Adapted from 3rd edition, Encyclopaedia of Occupational Health and Safety

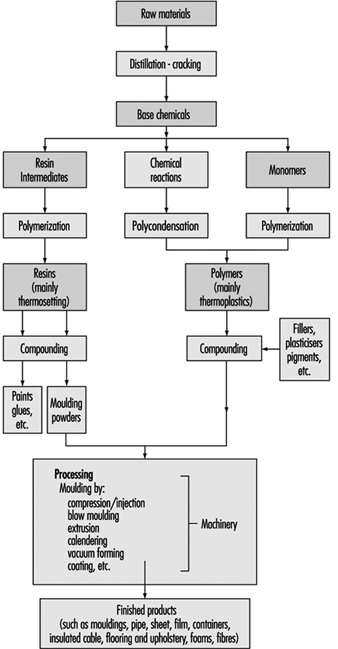

The plastics industry is divided into two major sectors, the inter-relationship of which can be seen in figure 1. The first sector comprises the raw material suppliers who manufacture polymers and moulding compounds from intermediates which they may also have produced themselves. In terms of invested capital this is usually the largest of the two sectors. The second sector is made up of processors who convert the raw materials into saleable items using various processes such as extrusion and injection moulding. Other sectors include machinery manufacturers who supply equipment to the processors and suppliers of special additives for use within the industry.

Figure 1. Production sequence in the processing of plastics

Polymer Manufacturing

Plastics materials fall broadly into two distinct categories: thermoplastics materials, which can be softened repeatedly by the application of heat and thermosetting materials, which undergo a chemical change when heated and shaped and cannot thereafter be reshaped by the application of heat. Several hundred individual polymers can be made with widely differing properties but as few as 20 types constitute about 90% of total world output. Thermoplastics are the largest group and their production is increasing at a higher rate than the thermosetting. In terms of production quantity the most important thermoplastics are high and low density polyethylene and polypropylene (the polyolefins), polyvinyl chloride (PVC) and polystyrene.

Important thermosetting resins are phenol-formaldehyde and urea-formaldehyde, both in the form of resins and moulding powders. Epoxy resins, unsaturated polyesters and polyurethanes are also significant. A smaller volume of “engineering plastics”, for example, polyacetals, polyamides and polycarbonates, have a high value in use in critical applications.

The considerable expansion of the plastics industry in the post Second World War world was greatly facilitated by the broadening of the range of the basic raw materials feeding it; availability and price of raw materials are crucial to any rapidly developing industry. Traditional raw materials could not have provided chemical intermediates in sufficient quantities at an acceptable cost to facilitate the economic commercial production of large-tonnage plastics materials and it was the development of the petrochemicals industry which made growth possible. Petroleum as a raw material is abundantly available, easily transported and handled and was, until the oil crisis of the 1970s, relatively cheap. Therefore, throughout the world, the plastics industry is primarily tied to the use of intermediates obtained from oil cracking and from natural gas. Unconventional feedstocks like biomass and coal have not yet had a major impact on supply to the plastics industry.

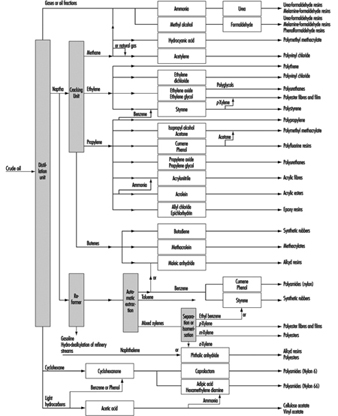

The flow chart in figure 2 illustrates the versatility of crude petroleum and natural gas feedstocks as starting points for the important thermosetting and thermoplastics materials. Following the first processes of crude oil distillation, naphtha feedstock is either cracked or reformed to provide useful intermediates. Thus the ethylene produced by the cracking process is of immediate use for the manufacture of polyethylene or for utilization in another process which provides a monomer, vinyl chloride—the basis of PVC. Propylene, which also arises during the cracking process, is used via either the cumene route or the isopropyl alcohol route for the manufacture of acetone needed for polymethylmethacrylate; it is also used in the manufacture of propylene oxide for polyester and polyether resins and again may be polymerized directly to polypropylene. Butenes find use in the manufacture of plasticisers and 1,3-butadiene is utilized directly for synthetic rubber manufacture. Aromatic hydrocarbons such as benzene, toluene and xylene are now widely produced from the derivatives of oil distillation operations, instead of being obtained from coal-coking processes; as the flow chart shows, these are intermediates in the manufacture of important plastics materials and auxiliary products such as plasticizers. The aromatic hydrocarbons are also a starting point for many polymers required in the synthetic fibres industry, some of which are discussed elsewhere in this Encyclopaedia.

