blast furnaces or from the many gas pipelines inside plants, accidentally causing acute carbon monoxide poisoning. Most cases of such poisoning occur during work around blast furnaces, especially during repairs. Other cases occur during work around hot stoves, tours of inspection around the furnace bodies, work near the furnace tops or work near cinder notches or the tapping notches. Carbon monoxide poisoning may also result from gas released from water-seal valves or seal pots in the steel-making plants or rolling mills; from sudden shutdown of blowing equipment, boiler rooms or ventilation fans; from leakage; from failure to properly ventilate or purge process vessels, pipelines or equipment prior to work; and during closing of pipe valves.

Dust and fumes

Dust and fumes are generated at many points in the manufacture of iron and steel. Dust and fumes are found in the preparation processes, especially sintering, in front of the blast furnaces and steel furnaces and in ingot making. Dusts and fumes from iron ore or ferrous metals do not readily cause pulmonary fibrosis and pneumoconiosis is infrequent. Some lung cancers are thought to be connected with carcinogens found in coke-oven emissions. Dense fumes emitted during the use of oxygen lances and from the use of oxygen in open-hearth furnaces may particularly affect crane operators.

Exposure to silica is a risk to workers engaged in lining, relining and repairing blast furnaces and steel furnaces and vessels with refractory materials, which may contain as much as 80% silica. Ladles are lined with fire-brick or bonded crushed silica and this lining requires frequent repair. The silica contained in refractory materials is partly in the form of silicates, which do not cause silicosis but rather pneumoconiosis. Workers are rarely exposed to heavy clouds of dust.

Alloy additions to furnaces making special steels sometimes bring potential exposure risks from chromium, manganese, lead and cadmium.

Miscellaneous hazards

Bench and top-side operations in coking operations in front of blast furnaces in iron making and furnace-front, ingot-making and continuous-casting operations in steel making all involve strenuous activities in a hot environment. Heat-illness prevention programmes must be implemented.

Furnaces may cause glare that can injure eyes unless suitable eye protection is provided and worn. Manual operations, such as furnace bricklaying, and hand-arm vibration in chippers and grinders may cause ergonomic problems.

Blower plants, oxygen plants, gas-discharge blowers and high-power electric furnaces may cause hearing damage. Furnace operators should be protected by enclosing the source of noise with sound-deadening material or by providing sound-proofed shelters. Reducing exposure time may also prove effective. Hearing protectors (earmuffs or earplugs) are often required in high-noise areas due to the unfeasibility of obtaining adequate noise reduction by other means.

Safety and Health Measures

Safety organization

Safety organization is of prime importance in the iron and steel industry, where safety depends so much on workers’ reaction to potential hazards. The first responsibility for management is to provide the safest possible physical conditions, but it is usually necessary to obtain everyone’s cooperation in safety programmes. Accident-prevention committees, workers’ safety delegates, safety incentives, competitions, suggestion schemes, slogans and warning notices can all play an important part in safety programmes. Involving all persons in site hazard assessments, behaviour observation and feedback exercises can promote positive safety attitudes and focus work groups working to prevent injuries and illnesses.

Accident statistics reveal danger areas and the need for additional physical protection as well as greater stress on housekeeping. The value of different types of protective clothing can be evaluated and the advantages can be communicated to the workers concerned.

Training

Training should include information about hazards, safe methods of work, avoidance of risks and the wearing of PPE. When new methods or processes are introduced, it may be necessary to retrain even those workers with long experience on older types of furnaces. Training and refresher courses for all levels of personnel are particularly valuable. They should familiarize personnel with safe working methods, unsafe acts to be proscribed, safety rules and the chief legal provisions associated with accident prevention. Training should be conducted by experts and should make use of effective audio-visual aids. Safety meetings or contacts should be held regularly for all persons to reinforce safety training and awareness.

