The Electromagnetic Spectrum: Basic Physical Characteristics

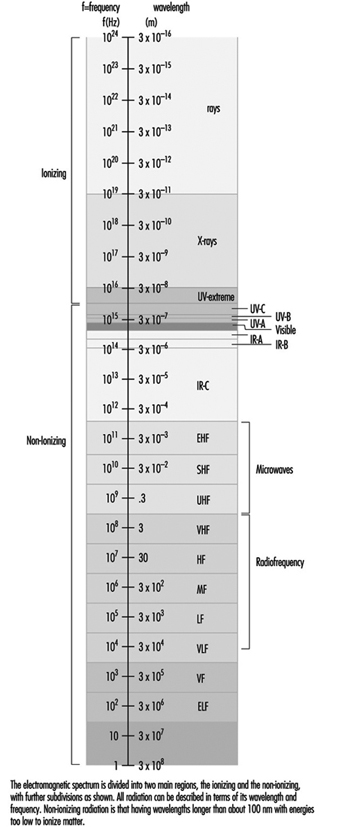

The most familiar form of electromagnetic energy is sunlight. The frequency of sunlight (visible light) is the dividing line between the more potent, ionizing radiation (x rays, cosmic rays) at higher frequencies and the more benign, non-ionizing radiation at lower frequencies. There is a spectrum of non-ionizing radiation. Within the context of this chapter, at the high end just below visible light is infrared radiation. Below that is the broad range of radio frequencies, which includes (in descending order) microwaves, cellular radio, television, FM radio and AM radio, short waves used in dielectric and induction heaters and, at the low end, fields with power frequency. The electromagnetic spectrum is illustrated in figure 1.

Figure 1. The electromagnetic spectrum

Just as visible light or sound permeates our environment, the space where we live and work, so do the energies of electromagnetic fields. Also, just as most of the sound energy we are exposed to is created by human activity, so too are the electromagnetic energies: from the weak levels emitted from our everyday electrical appliances—those that make our radio and TV sets work—to the high levels that medical practitioners apply for beneficial purposes—for example, diathermy (heat treatments). In general, the strength of such energies decreases rapidly with distance from the source. Natural levels of these fields in the environment are low.

Non-ionizing radiation (NIR) incorporates all radiation and fields of the electromagnetic spectrum that do not have enough energy to produce ionization of matter. That is, NIR is incapable of imparting enough energy to a molecule or atom to disrupt its structure by removing one or more electrons. The borderline between NIR and ionizing radiation is usually set at a wavelength of approximately 100 nanometres.

As with any form of energy, NIR energy has the potential to interact with biological systems, and the outcome may be of no significance, may be harmful in different degrees, or may be beneficial. With radiofrequency (RF) and microwave radiation, the main interaction mechanism is heating, but in the low-frequency part of the spectrum, fields of high intensity may induce currents in the body and thereby be hazardous. The interaction mechanisms for low-level field strengths are, however, unknown.

Quantities and Units

Fields at frequencies below about 300 MHz are quantified in terms of electric field strength (E) and magnetic field strength (H). E is expressed in volts per metre (V/m) and H in amperes per metre (A/m). Both are vector fields—that is, they are characterized by magnitude and direction at each point. For the low-frequency range the magnetic field is often expressed in terms of the flux density, B, with the SI unit tesla (T). When the fields in our daily environment are discussed, the subunit microtesla (μT) is usually the preferred unit. In some literature the flux density is expressed in gauss (G), and the conversion between these units is (for fields in air):

1 T = 104 G or 0.1 μT = 1 mG and 1 A/m = 1.26 μT.

Reviews of concepts, quantities, units and terminology for non-ionizing radiation protection, including radiofrequency radiation, are available (NCRP 1981; Polk and Postow 1986; WHO 1993).

The term radiation simply means energy transmitted by waves. Electromagnetic waves are waves of electric and magnetic forces, where a wave motion is defined as propagation of disturbances in a physical system. A change in the electric field is accompanied by a change in the magnetic field, and vice versa. These phenomena were described in 1865 by J.C. Maxwell in four equations which have come to be known as Maxwell’s Equations.

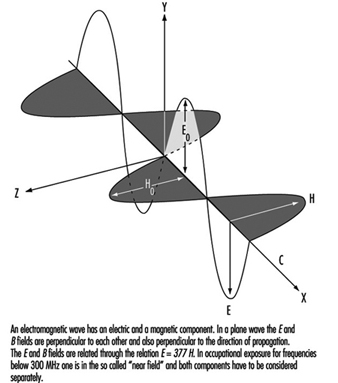

Electromagnetic waves are characterized by a set of parameters that include frequency (f), wavelength (λ), electric field strength, magnetic field strength, electric polarization (P) (the direction of the E field), velocity of propagation (c) and Poynting vector (S). Figure 2 illustrates the propagation of an electromagnetic wave in free space. The frequency is defined as the number of complete changes of the electric or magnetic field at a given point per second, and is expressed in hertz (Hz). The wavelength is the distance between two consecutive crests or troughs of the wave (maxima or minima). The frequency, wavelength and wave velocity (v) are interrelated as follows:

v = f λ

Figure 2. A plane wave propagating with the speed of light in the x-direction

The velocity of an electromagnetic wave in free space is equal to the velocity of light, but the velocity in materials depends on the electrical properties of the material—that is, on its permittivity (ε) and permeability (μ). The permittivity concerns the material interactions with the electric field, and the permeability expresses the interactions with the magnetic field. Biological substances have permittivities that differ vastly from that of free space, being dependant on wavelength (especially in the RF range) and tissue type. The permeability of biological substances, however, is equal to that of free space.

In a plane wave, as illustrated in figure 2 , the electric field is perpendicular to the magnetic field and the direction of propagation is perpendicular to both the electric and the magnetic fields.

For a plane wave, the ratio of the value of the electric field strength to the value of the magnetic field strength, which is constant, is known as the characteristic impedance (Z):

Z = E/H

In free space, Z= 120π ≈ 377Ω but otherwise Z depends on the permittivity and permeability of the material the wave is travelling through.

Energy transfer is described by the Poynting vector, which represents the magnitude and direction of the electromagnetic flux density:

S = E x H

For a propagating wave, the integral of S over any surface represents the instantaneous power transmitted through this surface (power density). The magnitude of the Poynting vector is expressed in watts per square metre (W/m2) (in some literature the unit mW/cm2 is used—the conversion to SI units is 1 mW/cm2 = 10 W/m2) and for plane waves is related to the values of the electric and magnetic field strengths:

S = E2 / 120π = E2 / 377

and

S =120π H2 = 377 H2

Not all exposure conditions encountered in practice can be represented by plane waves. At distances close to sources of radio-frequency radiation the relationships characteristic of plane waves are not satisfied. The electromagnetic field radiated by an antenna can be divided into two regions: the near-field zone and the far-field zone. The boundary between these zones is usually put at:

r = 2a2 / λ

where a is the greatest dimension of the antenna.

In the near-field zone, exposure has to be characterized by both the electric and the magnetic fields. In the far-field one of these suffices, as they are interrelated by the above equations involving E and H. In practice, the near-field situation is often realized at frequencies below 300 Mhz.

Exposure to RF fields is further complicated by interactions of electromagnetic waves with objects. In general, when electromagnetic waves encounter an object some of the incident energy is reflected, some is absorbed and some is transmitted. The proportions of energy transmitted, absorbed or reflected by the object depend on the frequency and polarization of the field and the electrical properties and shape of the object. A superimposition of the incident and reflected waves results in standing waves and spatially non-uniform field distribution. Since waves are totally reflected from metallic objects, standing waves form close to such objects.