Figure 2. Production of raw materials into plastics

Many widely differing processes contribute to the final production of a finished article made wholly or partly of plastics. Some processes are purely chemical, some involve purely mechanical mixing procedures while others-particularly those towards the lower end of the diagram-involve extensive use of specialized machinery. Some of this machinery resembles that used in rubber, glass, paper and textile industries; the remainder is specific to the plastics industry.

Plastics processing

The plastics processing industry converts bulk polymeric material into finished articles.

Raw materials

The processing section of the plastics industry receives its raw materials for production in the following forms:

- fully compounded polymeric material, in the form of pellets, granules or powder, which is fed directly into the machinery for processing

- uncompounded polymer, in the form of granules or powder, which must be compounded with additives before it is suitable for feeding into to machinery

- polymeric sheet, rod, tube and foil materials which are processed further by the industry

- miscellaneous materials which can be fully polymerized matter in the form of suspensions or emulsions (generally known as latices) or liquids or solids which can polymerise, or substances in an intermediate state between the reactive raw materials and the final polymer. Some of these are liquids and some true solutions of partially polymerised matter in water of controlled acidity (pH) or in organic solvents.

Compounding

The manufacture of compound from polymer entails the mixing of the polymer with additives. Though a great variety of machinery is employed for this purpose, where powders are dealt with, ball mills or high-speed propeller mixers are most common, and where plastic masses are being mixed, kneading machines such as the open rolls or Banbury-type mixers, or extruders themselves are normally employed.

The additives required by the industry are many in number, and range widely in chemical type. Of some 20 classes, the most important are:

- plasticisers—generally esters of low volatility

- antioxidants—organic chemicals to protect against thermal decomposition during processing

- stabilisers—inorganic and organic chemicals to protect against thermal decomposition and against degradation from radiant energy

- lubricants

- fillers—inexpensive matter to confer special properties or to cheapen compositions

- colourants—inorganic or organic matter to colour compounds

- blowing agents—gases or chemicals that emit gases to produce plastic foams.

Conversion processes

All the conversion processes call on the “plastic” phenomenon of polymeric materials and fall into two types. Firstly, those where the polymer is brought by heat to a plastic state in which it is given a mechanical constriction leading to a form which it retains on consolidation and cooling. Secondly, those in which a polymerisable material-which may be partially polymerised-is fully polymerised by the action of heat, or of a catalyst or by both acting together whilst under a mechanical constraint leading to a form which it retains when fully polymerised and cold. Plastics technology has developed to exploit these properties to produce goods with the minimum of human effort and the greatest consistency in physical properties. The following processes are commonly used.

Compression moulding

This consists of heating a plastic material, which can be in the form of granules or powder, in a mould which is held in a press. When the material becomes “plastic” the pressure forces it to conform to the shape of the mould. If the plastic is of the type that hardens on heating, the formed article is removed after a short heating period by opening the press. If the plastic does not harden on heating, cooling must be effected before the press can be opened. Articles made by compression moulding include bottle caps, jar closures, electric plugs and sockets, toilet seats, trays and fancy goods. Compression moulding is also employed to make sheet for subsequent forming in the vacuum forming process or for building into tanks and large containers by welding or by lining existing metal tanks.

Transfer moulding

This is a modification of compression moulding. The thermosetting material is heated in a cavity and then forced by a plunger into the mould, which is physically separate and independently heated from the heating cavity. It is preferred to normal compression moulding when the final article has to carry delicate metallic inserts such as in small electrical switchgear, or when, as in very thick objects, completion of the chemical reaction could not be obtained by normal compression moulding.

