Coffee Industry

General Overview

Coffee as a beverage was introduced in Europe during the sixteenth century, first in Germany and then throughout the European continent during the following century, especially to France and Holland. Afterwards, it spread to the rest of the world.

Since coffee will not keep its characteristic smell and flavour for long, after roasting and grinding, industrial establishments to roast and grind coffee have become needed wherever coffee is consumed. The establishments are usually small or medium-sized plants, but large factories do exist, mainly to produce regular as well as instant (soluble) coffee.

It is difficult to estimate the number of workers employed by the coffee industry. Some of the smaller plants do not keep registries, and figures are not entirely reliable. Considering a total consumption of approximately 100 million 60 kg bags of coffee during the year 1995, the worldwide coffee trade represents about US$50 million. Table 1 lists selected coffee-importing countries, giving an idea of the present world consumption.

Table 1. Selected coffee importers (in tonnes).

|

Country |

1990 |

1991 |

1992 |

|

United States |

1,186,244 |

1,145,916 |

1,311,986 |

|

France |

349,306 |

364,214 |

368,370 |

|

Japan |

293,969 |

302,955 |

295,502 |

|

Spain |

177,681 |

176,344 |

185,601 |

|

United Kingdom |

129,924 |

119,020 |

128,702 |

|

Austria |

108,797 |

118,935 |

125,245 |

|

Canada |

120,955 |

126,165 |

117,897 |

Source: FAO 1992.

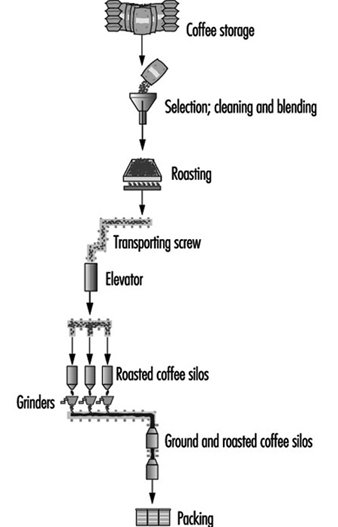

Coffee manufacturing is a relatively simple process, including cleaning, roasting, grinding and packing processes, as shown in figure 1. However, modern technology has led to complex processes, with an increase in speed of production and requiring laboratories for quality-control testing of the product.

Figure 1. Flow chart of coffee manufacturing.

Coffee beans arrive at factories in 60 kg bags, which are unloaded mechanically or manually. In the latter case, usually two workers hold a bag and place it upon another worker’s head. This worker will carry the bag to be stored. Even when transportation is done on coveyor belts, some physical effort with high energy consumption is required.

The use of instant coffee has steadily increased, reaching approximately 20% of the world consumption. Instant coffee is obtained through a complex process in which blasts of hot air blow over coffee extracts, followed by evaporation, cooling and lyophilization (freeze drying), varying in details from one factory to another. In the manufacture of decaffeinated coffee, which represents over 10% of the consumption in the United States and in Europe, some plants still utilize chlorinated solvents (such as methylene chloride), which is removed by a blast of water vapour.

Potential Risks and Health Effects

To start coffee processing, bags are opened with a small knife, and the beans are thrown inside a bin to be cleaned. The work area is noisy and a large amount of residual particulate material remains in suspension, released from the cleaning machine.

Roasting exposes workers to risks of burns and thermal discomfort. Bean mixing, or blending, is done automatically, as is grinding, in areas which may be deficient in lighting due to interference from suspended coffee dust. Dirt may accumulate, noise levels may be high and mechanization requires work at a high speed.

After grinding, bags of different materials and sizes are filled and then packed, usually in cardboard boxes. When performed manually, these operations require high-speed repetitive motion of hands and arms. Cardboard boxes are transported to storage areas and then to their final destination.

