The present article draws heavily on two publications: FAO 1996 and FAO/ILO 1980. This article is an overview; numerous other references are available. For specific guidance on preventive measures, see ILO 1998.

Wood harvesting is the preparation of logs in a forest or tree plantation according to the requirements of a user, and delivery of logs to a consumer. It includes the cutting of trees, their conversion into logs, extraction and long distance transport to a consumer or processing plant. The terms forest harvesting, wood harvesting or logging are often used synonymously. Long-distance transport and the harvesting of non-wood forest products are dealt with in separate articles in this chapter.

Operations

While many different methods are used for wood harvesting, they all involve a similar sequence of operations:

- tree felling: severing a tree from the stump and bringing it down

- topping and debranching (delimbing): cutting off the unusable tree crown and the branches

- debarking: removing the bark from the stem; this operation is often done at the processing plant rather than in the forest; in fuelwood harvesting it is not done at all

- extraction: moving the stems or logs from the stump to a place close to a forest road where they can be sorted, piled and often stored temporarily, awaiting long distance transport

- log making/cross-cutting (bucking): cutting the stem to the length specified by the intended use of the log

- scaling: determining the quantity of logs produced, usually by measuring volume (for small dimension timber also by weight; the latter is common for pulpwood; weighing is done at the processing plant in that case)

- sorting, piling and temporary storage: logs are usually of variable dimensions and quality, and are therefore classified into assortments according to their potential use as pulpwood, sawlogs and so on, and piled until a full load, usually a truckload, has been assembled; the cleared area where these operations, as well as scaling and loading, take place is called a “landing”

- loading: moving the logs onto the transport medium, typically a truck, and attaching the load.

These operations are not necessarily carried out in the above sequence. Depending on the forest type, the kind of product desired and the technology available, it may be more advantageous to carry out an operation either earlier (i.e., closer to the stump) or later (i.e., at the landing or even at the processing plant). One common classification of harvesting methods is based on distinguishing between:

- full-tree systems, where trees are extracted to the roadside, the landing or the processing plant with the full crown

- short-wood systems, where topping, debranching and cross-cutting is done close to the stump (logs are usually not longer than 4 to 6 m)

- tree-length systems, where tops and branches are removed before extraction.

The most important group of harvesting methods for industrial wood is based on tree length. Short-wood systems are standard in northern Europe and also common for small-dimension timber and fuelwood in many other parts of the world. Their share is likely to increase. Full-tree systems are the least common in industrial wood harvesting, and are used in only a limited number of countries (e.g., Canada, the Russian Federation and the United States). There they account for less than 10% of volume. The importance of this method is diminishing.

For work organization, safety analysis and inspection, it is useful to conceive of three distinct work areas in a wood harvesting operation:

- the felling site or stump

- the forest terrain between the stump and the forest road

- the landing.

It is also worthwhile to examine whether the operations take place largely independently in space and time or whether they are closely related and interdependent. The latter is often the case in harvesting systems where all steps are synchronized. Any disturbance thus disrupts the entire chain, from felling to transport. These so-called hot-logging systems can create extra pressure and strain if not carefully balanced.

The stage in the life cycle of a forest during which wood harvesting takes place, and the harvesting pattern, will affect both the technical process and its associated hazards. Wood harvesting occurs either as thinning or as final cut. Thinning is the removal of some, usually undesirable, trees from a young stand to improve the growth and quality of the remaining trees. It is usually selective (i.e., individual trees are removed without creating major gaps). The spatial pattern generated is similar to that in selective final cutting. In the latter case, however, the trees are mature and often large. Even so, only some of the trees are removed and a significant tree cover remains. In both cases orientation on the worksite is difficult because remaining trees and vegetation block the view. It can be very difficult to bring trees down because their crowns tend to be intercepted by the crowns of remaining trees. There is a high risk of falling debris from the crowns. Both situations are difficult to mechanize. Thinning and selective cutting therefore require more planning and skill to be done safely.

The alternative to selective felling for final harvest is the removal of all trees from a site, called “clear cutting”. Clearcuts can be small, say 1 to 5 hectares, or very large, covering several square kilometres. Large clearcuts are severely criticized on environmental and scenic grounds in many countries. Whatever the pattern of the cut, harvesting old growth and natural forest usually involves greater risk than harvesting younger stands or human-made forests because trees are large and have tremendous inertia when falling. Their branches may be intertwined with the crowns of other trees and climbers, causing them to break off branches of other trees as they fall. Many trees are dead or have internal rot which may not be apparent until late in the felling process. Their behaviour during felling is often unpredictable. Rotten trees may break off and fall in unexpected directions. Unlike green trees, dead and dry trees, called snags in North America, fall quickly.

