When pollutants generated at a worksite are to be controlled by ventilating the entire locale we speak of general ventilation. The use of general ventilation implies accepting the fact that the pollutant will be distributed to some degree through the entire space of the worksite, and could therefore affect workers who are far from the source of contamination. General ventilation is, therefore, a strategy that is the opposite of localized extraction. Localized extraction seeks to eliminate the pollutant by intercepting it as closely as possible to the source (see “Indoor air: methods for control and cleaning”, elsewhere in this chapter).

One of the basic objectives of any general ventilation system is the control of body odours. This can be achieved by supplying no less than 0.45 cubic metres per minute, m3/min, of new air per occupant. When smoking is frequent or the work is physically strenuous, the rate of ventilation required is greater, and may surpass 0.9 m3/min per person.

If the only environmental problems that the ventilation system must overcome are the ones just described, it is a good idea to keep in mind that every space has a certain level of “natural” air renewal by means of so-called “infiltration,” which occurs through doors and windows, even when they are closed, and through other sites of wall penetration. Air-conditioning manuals usually provide ample information in this regard, but it can be said that as a minimum the level of ventilation due to infiltration falls between 0.25 and 0.5 renewals per hour. An industrial site will commonly experience between 0.5 and 3 renewals of air per hour.

When used to control chemical pollutants, general ventilation must be limited to only those situations where the amounts of pollutants generated are not very high, where their toxicity is relatively moderate and where workers do not carry out their tasks in the immediate vicinity of the source of contamination. If these injunctions are not respected, it will be difficult to obtain acceptance for adequate control of the work environment because such high renewal rates must be used that the high air speeds will likely create discomfort, and because high renewal rates are expensive to maintain. It is therefore unusual to recommend the use of general ventilation for the control of chemical substances except in the case of solvents which have admissible concentrations of more than 100 parts per million.

When, on the other hand, the goal of general ventilation is to maintain the thermal characteristics of the work environment with a view to legally acceptable limits or technical recommendations such as the International Organization for Standardization (ISO) guidelines, this method has fewer limitations. General ventilation is therefore used more often to control the thermal environment than to limit chemical contamination, but its usefulness as a complement of localized extraction techniques should be clearly recognized.

While for many years the phrases general ventilation and ventilation by dilution were considered synonymous, today that is no longer the case because of a new general ventilation strategy: ventilation by displacement. Even though ventilation by dilution and ventilation by displacement fit within the definition of general ventilation we have outlined above, they both differ widely in the strategy they employ to control contamination.

Ventilation by dilution has the goal of mixing the air that is introduced mechanically as completely as possible with all the air that is already within the space, so that the concentration of a given pollutant will be as uniform as possible throughout (or so that the temperature will be as uniform as possible, if thermal control is the goal desired). To achieve this uniform mixture air is injected from the ceiling as streams at a relatively high speed, and these streams generate a strong circulation of air. The result is a high degree of mixing of the new air with the air already present inside the space.

Ventilation by displacement, in its ideal conceptualization, consists of injecting air into a space in such a way that new air displaces the air previously there without mixing with it. Ventilation by displacement is achieved by injecting new air into a space at a low speed and close to the floor, and extracting air near the ceiling. Using ventilation by displacement to control the thermal environment has the advantage that it profits from the natural movement of air generated by density variations that are themselves due to temperature differences. Even though ventilation by displacement is already widely used in industrial situations, the scientific literature on the subject is still quite limited, and the evaluation of its effectiveness is therefore still difficult.

Ventilation by Dilution

The design of a system of ventilation by dilution is based on the hypothesis that the concentration of the pollutant is the same throughout the space in question. This is the model that chemical engineers often refer to as a stirred tank.

If you assume that the air that is injected into the space is free of the pollutant and that at the initial time the concentration within the space is zero, you will need to know two facts in order to calculate the required rate of ventilation: the amount of the pollutant that is generated in the space and the level of environmental concentration that is sought (which hypothetically would be the same throughout).