The strong odour characteristic of the coffee industry may bother workers inside the plants, and the surrounding community as well. The significance of this problem as a potential health risk has not yet been clarified. The odour of coffee is due to a mixture of different products; research is ongoing to identify individual effects of these chemicals. Some components of the coffee dust and some of the odour-producing substances are known to be allergens.

Potential risks in instant-coffee plants are similar to those in regular coffee production; in addition, there are risks due to hot steam and boiler explosions. In the removal of caffeine, even when performed automatically, the risk of solvent exposure may be present.

Other potential risks which may affect workers’ health are similar to those found in food industries in general. Risks for accidents arise from cuts from knives used in bag opening, burns during roasting and crushing during grinding operations, especially in old machinery without automatic machine guarding. There are fire and explosion hazards from the large amounts of dust, unsafe electric wiring and gas used for heating the roasters.

Several hazards may be found in the coffee industry including, among others: hearing loss due to excessive noise, thermal stress during roasting, poisoning from pesticides and musculoskeletal disorders, especially affecting the backs of workers who lift and carry heavy bags.

Allergic disorders affecting the eye, skin or respiratory system may occur in any area in a coffee plant. It is the coffee dust which is associated with bronchitis with lung function impairment; rhinitis and conjunctivitis are also concerns (Sekimpi et al. 1996). Allergic reactions to contaminants of bags previously used for other materials, such as castor bean seeds, have also occurred (Romano et al. 1995).

Repetitive-motion disorders may result from high-speed motion in packing operations, especially where workers are not warned of the risk.

In less developed countries, effects of occupational risks may develop early because conditions of work may be inadequate and, moreover, other social and public health factors may contribute to disease. Such factors include: low salaries, inadequate medical care and social security, improper housing and sanitation, low levels of education, illiteracy, endemic diseases and malnutrition.

Preventive Measures

Machine guarding, general ventilation and local exhaust systems, noise abatement, housekeeping and cleaning, decreased bag weights, substitutes of solvents used in caffeine extraction, periodic inspection and preventive maintenance of boilers are examples of preventive measures that are required for ensuring adequate levels of industrial hygiene and safety. Odour intensity may be reduced through modification of roasting procedures. The organization of work can be modified so that repetitive-motion disorders may be avoided through alteration of working position and rhythm, as well as the introduction of systematic breaks and regular exercises, among other practices.

Periodic health screening should stress evaluation of exposure to herbicides and pesticides, spinal disorders and early signs of repetitive-motion disorders. Scratch tests using extracts from coffee beans, even if not universally accepted as completely reliable, may be useful in the identification of hypersusceptible individuals. Lung function tests may aid in the early diagnosis of obstructive respiratory conditions.

Health education is an important instrument to enable workers to identify health risks and their consequences and to become aware of their right to a healthy working environment.

Governmental action is required, through legislation and enforcement; employers’ participation is needed in providing and maintaining adequate working conditions.

Soft Drink Bottling and Canning

In most established markets around the world, soft drinks now rank first among manufactured beverages, surpassing even milk and coffee in terms of per capita consumption.

Including ready-to-drink, packaged products and bulk mixes for fountain dispensing, soft drinks are available in almost every conceivable size and flavour and in virtually every channel of retail distribution. Complementing this universal availability, much of the soft drink category’s growth can be attributed to convenient packaging. As consumers have become increasingly mobile, they have opted for easier-to-carry packaged goods. With the advent of the aluminium can and, more recently, the resealable plastic bottle, soft drink packaging has become lighter and more portable.

Stringent quality-control standards and state-of-the-art water treatment processes also have afforded the soft drink industry a high degree of confidence regarding product purity. Moreover, the manufacturing or bottling plants that produce soft drinks have evolved into highly mechanized, efficient and spotlessly clean food-processing facilities.

