General Profile

Crude oils and natural gases are mixtures of hydrocarbon molecules (organic compounds of carbon and hydrogen atoms) containing from 1 to 60 carbon atoms. The properties of these hydrocarbons depend on the number and arrangement of the carbon and hydrogen atoms in their molecules. The basic hydrocarbon molecule is 1 carbon atom linked with 4 hydrogen atoms (methane). All other variations of petroleum hydrocarbons evolve from this molecule. Hydrocarbons containing up to 4 carbon atoms are usually gases; those with 5 to 19 carbon atoms are usually liquids; and those with 20 or more are solids. In addition to hydrocarbons, crude oils and natural gases contain sulphur, nitrogen and oxygen compounds together with trace quantities of metals and other elements.

Crude oil and natural gas are believed to have been formed over millions of years by the decay of vegetation and marine organisms, compressed under the weight of sedimentation. Because oil and gas are lighter than water, they rose up to fill the voids in these overlying formations. This upward movement stopped when the oil and gas reached dense, overlying, impervious strata or nonporous rock. The oil and gas filled the spaces in porous rock seams and natural underground reservoirs, such as saturated sands, with the lighter gas on top of the heavier oil. These spaces were originally horizontal, but shifting of the earth’s crust created pockets, called faults, anticlines, salt domes and stratigraphic traps, where the oil and gas collected in reservoirs.

Shale Oil

Shale oil, or kerogen, is a mixture of solid hydrocarbons and other organic compounds containing nitrogen, oxygen and sulphur. It is extracted, by heating, from a rock called oil shale, yielding from 15 to 50 gallons of oil per ton of rock.

Exploration and production is the common terminology applied to that portion of the petroleum industry which is responsible for exploring for and discovering new crude oil and gas fields, drilling wells and bringing the products to the surface. Historically, crude oil, which had naturally seeped to the surface, was collected for use as medicine, protective coatings and fuel for lamps. Natural gas seepage was recorded as fires burning on the surface of the earth. It was not until 1859 that methods of drilling and obtaining large commercial quantities of crude oil were developed.

Crude oil and natural gas are found throughout the world, beneath both land and water, as follows:

- Western Hemisphere Intercontinental Basin (US Gulf Coast, Mexico, Venezuela)

- Middle East (Arabian Peninsula, Persian Gulf, Black and Caspian Seas)

- Indonesia and South China Sea

- North and West Africa (Sahara and Nigeria)

- North America (Alaska, Newfoundland, California and Mid-continent United States and Canada)

- Far East (Siberia and China)

- North Sea.

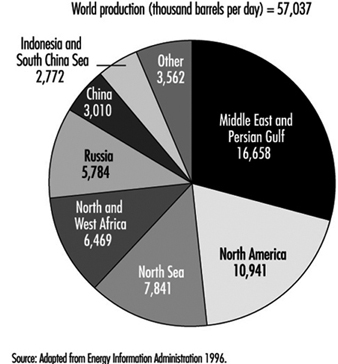

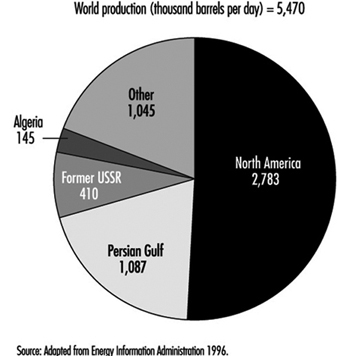

Figure 1 and figure 2 show world crude oil and natural gas production for 1995.

Figure 1. World crude oil production for 1995

Figure 2. World natural gas plant liquids production - 1995

The names of crude oils often identify both the type of crude and areas where they were originally discovered. For example, the first commercial crude oil, Pennsylvania Crude, is named after its place of origin in the United States. Other examples are Saudi Light and Venezuelan Heavy. Two benchmark crudes used to set world crude prices are Texas Light Sweet and North Sea Brent.

Classification of crude oils

Crude oils are complex mixtures containing many different, individual hydrocarbon compounds; they differ in appearance and composition from one oil field to another, and sometimes are even different from wells relatively near one another. Crude oils range in consistency from watery to tar-like solids, and in colour from clear to black. An “average” crude oil contains about 84% carbon; 14% hydrogen; 1 to 3% sulphur; and less than 1% of nitrogen, oxygen, metals and salts. See table 1 and table 2.

Table 1. Typical approximate characteristics and properties and gasoline potential of various typical crude oils.

|

Crude source and name * |

Paraffins |

Aromatics |

Naphthenes |

Sulphur |

API gravity |

Naphthene yield |

Octane number |

|

Nigerian Light |

37 |

9 |

54 |

0.2 |

36 |

28 |

60 |

|

Saudi Light |

63 |

19 |

18 |

2 |

34 |

22 |

40 |

|

Saudi Heavy |

60 |

15 |

25 |

2.1 |

28 |

23 |

35 |

|

Venezuela Heavy |

35 |

12 |

53 |

2.3 |

30 |

2 |

60 |

|

Venezuela Light |

52 |

14 |

34 |

1.5 |

24 |

18 |

50 |

|

USA Midcontinental Sweet |

— |

— |

— |

0.4 |

40 |

— |

— |

|

USA West Texas Sour |

46 |

22 |

32 |

1.9 |

32 |

33 |

55 |

|

North Sea Brent |

50 |

16 |

34 |

0.4 |

37 |

31 |

50 |

* Representative average numbers.

Table 2. Composition of crude oil and natural gas

Hydrocarbons

Paraffins: The paraffinic saturated chain type hydrocarbon (aliphatic) molecules in crude oil have the formula CnH2n+2, and can be either straight chains (normal) or branched chains (isomers) of carbon atoms. The lighter, straight chain paraffin molecules are found in gases and paraffin waxes. The branched chain paraffins are usually found in heavier fractions of crude oil and have higher octane numbers than normal paraffins.

Aromatics: Aromatics are unsaturated ring type hydrocarbon (cyclic) compounds. Naphthalenes are fused double ring aromatic compounds. The most complex aromatics, polynuclears (three or more fused aromatic rings), are found in heavier fractions of crude oil.

Naphthenes: Naphthenes are saturated ring type hydrocarbon groupings, with the formula

CnH2n, arranged in the form of closed rings (cyclic), found in all fractions of crude oil except the very lightest. Single ring naphthenes (mono-cycloparaffins) with 5 and 6 carbon atoms predominate, with two ring naphthenes (dicycloparaffins) found in the heavier ends of naphtha.

Non-hydrocarbons

Sulphur and sulphur compounds: Sulphur is present in natural gas and crude oil as hydrogen sulphide (H2S), as compounds (thiols, mercaptans, sulphides, polysulphides, etc.) or as elemental sulphur. Each gas and crude oil has different amounts and types of sulphur compounds, but as a rule the proportion, stability and complexity of the compounds are greater in heavier crude oil fractions.

Sulphur compounds called mercaptans, which exhibit distinct odours detectable at very low concentrations, are found in gas, petroleum crude oils and distillates. The most common are methyl and ethyl mercaptans. Mercaptans are often added to commercial gas (LNG and LPG) to provide an odour for leak detection.

The potential for exposure to toxic levels of H2S exists when working in drilling, production, transportation and processing crude oil and natural gas. The combustion of petroleum hydrocarbons containing sulphur produces undesirables such as sulphuric acid and sulphur dioxide.