Under these conditions, the corresponding calculations yield the following equation:

![]()

where

c(t) = the concentration of the contaminant in the space at time t

a = the amount of the pollutant generated (mass per unit of time)

Q = the rate at which new air is supplied (volume per unit of time)

V = the volume of the space in question.

The above equation shows that the concentration will tend to a steady state at the value a/Q, and that it will do so faster the smaller the value of Q/V, frequently referred to as “the number of renewals per unit of time”. Although occasionally the index of the quality of ventilation is regarded as practically equivalent to that value, the above equation clearly shows that its influence is limited to controlling the speed of stabilization of the environmental conditions, but not the level of concentration at which such a steady state will occur. That will depend only on the amount of the pollutant that is generated (a), and on the rate of ventilation (Q).

When the air of a given space is contaminated but no new amounts of the pollutant are generated, the speed of diminution of the concentration over a period of time is given by the following expression:

![]()

where Q and V have the meaning described above, t1 and t2 are, respectively, the initial and the final times and c1 and c2 are the initial and final concentrations.

Expressions can be found for calculations in instances where the initial concentration is not zero (Constance 1983; ACGIH 1992), where the air injected into the space is not totally devoid of the pollutant (because to reduce heating costs in the winter part of the air is recycled, for example), or where the amounts of the pollutant generated vary as a function of time.

If we disregard the transition stage and assume that the steady state has been achieved, the equation indicates that the rate of ventilation is equivalent to a/clim, where clim is the value of the concentration that must be maintained in the given space. This value will be established by regulations or, as an ancillary norm, by technical recommendations such as the threshold limit values (TLV) of the American Conference of Governmental Industrial Hygienists (ACGIH), which recommends that the rate of ventilation be calculated by the formula

![]()

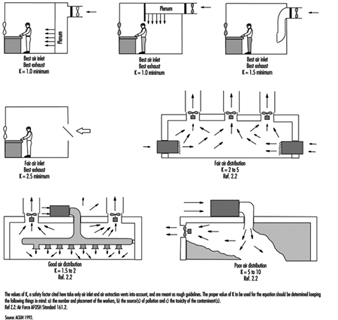

where a and clim have the meaning already described and K is a safety factor. A value of K between 1 and 10 must be selected as a function of the efficacy of the air mixture in the given space, of the toxicity of the solvent (the smaller clim is, the greater the value of K will be), and of any other circumstance deemed relevant by the industrial hygienist. The ACGIH, among others, cites the duration of the process, the cycle of operations and the usual location of the workers with respect to the sources of emission of the pollutant, the number of these sources and their location in the given space, the seasonal changes in the amount of natural ventilation and the anticipated reduction in the functional efficacy of the ventilation equipment as other determining criteria.

In any case, the use of the above formula requires a reasonably exact knowledge of the values of a and K that should be used, and we therefore provide some suggestions in this regard.

The amount of pollutant generated may quite frequently be estimated by the amount of certain materials consumed in the process that generates the pollutant. So, in the case of a solvent, the amount used will be a good indication of the maximum amount that can be found in the environment.

As indicated above, the value of K should be determined as a function of the efficacy of the air mixture in the given space. This value will, therefore, be smaller in direct proportion to how good the estimation is of finding the same concentration of the pollutant at any point within the given space. This, in turn, will depend on how air is distributed within the space being ventilated.

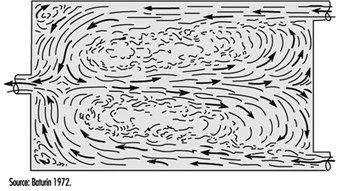

According to these criteria, minimum values of K should be used when air is injected into the space in a distributed fashion (by using a plenum, for example), and when the injection and extraction of air are at opposite ends of the given space. On the other hand, higher values for K should be used when air is supplied intermittently and air is extracted at points close to the intake of new air (figure 1).

Figure 1. Schematic of air circulation in room with two supply openings

It should be noted that when air is injected into a given space—especially if it is done at a high speed—the stream of air created will exert a considerable pull on the air surrounding it. This air then mixes with the stream and slows it down, creating measurable turbulence as well. As a consequence, this process results in intense mixing of the air already in the space and the new air that is injected, generating internal air currents. Predicting these currents, even generally, requires a large dose of experience (figure 2).