Since the interaction of RF fields with biological systems depends on many different field characteristics and the fields encountered in practice are complex, the following factors should be considered in describing exposures to RF fields:

- whether exposure occurs in the near- or far-field zone

- if near-field, then values for both E and H are needed; if far-field, then either E or H

- spatial variation of the magnitude of the field(s)

- field polarization, that is, the direction of the electric field with respect to the direction of wave propagation.

For exposure to low-frequency magnetic fields it is still not clear whether the field strength or flux density is the only important consideration. It may turn out that other factors are also important, such as the exposure time or the rapidity of the field changes.

The term electromagnetic field (EMF), as it is used in the news media and popular press, usually refers to electric and magnetic fields at the low-frequency end of the spectrum, but it can also be used in a much broader sense to include the whole spectrum of electromagnetic radiation. Note that in the low-frequency range the E and B fields are not coupled or interrelated in the same way that they are at higher frequencies, and it is therefore more accurate to refer to them as “electric and magnetic fields” rather than EMFs.

Electric and Magnetic Fields and Health Outcomes

In recent years interest has increased in the biological effects and possible health outcomes of weak electric and magnetic fields. Studies have been presented on magnetic fields and cancer, on reproduction and on neurobehavioural reactions. In what follows, a summary is given of what we know, what still needs to be investigated and, particularly, what policy is appropriate—whether it should involve no restrictions of exposure at all, “prudent avoidance” or expensive interventions.

What we Know

Cancer

Epidemiological studies on childhood leukaemia and residential exposure from power lines seem to indicate a slight risk increase, and excess leukaemia and brain tumour risks have been reported in “electrical” occupations. Recent studies with improved techniques for exposure assessment have generally strengthened the evidence of an association. There is, however, still a lack of clarity as to exposure characteristics—for example, magnetic field frequency and exposure intermittence; and not much is known about possible confounding or effect-modifying factors. Furthermore, most of the occupational studies have indicated one special form of leukaemia, acute myeloid leukaemia, while others have found higher incidences for another form, chronic lymphatic leukaemia. The few animal cancer studies reported have not given much help with risk assessment, and in spite of a large number of experimental cell studies, no plausible and understandable mechanism has been presented by which a carcinogenic effect could be explained.

Reproduction, with special reference to pregnancy outcomes

In epidemiological studies, adverse pregnancy outcomes and childhood cancer have been reported after maternal as well as paternal exposure to magnetic fields, the paternal exposure indicating a genotoxic effect. Efforts to replicate positive results by other research teams have not been successful. Epidemiological studies on visual display unit (VDU) operators, who are exposed to the electric and magnetic fields emitted by their screens, have been mainly negative, and animal teratogenic studies with VDU-like fields have been too contradictory to support trustworthy conclusions.

Neurobehavioural reactions

Provocation studies on young volunteers seem to indicate such physiological changes as slowing of heart rate and electroencephalogram (EEG) changes after exposure to relatively weak electric and magnetic fields. The recent phenomenon of hypersensitivity to electricity seems to be multifactorial in origin, and it is not clear whether the fields are involved or not. A great variety of symptoms and discomforts has been reported, mainly of the skin and the nervous system. Most of the patients have diffuse skin complaints in the face, such as flush, rosiness, ruddiness, heat, warmth, pricking sensations, ache and tightness. Symptoms associated with the nervous system are also described, such as headache, dizziness, fatigue and faintness, tingling and pricking sensations in the extremities, shortness of breath, heart palpitations, profuse sweatings, depressions and memory difficulties. No characteristic organic neurological disease symptoms have been presented.

Exposure

Exposure to fields occurs throughout society: in the home, at work, in schools and by the operation of electrically powered means of transport. Wherever there are electric wires, electric motors and electronic equipment, electric and magnetic fields are created. Average workday field strengths of 0.2 to 0.4 μT (microtesla) appear to be the level above which there could be an increased risk, and similar levels have been calculated for annual averages for subjects living under or near power lines.

Many people are similarly exposed above these levels, though for shorter periods, in their homes (via electric radiators, shavers, hair-dryers and other household appliances, or stray currents due to imbalances in the electrical grounding system in a building), at work (in certain industries and offices involving proximity to electric and electronic equipment) or while travelling in trains and other electrically driven conveyances. The importance of such intermittent exposure is not known. There are other uncertainties as to exposure (involving questions relating to the importance of field frequency, to other modifying or confounding factors, or to knowledge of the total exposure day and night) and effect (given the consistency in findings as to type of cancer), and in the epidemiological studies, which make it necessary to evaluate all risk assessments with great caution.

Risk assessments

In Scandinavian residential studies, results indicate a doubled leukaemia risk above 0.2 μT, the exposure levels corresponding to those typically encountered within 50 to 100 metres of an overhead power line. The number of childhood leukaemia cases under power lines are few, however, and the risk is therefore low compared to other environmental hazards in society. It has been calculated that each year in Sweden there are two cases of childhood leukaemia under or near power lines. One of these cases may be attributable to the magnetic field risk, if any.

Occupational exposures to magnetic fields are generally higher than residential exposures, and calculations of leukaemia and brain tumour risks for exposed workers give higher values than for children living close to power lines. From calculations based on the attributable risk discovered in a Swedish study, approximately 20 cases of leukaemia and 20 cases of brain tumours could be attributed to magnetic fields each year. These figures are to be compared with the total number of 40,000 annual cancer cases in Sweden, of which 800 have been calculated to have an occupational origin.

What Still Needs to be Investigated

It is quite clear that more research is needed in order to secure a satisfactory understanding of the epidemiological study results obtained so far. There are additional epidemiological studies in progress in different countries around the world, but the question is whether these will add more to the knowledge we already have. As a matter of fact it is not known which characteristics of the fields are causal to the effects, if any. Thus, we definitely need more studies on possible mechanisms to explain the findings we have assembled.

There are in the literature, however, a vast number of in vitro studies devoted to the search for possible mechanisms. Several cancer promotion models have been presented, based on changes in the cell surface and in the cell membrane transport of calcium ions, disruption of cell communication, modulation of cell growth, activation of specific gene sequences by modulated ribonucleic acid (RNA) transcription, depression of pineal melatonin production, modulation of ornithine decarboxylase activity and possible disruption of hormonal and immune-system anti-tumour control mechanisms. Each of these mechanisms has features applicable to explaining reported magnetic field cancer effects; however, none has been free of problems and essential objections.

Melatonin and magnetite

There are two possible mechanisms that may be relevant to cancer promotion and thus deserve special attention. One of these has to do with the reduction of nocturnal melatonin levels induced by magnetic fields and the other is related to the discovery of magnetite crystals in human tissues.

It is known from animal studies that melatonin, via an effect on circulating sex hormone levels, has an indirect oncostatic effect. It has also been indicated in animal studies that magnetic fields suppress pineal melatonin production, a finding that suggests a theoretical mechanism for the reported increase in (for example) breast cancer that may be due to exposure to such fields. Recently, an alternative explanation for the increased cancer risk has been proposed. Melatonin has been found to be a most potent hydroxyl radical scavenger, and consequently the damage to DNA that might be done by free radicals is markedly inhibited by melatonin. If melatonin levels are suppressed, for example by magnetic fields, the DNA is left more vulnerable to oxidative attack. This theory explains how the depression of melatonin by magnetic fields could result in a higher incidence of cancer in any tissue.

But do human melatonin blood levels diminish when individuals are exposed to weak magnetic fields? There exist some indications that this may be so, but further research is needed. For some years it has been known that the ability of birds to orient themselves during seasonal migrations is mediated via magnetite crystals in cells that respond to the earth’s magnetic field. Now, as mentioned above, magnetite crystals have also been demonstrated to exist in human cells in a concentration high enough theoretically to respond to weak magnetic fields. Thus the role of magnetite crystals should be considered in any discussions on the possible mechanisms that may be proposed as to the potentially harmful effects of electric and magnetic fields.