Oxygen compounds: Oxygen compounds, such as phenols, ketones and carboxylic acids, are found in crude oils in varying amounts.

Nitrogen compounds: Nitrogen is found in lighter fractions of crude oil as basic compounds, and more often in heavier fractions of crude oil as non-basic compounds which may also include trace metals.

Trace metals: Trace amounts, or small quantities of metals, including copper, nickel, iron, arsenic and vanadium, are often found in crude oils in small quantities.

Inorganic salts: Crude oils often contain inorganic salts, such as sodium chloride, magnesium chloride and calcium chloride, suspended in the crude or dissolved in entrained water (brine).

Carbon dioxide: Carbon dioxide may result from the decomposition of bicarbonates present in, or added to crude, or from steam used in the distillation process.

Naphthenic acids: Some crude oils contain naphthenic (organic) acids, which may become corrosive at temperatures above 232 °C when the acid value of the crude is above a certain level.

Normally occurring radioactive materials: Normally occurring radioactive materials (NORMs) are often present in crude oil, in the drilling deposits and in the drilling mud, and can present a hazard from low levels of radioactivity.

Relatively simple crude-oil assays are used to classify crude oils as paraffinic, naphthenic, aromatic or mixed, based on the predominant proportion of similar hydrocarbon molecules. Mixed-base crudes have varying amounts of each type of hydrocarbon. One assay method (US Bureau of Mines) is based on distillation, and another method (UOP “K” factor) is based on gravity and boiling points. More comprehensive crude assays are conducted to determine the value of the crude (i.e., its yield and quality of useful products) and processing parameters. Crude oils are usually grouped according to yield structure, with high-octane gasoline being one of the more desirable products. Refinery crude oil feedstocks usually consist of mixtures of two or more different crude oils.

Crude oils are also defined in terms of API (specific) gravity. For example, heavier crude oils have low API gravities (and high specific gravities). A low-API gravity crude oil may have either a high or low flashpoint, depending on its lightest ends (more volatile constituents). Because of the importance of temperature and pressure in the refining process, crude oils are further classified as to viscosity, pour points and boiling ranges. Other physical and chemical characteristics, such as colour and carbon residue content, are also considered. Crude oils with high carbon, low hydrogen and low API gravity are usually rich in aromatics; while those with low carbon, high hydrogen and high API gravity are usually rich in paraffins.

Crude oils which contain appreciable quantities of hydrogen sulphide or other reactive sulphur compounds are called “sour.” Those with less sulphur are called “sweet.” Some exceptions to this rule are West Texas crudes (which are always considered “sour” regardless of their H2S content) and Arabian high-sulphur crudes (which are not considered “sour” because their sulphur compounds are not highly reactive).

Compressed Natural Gas and Liquefied Hydrocarbon Gases

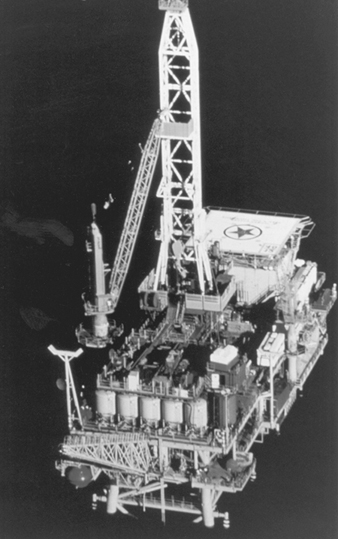

The composition of naturally occurring hydrocarbon gases is similar to crude oils in that they contain a mixture of different hydrocarbon molecules depending on their source. They can be extracted as natural gas (almost free of liquids) from gas fields; petroleum-associated gas which is extracted with oil from gas and oil fields; and gas from gas condensate fields, where some of the liquid components of oil convert into the gaseous state when pressure is high (10 to 70 mPa). When the pressure is decreased (to 4 to 8 mPa) condensate containing heavier hydrocarbons separates from the gas by condensation. Gas is extracted from wells reaching up to 4 miles (6.4 km) or more in depth, with seam pressures varying from 3 mPa up to as high as 70 mPa. (See figure 3.)

Figure 3. Offshore natural gas well set in 87.5 metres of water in the Pitas Point area of the Santa Barbara Channel, Southern California

American Petroleum Institute

Natural gas contains 90 to 99% hydrocarbons, which consist predominately of methane (the simplest hydrocarbon) together with smaller amounts of ethane, propane and butane. Natural gas also contains traces of nitrogen, water vapour, carbon dioxide, hydrogen sulphide and occasional inert gases such as argon or helium. Natural gases containing more than 50 g/m3 of hydrocarbons with molecules of three or more carbon atoms (C3 or higher) are classified as “lean” gases.

Depending how it is used as a fuel, natural gas is either compressed or liquefied. Natural gas from gas and gas condensate fields is processed in the field to meet specific transportation criteria before being compressed and fed into gas pipelines. This preparation includes removal of water with driers (dehydrators, separators and heaters), oil removal using coalescing filters, and the removal of solids by filtration. Hydrogen sulphide and carbon dioxide are also removed from natural gas, so that they do not corrode pipelines and transportation and compression equipment. Propane, butane and pentane, present in natural gas, are also removed before transmission so they will not condense and form liquids in the system. (See the section “Natural gas production and processing operations.”)

Natural gas is transported by pipeline from gas fields to liquefication plants, where it is compressed and cooled to approximately –162 ºC to produce liquefied natural gas (LNG) (see figure 4). The composition of LNG is different from natural gas due to the removal of some impurities and components during the liquefaction process. LNG is primarily used to augment natural gas supplies during peak demand periods and to supply gas in remote areas away from major pipelines. It is regasified by adding nitrogen and air to make it comparable to natural gas before being fed into gas supply lines. LNG is also used as a motor-vehicle fuel as an alternative to gasoline.

Figure 4. World’s largest LNG plant at Arzew, Algeria

American Petroleum Institute

Petroleum-associated gases and condensate gases are classified as “rich” gases, because they contain significant amounts of ethane, propane, butane and other saturated hydrocarbons. Petroleum-associated and condensate gases are separated and liquefied to produce liquefied petroleum gas (LPG) by compression, adsorption, absorption and cooling at oil and gas process plants. These gas plants also produce natural gasoline and other hydrocarbon fractions.

Unlike natural gas, petroleum-associated gas and condensate gas, oil processing gases (produced as by-products of refinery processing) contain considerable amounts of hydrogen and unsaturated hydrocarbons (ethylene, propylene and so on). The composition of oil processing gases depends upon each specific process and the crude oils used. For example, gases obtained as a result of thermal cracking usually contain significant amounts of olefins, while those obtained from catalytic cracking contain more isobutanes. Pyrolysis gases contain ethylene and hydrogen. The composition of natural gases and typical oil processing gases is shown in table 3.