Injection moulding

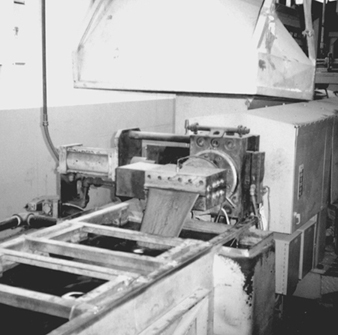

In this process, plastics granules or powders are heated in a cylinder (known as the barrel), which is separate from the mould. The material is heated until it becomes fluid, while it is conveyed through the barrel by a helical screw and then forced into the mould where it cools and hardens. The mould is then opened mechanically and the formed articles are removed (see figure 3). This process is one of the most important in the plastics industry. It has been extensively developed and has become capable of making articles of considerable complexity at very low cost.

Figure 3. An operator removing a polypropylene bowl from an injection-moulding machine.

Though transfer and injection moulding are identical in principle, the machinery employed is very different. Transfer moulding is normally restricted to thermosetting materials and injection moulding to thermoplastics.

Extrusion

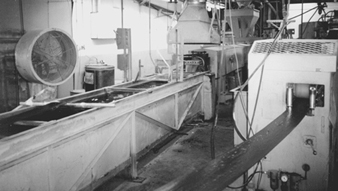

This is the process in which a machine softens a plastic and forces it through a die which gives it the shape that it retains on cooling. The products of extrusion are tubes or rods which may have cross sections of almost any configuration (see figure 4). Tubes for industrial or domestic purposes are produced in this way, but other articles can be made by subsidiary processes. For example, sachets can be made by cutting tubes and sealing both ends, and bags from thin-walled flexible tubes by cutting and sealing one end.

The process of extrusion has two major types. In one, a flat sheet is produced. This sheet can be converted into useful goods by other processes, such as vacuum forming.

Figure 4. Plastic extrusion: The ribbon is chopped to make pellets for injection moulding machines.

Ray Woodcock

The second is a process in which the extruded tube is formed and when still hot is greatly expanded by a pressure of air maintained inside the tube. This results in a tube which can be several feet in diameter with a very thin wall. On slitting, this tube gives film which is extensively used in the packaging industry for wrapping. Alternatively the tube can be folded flat to give a two-layer sheet which can be used to make simple bags by cutting and sealing. Figure 5 provides an example of appropriate local ventilation on an extrusion process.

Figure 5. Plastic extrusion with local exhaust hood and water bath at extruder head

Ray Woodcock

Calendering

In this process, a plastic is fed to two or more heated rollers and forced into a sheet by passing through a nip between two such rollers and cooling thereafter. Sheet thicker than film is made in this way. Sheet so made is employed in industrial and domestic applications and as the raw material in the manufacture of clothing and inflated goods such as toys (see figure 6).

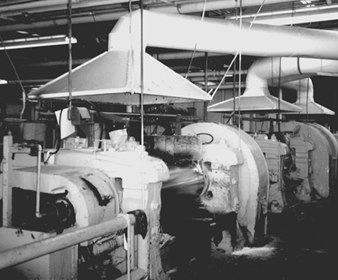

Figure 6. Canopy hoods to capture hot emissions from warm-up mills on a calender process

Ray Woodcock

Blow moulding

This process can be regarded as a combination of the process of extrusion and thermo-forming. A tube is extruded downwards into an opened mould; as it reaches the bottom the mould is closed round it and the tube expanded by air pressure. Thus the plastic is forced to the sides of the mould and the top and bottom sealed. On cooling, the article is taken from the mould. This process makes hollow articles of which bottles are the most important.

The compression and impact strength of certain plastic products made by blow moulding can be considerably improved by using stretch-blow moulding techniques. This is achieved by producing a pre-form which is subsequently expanded by air pressure and stretched biaxially. This has led to such an improvement in the burst pressure strength of PVC bottles that they are used for carbonated drinks.

Rotational moulding

This process is used for the production of moulded articles by heating and cooling a hollow form which is rotated to enable gravity to distribute finely divided powder or liquid over the inner surface of that form. Articles produced by this method include footballs, dolls and other similar articles.

Film casting

Apart from the extrusion process, films can be formed by extruding a hot polymer on to a highly polished metal drum, or a solution of polymer can be sprayed on to a moving belt.

An important application of certain plastics is the coating of paper. In this, a film of molten plastic is extruded on to paper under conditions in which the plastic adheres to the paper. Board can be coated in the same way. Paper and board so coated are widely used in packaging, and board of this type is used in box making.