The need for knowledge on mechanisms

To summarize, there is a clear need for more studies on such possible mechanisms. Epidemiologists need information as to which characteristics of the electric and magnetic fields they should focus upon in their exposure assessments. In most epidemiological studies, mean or median field strengths (with frequencies of 50 to 60 Hz) have been used; in others, cumulative measures of exposure were studied. In a recent study, fields of higher frequencies were found to be related to risk. In some animal studies, finally, field transients have been found to be important. For epidemiologists the problem is not on the effect side; registers on diseases exist in many countries today. The problem is that epidemiologists do not know the relevant exposure characteristics to consider in their studies.

What Policy is Appropriate

Systems of protection

Generally, there are different systems of protection to be considered with respect to regulations, guidelines and policies. Most often the health-based system is selected, in which a specific adverse health effect can be identified at a certain exposure level, irrespective of exposure type, chemical or physical. A second system could be characterized as an optimization of a known and accepted hazard, which has no threshold below which the risk is absent. An example of an exposure falling within this kind of system is ionizing radiation. A third system covers hazards or risks where causal relationships between exposure and outcome have not been shown with reasonable certainty, but for which there are general concerns about possible risks. This lattermost system of protection has been denoted the principle of caution, or more recently prudent avoidance, which can be summarized as the future low-cost avoidance of unnecessary exposure in the absence of scientific certainty. Exposure to electric and magnetic fields has been discussed in this way, and systematic strategies have been presented, for instance, on how future power lines should be routed, workplaces arranged and household appliances designed in order to minimize exposure.

It is apparent that the system of optimization is not applicable in connection with restrictions of electric and magnetic fields, simply because they are not known and accepted as risks. The other two systems, however, are both presently under consideration.

Regulations and guidelines for restriction of exposure under the health-based system

In international guidelines limits for restrictions of field exposure are several orders of magnitude above what can be measured from overhead power lines and found in electrical occupations. The International Radiation Protection Association (IRPA) issued Guidelines on limits of exposure to 50/60 Hz electric and magnetic fields in 1990, which has been adopted as a basis for many national standards. Since important new studies were published thereafter, an addendum was issued in 1993 by the International Commission on Non-Ionizing Radiation Protection (ICNIRP). Furthermore, in 1993 risk assessments in agreement with that of IRPA were also made in the United Kingdom.

These documents emphasize that the state of scientific knowledge today does not warrant limiting exposure levels for the public and the workforce down to the μT level, and that further data are required to confirm whether or not health hazards are present. The IRPA and ICNIRP guidelines are based on the effects of field-induced currents in the body, corresponding to those normally found in the body (up to about 10 mA/m2). Occupational exposure to magnetic fields of 50/60 Hz is recommended to be limited to 0.5 mT for all-day exposure and 5 mT for short exposures of up to two hours. It is recommended that exposure to electric fields be limited to 10 and 30 kV/m. The 24-hour limit for the public is set at 5 kV/m and 0.1 mT.

These discussions on the regulation of exposure are based entirely on cancer reports. In studies of other possible health effects related to electric and magnetic fields (for example, reproductive and neurobehavioural disorders), results are generally considered insufficiently clear and consistent to constitute a scientific basis for restricting exposure.

The principle of caution or prudent avoidance

There is no real difference between the two concepts; prudent avoidance has been used more specifically, though, in discussions of electric and magnetic fields. As said above, prudent avoidance can be summarized as the future, low-cost avoidance of unnecessary exposure as long as there is scientific uncertainty about the health effects. It has been adopted in Sweden, but not in other countries.

In Sweden, five government authorities (the Swedish Radiation Protection Institute; the National Electricity Safety Board; the National Board of Health and Welfare; the National Board of Occupational Safety and Health; and the National Board of Housing, Building and Planning) jointly have stated that “the total knowledge now accumulating justifies taking steps to reduce field power”. Provided the cost is reasonable, the policy is to protect people from high magnetic exposures of long duration. During the installation of new equipment or new power lines that may cause high magnetic field exposures, solutions giving lower exposures should be chosen provided these solutions do not imply large inconveniences or costs. Generally, as stated by the Radiation Protection Institute, steps can be taken to reduce the magnetic field in cases where the exposure levels exceed the normally occurring levels by more than a factor of ten, provided such reductions can be done at a reasonable cost. In situations where the exposure levels from existing installations do not exceed the normally occurring levels by a factor of ten, costly rebuilding should be avoided. Needless to say, the present avoidance concept has been criticized by many experts in different countries, such as by experts in the electricity supply industry.

Conclusions

In the present paper a summary has been given of what we know on the possible health effects of electric and magnetic fields, and what still needs to be investigated. No answer has been given to the question of which policy should be adopted, but optional systems of protection have been presented. In this connection, it seems clear that the scientific database at hand is insufficient to develop limits of exposure at the μT level, which means in turn that there are no reasons for expensive interventions at these exposure levels. Whether some form of strategy of caution (e.g., prudent avoidance) should be adopted or not is a matter for decisions by public and occupational health authorities of individual countries. If such a strategy is not adopted it usually means that no restrictions of exposure are imposed because the health-based threshold limits are well above everyday public and occupational exposure. So, if opinions differ today as to regulations, guidelines and policies, there is a general consensus among standard setters that more research is needed to get a solid basis for future actions.

Case Study: Outdoor Markets

The informal sector accounts for between 20 and 70% of the urban workforce in developing countries (with the average being 40%); and the traders and hawkers of outdoor markets comprise a significant portion of this sector. Such work is by its very nature precarious. It involves long hours and low pay. Average earnings may not total 40% of levels found in the formal sector. Not only do many workers in outdoor markets lack permanent locations to conduct their business, they also may be compelled to do without supporting infrastructural facilities. They do not enjoy the same legal protection or social insurance as workers in the formal sector and are subject to harassment. Occupationally related morbidity and mortality rates generally go unrecorded (Bequele 1985).

Figure 1. Outdoor food market in Malatia, Solomon Islands, 1995

C. Geefhuyson

Workers in outdoor markets in both developing and developed countries, such as those shown in figure 1 and figure 2 , are exposed to numerous health and safety hazards. They are exposed to exhaust from motor vehicles, which contains such things as carbon monoxide and polycyclic aromatic hydrocarbons. Workers are also exposed to the weather. In tropical and desert locations they are subject to heat stress and dehydration. In cooler climates they are exposed to freezing temperatures, which can cause problems such as numbness, shivering and frostbite. Workers in outdoor markets may not have access to adequate hygiene facilities.

Figure 2. Heavy baskets of sea urchins being distributed by a small operator-owner, Japan, 1989

L. Manderson

The informal sector generally and outdoor markets specifically involve child labour. Roughly 250 million children are engaged in full- and part-time work around the world (ILO 1996); street traders are the most visible child workers. Children who work, including street traders, typically are denied education and often are forced to perform tasks, such as lifting heavy loads, which can result in permanent disabilities.

The Retail Industry

The retail trade is the selling of goods to consumers. Enterprises sell everything from automobiles to clothing, from food to television sets. In many countries what once was an industry comprised mainly of small shops and stores, now largely consists of multinational conglomerates which own huge megastores competing for the global market. Competition and technological changes have changed job descriptions, the hazards associated with those jobs and the nature of the workforce itself.

In the developed nations, small retailers struggle to compete with large corporate retailers. In the United States, Canada and throughout the European Community and the Pacific Rim, the retail trade has moved from the city centre to suburban shopping malls. Instead of the neighbourhood “mom and pop” stores, multinational chain stores sell the same products and the same brand names, effectively limiting consumer choice of product and forcing competition out of the market by their buying power, advertising capabilities and lower prices. Many times a large store will take a loss on certain products in order to bring customers into a store; this technique frequently generates other sales.