Table 3. Typical approximate composition of natural and oil processing gases (per cent by volume)

|

Type gas |

H2 |

CH4 |

C2H6 |

C3H4 |

C3H8 |

C3H6 |

C4H10 |

C4H8 |

N2+CO2 |

C5+ |

|

Natural gas |

n/a |

98 |

0.4 |

n/a |

0.15 |

n/a |

0.05 |

n/a |

1.4 |

n/a |

|

Petroleum- |

n/a |

42 |

20 |

n/a |

17 |

n/a |

8 |

n/a |

10 |

3 |

|

Oil processing gases |

|

|

|

|

|

|

|

|

|

|

Combustible natural gas, with a calorific value of 35.7 to 41.9 MJ/m3 (8,500 to 10,000 kcal/m3), is primarily used as a fuel to produce heat in domestic, agricultural, commercial and industrial applications. The natural gas hydrocarbon also is used as feedstock for petrochemical and chemical processes. Synthesis gas (CO + H2) is processed from methane by oxygenation or water vapour conversion, and used to produce ammonia, alcohol and other organic chemicals. Compressed natural gas (CNG) and liquefied natural gas (LNG) are both used as fuel for internal combustion engines. Oil processing liquefied petroleum gases (LPG) have higher calorific values of 93.7 MJ/m3 (propane) (22,400 kcal/m3) and 122.9 MJ/m3 (butane) (29,900 kcal/m3) and are used as fuel in homes, businesses and industry as well as in motor vehicles (NFPA 1991). The unsaturated hydrocarbons (ethylene, propylene and so on) derived from oil processing gases may be converted into high-octane gasoline or used as raw materials in the petrochemical and chemical-processing industries.

Properties of Hydrocarbon Gases

According to the US National Fire Protection Association, flammable (combustible) gases are those which burn in the concentrations of oxygen normally present in air. The burning of flammable gases is similar to that of flammable hydrocarbon liquid vapours, as a specific ignition temperature is needed to initiate the burning reaction and each will burn only within a certain defined range of gas-air mixtures. Flammable liquids have a flashpoint (the temperature (always below the boiling point) at which they emit sufficient vapours for combustion). There is no apparent flashpoint for flammable gases, as they are normally at temperatures above their boiling points, even when liquefied, and are therefore always at temperatures well in excess of their flashpoints.

The US National Fire Protection Association (1976) defines compressed and liquefied gases, as follows:

- “Compressed gases are those which at all normal atmospheric temperatures inside their containers, exist solely in the gaseous state under pressure.”

- “Liquefied gases are those which at normal atmospheric temperatures inside their containers, exist partly in the liquid state and partly in the gaseous state, and are under pressure as long as any liquid remains in the container.”

The major factor which determines the pressure inside the vessel is the temperature of the liquid stored. When exposed to the atmosphere, the liquefied gas very rapidly vaporizes, travelling along the ground or water surface unless dispersed into the air by wind or mechanical air movement. At normal atmospheric temperatures, about one-third of the liquid in the container will vaporize.

Flammable gases are further classified as fuel gas and industrial gas. Fuel gases, including natural gas and liquefied petroleum gases (propane and butane), are burned with air to produce heat in ovens, furnaces, water heaters and boilers. Flammable industrial gases, such as acetylene, are used in processing, welding, cutting and heat treating operations. The differences in properties of liquefied natural gas (LNG) and liquefied petroleum gases (LPG) are shown in table 3.

Searching for Oil and Gas

The search for oil and gas requires a knowledge of geography, geology and geophysics. Crude oil is usually found in certain types of geological structures, such as anticlines, fault traps and salt domes, which lie under various terrains and in a wide range of climates. After selecting an area of interest, many different types of geophysical surveys are conducted and measurements performed in order to obtain a precise evaluation of the subsurface formations, including:

- Magnetometric surveys. Magnetometers hung from airplanes measure variations in the earth’s magnetic field in order to locate sedimentary rock formations which generally have low magnetic properties when compared to other rocks.

- Aerial photogrammetric surveys. Photographs taken with special cameras in airplanes, provide three-dimensional views of the earth which are used to determine land formations with potential oil and gas deposits.

- Gravimetric surveys. Because large masses of dense rock increase the pull of gravity, gravimeters are used to provide information regarding underlying formations by measuring minute differences in gravity.

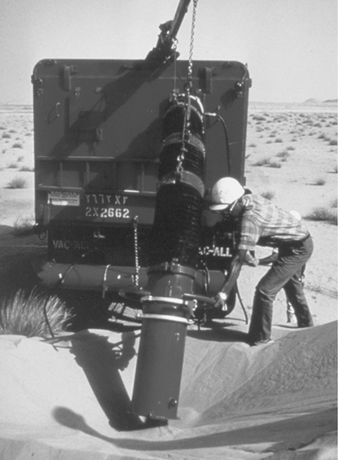

- Seismic surveys. Seismic studies provide information on the general characteristics of the subsurface structure (see figure 5). Measurements are obtained from shock waves generated by setting off explosive charges in small-diameter holes, from the use of vibrating or percussion devices on both land and in water, and from underwater blasts of compressed air. The elapsed time between the beginning of the shock wave and the return of the echo is used to determine the depth of the reflecting substrata. The recent use of super-computers to generate three-dimensional images greatly improves evaluation of seismic test results.

Figure 5. Saudi Arabia, seismic operations

American Petroleum Institute

- Radiographic surveys. Radiography is the use of radio waves to provide information similar to that obtained from seismic surveys.

- Stratigraphic surveys. Stratigraphic sampling is the analysis of cores of subsurface rock strata for traces of gas and oil. A cylindrical length of rock, called a core, is cut by a hollow bit and pushed up into a tube (core barrel) attached to the bit. The core barrel is brought to the surface and the core is removed for analysis.

When the surveys and measurements indicate the presence of formations or strata which may contain petroleum, exploratory wells are drilled to determine whether or not oil or gas is actually present and, if so, whether it is available and obtainable in commercially viable quantities.

Offshore Operations

Although the first offshore oil well was drilled in the early 1900s off of the coast of California, the beginning of modern marine drilling was in 1938, with a discovery in the Gulf of Mexico, 1 mile (1.6 km) from the US coastline. After the Second World War, offshore drilling expanded quickly, first in shallow waters adjacent to known land-based production areas, and then to other shallow and deep water areas around the world, and in climates varying from the Arctic to the Persian Gulf. In the beginning, offshore drilling was possible only in water depths of about 91 m; however, modern platforms are now able drill in waters over 3.2 km deep. Offshore oil activities include exploration, drilling, production, processing, underwater construction, maintenance and repair, and the transport of the oil and gas to shore by ship or pipeline.

Offshore platforms

Drilling platforms support drilling rigs, supplies and equipment for offshore or inland water operations, and range from floating or submergible barges and ships, to fixed-in-place platforms on steel legs used in shallow waters, to large, buoyant, reinforced concrete, gravity-type platforms used in deep waters. After the drilling is completed, marine platforms are used to support production equipment. The very largest production platforms have accommodations for over 250 crew members and other support personnel, heliports, processing plants and crude oil and gas condensate storage capability (see figure 6).

Figure 6. Drilling vessels; drill ship Ben Ocean Laneer

American Petroleum Institute

Typically, with deep water floating platform drilling, the wellhead equipment is lowered to the ocean floor and sealed to the well casing. The use of fibre-optic technology allows a large, central platform to remotely control and operate smaller satellite platforms and sub-sea templates. Production facilities on the large platform process the crude oil, gas and condensate from the satellite facilities, before it is shipped on-shore.

The type of platform used in underwater drilling is often determined by the type of well to be drilled (exploratory or production) and by the depth of the water (see table 4).

