Cotton Production

Cotton production practices begin after the previous crop is harvested. The first operations usually include shredding stalks, ripping out roots and disking the soil. Fertilizer and herbicides generally are applied and incorporated into the soil before the land is bedded in preparation for needed irrigation or planting. Since soil characteristics and past fertilization and cropping practices can cause a wide range of fertility levels in cotton soils, fertility programmes should be based on soil test analyses. Control of weeds is essential to obtain high lint yield and quality. Cotton yields and harvesting efficiency can be reduced by as much as 30% by weeds. Herbicides have been widely used in many countries for weed control since the early 1960s. Application methods include pre-planting treatment to foliage of existing weeds, incorporation into pre-plant soil and treatment at pre-emergence and post-emergence stages.

Several factors that play an important role in achieving a good stand of cotton plants include seed-bed preparation, soil moisture, soil temperature, seed quality, seedling disease infestation, fungicides and soil salinity. Planting high-quality seed in a well-prepared seed-bed is a key factor in achieving early, uniform stands of vigorous seedlings. High-quality planting seed should have a germination rate of 50% or higher in a cool test. In a cool/warm test, the seed vigour index should be 140 or higher. Seeding rates of 12 to 18 seeds/metre of row are recommended to obtain a plant population of 14,000 to 20,000 plants/hectare. A suitable planter metering system should be used to ensure uniform spacing of seed regardless of seed size. Seed germination and seedling emergence rates are closely associated with a temperature range of 15 to 38 ºC.

Early-season seedling diseases can hamper uniform stands and result in the need to replant. Important seedling disease pathogens such as Pythium, Rhizoctonia, Fusarium and Thielaviopsis can reduce plant stands and cause long skips between seedlings. Only seed that has been properly treated with one or more fungicides should be planted.

Cotton is similar to other crops with respect to water use during different plant developmental stages. Water use is generally less than 0.25 cm/day from emergence to the first square. During this period, loss of soil moisture by evaporation may exceed the amount of water transpired by the plant. Water use increases sharply as the first blooms appear and reaches a maximum level of 1 cm/day during the peak bloom stage. Water requirement refers to the total amount of water (rainfall and irrigation) needed to produce a crop of cotton.

Insect populations can have an important impact on cotton quality and yield. Early-season population management is important in promoting balanced fruiting/vegetative development of the crop. Protecting early fruit positions is essential to achieving a profitable crop. Over 80% of the yield is set in the first 3 to 4 weeks of fruiting. During the fruiting period, producers should scout their cotton at least twice a week to monitor insect activity and damage.

A well-managed defoliation programme reduces leaf trash that can adversely affect the grade of the harvested cotton. Growth regulators such as PIX are useful defoliators because they control vegetative growth and contribute to earlier fruiting.

Harvesting

Two types of mechanical harvesting equipment are used to harvest cotton: the spindle picker and the cotton stripper. The spindle picker is a selective-type harvester that uses tapered, barbed spindles to remove seed cotton from bolls. This harvester can be used on a field more than once to provide stratified harvests. On the other hand, the cotton stripper is a nonselective or once-over harvester that removes not only the well-opened bolls but also the cracked and unopened bolls along with the burs and other foreign matter.

Agronomic practices that produce a high-quality uniform crop will generally contribute to good harvesting efficiency. The field should be well drained and rows laid out for effective use of machinery. Row ends should be free of weeds and grass, and should have a field border of 7.6 to 9 m for turning and aligning the harvesters with the rows. The border also should be free of weeds and grass. Disking creates adverse conditions in rainy weather, so chemical weed control or mowing should be used instead. Plant height should not exceed about 1.2 m for cotton that is to be picked, and about 0.9 m for cotton that is to be stripped. Plant height can be controlled to some extent by using chemical growth regulators at the proper growth stage. Production practices that set the bottom boll at least 10 cm above the ground should be used. Culturing practices such as fertilization, cultivation and irrigation during the growing season should be carefully managed to produce a uniform crop of well-developed cotton.

Chemical defoliation is a culturing practice that induces abscission (shedding) of foliage. Defoliants may be applied to help minimize green-leaf-trash contamination and promote faster drying of early morning dew on the lint. Defoliants should not be applied until at least 60% of the bolls are open. After a defoliant is applied, the crop should not be harvested for at least 7 to 14 days (the period will vary depending on chemicals used and weather conditions). Chemical desiccants may also be used to prepare plants for harvest. Desiccation is the rapid loss of water from the plant tissue and subsequent death of the tissue. The dead foliage remains attached to the plant.

The current trend in cotton production is toward a shorter season and one-time harvest. Chemicals that accelerate the boll opening process are applied with the defoliant or soon after the leaves drop. These chemicals allow earlier harvests and increase the percentage of bolls that are ready to be harvested during the first harvest. Because these chemicals have the ability to open or partially open immature bolls, the quality of the crop may be severely impacted (i.e., the micronaire may be low) if the chemicals are applied too early.