Technological developments

Technological development in wood harvesting has been very rapid over the second half of the 20th century. Average productivity has been soaring in the process. Today, many different harvesting methods are in use, sometimes side by side in the same country. An overview of systems in use in Germany in the mid-1980s, for example, describes almost 40 different configurations of equipment and methods (Dummel and Branz 1986).

While some harvesting methods are technologically far more complex than others, no single method is inherently superior. The choice will usually depend on the customer specifications for the logs, on forest conditions and terrain, on environmental considerations, and often decisively on cost. Some methods are also technically limited to small and medium-size trees and relatively gentle terrain, with slopes not exceeding 15 to 20°.

Cost and performance of a harvesting system can vary over a wide range, depending on how well the system fits the conditions of the site and, equally important, on the skill of the workers and how well the operation is organized. Hand tools and manual extraction, for example, make perfect economic and social sense in countries with high unemployment, low labour and high capital cost, or in small-scale operations. Fully mechanized methods can achieve very high daily outputs but involve large capital investments. Modern harvesters under favourable conditions can produce upwards of 200 m3 of logs per 8-hour day. A chain-saw operator is unlikely to produce more than 10% of that. A harvester or big cable yarder costs around US$500,000 compared to US$1,000 to US$2,000 for a chain-saw and US$200 for a good quality cross-cut handsaw.

Common Methods, Equipment and Hazards

Felling and preparation for extraction

This stage includes felling and removal of crown and branches; it may include debarking, cross-cutting and scaling. It is one of the most hazardous industrial occupations. Hand tools and chain-saws or machines are used in felling and debranching trees and crosscutting trees into logs. Hand tools include cutting tools such as axes, splitting hammers, bush hooks and bush knives, and hand saws such as cross-cut saws and bow saws. Chain-saws are widely used in most countries. In spite of major efforts and progress by regulators and manufacturers to improve chain-saws, they remain the single most dangerous type of machine in forestry. Most serious accidents and many health problems are associated with their use.

The first activity to be carried out is felling, or severing the tree from the stump as close to the ground as conditions permit. The lower part of the stem is typically the most valuable part, as it contains a high volume, and has no knots and an even wood texture. It should therefore not split, and no fibre should be torn out from the butt. Controlling the direction of the fall is important, not only to protect the tree and those to be left standing, but also to protect the workers and to make extraction easier. In manual felling, this control is achieved by a special sequence and configuration of cuts.

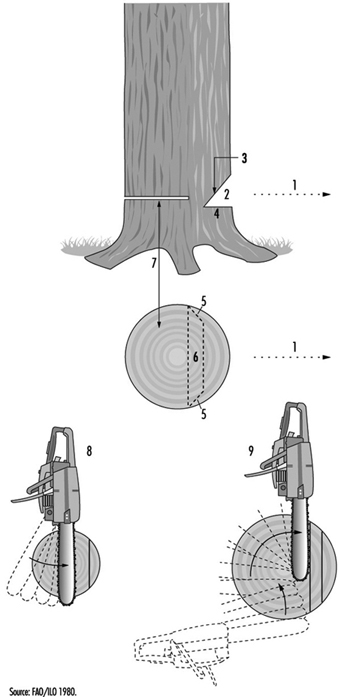

The standard method for chain-saws is depicted in figure 1. After determining the felling direction (1) and clearing the tree’s base and escape routes, sawing starts with the undercut (2), which should penetrate approximately one-fifth to one-quarter of the diameter into the tree. The opening of the undercut should be at an angle of about 45°. The oblique cut (3) is made prior to the horizontal cut (4), which must meet the oblique cut in a straight line facing the felling direction at a 90o angle. If stumps are liable to tear splinters from the tree, as is common with softer woods, the undercut should be terminated with small lateral cuts (5) on both sides of the hinge (6). The back cut (7) must also be horizontal . It should be made 2.5 to 5 cm higher than the base of the undercut. If the tree’s diameter is smaller than the guide bar, the back cut can be made in a single movement (8). Otherwise, the saw must be moved several times (9). The standard method is used for trees with more than 15 cm butt diameter. The standard technique is modified if trees have one-side crowns, are leaning in one direction or have a diameter more than twice the length of the chain-saw blade. Detailed instructions are included in FAO/ILO (1980) and many other training manuals for chain-saw operators.

Figure 1. Chain-saw felling: Sequence of cuts.