Table 4. Platform types for underwater drilling

|

Platform type |

Depth (m) |

Description |

|

Submersible barges and platforms |

15–30 |

Barges or platforms, towed to the site and sunk to rest on the bottom. Lower buoyant column keeps rigs afloat |

|

Jack-ups (on legs) |

30–100 |

Mobile, self-elevating buoyant platforms whose legs are jacked up for towing. At the site, the legs are lowered to |

|

Floating platforms |

100–3,000+ |

Large, self-contained, multi-level, reinforced concrete gravity structures, towed to the site, submerged with |

|

Smaller floating platforms, similarly suspended, which support only the drilling rig and are serviced by a floating |

||

|

Drilling barges |

30–300 |

Self-propelled, floating or semi-submersible barges. |

|

Drill ships |

120–3,500+ |

Highly sophisticated, specially designed, floating or semi-submersible ships. |

|

Fixed on site platforms |

0–250 |

Platforms built on steel supports (jackets) which are sunk and fixed in place, and artificial islands used as |

|

Sub-sea templates |

n/a |

Underwater production installations. |

Types of Wells

Exploratory wells.

Following the analysis of geological data and geophysical surveys, exploratory wells are drilled, either on land or offshore. Exploratory wells which are drilled in areas where neither oil nor gas has been previously found are called “wildcats.” Those wells which strike oil or gas are called “discovery wells.” Other exploratory wells, known as “step-out” or “appraisal” wells, are drilled to determine the limits of a field following discovery, or to search for new oil- and gas-bearing formations next to, or beneath, those already known to contain product. A well which does not find any oil or gas, or finds too little to produce economically, is called a “dry hole”.

Developmental wells.

After a discovery, the area of the reservoir is roughly determined with a series of step-out or appraisal wells. Developmental wells are then drilled to produce gas and oil. The number of developmental wells to be drilled is determined by the expected definition of the new field, both in size and in productivity. Because of the uncertainty as to how reservoirs are shaped or confined, some developmental wells may turn out to be dry holes. Occasionally, drilling and producing occurs simultaneously.

Geopressure/geothermal wells.

Geopressure/geothermal wells are those which produce extremely high-pressure (7,000 psi) and high-temperature (149 ºC) water which may contain hydrocarbons. The water becomes a rapidly expanding cloud of hot steam and vapours upon release to the atmosphere from a leak or rupture.

Stripper wells.

Stripper wells are those which produce less than ten barrels of oil a day from a reservoir.

Multiple completion wells.

When multiple producing formations are discovered when drilling a single well, a separate string of pipe may be run into a single well for each individual formation. Oil and gas from each formation is directed into its respective piping and isolated from one another by packers, which seal the annular spaces between the piping string and the casing. These wells are known as multiple completion wells.

Injection wells.

Injection wells pump air, water, gas or chemicals into reservoirs of producing fields, either to maintain pressure or move oil toward producing wells by hydraulic force or increased pressure.

Service wells.

Service wells include those used for fishing and wire-line operations, packer/plug placement or removal and reworking. Service wells are also drilled for underground disposal of salt water, which is separated from crude oil and gas.

Drilling Methods

Drilling rigs.

Basic drilling rigs contain a derrick (tower), a drilling pipe, a large winch to lower and lift out the drilling pipe, a drilling table which rotates the drilling pipe and bit, a mud mixer and pump and an engine to drive the table and winch (see figure 7). Small drilling rigs used to drill exploratory or seismic wells may be mounted on trucks for movement from site to site. Larger drilling rigs are either erected onsite or have portable, hinged (jack knife) derricks for easy handling and erection.

Figure 7. Drilling rig on Elf Ringnes Island in the Canadian Arctic

American Petroleum Institute

Percussion or cable drilling.

The oldest drilling technique is percussion or cable drilling. This slow, limited depth method, which is seldom used, involves crushing rock by raising and dropping a heavy chisel bit and stem on the end of a cable. At intervals, the bit is removed and the cuttings are suspended in water and removed by flushing or pumping to the surface. As the hole deepens, it is lined with steel casing to prevent cave-in and protect against contamination of groundwater. Considerable work is required to drill even a shallow well, and upon striking oil or gas, there is no way to control the immediate flow of product to the surface.

Rotary drilling.

Rotary drilling is the most common method and is used to drill both exploratory and production wells at depths over 5 miles (7,000 m). Lightweight drills, mounted on trucks, are used to drill low-depth seismic wells on land. Medium and heavy rotary mobile and floating drills are used for drilling exploration and production wells. Rotary drilling equipment is mounted on a drilling platform with a 30- to 40-m-high derrick, and includes a rotary table, engine, mud mixer and injector pump, a wire-line drum hoist or winch, and many sections of pipe, each approximately 27 m long. The rotary table turns a square kelly connected to the drilling pipe. The square kelly has a mud swivel on the top which is connected to blowout preventors. The drill pipe rotates at a speed of from 40 to 250 rpm, turning either a drill which has drag bits with fixed chisel-like cutting edges or a drill whose bit has rolling cutters with hardened teeth.

Rotary percussion drilling.

Rotary percussion drilling is a combination method whereby a rotary drill uses a circulating hydraulic fluid to operate a hammer-like mechanism, thereby creating a series of rapid percussion blows which allow the drill to simultaneously bore and pound into the earth.

Electro and turbo drilling.

Most rotary tables, winches and pumps of heavy drills are usually driven by electric motors or turbines, which allows for increased flexibility in operations and remote-controlled drilling. Electro drill and turbo drill are newer methods which provide more direct power to the drill bit by connecting the drilling motor just above the bit at the bottom of the hole.

Directional drilling.

Directional drilling is a rotary drilling technique which directs the drill string along a curved path as the hole deepens. Directional drilling is used to reach deposits which are inaccessible by vertical drilling. It also reduces costs, as a number of wells can be drilled in different directions from a single platform. Extended-reach drilling allows tapping into undersea reservoirs from the shore. Many of these techniques are possible by using computers to direct automatic drilling machines and flexible pipe (coiled tubing), which is raised and lowered without connecting and disconnecting sections.

Other drilling methods.

Abrasive drilling uses an abrasive material under pressure (instead of using a drill stem and bit) to cut through the substrata. Other drilling methods include explosive drilling and flame piercing.

Abandonment.

When oil and gas reservoirs are no longer productive, the wells are typically plugged with cement to prevent flow or leakage to the surface and to protect the underground strata and water. Equipment is removed and the sites of abandoned wells are cleaned up and returned to normal conditions.

Drilling Operations

Drilling techniques

The drilling platform provides a base for workers to couple and uncouple the sections of drilling pipe which are used to increase the depth of drilling. As the hole deepens, additional lengths of pipe are added and the drilling string is suspended from the derrick. When a drilling bit needs to be changed, the entire drilling string of pipe is pulled out of the hole, and each section is detached and stacked vertically inside the derrick. After the new bit is fitted in place, the process is reversed, and the pipe is returned to the hole to continue drilling.

Care is needed to assure that the drilling string pipe does not split apart and drop into the hole, as it may be difficult and costly to fish out and may even result in the loss of the well. Another potential problem is if drilling tools stick in the hole when drilling stops. For this reason, once drilling begins, it usually continues until the well is completed.