In developing countries with predominantly agrarian economies, bartering systems and open marketplaces are still common. However, in many developing countries, the large multinational retailers are beginning to enter the retail market.

Each type of establishment has its own hazards. Retail work in developing countries and countries in transition is often very different from retail work in developed countries; conglomerates with large chain stores are not yet dominant and retail work is mainly conducted in an open-air market, in all types of weather.

There is a trend among multinational conglomerates to try and change employment conditions: trade unionism is discouraged, staff is reduced to a bare minimum, wages go down, stores predominantly hire part-time workers, the average age of the workforce is lowered and benefit packages diminish.

Throughout the world store opening hours have changed so that some establishments even remain open 24 hours a day, 7 days per week. In the past, a worker who worked late at night or on a holiday received extra compensation; now, premium pay for working those hours has been taken away as such long hours become the norm. In the US, for example, traditional holidays are now negotiable when the store stays open on a 24-hour, 7-day basis.

The changes in the nature of how business is conducted has forced several fundamental changes in the workforce. Since many jobs have been marginalized to part-time work, the jobs themselves require little skill and workers receive no training. Workers who once saw a career in retail work, now find themselves changing jobs frequently or even leaving the field of retail work, which has become short term and part time.

The size of the workforce in the retail industry is difficult to estimate. The informal sector plays a significant role in developing countries (see “Case Study: Outdoor Markets”). Many times, health and safety problems go unnoticed, are not recorded by government and are considered to be part of the job.

In many of the countries that do keep statistics, retail, wholesale and restaurant and hotel workers are grouped into one category. Statistics from around the world show that the percentage of people who work in the wholesale, retail, restaurant and hotel trades ranges from over 20% in some countries in Asia to less than 3% in Burkina Faso (see table 1 ). Although men outnumber women in the labour force, the percentage of women in the retail industry is higher in at least half of the countries for which statistics are available.

Table 1. Labour statistics in the retail industry (selected countries)

|

Country |

Men in the labour force (%) |

Men in |

Women in the labour force (%) |

Women in |

Total population in |

Total number |

Injured people |

|

Burkina Faso |

51.3 |

1.0 |

48.7 |

1.5 |

2.6 |

1,858 |

8.71 |

|

Costa Rica |

69.9 |

11.0 |

30.1 |

7.4 |

18.4 |

156,782 |

7.02 |

|

Egypt |

75.9 |

7.3 |

24.1 |

1.2 |

8.4 |

60,859 |

2.52 |

|

Germany |

52.3 |

4.5 |

47.7 |

7.0 |

11.5 |

29,847 |

20.13 |

|

Greece |

63.0 |

10.9 |

37.0 |

7.0 |

17.0 |

23,959 |

10.54 |

|

Italy |

63.1 |

11.7 |

36.9 |

6.9 |

8.6 |

767,070 |

8.15 |

|

Japan |

59.5 |

11.0 |

40.5 |

10.9 |

21.9 |

2,245 |

9.7 |

|

Mexico |

69.1 |

10.8 |

30.9 |

9.6 |

20.5 |

456,843 |

16.96 |

|

Netherlands |

58.9 |

9.1 |

41.1 |

8.0 |

17.1 |

64,657 |

16.5 |

|

Norway |

54.5 |

7.9 |

45.5 |

8.9 |

16.7 |

26,473 |

5.0 |

|

Singapore |

59.8 |

13.2 |

40.2 |

9.0 |

22.0 |

4,019 |

0.27 |

|

Sweden |

52.0 |

6.8 |

48.0 |

6.5 |

13.3 |

43,459 |

6.6 |

|

Thailand |

55.5 |

5.8 |

49.5 |

6.8 |

12.6 |

103,296 |

3.18 |

|

United Kingdom |

56.2 |

8.3 |

43.8 |

9.5 |

17.8 |

157,947 |

11.09 |

|

United States |

54 |

11.1 |

46.0 |

10.0 |

21 |

295,340 |

23.610 |

1 Including commuting accidents; including occupational diseases.

2 Including commuting accidents; establishments employing 100 or more workers.

3 The series related to the territory of the Federal Republic of Germany before 1990;

including commuting accidents.

4 Including occupational diseases;.including non-fatal cases without lost workdays.

5 Including commuting accidents; persons losing more than three workdays

per period of disability.

6 Including non-fatal cases without lost workdays.

7 Including commuting accidents; including occupational diseases;

including non-fatal cases without lost workdays.

8 Including commuting accidents.

9 Employees only; excluding traffic accidents; year beginning April, 1993.

10 Including occupational diseases.

Sources: Country reports: Costa Rica 1994; Greece 1992, 1994; Mexico 1992, 1996; Singapore 1994, 1995; Thailand 1994, 1995; Euro-FIET Commerce Trade Section 1996; ILO 1994, 1995; Price Waterhouse 1991.

Operations, Hazards and Prevention

Cashiers

Many cashiers work at mechanized registers that require them to punch a keypad thousands of times per day to ring up the price of the article. The key punching is usually done with the right hand while products are moved from in front of the cashier to the rear of the cashier for packaging with the left hand. These work activities frequently involve poorly designed workstations, causing cashiers to lift heavy products, reach extensively for products and frequently twist the body in order to move products from one area to another. This job function places different burdens on each side of the body, causing lower-back pain, upper-extremity illnesses and repetitive-motion illnesses including tendinitis, carpal tunnel syndrome, tenosynovitis, thoracic outlet syndrome and hip, leg and foot problems.

Well-designed workstations, with automatic scanners, flexible work height conveyors, lowered bagging stations, extra personnel to bag the products and flexible seats (so that cashiers can sit to relieve lower-back and leg pressures) help eliminate upper- extremity pressures, strains and twisting motions.

Lasers

Bar-code readers and hand-held scanners in supermarkets are generally Class 2 lasers, which produce infrared radiation in the wavelength range of 760 to 1,400 nm; they are considered nonhazardous unless there is prolonged viewing of the laser beam. A laser produces a high-intensity light which can damage the retina of the eye. The eyes are vulnerable to heat, have no heat sensors and do not dissipate heat efficiently. Recommended safe practices should include, at a minimum, training workers about the hazards of looking into the beam of light and the damage to the eye that can result. Baseline eye examinations should be included in a worker protection programme to ensure that no damage has occurred.

Clerks

Retail clerks move large quantities of product from trucks to the loading dock and then to the shelves in the sales area of the store. Products come packaged in cartons of various weights. Manually unloading trucks and moving the product cartons to the front of the store may cause musculoskeletal problems. Pricing the items and placing them on the shelves puts tremendous pressure on the back, legs and neck. Using a pricing gun can cause carpal tunnel syndrome and other RSIs by putting excessive and repeated strain on the wrist, fingers and palm of the hand. Opening cartons with a knife or blade can lead to cuts on the hands, arms and other parts of the body. Cutting through cardboard with a dull knife requires extra pressure, which puts extra strain on the palms of the hands.

Mechanical lifting aids, such as fork-lift trucks, manual high-low trucks, dollies and carts help move items from one part of the store to another. Tables, scissor jacks and movable carts can help bring the items to a good height and help clerks place product on the shelves without back strain from lifting and twisting. Automated pricing guns or packaged goods already labelled will prevent wrist and upper extremity strains from repeated motions. Sharp knives will prevent forceful motions when opening cartons.