Thermo-forming

Under this heading are grouped a number of processes in which a sheet of a plastic material, more often than not thermoplastic, is heated, generally in an oven, and after clamping at the perimeter is forced to a predesigned shape by pressure which may be from mechanically operated rams or by compressed air or steam. For very large articles the “rubbery” hot sheet is manhandled with tongs over formers. Products so made include external light fittings, advertising and directional road signs, baths and other toilet goods and contact lenses.

Vacuum-forming

There are many processes which come under this general heading, all of which are aspects of thermal forming, but they all have in common that a sheet of plastic is heated in a machine above a cavity, around the edge of which it is clamped, and when pliable it is forced by suction into the cavity, where it takes some specific form and cools. In a subsequent operation, the article is trimmed free from the sheet. These processes produce very cheaply thin-walled containers of all types, as well as display and advertising goods, trays and similar articles, and shock-absorbing materials for packing goods such as fancy cakes, soft fruit and cut meat.

Laminating

In all of the various laminating processes, two or more materials in the form of sheets are compressed to give a consolidated sheet or panel of special properties. At one extreme are found decorative laminates made from phenolic and amino resins, at the other complex films used in packaging having, for example, cellulose, polyethylene and metal foil in their constitution.

Resin technology processes

These include plywood manufacture, furniture manufacture and the construction of large and elaborate articles such as car bodies and boat hulls from glass fibre impregnated with polyester or epoxy resins. In all these processes, a liquid resin is caused to consolidate under the action of heat or of a catalyst and so bind together discrete particles or fibres or mechanically weak films or sheets, resulting in a robust panel of rigid construction. These resins can be applied by hand layup techniques such as brushing and dipping or by spraying.

Small objects such as souvenirs and plastic jewellery can also be made by casting, where the liquid resin and catalyst are mixed together and poured into a mould.

Finishing processes

Included under this heading are a number of processes common to many industries, for example the use of paints and adhesives. There are, however, a number of specific techniques used for the welding of plastics. These include the use of solvents such as chlorinated hydrocarbons, methyl ethyl ketone (MEK) and toluene, which are used for bonding together rigid plastic sheets for general fabrication, advertising display stands and similar work. Radiofrequency (RF) radiation utilizes a combination of mechanical pressure and electromagnetic radiation with frequencies generally in the range of 10 to 100 mHz. This method is commonly used for welding together flexible plastic material in the manufacture of wallets, briefcases and children’s push chairs (see the accompanying box). Ultrasonic energies are also used in combination with mechanical pressure for a similar range of work.

RF dielectric heaters and sealers

Radiofrequency (RF) heaters and sealers are used in many industries to heat, melt or cure dielectric materials, such as plastics, rubber and glue which are electrical and thermal insulators and hard to heat using normal methods. RF heaters are commonly used for sealing polyvinyl chloride (e.g., manufacture of plastic products such as raincoats, seat covers and packaging materials); curing of glues used in woodworking; embossing and drying of textiles, paper, leather and plastics; and curing of many materials containing plastic resins.

RF heaters use RF radiation in the frequency range 10 to 100MHz with output power from under 1kW to about 100kW to produce heat. The material to be heated is placed between two electrodes under pressure, and the RF power is applied for periods ranging from a few seconds to about a minute, depending on the use. RF heaters can produce high stray RF electric and magnetic fields in the surrounding environment, especially if the electrodes are unshielded.

Absorption of RF energy by the human body can cause localized and whole body heating, which can have adverse health effects. The body temperature can rise 1 °C or more, which can cause cardiovascular effects such as increased heart rate and cardiac output. Localized effects include eye cataracts, lowered sperm counts in the male reproductive system and teratogenic effects in the developing foetus.

Indirect hazards include RF burns from direct contact with metal parts of the heater which are painful, deep seated and slow to heal; hand numbness; and neurological effects, including carpal tunnel syndrome and peripheral nervous system effects.

Controls

The two basic types of controls that can be used to reduce hazards from RF heaters are work practices and shielding. Shielding, of course, is preferred, but proper maintenance procedures and other work practices can also reduce exposure. Limiting the amount of time the operator is exposed, an administrative control, has also been used.

Proper maintenance or repair procedures are important because failure to properly reinstall shielding, interlocks, cabinet panels and fasteners can result in excessive RF leakage. In addition, electric power to the heater should be disconnected and locked out or tagged out to protect maintenance personnel.

Operator exposure levels can be reduced by keeping the operator’s hands and upper body as far as possible from the RF heater. The operator’s control panels for some automated heaters are positioned at a distance from the heater electrodes by using shuttle trays, turning tables or conveyor belts to feed the heater.