Engineering and administrative measures

All dangerous parts of machinery and equipment, including lifts, conveyors, long travel shafts and gearing on overhead cranes, should be securely guarded. A regular system of inspection, examination and maintenance is necessary for all machinery and equipment of the plant, particularly for cranes, lifting tackle, chains and hooks. An effective lockout/tagout programme should be in operation for maintenance and repair. Defective tackle should be scrapped. Safe working loads should be clearly marked, and tackle not in use should be stored neatly. Means of access to overhead cranes should, where possible, be by stairway. If a vertical ladder must be used, it should be hooped at intervals. Effective arrangements should be made to limit the travel of overhead cranes when persons are at work in the vicinity. It may be necessary, as required by law in certain countries, to install appropriate switchgear on overhead cranes to prevent collisions if two or more cranes travel on the same runway.

Locomotives, rails, wagons, buggies and couplings should be of good design and maintained in good repair, and an effective system of signalling and warning should be in operation. Riding on couplings or passing between wagons should be prohibited. No operation should be carried on in the track of rail equipment unless measures have been taken to restrict access or movement of equipment.

Great care is needed in storing oxygen. Supplies to different parts of the works should be piped and clearly identified. All lances should be kept clean.

There is a never-ending need for good housekeeping. Falls and stumbles caused by obstructed floors or implements and tools left lying carelessly can cause injury in themselves but can also throw a person against hot or molten material. All materials should be carefully stacked, and storage racks should be conveniently placed for tools. Spills of grease or oil should be immediately cleaned. Lighting of all parts of the shops and machine guards should be of a high standard.

Industrial hygiene

Good general ventilation throughout the plant and local exhaust ventilation (LEV) wherever substantial quantities of dust and fumes are generated or gas may escape are necessary, together with the highest possible standards of cleanliness and housekeeping. Gas equipment must be regularly inspected and well maintained so as to prevent any gas leakage. Whenever any work is to be done in an environment likely to contain gas, carbon monoxide gas detectors should be used to ensure safety. When work in a dangerous area is unavoidable, self-contained or supplied-air respirators should be worn. Breathing-air cylinders should always be kept in readiness, and the operatives should be thoroughly trained in methods of operating them.

With a view to improving the work environment, induced ventilation should be installed to supply cool air. Local blowers may be located to give individual relief, especially in hot working places. Heat protection can be provided by installing heat shields between workers and radiant heat sources, such as furnaces or hot metal, by installing water screens or air curtains in front of furnaces or by installing heat-proof wire screens. A suit and hood of heat-resistant material with air-line breathing apparatus gives the best protection to furnace workers. As work in the furnaces is extremely hot, cool-air lines may also be led into the suit. Fixed arrangements to allow cooling time before entry into the furnaces are also essential.

Acclimatization leads to natural adjustment in the salt content of body sweat. The incidence of heat affections may be much lessened by adjustments of the workload and by well-spaced rest periods, especially if these are spent in a cool room, air- conditioned if necessary. As palliatives, a plentiful supply of water and other suitable beverages should be provided and there should be facilities for taking light meals. The temperature of cool drinks should not be too low and workers should be trained not to swallow too much cool liquid at a time; light meals are to be preferred during working hours. Salt replacement is needed for jobs involving profuse sweating and is best achieved by increasing salt intake with regular meals.

In cold climates, care is required to prevent the ill-effects of prolonged exposure to cold or sudden and violent changes of temperature. Canteen, washing and sanitary facilities should preferably be close at hand. Washing facilities should include showers; changing rooms and lockers should be provided and maintained in a clean and sanitary condition.

Wherever possible, sources of noise should be isolated. Remote central panels remove some operatives from the noisy areas; hearing protection should be required in the worst areas. In addition to enclosing noisy machinery with sound-absorbing material or protecting the workers with sound-proofed shelters, hearing protection programmes have been found to be effective means of controlling noise-induced hearing loss.

Personal protective equipment

All parts of the body are at risk in most operations, but the type of protective wear required will vary according to the location. Those working at furnaces need clothing that protects against burns—overalls of fire-resisting material, spats, boots, gloves, helmets with face shields or goggles against flying sparks and also against glare. Safety boots, safety glasses and hard hats are imperative in almost all occupations and gloves are widely necessary. The protective clothing needs to take account of the risks to health and comfort from excessive heat; for example a fire-resisting hood with wire mesh visor gives good protection against sparks and is resistant to heat; various synthetic fibres have also proved efficient in heat resistance. Strict supervision and continuous propaganda are necessary to ensure that personal protective equipment is worn and correctly maintained.