Meat cutters and delicatessen workers

Meat cutters and delicatessen workers work with saws, grinders, slicers and knives (see figure 1). When machine blades are not guarded, get jammed or become loose, fingers can be severed, cut, crushed or bruised. Machines must be securely anchored to the floor to prevent tipping and moving. Blades must be kept free of debris. If a machine is jammed, wooden devices should be used to unjam the machine with the power off. No machines should be unjammed with the power still on. Knives should be kept sharp to avoid problems in the wrists, hands and arms. The handles of knives, cleavers and clubs should be kept clean and unslippery.

Figure 1. Small-scale manual cutting of dried meet for local sale, Japan, 1989

L. Manderson

When meat is mechanically weighed and packaged on a styrofoam tray in a plastic film sealed with a heating element, vapours and gases from the heated plastic may cause “meat wrapper’s asthma” and eye, nose and throat irritation, difficulty in breathing, chest pains, chills and fever. Local exhaust ventilation (LEV) should be placed near the heating element so that these vapours are not breathed in by workers, but are vented outside the workplace.

Meat cutters enter and leave freezers many times during the day. Work clothing should include heavy clothing for freezer work.

Floors and walkways can become slippery from meat, grease and water. Slips, trips and falls are common causes of injury. All waste material must be carefully discarded and kept off walking surfaces. Walking and standing mats must be cleaned daily or whenever they become soiled.

Chemical exposures

Retail workers are increasingly exposed to hazardous chemicals in cleaning products, pesticides, rodenticides, fungicides and preservatives. Hardware store workers, automotive distributive workers and others are potentially exposed to hazardous chemicals because of the stock of paints, solvents, acids, caustics and compressed gases. The hazardous or toxic chemicals vary depending on the nature of the products that are stocked in each establishment. These can include materials not necessarily considered hazardous. Department store workers, for example, can develop sensitivities and allergies to perfumes that are sprayed as demonstrations.

Cleaning products that are used to clean surfaces in supermarkets and other retail establishments may contain chlorine, ammonia, alcohols, caustics and organic solvents. These products may be used by cleaning crews during the night shift, in stores without natural ventilation and when the mechanical ventilation system is not working at full capacity. These chemical products affect the body when used in the workplace in industrial strengths and amounts. Chemical safety information must be readily available in the workplace for workers to read. Chemical containers must be labelled with the name of the chemical and how the product affects the body, as well as which protective equipment must be used to prevent illness. Workers need to be trained about the health hazards associated with the use of chemicals, how the chemicals enter the body and how to avoid exposure.

Retail workers who set up shop on the street are exposed to exhaust from motor vehicle traffic, as are the back-of-the-store workers who inhale exhaust from idling delivery trucks in the truck bays. The incomplete combustion products in motor vehicle exhaust include, among other things, carbon monoxide and polycyclic aromatic hydrocarbons. Exhaust gases and particulates affect the body is several ways. Carbon monoxide causes dizziness and nausea and acts as an asphyxiant, limiting the blood’s ability to use oxygen. Delivery trucks should turn off their engines while unloading. Mechanical general exhaust ventilation may be needed to vent the contaminated air away from workers. Routine scheduled maintenance and cleaning is needed to maintain the ventilation system.

Formaldehyde is frequently used on clothing and other textiles to prevent mildew. It can affect those who breathe it in. In stores with larger stocks of clothing and textiles without adequate natural or mechanical ventilation systems, formaldehyde gas can build up and irritate the eyes, nose and throat. Formaldehyde can cause skin and respiratory irritation and allergies and is considered a probable carcinogen.

Pesticides, rodenticides and fungicides are frequently used to keep vermin out of establishments. They can affect the nervous, respiratory and circulatory systems of human beings as well as insects, rodents and plants. It is important not to spray chemicals indiscriminately when people are present and to keep people away from sprayed areas until it is safe to enter them again. The pesticide applicator must be trained in safe work methods before pesticides are applied.

“Tight” buildings—those without windows that can open and without natural ventilation—are dependent on mechanical ventilation systems. These systems must provide an adequate exchange of air within the space and must include adequate fresh outdoor air. The air must be heated or cooled depending on the ambient temperature outside.

Sanitation

Personal hygiene is important in the retail industry, especially when employees handle food, money and hazardous chemicals. Toilets and washing and drinking facilities must be sanitary and available in areas where employees can use them while on duty. Facilities must have clean running water, soap and towels. Employees must be encouraged to wash their hands thoroughly after using the toilet and before returning to work. Clean, cool drinking water should be available throughout the work area. Good housekeeping is necessary to prevent vermin and accumulation of garbage. Trash should be picked up on a regular basis.

Sanitation facilities are difficult to maintain in open-air markets, but an attempt must be made to provide toilets and washing facilities.

Weather

In open-air markets, retail workers are exposed to the elements and subject to the problems relating to heat and cold. In supermarkets, cashiers often work at the front of the store close to the doors that the public uses to enter and exit, exposing cashiers to hot and cold air drafts. Air shields in front of the doors that go to the outside will help block drafts and keep the air temperature at the cash register consistent with the rest of the store.

Fire prevention

There are many fire hazards in retail stores, including locked or blocked exits, limited entry and exits, combustible and flammable materials and faulty or temporary electrical wiring and heating systems. If workers are required to fight a fire, they must be trained in how to call for help, use fire extinguishers and evacuate the space. Fire extinguishers must be of the appropriate type for the type of fire and must be inspected regularly and maintained. Fire drills are necessary so that workers know how to get out of the facility during an emergency.

Stress

A new trend in retail work, when the establishment is owned by a large conglomerate, is to change full-time work to part-time work. Many large retail stores are now staying open 24 hours per day, and many stay open every day of the year, forcing workers to work “unsocial” hours. Disruption of the internal biological clock which controls natural physical phenomena such as sleep, causes symptoms such as sleepiness, gastro-intestinal disturbances, headaches and depression. Changing shifts, working on holidays and part-time work cause emotional and physical stress on the job and at home. “Normal” family life is severely compromised and meaningful social life is restricted.

Late night hours are more and more prevalent, increasing the feeling of insecurity about personal safety and the fear of robberies and other types of violence on the job. In the United States, for example, homicide is a major cause of death on the job for women, with many of these deaths occurring during robberies. Handling money or working alone or during late night hours should be avoided. A regular review of security measures should be part of a violence prevention and security programme.

Part-time pay, with few or no benefits, increases job stress and forces many workers to find additional jobs in order to support their families and maintain health benefits.

Telework

Telework—or working out of one’s home—is a growing trend in businesses internationally. This article discusses the occupational health and safety hazards of telework (from the Greek tele, meaning “far off”). The employer’s responsibility to provide safe and healthy working conditions to such employees will vary depending on the contract or understanding that exists between each teleworker and employer and on the applicable labour laws.

While telework is most widespread in the United States, where it involves over 8 million workers and accounts for 6.5% of the workforce, other countries also have significant numbers of teleworkers. There are more than 560,000 in the United Kingdom, 150,000 in Germany and 100,000 in Spain. There are over 32,000 in Ireland, which amount to 3.8% of the workforce (ILO 1997).

The growing trend toward telework arrangements can be explained by the following factors:

- business efforts to reduce the time, expense and environmental impact of commuting

- legislative efforts to reduce traffic-induced air pollution trends

- changes in technology, computerization and electronic communication that enable businesses to employ workers in disparate geographic locations

- costs of maintaining large office spaces needed to accommodate large numbers of employees

- accommodation of workers who prefer telework due to physical disability, parenting needs or other family responsibilities or other reasons

- a strategy to reduce absenteeism

- recognition that workers have varying internal cycles of productivity and creativity.

Increased productivity is another factor, as a number of studies have demonstrated that telework can result in large productivity gains (ILO 1990b).

Telework may be contracted in several ways:

- The employee works full time (or part time) at home for their employer and is entitled to all of the same benefits provided by that employer to all onsite workers.