Drilling mud

Drilling mud is a fluid composed of water or oil and clay with chemical additives (e.g., formaldehyde, lime, sodium hydrazide, barite). Caustic soda is often added to control the pH (acidity) of drilling mud and to neutralize potentially hazardous mud additives and completion fluids. Drilling mud is pumped into the well under pressure from the mixing tank on the drilling platform, down the inside of the drilling pipe to the drill bit. It then rises between the outside of the drill pipe and the sides of the hole, returning to the surface, where it is filtered and recirculated.

Drilling mud is used to cool and lubricate the drilling bit, lubricate the pipe and flush the rock cuttings from the drill hole. Drilling mud is also used to control flow from the well by lining the sides of the hole and resisting the pressure of any gas, oil or water which is met by the drill bit. Jets of mud may be applied under pressure at the bottom of the hole to aid in drilling.

Casing and cementation

The casing is a special heavy steel pipe which lines the well hole. It is used to prevent cave-in of the drill hole walls and protect fresh water strata by preventing leakage from the returning flow of mud during drilling operations. The casing also seals off water-permeated sands and high-pressure gas zones. Casing is initially used near the surface and is cemented into place to guide the drill pipe. A cement slurry is pumped down the drilling pipe and forced back up through the gap between the casing and the walls of the well hole. Once the cement sets and the casing is place, drilling continues using a smaller diameter bit.

After the surface casing is placed in the well, blowout preventors (large valves, bags or rams) are attached to the top of the casing, in what is called a stack. Following discovery of oil or gas, casing is set into the bottom of the well to keep dirt, rocks, salt water and other contaminants out of the well hole and to provide a conduit for the crude oil and gas extraction lines.

Completion, Enhanced Recovery and Workover Operations

Completion

Completion describes the process of bringing a well into production after the well has been drilled to the depth where oil or gas is expected to be found. Completion involves a number of operations, including penetration of the casing and cleaning out water and sediment from the pipeline so that flow is unimpeded. Special core bits are used to drill and extract cores up to 50 m long for analysis during the drilling operation to determine when penetration should be performed. The drill pipe and bit are first removed and the final string of casing is cemented into place. A perforating gun, which is a metal tube containing sockets holding either bullets or shaped explosive charges, is then lowered into the well. The charges are discharged by electrical impulse through the casing into reservoir to create openings for the oil and gas to flow into the well and to the surface.

The flow of crude oil and natural gas is controlled by a series of valves, called “Christmas trees”, which are placed at the top of the well head. Monitors and controls are installed to automatically or manually operate surface and subsurface safety valves, in the event of a change in pressure, fire or other hazardous condition. Once the oil and gas are produced they are separated, and water and sediment are removed from the crude oil.

Crude oil and gas production and conservation

Producing oil is basically a matter of displacement by either water or gas. At the time of initial drilling, almost all crude oil is under pressure. This natural pressure decreases as oil and gas is removed from the reservoir, during the three phases of a reservoir’s life.

- During the first phase, flush production, the flow is governed by the natural pressure in the reservoir which comes from dissolved gas in the oil, gas trapped under pressure above the oil and hydraulic pressure from water trapped under the oil.

- Artificial lift, the second phase, involves pumping pressurized gas into the reservoir when the natural pressure is expended.

- Phase three, stripper or marginal production, occurs when wells only produce intermittently.

Originally there was little understanding of the forces which affected oil and gas production. The study of oil and gas reservoir behaviour began at the beginning of the 20th century, when it was discovered that pumping water into a reservoir increased production. At that time, the industry was recovering between 10 and 20% of reservoir capacity, as compared to recent recovery rates of over 60% before wells become unproductive. The concept of control is that a faster rate of production more quickly dissipates the pressure in the reservoir, thereby reducing the total amount of oil which can be eventually recovered. Two measures used to conserve petroleum reservoirs are unitization and well spacing.

- Unitization is the operation of a field as one unit in order to apply secondary recovery methods and maintain pressure, even through a number of different operators may be involved. The total production is allocated on an equitable basis among the operators.

- Well spacing is the limiting and proper location of wells so as to achieve maximum production without dissipating a field due to overdrilling.

Methods of Recovering Additional Product

Productivity of oil and gas reservoirs is improved by a variety of recovery methods. One method is either to chemically or physically open passages in the strata to allow oil and gas to move more freely through reservoirs to the well. Water and gas are injected into reservoirs to maintain working pressure by natural displacement. Secondary recovery methods, including displacement by pressure, artificial lift and flooding, improve and restore reservoir pressure. Enhanced recovery is the use of various secondary recovery methods in multiple and different combinations. Enhanced recovery also includes more advanced methods of obtaining additional product from depleted reservoirs, such as thermal recovery, which uses heat instead of water or gas to force more crude oil out of reservoirs.

Acidizing

Acidizing is a method of increasing the output of a well by pumping acid directly into a producing reservoir to open flow channels through the reaction of chemicals and minerals. Hydrochloric (or regular) acid, was first used to dissolve limestone formations. It is still most commonly used; however, various chemicals are now added to the hydrochloric acid to control its reaction and to prevent corrosion and formation of emulsions.

Hydrofluoric acid, formic acid and acetic acid are also used, together with hydrochloric acid, depending on the type of rock or minerals in the reservoir. Hydrofluoric acid is always combined with one of the other three acids, and was originally used to dissolve sandstone. It is often called “mud acid”, as it is now used to clean perforations which have been plugged with drilling mud and to restore damaged permeability near the well hole. Formic and acetic acids are used in deep, ultra-hot limestone and dolomite reservoirs and as breakdown acids prior to perforation. Acetic acid is also added to wells as a neutralizing buffer agent to control the pH of well stimulation fluids. Almost all acids have additives, such as inhibitors to prevent reaction with the metal casings and surfactants to prevent formation of sludge and emulsions.

Fracturing

Fracturing describes the method used to increase the flow of oil or gas through a reservoir and into wells by force or pressure. Production may decrease because the reservoir formation is not permeable enough to allow the oil to flow freely toward the well. Fracturing forces open underground channels by pumping a fluid treated with special propping agents (including sand, metal, chemical pellets and shells) into the reservoir under high pressure to open fissures. Nitrogen may be added to the fluid to stimulate expansion. When the pressure is released, the fluid withdraws and the propping agents remain in place, holding the fissures open so that oil can flow more freely.

Massive fracturing (mass frac) involves pumping large amounts of fluid into wells to hydraulically create fissures which are thousands of feet in length. Massive fracturing is typically used to open gas wells where the reservoir formations are so dense that even gas cannot pass through them.

Pressure maintenance

Two common pressure maintenance techniques are the injection of water and gas (air, nitrogen, carbon dioxide and natural gas) into reservoirs where natural pressures are reduced or insufficient for production. Both methods require drilling auxiliary injection wells at designated locations to achieve the best results. The injection of water or gas to maintain the working pressure of the well is called natural displacement. The use of pressurized gas to increase the pressure in the reservoir is called artificial (gas) lift.

Water flooding

The most commonly used secondary enhanced recovery method is pumping water into an oil reservoir to push product toward producing wells. In five-spot water flooding, four injection wells are drilled to form a square with the producing well at the center. The injection is controlled to maintain an even advance of the water front through the reservoir toward the producing well. Some of the water used is salt water, obtained from the crude oil. In low-tension water flooding, a surfactant is added to the water to assist the flow of oil through the reservoir by reducing its adhesion to rock.