The exposure of both operating and non-operating personnel can be reduced by measuring RF levels. Since RF levels decrease with increasing distance from the heater, an “RF hazard area” can be identified around each heater. Workers can be alerted to not occupy these hazard areas when the RF heater is being operated. Where possible, nonconductive physical barriers should be used to keep people at a safe distance.

Ideally, RF heaters should have a box shield around the RF applicator to contain the RF radiation. The shield and all joints should have high conductivity for the interior electrical currents that will flow in the walls. There should be as few openings in the shield as possible, and they should be as small as is practical for operation. The openings should be directed away from the operator. Currents in the shield can be minimized by having separate conductors inside the cabinet to conduct high currents. The heater should be properly grounded, with the ground wire in the same pipe as the power line. The heater should have proper interlocks to prevent exposure to high voltages and high RF emissions.

It is much easier to incorporate this shielding into new designs of RF heaters by the manufacturer. Retrofitting is more difficult. Box enclosures can be effective. Proper grounding can also often be effective in reducing RF emissions. RF measurements have to be carefully taken afterwards to ensure that RF emissions have actually been reduced. The practice of enclosing the heater in a metal screen-encased room can actually increase exposure if the operator is also in that room, although it does reduce exposures outside the room.

Source: ICNIRP in press.

Hazards and Their Prevention

Polymer manufacturing

The special hazards of the polymers industry relate closely to those of the petrochemicals industry and depend to a large extent on the substances used. The health hazards of individual raw materials are found elsewhere in this Encyclopaedia. The danger of fire and explosion is an important general hazard. Many polymer/resin processes have a fire and explosion risk owing to the nature of the primary raw materials used. If adequate safeguards are not taken there is sometimes a risk during reaction, generally inside partly enclosed buildings, of flammable gases or liquids escaping at temperatures above their flash points. If the pressures involved are very high, provision should be made for adequate venting to the atmosphere. An excessive build-up of pressure due to unexpectedly fast exothermic reactions may occur and the handling of some additives and preparation of some catalysts may add to the explosion or fire risk. The industry has addressed these problems and particularly on the manufacture of phenolic resins has produced detailed guidance notes on plant design engineering and safe operating procedures.

Plastics processing

The plastics processing industry has injury hazards because of the machinery used, fire hazards because of the combustibility of plastics and their powders and health hazards because of the many chemicals used in the industry.

Injuries

The major area for injuries is in the plastics processing sector of the plastics industry. The majority of the plastics conversion processes depend almost entirely upon the use of machinery. As a result the principal hazards are those associated with the use of such machinery, not only during normal operation but also during cleaning, setting and maintenance of the machines.

Compression, transfer, injection and blow moulding machines all have press platens with a locking force of many tonnes per square centimetre. Adequate guarding should be fitted to prevent amputation or crushing injuries. This is generally achieved by enclosing the dangerous parts and by interlocking any movable guards with the machine controls. An interlocking guard should not allow dangerous movement within the guarded area with the guard open and should bring the dangerous parts to rest or reverse the dangerous motion if the guard is opened during the machine operation.

Where there is a severe risk of injury at machinery such as at the platens of moulding machines, and regular access to the danger area, then a higher standard of interlocking is called for. This may be achieved by a second independent interlocking arrangement at the guard to interrupt the power supply and prevent a dangerous motion when it is open.

For processes involving plastic sheet, a common machinery hazard found is in-running traps between rollers or between rollers and the sheet being processed. These occur at tension rollers and haul-off devices at extrusion plant and calenders. Safeguarding may be achieved by using a suitably located trip device, which immediately brings the rollers to rest or reverses the dangerous motion.

Many of the plastics processing machines operate at high temperatures and severe burns may be sustained if parts of the body come into contact with hot metal or plastics. Where practical, such parts should be protected when the temperature exceeds 50 ºC. In addition, blockages which occur on injection moulding machines and extruders can violently free themselves. A safe system of work should be followed when attempting to free frozen plugs of plastic, which should include the use of suitable gloves and face protection.