Using standard methods, skilled workers can fell a tree with a high degree of precision. Trees that have symmetrical crowns or those leaning a little in a direction other than the intended direction of fall may not fall at all or may fall at an angle from the intended direction. In these cases, tools such as felling levers for small trees or hammers and wedges for big trees need to be used to shift the tree’s natural centre of gravity in the desired direction.

Except for very small trees, axes are not suitable for felling and cross-cutting. With handsaws the process is relatively slow and errors can be detected and repaired. With chain-saws cuts are fast and the noise blocks out the signals from the tree, such as the sound of breaking fibre before it falls. If the tree does start to fall but is intercepted by other trees, a “hang-up” results, which is extremely dangerous, and must be dealt with immediately and professionally. Turning hooks and levers for smaller trees and manual or tractor-mounted winches for larger trees are used to bring hung-up trees down effectively and safely.

Hazards involved with felling include falling or rolling trees; falling or snapping branches; cutting tools; and noise, vibration and exhaust gases with chain-saws. Windfall is especially hazardous with wood and partially severed root systems under tension; hung-up trees are a frequent cause of severe and fatal accidents. All workers involved in felling should have received specific training. Tools for felling and for dealing with hung-up trees need to be onsite. Hazards associated with cross-cutting include the cutting tools as well as snapping wood and rolling stems or bolts, particularly on slopes.

Once a tree has been brought down, it is usually topped and debranched. In the majority of cases, this is still done with hand tools or chain-saws at the stump. Axes can be very effective for debranching. Where possible, trees are felled across a stem already on the ground. This stem thus serves as a natural workbench, raising the tree to be debranched to a more convenient height and allowing for complete debranching without having to turn the tree. The branches and the crown are cut from the stem and left on the site. The crowns of large, broad-leaved trees may have to be cut into smaller pieces or pulled aside because they would otherwise obstruct extraction to the roadside or landing.

Hazards involved with debranching include cuts with tools or chain-saws; high risk of chain-saw kick-back (see figure 2); snapping branches under tension; rolling logs; trips and falls; awkward work postures; and static work load if poor technique is used.

Figure 2. Chain-saw Kick-back.

In mechanized operations, the directional fall is achieved by holding the tree with a boom mounted on a sufficiently heavy base machine, and cutting the stem with a shear, circular saw or chain-saw integrated into the boom. To do this, the machine has to be driven rather close to the tree to be felled. The tree is then lowered into the desired direction by movements of the boom or of the base of the machine. The most common types of machines are feller-bunchers and harvesters.

Feller-bunchers are mostly mounted on machines with tracks, but they can also be equipped with tyres. The felling boom usually allows them to fell and collect a number of small trees (a bunch), which is then deposited along a skid trail. Some have a clam bunk to collect a load. When feller-bunchers are used, topping and debranching are usually done by machines at the landing.

With good machine design and careful operation, accident risk with feller-bunchers is relatively low, except when chain-saw operators work along with the machine. Health hazards, such as vibration, noise, dust and fumes, are significant, since base machines often are not built for forestry purposes. Feller-bunchers should not be used on excessive slopes, and the boom should not be overloaded, as felling direction becomes uncontrollable.

Harvesters are machines which integrate all felling operations except debarking. They usually have six to eight wheels, hydraulic traction and suspension, and articulated steering. They have booms with a reach of 6 to 10 m when loaded. A distinction is made between one-grip and two-grip harvesters. One-grip harvesters have one boom with a felling head fitted with devices for felling, debranching, topping and cross-cutting. They are used for small trees up to 40 cm butt diameter, mostly in thinnings but increasingly also in final cutting. A two-grip harvester has separate felling and processing heads. The latter is mounted on the base machine rather than on the boom. It can handle trees up to a stump diameter of 60 cm. Modern harvesters have an integrated, computer-assisted measuring device that can be programmed to make decisions about optimum cross-cutting depending on the assortments needed.

Harvesters are the dominant technology in large-scale harvesting in northern Europe, but presently account for a rather small share of harvesting worldwide. Their importance is, however, likely to rise fast as second growth, human-made forests and plantations become more important as sources of raw material.

Accident rates in harvester operation are typically low, though accident risk rises when chain-saw operators work along with harvesters. Maintenance of harvesters is hazardous; repairs are always under high work pressure, increasingly at night; there is high risk of slipping and falling, uncomfortable and awkward working postures, heavy lifting, contact with hydraulic oils and hot oils under pressure. The biggest hazards are static muscle tension and repetitive strain from operating controls and psychological stress.

Extraction

Extraction involves moving the stems or logs from the stump to a landing or roadside where they can be processed or piled into assortments. Extraction can be very heavy and hazardous work. It can also inflict substantial environmental damage to the forest and its regeneration, to soils and to watercourses. The major types of extraction systems commonly recognized are:

- ground-skidding systems: The stems or logs are dragged on the ground by machines, draught animals or humans.