Miscible flooding

Miscible fluid and miscible polymer flooding are enhanced recovery methods used to improve water injection by reducing the surface tension of crude oil. A fluid miscible (one that can be dissolved in the crude) is injected into a reservoir. This is followed by an injection of another fluid which pushes the crude and miscible fluid mixture toward the producing well. Miscible polymer flooding involves the use of a detergent to wash the crude oil from the strata. A gel or thickened water is injected behind the detergent to move the crude toward the producing well.

Fire flooding

Fire flooding, or in situ (in place) combustion, is an expensive thermal recovery method wherein large quantities of air or oxygen-containing gas is injected into the reservoir and a portion of the crude oil is ignited. The heat from the fire reduces the viscosity of the heavy crude oil so that it flows more easily. Hot gases, produced by the fire, increase the pressure in the reservoir and create a narrow burning front which pushes the thinner crude from the injection well to the producing well. The heavier crude remains in place, providing additional fuel as the flame front moves slowly forward. The burning process is closely monitored and controlled by regulating the injected air or gas.

Steam injection

Steam injection, or steam flooding, is a thermal recovery method which heats heavy crude oil and lowers its viscosity by injecting super-hot steam into the lowest stratum of relatively shallow reservoir. The steam is injected over a period of 10 to 14 days, and the well is shut for another week or so to allow the steam to thoroughly heat the reservoir. At the same time the increased heat expands reservoir gases, thereby increasing the pressure in the reservoir. The well is then reopened and the heated, less viscous crude flows up into the well. A newer method injects low-heat steam at lower pressure into larger sections of two, three or more zones simultaneously, developing a “steam chest” which squeezes down the oil in each of the zones. This provides a greater flow of oil to the surface, while using less steam.

Natural Gas Production and Processing Operations

There are two types of wells producing natural gas. Wet gas wells produce gas which contains dissolved liquids, and dry gas wells produce gas which cannot be easily liquefied

After natural gas is withdrawn from producing wells, it is sent to gas plants for processing. Gas processing requires a knowledge of how temperature and pressure interact and affect the properties of both fluids and gases. Almost all gas-processing plants handle gases that are mixtures of various hydrocarbon molecules. The purpose of gas processing is to separate these gases into components of similar composition by various processes such as absorption, fractionation and cycling, so they can be transported and used by consumers.

Absorption processes

Absorption involves three processing steps: recovery, removal and separation.

Recovery.

Removes undesirable residue gases and some methane by absorption from the natural gas. Absorption takes place in a counterflow vessel, where the well gas enters the bottom of the vessel and flows upward through absorption oil, which is flowing downward. The absorption oil is “lean” as it enters the top of the vessel, and “rich” as it leaves the bottom as it has absorbed the desirable hydrocarbons from the gas. The gas leaving the top of the unit is called “residue gas.”

Absorption may also be accomplished by refrigeration. The residue gas is used to pre-cool the inlet gas, which then passes through a gas chiller unit at temperatures from 0 to –40 ºC. Lean absorber oil is pumped through an oil chiller, before contacting the cool gas in the absorber unit. Most plants use propane as the refrigerant in the cooler units. Glycol is injected directly into the inlet gas stream to mix with any water in the gas in order to prevent freezing and formation of hydrates. The glycol-water mixture is separated from the hydrocarbon vapour and liquid in the glycol separator, and then reconcentrated by evaporating the water in a regenerator unit.

Removal.

The next step in the absorption process is removal, or demethanization. The remaining methane is removed from the rich oil in ethane recovery plants. This is usually a two-phase process, which first rejects at least one-half of the methane from the rich oil by reducing pressure and increasing temperature. The remaining rich oil usually contains enough ethane and propane to make reabsorption desirable. If not sold, the overhead gas is used as plant fuel or as a pre-saturator, or is recycled to the inlet gas in the main absorber.

Separation.

The final step in the absorption process, distillation, uses vapours as a medium to strip the desirable hydrocarbons from the rich absorption oil. Wet stills use steam vapours as the stripping medium. In dry stills, hydrocarbon vapours, obtained from partial vaporization of the hot oil pumped through the still reboiler, are used as the stripping medium. The still controls the final boiling point and molecular weight of the lean oil, and the boiling point of the final hydrocarbon product mix.

Other Processes

Fractionation.

Is the separation of the desirable hydrocarbon mixture from absorption plants, into specific, individual, relatively pure products. Fractionation is possible when the two liquids, called top product and bottom product, have different boiling points. The fractionation process has three parts: a tower to separate products, a reboiler to heat the input and a condenser to remove heat. The tower has an abundance of trays so that a lot of vapour and liquid contact occurs. The reboiler temperature determines the composition of the bottom product.

Sulphur recovery.

Hydrogen sulphide must be removed from gas before it is shipped for sale. This is accomplished in sulphur recovery plants.

Gas cycling.

Gas cycling is neither a means of pressure maintenance nor a secondary method of recovery, but is an enhanced recovery method used to increase production of natural gas liquids from “wet gas” reservoirs. After liquids are removed from the “wet gas” in cycling plants, the remaining “dry gas” is returned to the reservoir through injection wells. As the “dry gas” recirculates through the reservoir it absorbs more liquids. The production, processing and recirculation cycles are repeated until all of the recoverable liquids have been removed from the reservoir and only “dry gas” remains.

Site Development for Producing Oil and Gas Fields

Extensive site development is required to bring a new oil or gas field into production. Site access may be limited or constrained by both climatic and geographic conditions. The requirements include transportation; construction; maintenance, housing and administrative facilities; oil, gas and water separation equipment; crude oil and natural gas transport; water and waste disposal facilities; and many other services, facilities and kinds of equipment. Most of these are not readily available at the site and must be provided by either the drilling or producing company or by outside contractors.

Contractor activities

Contractors are typically used by oil and gas exploration and producing companies to provide some or all of the following supporting services required to drill and develop producing fields:

- Site preparation - brush clearing, road construction, ramps and walkways, bridges, aircraft landing areas, marine harbour, wharfs, docks and landings

- Erection and installation - drilling equipment, power and utilities, tanks and pipeline, housing, maintenance buildings, garages, hangers, service and administration buildings

- Underwater work - installation, inspection, repair and maintenance of underwater equipment and structures

- Maintenance and repair - drilling and production equipment preventive maintenance, vehicles and boats, machinery and buildings

- Contract services - food service; housekeeping; facility and perimeter protection and security; janitorial, recreation and support activity; warehousing and distribution of protective equipment, spare parts and disposable supplies

- Engineering and technical - testing and analyses, computer services, inspections, laboratories, non-destructive analysis, explosives storage and handling, fire protection, permits, environmental, medical and health, industrial hygiene and safety and spill response

- Outside services - telephone, radio and television, sewerage and garbage

- Transportation and material handling equipment - aircraft and helicopter, marine services, heavy-duty construction and materials handling equipment

Utilities

Whether exploration, drilling and producing operations take place on land or offshore, power, light electricity and other support utilities are required, including:

- Power generation - gas, electricity and steam

- Water - fresh water supply, purification and treatment and process water

- Sewerage and drainage - storm water, sanitary treatment and waste (oily) water treatment and disposal

- Communications - telephone, radio and television, computer and satellite communication

- Utilities - light, heat, ventilation and cooling.