- The employee works full time for the employer but only works out of the home during a specified number of days per week or month.

- The worker is defined as an independent contractor and does not receive benefits or equipment provided by the employer.

Health and Safety Hazards of Telework

The health and safety hazards of telework can include all of the same hazards found in conventional office environments, with several additional concerns.

Indoor air quality

Most homes are not equipped with mechanical ventilation systems. Instead, air exchanges in the home rely on natural ventilation. The effectiveness of this can depend on such factors as the type of insulation of the building and so on. Provision of a fresh supply of outside air cannot be guaranteed. If the natural ventilation is inadequate to remove sources of indoor air pollutants in the home work environment, then additional ventilation may be necessary.

Indoor air pollutants in the home environment may include the following:

- natural gas or carbon monoxide exposure from inefficient heating systems or leaky stoves

- vapours and gases from photocopiers, printers or other office machines

- ongoing passive exposure to chemicals, gases or dusts resulting from renovation or construction in the worker’s home

- exposure to the effluents of other activities if housed in a multi-use building (such as an apartment building with a nail salon, dry cleaner or fast food restaurant on the ground floor).

- exposure to radon hazards if office is located in the basement in parts of the world where radon arises from construction materials or the earth.

Fire hazards

Home electrical wiring is rarely designed to accommodate the needs of the electrical equipment typically used in telework, such as printers, copiers and other office machines. Installing such equipment without assessing the wiring limits of the dwelling could create a fire hazard. Local building codes may prohibit the adjustments necessary to accommodate increased equipment needs.

Teleworkers who rent their apartments may live in multi-unit dwellings with inadequate fire evacuation plans, blocked means of egress to fire exits or locked exit doors.

Ergonomics hazards

Home work environments often rely on the employee’s personal furnishings such as chairs, tables, shelves and other items to perform required tasks. Computer workstations in the home environment may not allow for the adjustments necessary for computer-intensive work. A shortage of adequate surface area, shelf space or storage areas may result in excessive bending, awkward postures, excessive reaching and other risk factors for cumulative trauma disorders (CTDs). Working in cold or unevenly heated environments can also contribute to musculoskeletal injuries.

Lighting

Inadequate lighting may result in awkward body postures, eye strain and visual disturbances. Task lighting may be necessary for work surfaces or document holders. Wall and furniture surfaces should be neutral with a non-glare finish. While this glare-reducing strategy is increasingly utilized in office environments, it is not yet a standard of home decoration and design.

Occupational stress

Full-time employment in the home environment deprives the worker of the interpersonal and professional benefits of continuous interaction with co-workers, colleagues and mentors. The isolation created by telework can prevent the worker from engaging in professional development activities, taking advantage of promotional opportunities and contributing ideas to the organization. Gregarious workers in particular may depend on human contact and suffer personally and professionally without it. The lack of administrative support services for employees who require clerical assistance presents an additional burden to teleworkers. The employer should make an effort to incorporate the teleworker into staff meetings and other group activities, either in person or electronically (tele-conferencing) as per physical and geographical limitations.

Employees with children, disabled family members or ageing parents may perceive distinct advantages of working at home. But attending to the needs of dependent family members can affect the concentration needed to focus on job responsibilities. The ensuing stress can negatively impact on the worker who is unable to perform to capacity in the home and fails to meet employer expectations. Telework should not be considered as a substitute for child or elder care. Since workers vary tremendously in their capacity to balance work and other responsibilities in the home environment, the need for support services must be evaluated on a case-by-case basis to prevent excessive occupational stress and subsequent loss in productivity. No worker should be required to adopt a telework arrangement against his or her will.

Injury and Illness Compensation

Occupational illnesses often occur over long periods of time from cumulative exposures. Prevention of these illnesses depends on rapid identification of risk factors, fixing the problem using a variety of methods and medical management of the affected worker when the first signs or symptoms of illness appear.

To date, employer responsibility for accidents and injuries in the home environment have been debated on a case-by-case basis. Most national occupational health and safety standards do not include formal policies addressing the safety of teleworkers. The serious impact of this trend must be carefully evaluated and addressed via international standard-setting.

When telework arrangements shift the employee’s status to that of an independent contractor, the burden of many responsibilities shift to the employee as well. Once the work is performed in the home by an independent contractor, the employer no longer feels obligated to provide a healthy and safe workplace, access to preventive and curative medical care for the worker and his or her family, social security, disability insurance and compensation for injured workers who need to recuperate. This trend eliminates worker benefits and protections that were won after decades of struggle and negotiation.

Protection for the Teleworker

The contract between the teleworker and the employer must address the overall work environment, safety and health standards, training and equipment. Employers should inspect the home workspace (at agreed-upon times) to ensure worker safety and to identify and correct risk factors that could contribute to illness or injury. The inspection should evaluate indoor air, ergonomics, trip hazards, lighting, chemical exposure and other concerns. Clear policy must be established regarding the provision of office supplies required for job tasks. Liability issues must be clearly defined regarding employer (and worker) assets that are lost or damaged due to fire, natural disaster or theft. Employees must be exempt from financial liability unless found to be negligent.

In addition, telework arrangements should be evaluated on a regular basis in order to identify workers who discover that working at home does not work for them.

Summary

The advantages of telework are extensive, and beneficial telework arrangements should be encouraged for job tasks and mature workers who will have much to gain by working at home. Telework has enabled disabled workers to achieve greater independence and seek professional opportunities not previously offered or available. In return, employers are able to retain valuable workers. However, the telework arrangement must ensure continuation of employee benefits and occupational health and safety protections.

Bank Teller Safety: The Situation in Germany

Working in the Bank: Now Safer for the Personnel

What long-term measures can be taken to reduce the attraction of robbing a bank? The new provisions in Germany’s Accident Prevention Regulation (APR) for “Teller’s window” (VBG 120) significantly minimizes the risk to employees of being injured or killed in bank robberies.

A precise knowledge of the conduct of bank robbers is crucial. To this end, the Administration Trade Organization has been studying bank robberies since 1966. These studies have shown that, for example, bank robbers prefer small bank branches with few employees. Approximately one-third of bank robberies occur shortly after opening or just before closing. The goal is to leave the robbed bank as quickly as possible (after 2 or 3 minutes) and with the largest possible haul. Many bank robbers work under the wide-spread misconception that DM 100,000 and more can be taken from a teller’s window. The results of these and other studies are contained in the sections “Building and equipping” and “Operations” in the “Teller’s window” APR. Measures that drastically reduce the bank robbers’ expectations are proposed here to protect the employee. The success of these measures depends upon the employees strictly adhering to them in daily practice.

What basic requirements are set in the “Teller’s window” APR? In paragraph 7 of the “Teller’s window” APR, the central requirement is laid out: “Protecting the insured requires securing the banknotes so as to considerably reduce the incentive for robbery”.

What does that mean in daily practice? Easily accessible money should be kept and worked with in publicly accessible areas only within rooms separated from the public by bullet-proof or break-proof sections.

The maximum amount of accessible money allowed is given in paragraph 32: a combined maximum of DM 50,000 is allowed if there are bullet-proof tellers’ windows, other break-proof safeguards and at least 6 employees present. DM 10,000 may not be exceeded when using break-proof safeguards (but not bullet-proof tellers’ windows) in connection with containers equipped with time-staggered releases. There must be at least 2 employees present at all times, who must be in eye-contact.

To keep the incentive for bank robbery as low as possible, amounts of accessible money should be kept well below the maximums set in the “Teller’s window” APR. In addition, paragraph 25 calls for company instructions to set the maximum allowable accessible amounts for each branch. Larger amounts necessary for business and other needs should be secured in time-lock containers to make access by bank robbers more difficult.

