General developments in microelectronics and in the technology of sensors give reason to hope that an improvement in occupational safety can be achieved through the availability of reliable, hardy, low-maintenance and inexpensive presence and approach detectors. This article will describe sensor technology, the different detection procedures, the conditions and restrictions applicable to the use of sensor systems, and some completed studies and standardization work in Germany.

Presence Detector Criteria

The development and practical testing of presence detectors is one of the greatest future challenges to technical efforts in improving occupational safety and to the protection of personnel in general. Presence detectors are sensors that reliably and with certainty signal the near presence or approach of a person. In addition, this warning must occur rapidly so that evasive action, braking or the shutting off of a stationary machine can take place before the predicted contact occurs. Whether the people are big or small, whatever their posture, or how they are clothed should have no effect on the reliability of the sensor. In addition, the sensor must possess certainty of functioning and be sturdy and inexpensive, so that it can be used under the most demanding conditions, such as on construction sites and for mobile applications, with minimal maintenance. Sensors must be like an airbag in that they are maintenance-free and always ready. Given some users’ reluctance to maintain what they may regard as nonessential equipment, sensors may be left unserviced for years. Another feature of presence detectors, one that is much more likely to be requested, is that they also detect obstacles other than human beings and alert the operator in time to take defensive action, thus reducing costs of repair and material damage. This is a reason for installing presence detectors that should not be under-appreciated.

Detector Applications

Innumerable fatal accidents and serious injuries which look like unavoidable, individual acts of fate, may be avoided or minimized provided that presence detectors become more accepted as a prevention measure in the field of occupational safety. The newspapers report these accidents all too often: here a person was struck by a backwards-moving loader, there the operator did not see someone who was run over by the front wheel of a power shovel. Trucks moving backwards on streets, company premises and construction sites are the cause of many accidents to people. Today’s thoroughly rationalized companies no longer provide co-drivers or other persons to act as guides for the driver who is backing up a truck. These examples of moving accidents can be easily extended to other mobile equipment, such as fork-lift trucks. However, the use of sensors is urgently needed to prevent accidents involving semi-mobile and purely stationary equipment. An example is the rear areas of large loading machines, which have been identified by safety personnel as potentially hazardous areas which could be improved through the use of inexpensive sensors. Many variations of presence detectors can be adapted innovatively to other vehicles and large mobile equipment to protect against the types of accidents discussed in this article, which generally cause extensive damage and serious, if not fatal, injuries.

The tendency of innovative solutions to become more widespread would seem to promise that presence detectors will become the standard safety technology in other applications; however, this is not the case anywhere. The breakthrough, motivated by accidents and high material damages, is expected in monitoring behind delivery vans and heavy trucks and for the most innovative areas of the “new technologies”—the mobile robot machines of the future.

The variation of the fields of application for presence detectors and the variability of the tasks—for example, tolerating objects (even moving objects, under certain conditions) that belong to a detection field and that should not trigger a signal—require sensors in which “intelligent” assessment technology supports the mechanisms of sensor function. This technology, which is a matter for future development, can be elaborated from methods drawing upon the field of artificial intelligence (Schreiber and Kuhn 1995). To date, a limited universality has severely restricted current uses of sensors. There are light curtains; light bars; contact mats; passive infrared sensors; ultrasound and radar motion detectors that use the Doppler effect; sensors that make elapsed time measurements of ultrasound, radar and light impulses; and laser scanners. Normal television cameras connected to monitors are not included in this list because they are not presence detectors. However, those cameras which do activate automatically upon sensing the presence of a person, are included.

Sensor Technology

Today the main sensor issues are (1) optimizing the use of the physical effects (infrared, light, ultrasound, radar, etc.) and (2) self-monitoring. Laser scanners are being intensively developed for use as navigational instruments for mobile robots. For this, two tasks, partially different in principle, must be solved: the navigation of the robot and the protection of persons (and material or equipment) present so that they are not struck, run over or grabbed (Freund, Dierks and Rossman 1993). Future mobile robots cannot retain the same safety philosophy of “spatial separation of robot and person” which is strictly applied to today’s stationary industrial robots. This means putting a high premium on the reliable functioning of the presence detector to be used.

The use of “new technology” is often linked to problems of acceptance, and it can be assumed that the general use of mobile robots that can move and grasp, among people in plants, in public traffic areas, or even in homes or recreational areas, will be accepted only if they are equipped with very highly developed, sophisticated and reliable presence detectors. Spectacular accidents must be avoided at all costs in order to avoid exacerbating a possible acceptance problem. The current level of expenditure for the development of this type of occupational protective sensors does not come close to taking this consideration into account. To save a lot of costs, presence detectors should be developed and tested simultaneously with the mobile robots and the navigational systems, not afterwards.