Most modern machine functions are now controlled by programmed electronic control or computer systems which may also control mechanical take-off devices or are linked with robots. On new machinery there is less need for an operator to approach the danger areas and it follows that safety at machinery should correspondingly improve. There is, however, a greater need for setters and engineers to approach these parts. It is essential therefore that an adequate lockout/tagout programme be instituted before this type of work is carried out, particularly where full protection by the machine safety devices cannot be achieved. In addition adequate back up or emergency systems should be so designed and devised to deal with situations when the programmed control fails for any reason, for example, during the loss of the power supply.

It is important that machines be properly laid out in the workshop with good clear working spaces for each. This assists in maintaining high standards of cleanliness and tidiness. The machines themselves should also be properly maintained and the safety devices should be checked on a routine basis.

Good housekeeping is essential and particular attention should be paid to keeping the floors clean. Without routine cleaning, floors will become badly contaminated from machine oil or spilled plastics granules. Methods of work including safe means of access to areas above floor level should also be considered and provided.

Adequate spacing should also be allowed for the storage of raw materials and finished goods; these areas should be clearly designated.

Plastics are good electrical insulators and, because of this, static charges can build up on machinery on which sheet or film travels. These charges can have a potential high enough to cause a serious accident or act as sources of ignition. Static eliminators should be used to reduce these charges and metal parts properly earthed or grounded.

Increasingly, waste plastics material is being reprocessed using granulators and blending with new stock. Granulators should be totally enclosed to prevent any possibility of reaching the rotors through the discharge and feed openings. The design of the feed openings on large machines should be such as to prevent whole body entry. The rotors operate at high speed and covers should not be removed until they have come to rest. Where interlocking guards are fitted, they should prevent contact with the blades until they have completely stopped.

Fire and explosion hazards

Plastics are combustible materials, although not all polymers support combustion. In finely divided powder form, many can form explosive concentrations in air. Where this is a risk, the powders should be controlled, preferably in an enclosed system, with sufficient relief panels venting at low pressure (about 0.05 bar) to a safe place. Scrupulous cleanliness is essential to prevent accumulations in the workrooms which may become airborne and cause a secondary explosion.

Polymers may be subject to thermal degradation and pyrolysis at temperatures not greatly above normal processing temperatures. Under these circumstances, sufficient pressures may build up in the barrel of an extruder, for example, to eject molten plastic and any solid plug of plastic causing an initial blockage.

Flammable liquids are commonly used in this industry, for example, as paints, adhesives, cleaning agents and in solvent welding. Glass-fibre (polyester) resins also evolve flammable styrene vapours. Stocks of such liquids should be reduced to a minimum in the workroom and stored in a safe place when not in use. Storage areas should include safe places in the open air or a fire resisting store.

Peroxides used in the manufacture of glass reinforced plastics (GRP) resins should be stored separately from flammable liquids and other combustible materials and not subjected to extremes of temperatures since they are explosive when heated.

Health hazards

There are a number of potential health hazards associated with the processing of plastics. The raw plastics are rarely used on their own and appropriate precautions should be taken regarding the additives used in the various formulations. Additives used include lead soaps in PVC and certain organic and cadmium dyestuffs.

There is a significant risk of dermatitis from liquids and powders usually from “reactive chemicals” such as phenol formaldehyde resins (before crosslinking), urethanes and unsaturated polyester resins used in the production of GRP products. Suitable protective clothing should be worn.

It is possible for fumes to be generated from the thermal degradation of polymers during hot processing. Engineering controls can minimize the problem. Particular care, however, must be taken to avoid inhalation of pyrolysis products under adverse conditions, for example, purging of the extruder barrel. Conditions of good LEV may be necessary. Problems have occurred, for example, where operators have been overcome by hydrochloric acid gas and suffered from “polymer fume fever” following overheating of PVC and polytetrafluorethylene (PTFE), respectively. The accompanying box details some chemical decomposition products of plastics.

Table 1. Volatile products of the decomposition of plastics (reference components)*

*Reprinted from BIA 1997, with permission.

In many industrial sectors, plastics are subject to thermal stress. Temperatures range from relatively low values in plastics processing (e.g., 150 to 250 ºC) to extreme cases, e.g., where painted sheet metal or plastic-coated pipes are welded). The question that constantly arises in such cases is whether toxic concentrations of volatile pyrolysis products occur in work areas.

To answer this question, the substances released first need to be determined and then the concentrations need to be measured. While the second step is in principle feasible, it is usually not possible to determine the relevant pyrolysis products in the field. The Berufsgenossenschaftliches Institut für Arbeitssicherheit (BIA) has therefore been examining this problem for years and in the course of many laboratory tests has determined volatile decomposition products for plastics. The test results for the individual types of plastic have been published (Lichtenstein and Quellmalz 1984, 1986a, 1986b, 1986c).