Working Conditions, Health and Safety

Work on drilling rigs usually involves a minimum crew of 6 people (primary and secondary drillers, three assistant drillers or helpers (roughnecks) and a cathead person) reporting to a site supervisor or foreman (tool pusher) who is responsible for the drilling progression. The primary and secondary drillers have overall responsibility for drilling operations and supervision of the drilling crew during their respective shifts. Drillers should be familiar with the capabilities and limitations of their crews, as work can progress only as fast as the slowest crew member.

Assistant drillers are stationed on the platform to operate equipment, read instruments and perform routine maintenance and repair work. The cathead person is required to climb up near the top of the derrick when drill pipe is being fed into or drawn out of the well hole and assist in moving the sections of pipe into and out of the stack. During drilling, the cathead person also operates the mud pump and provides general assistance to the drilling crew.

Persons who assemble, place, discharge and retrieve perforating guns should be trained, familiar with the hazards of explosives and qualified to handle explosives, primer cord and blasting caps. Other personnel working in and around oil fields include geologists, engineers, mechanics, drivers, maintenance personnel, electricians, pipeline operators and labourers.

Wells are drilled around the clock, on either 8- or 12-hour shifts, and workers require considerable experience, skill and stamina to meet the rigorous physical and mental demands of the job. Overextending a crew may result in a serious accident or injury. Drilling requires close teamwork and coordination in order to accomplish the tasks in a safe and timely fashion. Because of these and other requirements, consideration must be given to the morale and health and safety of workers. Adequate periods of rest and relaxation, nutritious food and appropriate hygiene and living quarters, including air conditioning in hot, humid climates and heating in cold-weather areas, are essential.

The primary occupational hazards associated with exploration and production operations include illnesses from exposure to geographical and climatic elements, stress from travelling long distances over water or harsh terrain and personal injury. Psychological problems may result from the physical isolation of exploratory sites and their remoteness from base camps and the extended work periods required on offshore drilling platforms and at remote onshore sites. Many other hazards particular to offshore operations, such as underwater diving, are covered elsewhere in this Encyclopaedia.

Offshore work is dangerous at all times, both when on and off the job. Some workers cannot handle the stress of working offshore at a demanding pace, for extended periods of time, under relative confinement and subject to ever changing environmental conditions. The signs of stress in workers include unusual irritability, other signs of mental distress, excessive drinking or smoking and use of drugs. Problems of insomnia, which may be aggravated by high levels of vibration and noise, have been reported by workers on platforms. Fraternization among workers and frequent shore leave may reduce stress. Seasickness and drowning, as well as exposure to severe weather conditions, are other hazards in offshore work.

Illnesses such as respiratory tract diseases result from exposure to harsh climates, infections or parasitic diseases in areas where these are endemic. Although many of these diseases are still in need of epidemiological study in drilling workers, it is known that oil workers have experienced periarthritis of the shoulder and shoulder blade, humeral epicondylitis, arthrosis of the cervical spine and polyneuritis of the upper limbs. The potential for illnesses as a result of exposure to noise and vibration is also present in drilling operations. The severity and frequency of these drilling-related illnesses appears to be proportional to the length of service and exposure to adverse working conditions (Duck 1983; Ghosh 1983; Montillier 1983).

Injuries while working in drilling and production activities may result from many causes, including slips and falls, pipe handling, lifting pipe and equipment, misuse of tools and mishandling explosives. Burns may be caused by steam, fire, acid or mud containing chemicals such as sodium hydroxide. Dermatitis and skin injuries may result from exposure to crude oil and chemicals.

The possibility exists for acute and chronic exposure to a wide variety of unhealthful materials and chemicals which are present in oil and gas drilling and production. Some chemicals and materials which may be present in potentially hazardous amounts are listed in table 2 and include:

- Crude oil, natural gas and hydrogen sulphide gas during drilling and blowouts

- Heavy metals, benzene and other contaminants present in crude

- Asbestos, formaldehyde, hydrochloric acid and other hazardous chemicals and materials

- Normally occurring radioactive materials (NORMs) and equipment with radioactive sources.

Safety

Drilling and production take place in all types of climates and under varying weather conditions, from tropical jungles and deserts to the frozen Arctic, and from dry land to the North Sea. Drilling crews have to work in difficult conditions, subject to noise, vibration, inclement weather, physical hazards and mechanical failures. The platform, rotary table and equipment are usually slippery and vibrate from the engine and drilling operation, requiring workers to make deliberate and careful movements. The hazard exists for slips and falls from heights when climbing the rig and derrick, and there is risk of exposure to crude oil, gas, mud and engine exhaust fumes. The operation of rapidly disconnecting and then reconnecting drill pipe requires training, skill and precision by workers in order to be done safely time after time.

Construction, drilling and production crews working offshore have to contend with the same hazards as crews working on land, and with the additional hazards specific to offshore work. These include the possibility of collapse of the platform at sea and provisions for specialized evacuation procedures and survival equipment in event of an emergency. Another important consideration when working offshore is the requirement for both deep-sea and shallow-water diving to install, maintain and inspect equipment.

Fire and explosion

There is always a risk of blowout when perforating a well, with a gas or vapour cloud release, followed by explosion and fire. Additional potential for fire and explosion exists in gas process operations.

Offshore platform and drilling rig workers should be carefully evaluated after having a thorough physical examination. The selection of offshore crew members with a history or evidence of pulmonary, cardiovascular or neurological diseases, epilepsy, diabetes, psychological disturbances and drug or alcohol addiction requires careful consideration. Because workers will be expected to use respiratory protection equipment and, in particular, those trained and equipped to fight fires, they must be physically and mentally evaluated for capability of carrying out these tasks. The medical examination should include psychological evaluation reflective of the particular job requirements.

Emergency medical services on offshore drilling rigs and production platforms should include provisions for a small dispensary or clinic, staffed by a qualified medical practitioner on board at all times. The type of medical service provided will be determined by the availability, distance and quality of the available onshore services. Evacuation may be by ship or helicopter, or a physician may travel to the platform or provide medical advice by radio to the onboard practitioner, when needed. A medical ship may be stationed where a number of large platforms operate in a small area, such as the North Sea, to be more readily available and quickly provide service to a sick or injured worker.

Persons not actually working on drilling rigs or platforms should also be given pre-employment and periodic medical examinations, particularly if they are employed to work in abnormal climates or under harsh conditions. These examinations should take into consideration the particular physical and psychological demands of the job.

Personal protection

An occupational hygiene monitoring and sampling programme, in conjunction with a medical surveillance programme, should be implemented to evaluate systematically the extent and effect of hazardous exposures to workers. Monitoring for flammable vapours and toxic exposures, such as hydrogen sulphide, should be implemented during exploration, drilling and production operations. Virtually no exposure to H2S should be permitted, especially on offshore platforms. An effective method of controlling exposure is by using properly weighted drilling mud to keep H2S from entering the well and by adding chemicals to the mud to neutralize any entrapped H2S. All workers should be trained to recognize the presence of H2S and take immediate preventive measures to reduce the possibility of toxic exposure and explosions.