Figure 2. Suggested K factors for inlet and exhaust locations

In order to avoid problems that result from workers’ being subjected to streams of air at relatively high speeds, air is commonly injected by way of diffusing grates designed in such a way that they facilitate the rapid mixing of new air with the air already present in the space. In this way, the areas where air moves at high speeds are kept as small as possible.

The stream effect just described is not produced near points where air escapes or is extracted through doors, windows, extraction vents or other openings. Air reaches extraction grates from all directions, so even at a relatively short distance from them, air movement is not easily perceived as an air current.

In any case, in dealing with air distribution, it is important to keep in mind the convenience of placing workstations, to the extent possible, in such a way that new air reaches the workers before it reaches the sources of contamination.

When in the given space there are important sources of heat, the movement of air will largely be conditioned by the convection currents that are due to density differences between denser, cold air and lighter, warm air. In spaces of this kind, the designer of air distribution must not fail to keep in mind the existence of these heat sources, or the movement of air may turn out to be very different from the one predicted.

The presence of chemical contamination, on the other hand, does not alter in a measurable way the density of air. While in a pure state the pollutants may have a density that is very different from that of air (usually much greater), given the real, existing concentrations in the workplace, the mix of air and pollutant does not have a density significantly different than the density of pure air.

Furthermore, it should be pointed out that one of the most common mistakes made in applying this type of ventilation is supplying the space only with air extractors, without any forethought given to adequate intakes of air. In these cases, the effectiveness of the extraction ventilators is diminished and, therefore, the actual rates of air extraction are much less than planned. The result is greater ambient concentrations of the pollutant in the given space than those initially calculated.

To avoid this problem some thought should be given to how air will be introduced into the space. The recommended course of action is to use immission ventilators as well as extraction ventilators. Normally, the rate of extraction should be greater than the rate of immission in order to allow for infiltration through windows and other openings. In addition, it is advisable to keep the space under slightly negative pressure to prevent the contamination generated from drifting into areas that are not contaminated.

Ventilation by Displacement

As mentioned above, with ventilation by displacement one seeks to minimize the mixing of new air and the air previously found in the given space, and tries to adjust the system to the model known as plug flow. This is usually accomplished by introducing air at slow speeds and at low elevations in the given space and extracting it near the ceiling; this has two advantages over ventilation by dilution.

In the first place, it makes lower rates of air renewal possible, because pollution concentrates near the ceiling of the space, where there are no workers to breathe it. The average concentration in the given space will then be higher than the clim value we have referred to before, but that does not imply a higher risk for the workers because in the occupied zone of the given space the concentration of the pollutant will be the same or lower than a clim.

In addition, when the goal of ventilation is the control of the thermal environment, ventilation by displacement makes it possible to introduce warmer air into the given space than would be required by a system of ventilation by dilution. This is because the warm air that is extracted is at a temperature several degrees higher than the temperature in the occupied zone of the space.

The fundamental principles of ventilation by displacement were developed by Sandberg, who in the early 1980s developed a general theory for the analysis of situations where there were nonuniform concentrations of pollutants in enclosed spaces. This allowed us to overcome the theoretical limitations of ventilation by dilution (which presupposes a uniform concentration throughout the given space) and opened the way for practical applications (Sandberg 1981).

Even though ventilation by displacement is widely used in some countries, particularly in Scandinavia, very few studies have been published in which the efficacy of different methods are compared in actual installations. This is no doubt because of the practical difficulties of installing two different ventilation systems in a real factory, and because the experimental analysis of these types of systems require the use of tracers. Tracing is done by adding a tracer gas to the air ventilation current and then measuring the concentrations of the gas at different points within the space and in the extracted air. This sort of examination makes it possible to infer how air is distributed within the space and to then compare the efficacy of different ventilation systems.

The few studies available that have been carried out in actual existing installations are not conclusive, except as regards the fact that systems that employ ventilation by displacement provide better air renewal. In these studies, however, reservations are often expressed about the results in so far as they have not been confirmed by measurements of the ambient level of contamination at the worksites.