Ergonomics

The ergonomic approach (i.e. investigation of the worker-machine-environment relationship) is of particular importance at certain operations in the iron and steel industry. An appropriate ergonomic study is necessary not only to investigate conditions while a worker is carrying out various operations, but also to explore the impact of the environment on the worker and the functional design of the machinery used.

Medical supervision

Pre-placement medical examinations are of great importance in selecting persons suitable for the arduous work in iron and steel making. For most work, a good physique is required: hypertension, heart diseases, obesity and chronic gastroenteritis disqualify individuals from work in hot surroundings. Special care is needed in the selection of crane drivers, both for physical and mental capacities.

Medical supervision should pay particular attention to those exposed to heat stress; periodic chest examinations should be provided for those exposed to dust, and audiometric examinations for those exposed to noise; mobile equipment operators should also receive periodic medical examinations to ensure their continued fitness for the job.

Constant supervision of all resuscitative appliances is necessary, as is training of workers in first-aid revival procedure.

A central first-aid station with the requisite medical equipment for emergency assistance should also be provided. If possible, there should be an ambulance for the transport of severely injured persons to the nearest hospital under the care of a qualified ambulance attendant. In larger plants first-aid stations or boxes should be located at several central points.

Coke Operations

Coal preparation

The most important single factor for producing metallurgical coke is the selection of coals. Coals with low ash and low sulphur content are most desirable. Low-volatile coal in amounts up to 40% are usually blended with high-volatile coal to achieve the desired characteristics. The most important physical property of metallurgical coke is its strength and ability to withstand breakage and abrasion during handling and use in the blast furnace. The coal-handling operations consist of unloading from railroad cars, marine barges or trucks; blending of the coal; proportioning; pulverizing; bulk-density control using diesel grade or similar oil; and conveying to the coke battery bunkers.

Coking

For the most part coke is produced in by-product coking ovens that are designed and operated to collect the volatile material from the coal. The ovens consist of three main parts: the coking chambers, the heating flues and the regenerative chamber. Apart from the steel and concrete structural support, the ovens are constructed of refractory brick. Typically each battery contains approximately 45 separate ovens. The coking chambers are generally 1.82 to 6.7 metres in height, 9.14 to 15.5 metres in length and 1,535 °C at the heating flue base. The time required for coking varies with oven dimensions, but usually ranges between 16 and 20 hours.

In large vertical ovens, the coal is charged through openings in the top from a rail-type “larry car” that transports the coal from the coal bunker. After the coal has become coke, the coke is pushed out of the oven from one side by a power-driven ram or “pusher”. The ram is slightly smaller than the oven dimensions so that contact with the oven interior surfaces is avoided. The coke is collected in a rail-type car or in the side of the battery opposite the pusher and transported to the quenching facility. The hot coke is wet quenched with water prior to discharge on the coke wharf. At some batteries, the hot coke is dry quenched to recover sensible heat for the generation of steam.

The reactions during the carbonization of coal for the production of coke are complex. Coal decomposition products initially include water, oxides of carbon, hydrogen sulphide, hydro-aromatic compounds, paraffins, olefins, phenolic and nitrogen-containing compounds. Synthesis and degradation occur among the primary products that produce large amounts of hydrogen, methane, and aromatic hydrocarbons. Further decomposition of the complex nitrogen containing compounds produce ammonia, hydrogen cyanide, pyridine bases and nitrogen. The continual removal of hydrogen from the residue in the oven produces hard coke.

The by-product coke ovens that have equipment for recovering and processing coal chemicals produce the materials listed in table 1.

Table 1. Recoverable by-products of coke ovens

|

By-product |

Recoverable constituents |

|

Coke oven gas |

Hydrogen, methane, ethane, carbon monoxide, carbon dioxide, ethylene, |

|

Ammonia liquor |

Free and fixed ammonia |

|

Tar |

Pyridine, tar acids, naphthalene, creosote oil and coal-tar pitch |

|

Light oil |

Varying amounts of coal gas products with boiling points from about 40 ºC |

After sufficient cooling so that conveyor-belt damage will not occur, the coke is moved to the screening and crushing station where it is sized for blast-furnace use.