Storage

The moisture content of cotton before and during storage is critical; excess moisture causes stored cotton to overheat, resulting in lint discolouration, lower seed germination and possibly spontaneous combustion. Seed cotton with a moisture content above 12% should not be stored. Also, the internal temperature of newly built modules should be monitored for the first 5 to 7 days of cotton storage; modules that experience a 11 ºC rise or are above 49 ºC should be ginned immediately to avoid the possibility of major loss.

Several variables affect seed and fibre quality during seed cotton storage. Moisture content is the most important. Other variables include length of storage, amount of high-moisture foreign matter, variation in moisture content throughout the stored mass, initial temperature of the seed cotton, temperature of the seed cotton during storage, weather factors during storage (temperature, relative humidity, rainfall) and protection of the cotton from rain and wet ground. Yellowing is accelerated at high temperatures. Both temperature rise and maximum temperature are important. Temperature rise is directly related to the heat generated by biological activity.

Ginning process

About 80 million bales of cotton are produced annually worldwide, of which about 20 million are produced by about 1,300 gins in the United States. The principal function of the cotton gin is to separate lint from seed, but the gin must also be equipped to remove a large percentage of the foreign matter from the cotton that would significantly reduce the value of the ginned lint. A ginner must have two objectives: (1) to produce lint of satisfactory quality for the grower’s market and (2) to gin the cotton with minimum reduction in fibre spinning quality, so that the cotton will meet the demands of its ultimate users, the spinner and the consumer. Accordingly, quality preservation during ginning requires the proper selection and operation of each machine in a ginning system. Mechanical handling and drying may modify the natural quality characteristics of cotton. At best, a ginner can only preserve the quality characteristics inherent in the cotton when it enters the gin. The following paragraphs briefly discuss the function of the major mechanical equipment and processes in the gin.

Seed-cotton machinery

Cotton is transported from a trailer or module into a green-boll trap in the gin, where green bolls, rocks and other heavy foreign matter are removed. The automatic feed control provides an even, well-dispersed flow of cotton so that the gin’s cleaning and drying system will operate more efficiently. Cotton that is not well dispersed can travel through the drying system in clumps, and only the surface of that cotton will be dried.

In the first stage of drying, heated air conveys the cotton through the shelves for 10 to 15 seconds. The temperature of the conveying air is regulated to control the amount of drying. To prevent fibre damage, the temperature to which the cotton is exposed during normal operation should never exceed 177 ºC. Temperatures above 150 ºC can cause permanent physical changes in cotton fibres. Dryer-temperature sensors should be located as near as possible to the point where cotton and heated air come together. If the temperature sensor is located near the exit of the tower dryer, the mixpoint temperature could actually be 55 to 110 ºC higher than the temperature at the downstream sensor. The temperature drop downstream results from the cooling effect of evaporation and from heat loss through the walls of machinery and piping. The drying continues as the warm air moves the seed cotton to the cylinder cleaner, which consists of 6 or 7 revolving spiked cylinders that rotate at 400 to 500 rpm. These cylinders scrub the cotton over a series of grid rods or screens, agitate the cotton and allow fine foreign materials, such as leaves, trash and dirt, to pass through the openings for disposal. Cylinder cleaners break up large wads and generally condition the cotton for additional cleaning and drying. Processing rates of about 6 bales per hour per metre of cylinder length are common.

The stick machine removes larger foreign matter, such as burs and sticks, from the cotton. Stick machines use the centrifugal force created by saw cylinders rotating at 300 to 400 rpm to “sling off” foreign material while the fibre is held by the saw. The foreign matter that is slung off the reclaimer feeds into the trash-handling system. Processing rates of 4.9 to 6.6 bales/hr/m of cylinder length are common.

Ginning (lint-seed separation)

After going through another stage of drying and cylinder cleaning, cotton is distributed to each gin stand by the conveyor-distributor. Located above the gin stand, the extractor-feeder meters seed cotton uniformly to the gin stand at controllable rates, and cleans seed cotton as a secondary function. The moisture content of cotton fibre at the extractor-feeder apron is critical. The moisture must be low enough that foreign matter can be easily removed in the gin stand. However, the moisture must not be so low (below 5%) as to result in the breakage of individual fibres as they are separated from the seed. This breakage causes an appreciable reduction both in fibre length and lint turnout. From a quality standpoint, cotton with a higher content of short fibres produces excessive waste at the textile mill and is less desirable. Excessive breakage of fibres can be avoided by maintaining a fibre moisture content of 6 to 7% at the extractor-feeder apron.