Tellers’ windows that are not equipped with bullet-proof or break-proof safety guards and have no central money supply facility or employee-operated automatic teller machine should not have any accessible banknotes on hand.

Securing Windows and Doors

Personnel entrance and exit doors to teller areas containing cash must be secured against viewing or entering from outside, so that bank robbers cannot easily intercept employees entering and leaving bank rooms. The employee must be able to ensure, with built-in peepholes, that no danger exists.

To prevent unnoticed entrance by bank robbers into bank rooms, door closers must ensure that doors are always kept closed.

Since a considerable incentive for theft arises from viewing banknotes, windows behind which banknotes are handled must be secured against viewing or penetrating. Statistics show that holding strictly to this requirement results in very few bank robberies through windows or personnel entrances.

In contrast to personnel entrance and exit doors, doors for public traffic must have a clear view. Bank robbers can thereby be recognized early and an alarm sounded to bring assistance. Therefore it is important that the view not be obstructed by placards or the like.

Optimal Room Surveillance

In order to be able to identify the bank robber as quickly as possible, and to have effective evidence for court, optimal room surveillance equipment is prescribed in the “Teller’s window” APR. This is also important for determining whether the robber extorted money or threatened employees, since particularly brutal actions increase the penalty. Good pictures reduce the incentive to rob a bank.

The instruction “Installation directions for optimal room surveillance equipment (ORSE) SP 9.7/5” of July 1993 permitted only individual cameras as standard ORSE. Photographs are superior to video shots for identification because of greater detail recognition, resulting in better evidence. The disadvantage lies in the fact that photos are available only after the camera is triggered. Because of technical advances, the Administration technical committee now also permits the use of video cameras as possible ORSE. The corresponding instruction is now being prepared; it provides that the limited resolution of video pictures should be compensated for by using 2 views. For this, at least 2 cameras must be installed for recognizing the robber and for videotaping essential events.

Appropriate installation of the video technology can continuously record, and a “wanted” photo can thus be available without special triggering. The further advantages of the system include colour shots, quicker availability of “wanted” photos, transmission of the pictures to the police even during the robbery and the ability to constantly check the functioning of the camera.

Teller’s Window Security

The “Teller’s window” APR authorizes:

- bullet-proof and break-proof glass enclosures and tellers’ booths

- power-driven separations

- break-proof separations in connection with bullet-proof screens

- central money supply equipment

- employee-operated teller machines.

Furthermore, customer-operated teller machines support the requirements of paragraph 7, since their use can reduce the amount of money in the booth or separated room.

In order to comply with the “Teller’s window” APR, the number of employees needed at the counter and the amounts to be taken in and paid out (quantity and number) must be known before a tellers’ counter is built or remodeled. Optimal security can be achieved only when counter security corresponds to the actual flow of business.

Constant Presence with Eye contact

Certain teller security measures require a minimum of 2 to 6 employees having eye contact with each other. This requirement flows from the recognition that bank robbers prefer smaller branches with higher yields, where the tellers, when threatened with a gun, cannot withdraw behind bullet-proof shielding.

Break-proof teller shielding can be used only when 6 employees with eye contact are always present in the counter area. This does not mean a 6-person location, where not everyone is always at their workplace due to vacation, sickness, customer visits and so on. Experience shows that this condition can be fulfilled only when 8 to 10 employees work at the location. Alternatively, a floater service can possibly be used to ensure the necessary minimum number of employees.

To guarantee the constant presence of 2 employees with eye contact, the location must have 3 to 4 positions.

It is important that the facility not be opened before the required minimum number of employees are present. When consultations are taking place in adjoining rooms, the minimum number of employees at the windows must still be maintained.

Security through Separation

Small branches

“Small branches” are those where the presence of at least 2 employees with eye contact in the counter area is not ensured. For these branches, bullet-proof shielding in connection with break-proof separations offers good protection, since the employee does not have to leave the secured area in the event of a robbery. Consultations are carried on in an area protected by break-proof shielding. Good communication is possible here. The bullet-proof shield, behind which the accessible cash must be kept, should be placed so that employees cannot be threatened with a weapon from the customer area. Money transactions take place by way of a prescribed hatch or sliding drawer. Since the employee must go into the bullet-proof-secured area in the event of an attack, the necessary personal security is provided. This area must not be left under any circumstances, including while handing money over to the robber.

Bullet-proof full separation presents an alternative for 1- to 3-person teller operations. It offers mechanical protection against the typical bank robbery, since all employees are separated from the robber by bullet-proof shielding. The disadvantage here is that communication with customers is reduced in the interest of security. So full bullet-proof separation is appropriate only for small branches.

Larger branches

The teller’s booth is a form of security in which only the teller’s work station is separated from the customer area. This possibility makes sense only for teller jobs in which the teller is fully occupied by his or her work in the booth and does not have to leave it.

Before installing a booth, it is necessary to determine whether the teller is fully occupied handling money. In smaller branches with only 2 to 4 employees, this is often not the case. If the teller has other tasks outside the booth, the security requirements of the APR are not met, since the teller is supposed to always be separated from the customers for protection against bodily attack. In practice what repeatedly happens is that while the teller is performing tasks outside the booth, the door is held open with a wedge or the key is left in the lock. Thus the security of the teller’s booth is compromised, which is of great interest to potential robbers.

The bullet-proof teller’s booth does hinder communication between the teller and customers. But since longer discussions take place in unsecured workplaces anyway, this does not present a big problem. More serious problems include ensuring draft-free ventilation and air-conditioning in small teller’s booths.

For power-driven separations, a movable steel wall, built into the counter, is raised in emergencies by way of several arranged triggers in second intervals. This creates a bullet-proof separation, with the employees behind it in a secure area. To prevent a robber from entering unnoticed, it must be activated whenever there are no employees in the vault area, or when work is being done that requires personnel to turn away from the counters. In order to avoid constant activation of the steel wall, this type of security should be used only in 2- to 4-person teller areas.

Furthermore, the tellers’ workstations can be isolated with bullet-proof separations. For this, full separations for all employees as well as tellers’ booths can be installed. This form of security, however, requires the constant presence of at least 6 employees with constant eye contact in the main hall.

Bullet-proof full separation and tellers’ booths can also be used when a minimum of 2 employees are present with eye contact and the accessible cash does not exceed DM 10,000. A time-release money container is required in this case so that the teller does not constantly have to leave the secured area to restock. Bank robbers avoid teller positions where they can expect only a small amount of cash or have to wait a long time for it. In this case, notice of the time-release container at the entrance and in the tellers’ area is important for the employees’ protection. This makes immediately clear to the potential robber that the employee has no control over the container and that only a small haul can be expected.

Security without Accessible Banknotes in the Main Hall

Security is possible even without building a separation between the employees and the customer area. But for this to reduce the incentive, no accessible quantities of money can be in the tellers’ area. Money taken in must be immediately secured. The money is kept in a cash box in an area not open to the public, so it cannot be threatened by the robber. The employees receive the necessary amounts of money through a tube delivery system in the main hall. Money taken in is sent to the cash box by this means. No minimum number of employees in the main hall is prescribed in this case. This type of security, however, results in longer waiting times for customers. The advantage is that bank robbers have virtually no chance of getting anything in a robbery.

Employee-operated automatic teller machines (ATMs) are a second way to make payments with cash that is not accessible in the main hall. These, referred to by the bank as AKT-designated machines, contain 4 to 6 magazines for holding banknotes in a time-released secured container. For payments, the required amount is called up using a keyboard, with which an alarm can also be sounded in emergencies. The money is delivered to the employee after a time delay. The length of the delay depends upon the amount of money and is set in paragraph 32 of the “Teller’s window” APR. These are set so that good service is possible, but the robber is scared off by the longer waiting times for larger amounts. Cash receipts should be secured by use of time- or double-closing containers.