With respect to motor vehicles, safety questions have gained increasing significance. Innovative passenger safety in automobiles includes three-point seat belts, child seats, airbags and the anti-lock brake system verified by serial crash tests. These safety measures represent a relatively increasing portion of production costs. The side airbag and radar sensor systems to measure the distance to the car ahead are evolutionary developments in passenger protection.

External motor vehicle safety—that is, the protection of third parties—is receiving increased attention. Recently, side protection has been required, primarily for trucks, to prevent motorcyclists, bicyclists and pedestrians from the danger of falling under the rear wheels. A next logical step would be monitoring the area behind large vehicles with presence detectors and installing rear area warning equipment. This would have the positive side effect of providing the funding required to develop, test and make available maximum performance, self-monitoring, maintenance-free and reliably functioning, inexpensive sensors for occupational safety purposes. The trial process that would go with the broad implementation of sensors or sensor systems would considerably facilitate innovation in other areas, such as power shovels, heavy loaders and other large mobile machines that back up as much as half the time during their operation. The evolutionary process from stationary robots to mobile robots is an additional path of development for presence detectors. For example, improvements could be made to the sensors currently used on mobile robot material movers or “driverless factory floor tractors”, which follow fixed paths and therefore have relatively low safety requirements. The use of presence detectors is the next logical step in improving safety in the area of material and passenger transport.

Detection Procedures

Various physical principles, available in connection with electronic measuring and self-monitoring methods and, to an extent, high-performance computing procedures, may be used to assess and solve the above-mentioned tasks. The apparently effortless and sure operation of automated machines (robots) so common in science-fiction films, will possibly be accomplished in the real world through the use of imaging techniques and high-performance pattern recognition algorithms in combination with distance measurement methods analogous to those employed by laser scanners. The paradoxical situation that everything that seems simple for people is difficult for automatons, must be recognized. For example, a difficult task such as excellent chess playing (which calls for forebrain activity) can be more easily simulated and carried out by automated machines than a simple task such as walking upright or carrying out hand-eye and other movement coordination (mediated by the mid- and hindbrain). A few of these principles, methods and procedures applicable to sensor applications are described below. In addition to these, there are a large number of special procedures for very special tasks that work in part with a combination of various types of physical effects.

Light barrier curtains and bars. Among the first presence detectors were light barrier curtains and bars. They have a flat monitoring geometry; that is, one who has passed the barrier will no longer be detected. An operator’s hand, or the presence of tools or parts held in an operator’s hand, for instance, can be quickly and reliably detected with these devices. They offer an important contribution to occupational safety for machines (like presses and punching machines) that require that material be put in by hand. The reliability has to be extremely high statistically, because when the hand reaches in only two to three times per minute, about one million operations are performed in just a few years. The mutual self-monitoring of sender and receiver components has been developed to such a very high technical level that it represents a standard for all other presence detection procedures.

Contact mats (switch mats). There are both passive and active (pump) types of electric and pneumatic contact mats and floors, which were initially used in large numbers in service functions (door openers), until they were replaced by motion detectors. Further development evolves with the use of presence detectors in all sorts of danger zones. For example, the development of automated manufacturing with a change in the function of the worker—from operating the machine to strictly monitoring its function—produced a corresponding demand for appropriate detectors. Standardization of this use is well advanced (DIN 1995a), and special limitations (layout, size, maximum allowed “dead” zones) necessitated the development of expertise for installation in this area of usage.

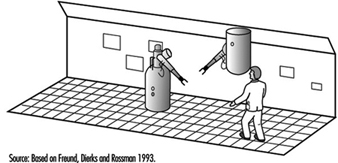

Interesting possible uses of contact mats arise in conjunction with computer-controlled multiple robot systems. An operator switches one or two elements so that the presence detector would pick up his or her exact position and inform the computer, which manages robot control systems with a built-in collision-avoidance system. In one test advanced by the German federal safety institute (BAU), a contact-mat floor, consisting of small electrical switch mats, was built under the robot arm’s work area for this purpose (Freund, Dierks and Rossman 1993). This presence detector had the form of a chessboard. The respectively activated mat field told the computer the operator’s position (figure 1) and when the operator approached too close to the robot, it moved away. Without the presence detector the robot system would not be able to ascertain the operator’s position, and the operator then could not be protected.

Figure 1. A person (right) and two robots in computed wrapper bodies

Reflectors (motion sensors and presence detectors). However meritorious the sensors discussed up to now may be, they are not presence detectors in the broader sense. Their suitability—primarily for reasons of occupational safety—for large vehicles and large mobile equipment presupposes two important characteristics: (1) the ability to monitor an area from one position, and (2) error-free functioning without the need for additional measures on the part of—for example, the use of reflector devices. Detecting the presence of a person entering the monitored area and remaining stopped until this person has gone also implies the need for detecting a person standing absolutely still. This distinguishes so-called motion sensors from presence detectors, at least in connection with mobile equipment; motion sensors are almost always triggered when the vehicle is put into motion.