- forwarders: The stems or logs are carried on a machine (in the case of fuelwood, also by humans).

- cable systems: The logs are conveyed from the stump to the landing by one or more suspended cables.

- aerial systems: Helicopters or balloons are used to airlift the logs.

Ground skidding, by far the most important extraction system both for industrial wood and fuelwood, is usually done with wheeled skidders specially designed for forestry operations. Crawler tractors and, especially, farm tractors can be cost effective in small private forests or for the extraction of small trees from tree plantations, but adaptations are needed to protect both the operators and the machines. Tractors are less robust, less well balanced and less protected than purpose-built machines. As with all machines used in forestry, hazards include over-turning, falling objects, penetrating objects, fire, whole-body vibration and noise. All-wheel drive is preferable, and a minimum of 20% of the machine weight should be maintained as load on the steered axle during operation, which may require attaching additional weight to the front of the machine. The engine and transmission may need extra mechanical protection. Minimum engine power should be 35 kW for small-dimension timber; 50 kW is usually adequate for normal-size logs.

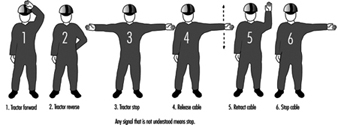

Grapple skidders drive directly to the individual or the pre-bunched stems, lift the front end of the load and drag it to the landing. Skidders with cable winches can operate from skid roads. Their loads are usually assembled through chokers, straps, chains or short cables that are attached to individual logs. A choker setter prepares the logs to be hooked up and, when the skidder returns from the landing, a number of chokers is attached to the main line and winched into the skidder. Most skidders have an arch onto which the front end of the load can be lifted to reduce friction during skidding. When skidders with powered winches are used, good communication between crew members through two-way radios or optical or acoustic signals is essential. Clear signals need to be agreed upon; any signal that is not understood means “Stop!”. Figure 3 shows proposed hand signals for skidders with powered winches.

Figure 3. International conventions for hand signals to be used for skidders with powered winches.

As a rule of thumb, ground skidding equipment should not be used on slopes of more than 15°. Crawler tractors may be used to extract large trees from relatively steep terrain, but they can cause substantial damage to soils if used carelessly. For environmental and safety reasons, all skidding operations should be suspended during exceptionally wet weather.

Extraction with draught animals is an economically viable option for small logs, particularly in thinning operations. Skidding distances must be short (typically 200 m or less) and slopes gentle. It is important to use appropriate harnesses providing maximum pulling power, and devices like skidding pans, sulkies or sledges that reduce skidding resistance.

Manual skidding is increasingly rare in industrial logging but continues to be practised in subsistence logging, particularly for fuelwood. It is limited to short distances and usually downhill, making use of gravity to move logs. While logs are typically small, this is very heavy work and can be hazardous on steep slopes. Efficiency and safety can be increased by using hooks, levers and other hand tools for lifting and pulling logs. Chutes, traditionally made from timber but also available as polyethylene half-tubes, can be an alternative to manual ground skidding of short logs in steep terrain.

Forwarders are extraction machines that carry a load of logs completely off the ground, either within their own frame or on a trailer. They usually have a mechanical or hydraulic crane for self-loading and unloading of logs. They tend to be used in combination with mechanized felling and processing equipment. The economic extraction distance is 2 to 4 times that of ground-skidders. Forwarders work best when logs are approximately uniform in size.

Accidents involving forwarders are typically similar to those of tractors and other forestry machines: overturning, penetrating and falling objects, electric power lines and maintenance problems. Health hazards include vibration, noise and hydraulic oils.

Using human beings to carry loads is still done for short logs like pulpwood or pit props in some industrial harvesting, and is the rule in fuelwood harvesting. Loads carried often exceed all recommended limits, particularly for women, who are often responsible for fuelwood gathering. Training in proper techniques that would avoid extreme strain on the spine and using devices like back packs that give a better weight distribution would ease their burden.

Cable extraction systems are fundamentally different from other extraction systems in that the machine itself does not travel. Logs are conveyed with a carriage moving along suspended cables. The cables are operated by a winching machine, also referred to as a yarder or hauler. The machine is installed either at the landing or at the opposite end of the cableway, often on a ridgetop. The cables are suspended above the ground on one or more “spar” trees, which may either be trees or steel towers. Many different types of cable systems are in use. Skylines or cable cranes have a carriage that can be moved along the mainline, and the cable can be released to allow lateral pulling of logs to the line, before they are lifted and forwarded to the landing. If the system permits full suspension of the load during hauling, soil disturbance is minimal. Because the machine is fixed, cable systems can be used in steep terrain and on wet soils. Cable systems in general are substantially more expensive than ground skidding and require careful planning and skilled operators.