At least 2 employees with eye contact must be constantly present when using an employee-operated ATM. For this reason, this form of security is appropriate only for locations in which 3 to 4 employees work. Discussions can take place in a conference room only when 2 or more employees are present in the customer area during the discussion.

In the case of a technical problem in an employee-operated ATM, appropriate instructions and measures should be prepared. These should include an emergency cash box and corresponding organizational procedures to ensure that work proceeds in accordance with the “Teller’s window” APR.

Company Directives and Instructions

The employer must prepare company directives for every teller’s window and regularly check on compliance. These directives should outline the possible events during a robbery and describe what to do during and after the robbery. Furthermore, daily instructions should be given, and use of the installed security equipment should be mandated. This is especially true when larger amounts of accessible banknotes are present. Instructions should also prescribe the manner of safekeeping for other valuable objects. Employees at the windows should be instructed in these company policies at least twice a year.

The purpose of these instructions is clear—to ensure that the employees follow the requirements of the “Teller’s window” APR for their own protection, and to significantly reduce the incentive for robbing a teller’s window.

Offices: A Hazard Summary

Office workers may perform a wide variety of tasks, including: answering the telephone; interacting with the public; handling money; receiving and delivering mail; opening mail; typing and transcribing; operating office machinery (e.g., computers, adding machines, duplicating machines and so on); filing; lifting supplies, parcels and so on; and professional work such as writing, editing, accounting, research, interviewing and the like. Table 1 lists standard clerical jobs.

Table 1. Standard clerical jobs

Clerks

Secretaries and keyboard-operating clerks

Stenographers and typists

Word-processor and related operators

Data entry operators

Calculating-machine operators

Secretaries

Numerical clerks

Accounting and bookkeeping clerks

Statistical and finance clerks

Material-recording and transport clerks

Stock clerks

Production clerks

Transport clerks

Library, mail and related clerks

Library and filing clerks

Mail carriers and sorting clerks

Coding, proof-reading and related clerks

Scribes and related clerks

Other office clerks

Cashiers, tellers and related clerks

Cashiers and ticket clerks

Tellers and other counter clerks

Bookmakers and croupiers

Pawnbrokers and money-lenders

Debt-collectors and related workers

Client information clerks

Travel agency and related clerks

Receptionists and information clerks

Telephone and switchboard operators

Source: ILO 1990a.

Office workers are often thought to have pleasant, safe environments to work in. Even though office work is not as hazardous as many other workplaces, there are a variety of safety and health problems that may be present in an office. Some of these can pose significant risks to office workers.

Some Hazards and Health Problems

Slips, trips and falls are a common cause of office injuries. Poor weather conditions such as rain, snow and ice create slip hazards outside of buildings, and inside when wet floors are not cleaned up promptly. Electrical and telephone cords placed in aisles and walkways are a common cause of trips. Carpeted offices can create trip hazards when old, frayed and buckling carpet is not repaired and shoe heels catch on it. Electrical floor outlet boxes can cause trips when they are located in aisles and walkways.

Cuts and bruises are seen in office settings from a variety of causes. Paper cuts are common from file folders, envelopes and paper edges. Workers can be injured from walking into tables, doors or drawers that have been left open and are unseen. Office supplies and materials that are improperly stored can cause injury if they fall onto a worker or are placed where a worker would inadvertently walk into them. Cuts can also be caused by office equipment such as paper cutters and sharp edges of drawers, cabinets and tables.

Electrical hazards occur when electrical cords are placed across aisles and walkways, subjecting the cords to damage. Improper use of extension cords is often seen in offices, for example, when these cords are used in place of fixed (permanently installed) outlets, have too many items plugged into them (so that there could be an electrical overload) or are the wrong size (thin extension cords used to energize heavy-duty cords). Adapter or “cheater” plugs are used in many offices. Most often they are used to connect equipment that must be grounded (three-pronged plug) into two-pronged outlets without connecting the plug to ground. This creates an unsafe electrical connection. Ground pins are sometimes broken off a plug to allow for the same two-prong connection.

Stress is a significant psychosocial health problem for many offices. Stress is caused by many factors, including noise from overcrowding and equipment, poor relationships with supervisors and/or co-workers, increase in workload and lack of control of work.

Musculoskeletal problems and soft tissue injuries such as tendinitis result from office furniture and equipment which is not fitted to a worker’s individual physical needs. Tendinitis can occur from repeated movement of certain body parts, such as finger problems from constant writing, or filing and retrieving files from cabinets that are too full. Many office workers suffer from a variety of RSIs such as carpal tunnel syndrome, thoracic outlet syndrome and ulcer nerve damage because of the ill-fitting equipment and the lack of rest breaks from continuous keying (on a computer) or other repetitive activities. Poorly designed furniture and equipment also contribute to poor posture and nerve compression of lower extremities, since many office workers sit for long periods of time; all of these factors contribute to low-back and lower-extremity problems, as does constant standing.

Continual use of computers and poor overall lighting create eye strain for office workers. Because of this, many workers experience a worsening of vision, headaches, burning eyes and eye fatigue. Adjustments in lighting and computer screen contrast, as well as frequent breaks in eye focus, are necessary to help eliminate eye problems. Lighting must be appropriate for the task.

Fire and emergency procedures are essential in an office. Many offices lack adequate procedures for workers to exit a building in case of fire or other emergency. These procedures, or emergency plans, should be in writing and should be practised (through fire drills) so that office occupants are familiar with where to go and what to do. This insures that all workers will promptly and safely evacuate in the event of a real fire or other emergency. Fire safety is often compromised in offices by blocking of exits, lack of exit signage, storage of incompatible chemicals or combustible materials, inoperative alarm or firefighting systems or total lack of adequate means of notification of workers in emergencies.

Violence

Violence in the workplace is now being recognized as a significant workplace hazard. As discussed in the chapter Violence, in the United States, for example, homicide is the leading cause of death for women workers and the third-leading cause of death for all workers. Non-fatal assaults occur much more frequently than most people realize. Office workers who interact with the public—for example, cashiers—can be at greater risk of violence. Violence can also be internal (worker against worker). The vast majority of office workplace violence, however, comes from people coming to the office from the outside. Government office workers are much more at risk for workplace violence incidents because these workers administer laws and regulations to which many citizens have hostile reactions, be they verbal or physical. In the United States, 18% of the workforce are government workers, but they constitute 30% of the victims of workplace violence.

Offices can be made safer by restricting access to work areas, changing or creating policies and procedures which help eliminate sources of hostility and provide for emergency procedures and installing security equipment which is appropriate for the particular office being improved. Measures for improving safety are illustrated in the article describing German requirements for bank teller safety.

Indoor Air Quality

Poor indoor air quality (IAQ) is probably the most frequent safety and health complaint from office workers. The effect of poor IAQ on productivity, absenteeism and morale is substantial. The US Environmental Protection Agency (EPA) has listed poor IAQ in their top 5 public health problems of the 1990s. Many reasons exist for poor air quality. Among them are closed or sealed buildings with inadequate amounts of outside air, overcrowding of offices, inadequate maintenance of ventilation systems, presence of chemicals such as pesticides and cleaning compounds, water damage and mould growth, installation of cubicles and walls which block off air flow to work areas, too much or too little humidity and dirty work environments (or poor housekeeping).

Table 2 lists common indoor air pollutants found in many offices. Office machines are also a source of many indoor air pollutants. Unfortunately, most offices have not designed their ventilation systems to take into account emissions from office equipment.

Table 2. Indoor air pollutants that may be found in office buildings

|

Pollutant |

Sources |

Health effects |

|

Ammonia |

Blueprint machines, cleaning solutions |

Respiratory system, eye and skin irritation |

|

Asbestos |