Motion sensors. The two basic types of motion sensors are: (1) “passive infrared sensors” (PIRS), which react to the smallest change in the infrared beam in the monitored area (the smallest detectable beam is approximately 10-9 W with a wavelength range of approximately 7 to 20 μm); and (2) ultrasound and microwave sensors using the Doppler principle, which determines the characteristics of an object’s motion according to the frequency changes. For example, the Doppler effect increases the frequency of a locomotive’s horn for an observer when it is approaching, and reduces the frequency when the locomotive is moving away. The Doppler effect makes possible the building of relatively simple approach sensors, as the receiver needs only to monitor the signal frequency of neighbouring frequency bands for the appearance of the Doppler frequency.

In the mid-1970s the use of motion detectors became prevalent in service function applications such as door openers, theft security and object protection. For stationary use, the detection of an approaching person toward a danger spot was adequate to give a timely warning or to turn off a machine. This was the basis for studying the suitability of motion detectors for their use in occupational safety, especially by means of PIRS (Mester et al. 1980). Because a clothed person generally has a higher temperature than the surrounding area (head 34°C, hands 31°C), detecting an approaching person is somewhat easier than detecting inanimate objects. To a limited extent, machine parts can move about in the monitored area without triggering the detector.

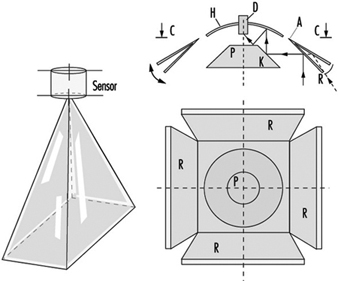

The passive method (without transmitter) has advantages and disadvantages. The advantage is that a PIRS does not add to noise and electrical smog problems. For theft security and object protection, it is particularly important that the detector not be easy to find. A sensor that is purely a receiver, however, can hardly monitor its own effectiveness, which is essential for occupational safety. One method for overcoming this drawback was to test small modulated (5 to 20 Hz) infrared emitters that were installed in the monitored area and that did not trigger the sensor, but whose beams were registered with a fixed electronic amplification set to the modulation frequency. This modification turned it from a “passive” sensor to an “active” sensor. In this way it was also possible to check the geometric accuracy of the monitored area. Mirrors can have blind spots, and a passive sensor’s direction can be thrown off by the rough activity in a plant. Figure 2 shows a test layout with a PIRS with a monitored geometry in the form of a pyramid mantle. Because of their great reach, passive infrared sensors are installed, for example, in the passageways of shelf storage areas.

Figure 2. Passive infrared sensor as approach detector in a danger area

Overall, tests showed that motion detectors are not suited to occupational safety. A night-time museum floor cannot be compared to danger zones in a workplace.

Ultra-sound, radar and light-impulse detectors. Sensors that use the pulse/echo principle—that is, elapsed time measurements of ultrasound, radar or light impulses—have great potential as presence detectors. With laser scanners, light impulses can sweep in rapid succession (usually in a rotatory fashion), for example, horizontally, and with the help of a computer one can obtain a distance profile of the objects on a plane that reflect light. If, for example, not only a single line is wanted, but the entirety of what lies before the mobile robot in the area up to a height of 2 metres, then great quantities of data must be processed to depict the surrounding area. A future “ideal” presence detector will consist of a combination of the following two processes:

- A pattern-recognition process will be employed, consisting of a camera and a computer. The latter can also be a “neuronal net”.

- A laser scanning process is further required to measure distances; this takes a bearing in a three-dimensional space over from a number of individual points selected by the pattern-recognition process, established to obtain the distance and motion by speed and direction.

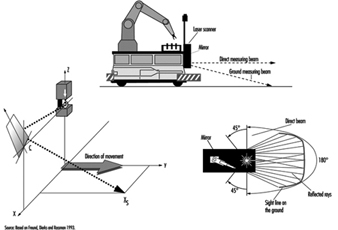

Figure 3 shows, from the previously cited BAU project (Freund, Dierks and Rossman 1993), the use of a laser scanner on a mobile robot that also assumes navigational tasks (via a direction-sensing beam) and collision protection for objects in the immediate vicinity (via a ground measurement beam for presence detection). Given these features, the mobile robot has the capability of active automated free driving (i.e., the ability to drive around obstacles). Technically, this is achieved by utilizing the 45° angle of the scanner rotation toward the rear on both sides (to port and starboard of the robot) in addition to the 180° angle toward the front. These beams are connected with a special mirror which acts as a light curtain on the floor in front of the mobile robot (providing a ground vision line). If a laser reflection comes from there, the robot stops. While laser and light scanners certified for occupational safety use are on the market, these presence detectors have great potential for further development.