Two types of gins are in common use—the saw gin and the roller gin. In 1794, Eli Whitney invented a gin that removed fibre from the seed by means of spikes or saws on a cylinder. In 1796, Henry Ogden Holmes invented a gin having saws and ribs; this gin replaced Whitney’s gin and made ginning a continuous-flow process rather than a batch process. Cotton (usually Gossypium hirsutum) enters the saw gin stand through a huller front. The saws grasp the cotton and draw it through widely spaced ribs known as huller ribs. The locks of cotton are drawn from the huller ribs into the bottom of the roll box. The actual ginning process—separation of lint and seed—takes place in the roll box of the gin stand. The ginning action is caused by a set of saws rotating between ginning ribs. The saw teeth pass between the ribs at the ginning point. Here the leading edge of the teeth is approximately parallel to the rib, and the teeth pull the fibres from the seed, which are too large to pass between the ribs. Ginning at rates above those recommended by the manufacturer can cause fibre quality reduction, seed damage and choke-ups. Gin stand saw speeds are also important. High speeds tend to increase the fibre damage done during ginning.

Roller-type gins provided the first mechanically aided means of separating extra-long staple cotton (Gossypium barbadense) lint from seed. The Churka gin, which has an unknown origin, consisted of two hard rollers that ran together at the same surface speed, pinching the fibre from the seed and producing about 1 kg of lint/day. In 1840, Fones McCarthy invented a more efficient roller gin that consisted of a leather ginning roller, a stationary knife held tightly against the roller and a reciprocating knife that pulled the seed from the lint as the lint was held by the roller and stationary knife. In the late 1950s, a rotary-knife roller gin was developed by the US Department of Agriculture (USDA) Agricultural Research Service’s Southwestern Cotton Ginning Research Laboratory, US gin manufacturers and private ginneries. This gin is currently the only roller-type gin used in the United States.

Lint cleaning

Cotton is conveyed from the gin stand through lint ducts to condensers and formed again into a batt. The batt is removed from the condenser drum and fed into the saw-type lint cleaner. Inside the lint cleaner, cotton passes through the feed rollers and over the feed plate, which applies the fibres to the lint cleaner saw. The saw carries cotton under grid bars, which are aided by centrifugal force and remove immature seeds and foreign matter. It is important that the clearance between the saw tips and grid bars be properly set. The grid bars must be straight with a sharp leading edge to avoid reducing cleaning efficiency and increasing lint loss. Increasing the lint cleaner’s feed rate above the manufacturer’s recommended rate will decrease cleaning efficiency and increase loss of good fibre. Roller-ginned cotton is usually cleaned with non-aggressive, non-saw-type cleaners to minimize fibre damage.

Lint cleaners can improve the grade of cotton by removing foreign matter. In some cases, lint cleaners may improve the colour of a lightly spotted cotton by blending to produce a white grade. They may also improve the colour grade of a spotted cotton to light spotted or perhaps white colour grade.

Packaging

The cleaned cotton is compressed into bales, which must then be covered to protect them from contamination during transportation and storage. Three types of bales are produced: modified flat, compress universal density and gin universal density. These bales are packaged at densities of 224 and 449 kg/m3 for the modified flat and universal density bales, respectively. In most gins cotton is packaged in a “double-box” press wherein the lint is initially compacted in one press box by a mechanical or hydraulic tramper; then the press box is rotated, and the lint is further compressed to about 320 or 641 kg/m3 by modified flat or gin universal density presses, respectively. Modified flat bales are recompressed to become compress universal density bales in a later operation to achieve optimum freight rates. In 1995, about 98% of the bales in the United States were gin universal density bales.

Fibre quality

Cotton quality is affected by every production step, including selecting the variety, harvesting and ginning. Certain quality characteristics are highly influenced by genetics, while others are determined mainly by environmental conditions or by harvesting and ginning practices. Problems during any step of production or processing can cause irreversible damage to fibre quality and reduce profits for the producer as well as the textile manufacturer.

Fibre quality is highest the day a cotton boll opens. Weathering, mechanical harvesting, handling, ginning and manufacturing can diminish the natural quality. There are many factors that indicate the overall quality of cotton fibre. The most important ones include strength, fibre length, short fibre content (fibres shorter than 1.27 cm), length uniformity, maturity, fineness, trash content, colour, seedcoat fragment and nep content, and stickiness. The market generally recognizes these factors even though not all are measured on each bale.

The ginning process can significantly affect fibre length, uniformity and the content of seedcoat fragments, trash, short fibres and neps. The two ginning practices that have the most impact on quality are the regulation of fibre moisture during ginning and cleaning and the degree of saw-type lint cleaning used.