Hazards

Physical hazards

During the coal unloading, preparation and handling operations, thousands of tonnes of coal are manipulated, producing dust, noise and vibrations. The presence of large quantities of accumulated dust can produce an explosion hazard in addition to the inhalation hazard.

During coking, ambient and radiant heat are the major physical concerns, particularly on the topside of the batteries, where the majority of the workers are deployed. Noise may be a problem in mobile equipment, primarily from drive mechanism and vibrating components that are not adequately maintained. Ionizing radiation and/or laser producing devices may be used for mobile equipment alignment purposes.

Chemical hazards

Mineral oil is typically used for operation purposes for bulk density control and dust suppression. Materials may be applied to the coal prior to being taken to the coal bunker to minimize the accumulation and to facilitate the disposal of hazardous waste from the by-products operations.

The major health concern associated with coking operations is emissions from the ovens during charging of the coal, coking and pushing of the coke. The emissions contain numerous polycyclic aromatic hydrocarbons (PAHs), some of which are carcinogenic. Materials utilized for sealing leaks in lids and doors may also be a concern during mixing and when lids and doors are removed. Asbestos and refracting ceramic filters may also be present in the form of insulating materials and gaskets, although suitable replacements have been used for products that previously contained asbestos.

Mechanical hazards

The coal-production hazards associated with railroad car, marine barge and vehicular traffic as well as conveyor belt movement must be recognized. The majority of accidents occur when workers are struck by, caught between, fall from, are entrained and entrapped in, or fail to lockout such equipment (including electrically).

The mechanical hazards of greatest concern are associated with the mobile equipment on the pusher side, coke side and the larry car on top of the battery. This equipment is in operation practically the entire work period and little space is provided between it and the operations. Caught-between and struck-by accidents associated with mobile rail-type equipment account for the highest number of fatal coke-oven production incidents. Skin surface burns from hot materials and surfaces and eye irritation from dust particles are responsible for more numerous, less severe occurrences.

Safety and Health Measures

To maintain dust concentrations during coal production at acceptable levels, containment and enclosure of screening, crushing and conveying systems are required. LEV may also be required in addition to wetting agents applied to the coal. Adequate mainten- ance programmes, belt programmes and clean-up programmes are required to minimize spillage and keep passageways alongside process and conveying equipment clear of coal. The conveyor system should use components known to be effective in reducing spillage and maintaining containment, such as belt cleaners, skirt boards, proper belt tension and so on.

Due to the health hazards associated with the PAHs released during the coking operations, it is important to contain and collect these emissions. This is best accomplished by a combination of engineering controls, work practices and a maintenance programme. It is also necessary to have an effective respirator programme. The controls should include the following:

- a charging procedure designed and operated to eliminate emissions by controlling the volume of coal being charged, properly aligning the car over the oven, tightly fitting drop sleeves and charging the coal in a sequence that allows an adequate channel on top of the coal to be maintained for flow of emissions to the collector mains and relidding immediately after charging

- drafting from two or more points in the oven being charged and an aspiration system designed and operated to maintain sufficient negative pressure and flow

- air seals on the pusher machine level bars to control infiltration during charging and carbon cutters to remove carbon build-up

- uniform collector-main pressure adequate to convey the emissions

- chuck door and gaskets as needed to maintain a tight seal and adequately cleaned and maintained pusher side and coke side sealing edges

- luting of lids and doors and maintaining door seals as necessary to control emissions after charging

- green pushes minimized by heating the coal uniformly for an adequate period

- installation of large enclosures over the entire coke side area to control emissions during the pushing of coke or use of travelling hoods to be moved to the individual ovens being pushed

- routine inspection, maintenance and repair for proper containment of emissions

- positive-pressure and temperature controlled operator cabs on mobile equipment to control worker exposure levels. To achieve the positive-pressure cab, structural integration is imperative, with tight fitting doors and windows and the elimination of separations in structural work.

Worker training is also necessary so that proper work practices are used and the importance of proper procedures to minimize emissions is understood.

Routine worker exposure monitoring should also be used to determine that levels are acceptable. Gas monitoring and rescue programmes should be in place, primarily due to the presence of carbon monoxide in coke-gas ovens. A medical surveillance programme should also be implemented.