Figure 3. Mobile robot with laser scanner for navigation and presence detection use

Ultrasound and radar sensors, which use the elapsed time from signal to response to determine distance, are less demanding from a technical perspective and thus can be produced more cheaply. The sensor area is club-shaped and has one or more smaller side clubs, which are symmetrically arranged. The speed of the signal’s spread (sound: 330 m/s; electromagnetic wave: 300,000 km/s) determines the requisite speed of the electronics utilized.

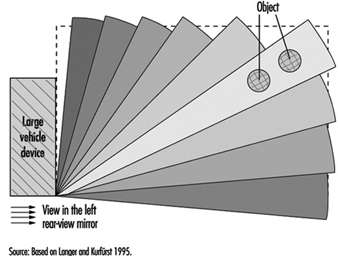

Rear-area warning devices. At the 1985 Hanover Exposition, BAU showed the results of an initial project on the use of ultrasound sensors for securing the area behind large vehicles (Langer and Kurfürst 1985). A full-sized model of a sensor head made of Polaroid™ sensors was set up on the back wall of a supply truck. Figure 4 shows its functioning schematically. The large diameter of this sensor produces relatively small-angled (approximately 18°), long-range club-shaped measured areas, arranged next to each other and set to different maximum signal ranges. In practice it allows one to set any desired monitored geometry, which is scanned by the sensors approximately four times per second for the presence or entrance of persons. Other demonstrated rear-area warning systems had several parallel individual arrayed sensors.

Figure 4. Disposition of measuring head and area monitored on the rear side of a truck

This vivid demonstration was a great success at the exhibition. It showed that securing the rear area of large vehicles and equipment is being studied in many places—for example, by specialized committees of the industrial trade associations (Berufsgenossenschaften), the municipal accident insurers (who are responsible for municipal vehicles), the state industry oversight officials, and the producers of sensors, who had been thinking more in terms of automobiles as service vehicles (in the sense of focusing on parking systems to protect against auto body damage). An ad hoc committee drawn from the groups to promote rear-area warning devices was formed spontaneously and took as a first task the preparation of a list of requirements from the perspective of occupational safety. Ten years have passed during which time much has been worked out in rear-area monitoring—possibly the most important task of presence detectors; but the big breakthrough is still missing.

Many projects have been conducted with ultrasound sensors—for example, on round-wood sorting cranes, hydraulic shovels, special municipal vehicles, and other utility vehicles, as well as on fork-lift trucks and loaders (Schreiber 1990). Rear-area warning devices are especially important for large machinery that backs up much of the time. Ultrasound presence detectors are used, for example, for the protection of specialized driverless vehicles such as robot material-handling machines. As compared to rubber bumpers, these sensors have a greater detection area which provides for braking before contact is made between the machine and an object. Corresponding sensors for automobiles are appropriate developments and involve considerably less stringent requirements.

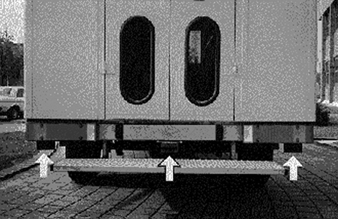

In the meantime, the Transportation System Technical Standards Committee of DIN worked up Standard 75031, “Obstacle detection devices during reversing” (DIN 1995b). The requirements and tests were set for two ranges: 1.8 m for supply trucks and 3.0 m—an additional warning area—for larger trucks. The monitored area is set through the recognition of cylindrical test bodies. The 3-m range is also about the limit of what is presently technically possible, as ultrasound sensors must have closed metal membranes, given their rough working conditions. The requirements for the sensor system’s self-monitoring are being set, as the required monitored geometry can be accomplished only with a system of three or more sensors. Figure 5 shows a rear-area warning device consisting of three ultrasound sensors (Microsonic GmbH 1996). The same applies for the notification device in the driver’s cab and the type of warning signal. The contents of DIN Standard 75031 are also laid out in the international technical ISO Report TR 12155, “Commercial vehicles—Obstacle detection device during reversing” (ISO 1994). Various sensor producers have developed prototypes in accordance with this standard.

Figure 5. Mid-sized truck equipped with a rear area warning device (Microsonic photo).

Conclusion

Since the early 1970s, several institutions and sensor manufacturers have worked to develop and establish “presence detectors”. In the special application of “rear-area warning devices” there are DIN Standard 75031 and ISO Report TR 12155. At present Deutsche Post AG is conducting a major test. Several sensor manufacturers have each equipped five mid-size trucks with such devices. A positive outcome of this test is very much in the interests of occupational safety. As was emphasized at the outset, presence detectors in the required numbers are a big challenge for safety technology in the many areas of application mentioned. They must therefore be realizable at low cost if damages to equipment, machinery and materials, and, above all, injuries to people, often very serious, are to be relegated to the past.