Persons engaged in exploration and production activities should have available and use appropriate personal protective equipment including:

- Head protection (hard hats and weather-proof liners)

- Gloves (oil-resistant, non-slip work gloves, fire insulated or thermal where needed)

- Arm protection (long sleeves or oil-proof gauntlets)

- Foot and leg protection (weather-protected, oil-impervious safety boots with steel toes and non-skid soles)

- Eye and face protection (safety glasses, goggles and face shield for acid handling)

- Skin protection from heat and cold (sun screen ointment and cold-weather face masks)

- Climatized and weather-proof clothing (parkas, rain gear)

- Where required, firefighting gear, flame-resistant clothing and acid-resistant aprons or suits.

Control rooms, living quarters and other spaces on large offshore platforms are usually pressurized to prevent the entry of harmful atmospheres, such as hydrogen sulphide gas, which may be released upon penetration or in an emergency. Respiratory protection may be needed in the event pressure fails, and when there is a possibility of exposure to toxic gases (hydrogen sulphide), asphyxiants (nitrogen, carbon dioxide), acids (hydrogen fluoride) or other atmospheric contaminants when working outside of pressurized areas.

When working around geopressure/geothermal wells, insulated gloves and full heat- and steam-protective suits with supplied breathing air should be considered, as contact with hot steam and vapours can cause burns to skin and lungs.

Safety harnesses and lifelines should be used when on catwalks and gangways, especially on offshore platforms and in inclement weather. When climbing rigs and derricks, harnesses and lifelines with an attached counterweight should be used. Personnel baskets, carrying four or five workers wearing personal flotation devices, are often used to transfer crews between boats and offshore platforms or drilling rigs. Another means of transfer is by “swing ropes.” Ropes used to swing from boats to platforms are hung directly above the edge of the boat landings, while those from platforms to boats should hang 3 or 4 feet from the outer edge.

Providing washing facilities for both workers and clothing and following proper hygiene practices are fundamental measures to control dermatitis and other skin diseases. Where needed, emergency eye wash stations and safety showers should be considered.

Safety protection measures

Oil and gas platform safety shutdown systems use various devices and monitors to detect leaks, fires, ruptures and other hazardous conditions, activate alarms and shut down operations in a planned, logical sequence. Where needed due to the nature of the gas or crude, non-destructive testing methods, such as ultrasonic, radiography, magnetic particle, liquid dye penetrant or visual inspections, should be used to determine the extent of corrosion of piping, heater tubes, treaters and vessels used in crude oil, condensate and gas production and processing.

Surface and sub-surface safety shut-in valves protect onshore installations, single wells in shallow water and multi-well offshore deep-water drilling and production platforms, and are automatically (or manually) activated in the event of fire, critical pressure changes, catastrophic failure at the well head or other emergency. They are also used to protect small injection wells and gas lift wells.

Inspection and care of cranes, winches, drums, wire rope and associated appurtenances is an important safety consideration in drilling. Dropping a pipeline string inside a well is a serious incident, which may result in the loss of the well. Injuries, and sometimes fatalities, can occur when personnel are struck by a wire rope which breaks while under tension. Safe operation of the drilling rig is also dependent on a smooth-running, well maintained draw works, with properly adjusted catheads and braking systems. When working on land, keep cranes a safe distance from electric power lines.

Handling of explosives during exploration and drilling operations should be under the control of a specifically qualified person. Some safety precautions to be considered while using a perforating gun include:

- Never strike or drop a loaded gun, or drop piping or other materials on a loaded gun.

- Clear the line of fire and evacuate unnecessary personnel from the drilling rig floor and the floor below as the perforating gun is lowered into and retrieved from the well hole.

- Control work on or around the wellhead while the gun is in the well.

- Restrict use of radios and prohibit arc welding while the gun is attached to the cable to prevent discharge from an inadvertent electric impulse.

Emergency preparedness planning and drills are important to the safety of workers on oil and gas drilling and production rigs and offshore platforms. Each different type of potential emergency (e.g., fire or explosion, flammable or toxic gas release, unusual weather conditions, worker overboard, and the need to abandon a platform) should be evaluated and specific response plans developed. Workers need to be trained in the correct actions to be taken in emergencies, and familiar with the equipment to be used.

Helicopter safety and survival in the event of dropping into water are important considerations for offshore platform operations and emergency preparedness. Pilots and passengers should wear seat-belts and, where required, survival gear during flight. Life vests should be worn at all times, both during flight and when transferring from helicopter to platform or ship. Careful attention to keep bodies and materials beneath the path of the rotor blade is required when entering, leaving or working around a helicopter.

Training of both onshore and offshore workers is essential to a safe operation. Workers should be required to attend regularly scheduled safety meetings, covering both mandatory and other subjects. Statutory regulations have been enacted by government agencies, including the US Occupational Safety and Health Administration, the US Coast Guard for offshore operations, and the equivalents in the United Kingdom, Norway and elsewhere, which regulate the safety and health of exploration and production workers, both onshore and offshore. The International Labour Organization Code of Practice Safety and Health in the Construction of Fixed Offshore Installations in the Petroleum Industry (1982) provides guidance in this area. The American Petroleum Institute has a number of standards and recommended practices covering safety and health related to exploration and production activities.

Fire protection and prevention measures

Fire prevention and protection, especially on offshore drilling rigs and production platforms, is an important element in the safety of the workers and continued operations. Workers should be trained and educated to recognize the fire triangle, as discussed in the Fire chapter, as it applies to flammable and combustible hydrocarbon liquids, gases and vapours and the potential hazards of fires and explosions. An awareness of fire prevention is essential and includes a knowledge of ignition sources such as welding, open flames, high temperatures, electrical energy, static sparks, explosives, oxidizers and incompatible materials.

Both passive and active fire-protection systems are used onshore and offshore.

- Passive systems include fireproofing, layout and spacing, equipment design, electrical classification and drainage.

- Detectors and sensors are installed which activate alarms, and may also activate automatic protection systems, upon detecting heat, flame, smoke, gas or vapours.

- Active fire protection includes fire water systems, fire water supply, pumps, hydrants, hoses and fixed sprinkler systems; dry chemical automatic systems and manual extinguishers; halon and carbon dioxide systems for confined or enclosed areas such as control rooms, computer rooms and laboratories; and foam water systems.

Employees who are expected to fight fires, from small fires in the incipient stages to large fires in enclosed spaces, such as on offshore platforms, must be properly trained and equipped. Workers assigned as fire brigade leaders and incident commanders need leadership capabilities and additional specialized training in advanced firefighting and fire-control techniques.

Environmental Protection

The major sources of air, water and ground pollution in oil and natural gas production are from oil spills or gas leaks on land or sea, hydrogen sulphide present in oil and gas escaping into the atmosphere, hazardous chemicals present in drilling mud contaminating water or land and combustion products of oil well fires. The potential public health effects of inhalation of smoke particulates from large-scale oil field fires has been of great concern since the oil well fires that occurred in Kuwait during the Persian Gulf War in 1991.

Pollution controls typically include:

- API separators and other waste and water treatment facilities

- Spill control, including booms for spills on water

- Spill containment, dikes and drainage to control oil spills and divert oily water to treatment facilities.

Gas dispersion modelling is conducted to ascertain the probable area which would be affected by a cloud of escaping toxic or flammable gas or vapour. Groundwater table studies are conducted to project the maximum extent of water pollution should oil contamination occur.

Workers should be trained and qualified to provide first aid response to mediate spills and leakage. Contractors who specialize in pollution remediation are usually engaged to manage large spill responses and remediation projects.