Hazards occur during installation, operation and dismantling of the cable system, and include mechanical impact by deformation of the cabin or stand; breaking of cables, anchors, spars or supports; inadvertent or uncontrollable movements of cables, carriages, chokers and loads; and squeezes, abrasions and so on from moving parts. Health hazards include noise, vibration and awkward working postures.

Aerial extraction systems are those which fully suspend logs in the air throughout the extraction process. The two types currently in use are balloon systems and helicopters, but only helicopters are widely used. Helicopters with a lifting capacity of about 11 tonnes are commercially available. The loads are suspended under the helicopter on a tether line (also called “tagline”). The tether lines are typically between 30 and 100 m long, depending both upon topography and the height of trees above which the helicopter must hover. The loads are attached with long chokers and are flown to the landing, where the chokers are released by remote control from the aircraft. When large logs are being extracted, an electrically operated grapple system may be used instead of chokers. Round-trip times are typically two to five minutes. Helicopters have a very high direct cost, but can also achieve high production rates and reduce or eliminate the need for expensive road construction. They also cause low environmental impact. In practice their use is limited to high-value timber in otherwise inaccessible regions or other special circumstances.

Because of the high production rates required to make the use of such equipment economical, the number of workers employed on helicopter operations is much larger than for other systems. This is true for landings, but also for workers in cutting operations. Helicopter logging can create major safety problems, including fatalities, if precautions are disregarded and crews ill prepared.

Log making and loading

Log making, if it takes place at the landing, is mostly done by chain-saw operators. It can also be carried out by a processor (i.e., a machine that delimbs, tops and cuts to length). Scaling is mostly done manually using measuring tape. For sorting and piling, logs are usually handled by machines like skidders, which use their front blade to push and lift logs, or by grapple loaders. Helpers with hand tools like levers often assist the machine operators. In fuelwood harvesting or where small logs are involved, loading onto trucks is usually done manually or by using a small winch. Loading large logs manually is very arduous and dangerous; these are usually handled by grapple or knuckle boom loaders. In some countries the logging trucks are equipped for self-loading. The logs are secured on the truck by lateral supports and cables that can be pulled tight.

In manual loading of timber, physical strain and workloads are extremely high. In both manual and mechanized loading, there is danger of getting hit by moving logs or equipment. Mechanized loading hazards include noise, dust, vibration, high mental workload, repetitive strain, overturning, penetrating or falling objects and hydraulic oils.

Standards and Regulations

At present most international safety standards applicable to forestry machinery are general—for example, roll-over protection. However, work is under way on specialized standards at the International Organization for Standardization (ISO). (See the article “Rules, legislation, regulations and codes of forest practice” in this chapter.)

Chain-saws are one of the few pieces of forestry equipment for which specific international regulations on safety features exist. Various ISO norms are relevant. They were incorporated and supplemented in 1994 in European Norm 608, Agricultural and forest machinery: Portable chain-saws—Safety. This standard contains detailed indications on design features. It also stipulates that manufacturers are required to provide comprehensive instructions and information on all aspects of operator/user maintenance and the safe use of the saw. This is to include safety clothing and personal protective equipment requirements as well as the need for training. All saws sold within the European Union have to be marked “Warning, see instruction handbook”. The standard lists the items to be included in the handbook.

Forestry machines are less well covered by international standards, and there is often no specific national regulation about required safety features. Forestry machines may also have significant ergonomic deficiencies. These play a major role in the development of serious health complaints among operators. In other cases, machines have a good design for a particular worker population, but are less suitable when imported into countries where workers have different body sizes, communication routines and so on. In the worst case machines are stripped of essential safety and health features to reduce prices for exports.

In order to guide testing organizations and those responsible for machine acquisition, specialized ergonomic checklists have been developed in various countries. Checklists usually address the following machine characteristics:

- access and exit areas like steps, ladders and doors

- cabin space and position of controls

- seat, arms, back and footrest of operator’s chair

- visibility when performing main operations

- “worker-machine interface”: type and arrangement of indicators and controls of machine functions

- physical environment, including vibration noise, gases and climatic factors

- safety, including roll-over, penetrating objects, fire and so on

- maintenance.

Specific examples of such checklists can be found in Golsse (1994) and Apud and Valdés (1995). Recommendations for machines and equipment as well as a list of existing ILO standards are included in ILO 1998.