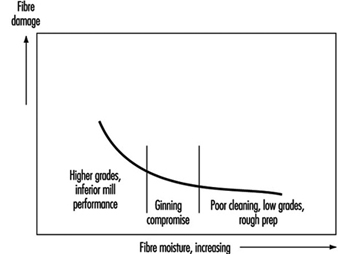

The recommended lint moisture range for ginning is 6 to 7%. Gin cleaners remove more trash at low moisture but not without more fibre damage. Higher fibre moisture preserves fibre length but results in ginning problems and poor cleaning, as illustrated in figure 1. If drying is increased to improve trash removal, yarn quality is reduced. Although yarn appearance improves with drying up to a point, because of increased foreign-matter removal, the effect of increased short-fibre content outweighs the benefits of foreign-matter removal.

Figure 1. Moisture-ginning cleaning compromise for cotton

Cleaning does little to change the true colour of the fibre, but combing the fibres and removing trash changes the perceived colour. Lint cleaning can sometimes blend fibre so that fewer bales are classified as spotted or light spotted. Ginning does not affect fineness and maturity. Each mechanical or pneumatic device used during cleaning and ginning increases the nep content, but lint cleaners have the most pronounced influence. The number of seedcoat fragments in ginned lint is affected by the seed condition and ginning action. Lint cleaners decrease the size but not the number of fragments. Yarn strength, yarn appearance and spinning-end breakage are three important spinning quality elements. All are affected by length uniformity and, therefore, by the proportion of short or broken fibres. These three elements are usually preserved best when cotton is ginned with minimum drying and cleaning machinery.

Recommendations for the sequence and amount of gin machinery to dry and clean spindle-harvested cotton were designed to achieve satisfactory bale value and to preserve the inherent quality of cotton. They have generally been followed and thus confirmed in the US cotton industry for several decades. The recommendations consider marketing-system premiums and discounts as well as the cleaning efficiency and fibre damage resulting from various gin machines. Some variation from these recommendations is necessary for special harvesting conditions.

When gin machinery is used in the recommended sequence, 75 to 85% of the foreign matter is usually removed from cotton. Unfortunately, this machinery also removes small quantities of good-quality cotton in the process of removing foreign matter, so the quantity of marketable cotton is reduced during cleaning. Cleaning cotton is therefore a compromise between foreign matter level and fibre loss and damage.

Safety and Health Concerns

The cotton ginning industry, like other processing industries, has many hazards. Information from workers’ compensation claims indicates that the number of injuries is highest for the hand/fingers, followed by back/spine, eye, foot/toes, arm/shoulder, leg, trunk and head injuries. While the industry has been active in hazard reduction and safety education, gin safety remains a major concern. The reasons for the concern include the high frequency of accidents and workers’ compensation claims, the large number of lost work days and the severity of the accidents. Total economic costs for gin injuries and health disorders include direct costs (medical and other compensation) and indirect costs (time lost from work, downtime, loss in earning power, higher insurance costs for workers’ compensation, loss of productivity and many other loss factors). Direct costs are easier to determine and much less expensive than indirect costs.

Many international safety and health regulations affecting cotton ginning are derived from US legislation administered by the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), which promulgates pesticides regulations.

Other agricultural regulations may also apply to a gin, including requirements for slow-moving vehicle emblems on trailers/tractors operating on public roadways, provisions for rollover protective structures on tractors operated by employees and provisions for proper living facilities for temporary labour. While gins are considered agricultural enterprises and are not specifically covered by many regulations, ginners will likely want to conform to other regulations, such as OSHA’s “Standards for General Industry, Part 1910”. There are three specific OSHA standards that ginners should consider: those for fire and other emergency plans (29 CFR 1910.38a), exits (29 CFR 1910.35-40) and occupational noise exposure (29 CFR 1910.95). Major exit requirements are given in 29 CFR 1910.36 and 29 CFR 1910.37. In other countries, where agricultural workers are included in mandatory coverage, such compliance will be compulsory. Compliance with noise and other safety and health standards is discussed elsewhere in this Encyclopaedia.

Employee participation in safety programmes

The most effective loss control programmes are those in which management motivates employees to be safety conscious. This motivation can be accomplished by establishing a safety policy that gets the employees involved in each element of the programme, by participating in safety training, by setting a good example and by providing employees with appropriate incentives.

Occupational health disorders are lessened by requiring that PPE be used in designated areas and that employees observe acceptable work practices. Hearing (plugs or muffs) and respiratory (dust mask) PPE should be used whenever working in areas having high noise or dust levels. Some people are more susceptible to noise and respiratory problems than others, and even with PPE should be reassigned to work areas with lower noise or dust levels. Health hazards associated with heavy lifting and excessive heat can be handled by training, use of materials-handling equipment, proper dress, ventilation and breaks from the heat.

All persons throughout the gin operation must be involved in gin safety. A safe work atmosphere can be established when everyone is motivated to participate fully in the loss control programme.