Following is a brief summary of the results to date. This table is intended as an aid for all those faced with the task of measuring hazardous substance concentrations in relevant work areas.The decomposition products listed for the individual plastics may serve as "reference components". It should be remembered, however, that pyrolysis may give rise to highly complex mixtures of substances, their compositions depending on many factors.

The table thus does not claim to be complete where the pyrolysis products listed as reference components are concerned (all determined in laboratory experiments). The occurrence of other substances with potential health risks cannot be ruled out. It is practically impossible to completely record all substances that occur.

|

Plastic |

Abbreviation |

Volatile substances |

|

Polyoxymethylene |

POM |

Formaldehyde |

|

Epoxy resins based on |

Phenol |

|

|

Chloroprene rubber |

CR |

Chloroprene(2-chlorobuta-1,3-diene), |

|

Polystyrene |

PS |

Styrene |

|

Acrylonitrile-butadiene-styrene- |

ABS |

Styrene, 1,3-butadiene, acrylonitrile |

|

Styrene-acrylonitrile copolymer |

SAN |

Acrylonitrile, styrene |

|

Polycarbonates |

PC |

Phenol |

|

Polyvinyl chloride |

PVC |

Hydrogen chloride, plasticisers |

|

Polyamide 6 |

PA 6 |

e-caprolactam |

|

Polyamide 66 |

PA 66 |

Cyclopentanone, |

|

Polyethylene |

HDPE, LDPE |

Unsaturated aliphatic hydrocarbons, |

|

Polytetrafluoroethylene |

PTFE |

Perfluorinated unsaturated |

|

Polymethyl methacrylate |

PMMA |

Methyl methacrylate |

|

Polyurethane |

PUR |

Depending on the type, widely varying |

|

Polypropylene |

PP |

Unsaturated and saturated aliphatic |

|

Polybutyle enterephthalate |

PBTP |

1,3-butadiene, benzene |

|

Polyacrylonitrile |

PAN |

Acrylonitrile, hydrogen cyanide2 |

|

Cellulose acetate |

CA |

Acetic acid |

Norbert Lichtenstein

1 Use is discontinuing.

2 Could not be detected with the analytical technique used (GC/MS) but is known from the literature.

There is also a danger of inhalation of toxic vapours from certain thermoset resins. Inhalation of isocyanates used with polyurethane resins can lead to chemical pneumonia and severe asthma and, once sensitized, persons should be transferred to alternative work. A similar problem exists with formaldehyde resins. In both these examples, a high standard of LEV is necessary. In the manufacture of GRP articles, significant quantities of styrene vapour is given off and this work must be done in conditions of good general ventilation in the workroom.

There are also certain hazards which are common to a number of industries. These include the use of solvents for dilution or for purposes mentioned previously. Chlorinated hydrocarbons are commonly used for cleaning and bonding and without adequate exhaust ventilation persons may well suffer from narcosis.

Waste disposal of plastics by burning should be done under carefully controlled conditions; for example, PTFE and urethanes should be in an area where the fumes are vented to a safe place.

Very high noise levels are generally obtained during the use of granulators, which may well lead to hearing loss to the operators and persons working nearby. This hazard can be confined by separating this equipment from other working areas. Preferably the noise levels should be reduced at source. This has successfully been achieved by coating the granulator with sound deadening material and fitting baffles at the feed opening. There may also be a hazard to hearing created by audible sound produced from ultrasonic welding machines as a normal accompaniment of the ultrasonic energies. Suitable enclosures can be designed to reduce the received noise levels and can be interlocked to prevent a mechanical hazard. As a minimum standard, persons working in areas of high noise levels should wear suitable hearing protection and there should be a suitable hearing conservation programme, including audiometric testing and training.

Burns are also a hazard. Some additives and catalysts for plastics production and processing can be highly reactive on contact with air and water and may readily cause chemical burns. Wherever molten thermoplastics are being handled or transported there is the danger of splashes of hot material and consequent burns and scalds. The severity of these burns may be increased by the tendency of hot thermoplastics, like hot wax, to adhere to the skin.

Organic peroxides are irritants and may cause blindness if splashed in the eye. Suitable eye protection should be worn.