As early as the 1960s, most bottlers were producing beverages through machinery that ran at 150 bottles per minute. As product demand has continued to skyrocket, soft drink manufacturers have shifted to faster machinery. Thanks to advances in production technology, filling lines now are able to run in excess of 1,200 containers per minute, with minimal downtime except for product or flavour changes. This highly automated environment has allowed soft drink manufacturers to reduce the number of employees required to operate the lines (see figure 1). Still, as production efficiencies have risen dramatically, plant safety has remained an ever-important consideration.

Figure 1. Control panel in an automated soft drink plant in Novosibirsk, Russia.

Soft drink bottling or manufacturing involves five major processes, each with its own safety issues that must be evaluated and controlled:

- treating water

- compounding ingredients

- carbonating product

- filling product

- packaging.

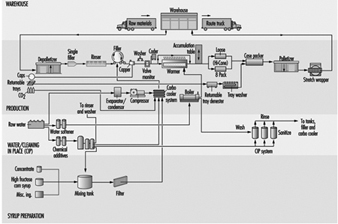

See figure 2.

Figure 2. Flow chart of basic bottling operations.

Soft drink manufacturing starts with water, which is treated and cleansed to meet exacting quality-control standards, usually exceeding the quality of the local water supply. This process is critical to achieving high product quality and consistent taste profiles.

As ingredients are being compounded, the treated water is piped into large, stainless-steel tanks. This is the stage at which various ingredients are added and mixed. Diet beverages are mixed with artificial, non-nutritive sweeteners such as aspartame or saccharin, whereas regularly sweetened drinks typically use liquid sugars like fructose or sucrose. It is during this stage of the production process that food colouring may be added. Flavoured, sparkling waters receive the desired flavouring at this stage, while plain waters are stored in the mixing tanks until the filling line calls for them. It is common for bottling companies to purchase concentrate from other firms.

In order for carbonation (absorption of carbon dioxide (CO2)) to occur, soft drinks are cooled using large, ammonia-based refrigeration systems. This is what gives carbonated products their effervescence and texture. CO2 is stored in a liquid state and piped into carbonation units as needed. This process can be manipulated to control the required rate of beverage absorption. Depending upon the product, soft drinks may contain from 15 to 75 psi of CO2. Fruit-flavoured soft drinks tend to have less carbonation than colas or sparkling water. Once carbonated, the product is ready to be dispensed into bottles and cans.

The filling room usually is separated from the rest of the facility, protecting open product from any possible contaminants. Again, the highly automated filling operation requires a minimal number of personnel. See figure 3 . Filling room operators monitor the equipment for efficiency, adding bulk lids or caps to the capping operation as necessary. Empty bottles and cans are transported automatically to the filling machine via bulk material-handling equipment.

Figure 3. Soft drink canning line showing filling operations.

Stringent quality-control procedures are followed throughout the production process. Technicians measure many variables, including CO2, sugar content and taste, to ensure that finished drinks meet required quality standards.

Packaging is the last stage prior to warehousing and delivery. This process also has become highly automated. Meeting various marketplace requirements, bottles or cans enter the packaging machinery and may be wrapped with cardboard to form cases or placed into reusable plastic trays or shells. The packaged products then enter a palletizing machine, which automatically stacks them onto pallets. (See figure 4.) Next, the loaded pallets are moved—typically via fork-lift—to a warehouse, where they are stored.

Figure 4. Eight-packs of 2-litre soft drink plastic bottles on the way to an automatic palletizer.

Hazard Prevention

Lifting-related injuries—especially to employees’ backs and shoulders—are not uncommon in the beverage business. While many technological advances have been made in material handling over the years, the industry continues to seek safer, more efficient ways to move heavy product.

Certainly, employees must be provided with the proper training on safe work practices. Injuries also can be minimized by limiting exposure to lifting through enhanced work-station design. Adjustable tables can be used to raise or lower material to waist level, for example, so that employees do not have to bend and lift as much. In this manner, most weight-related stress is transferred to a piece of equipment instead of the human body. All beverage manufacturers should implement ergonomics programmes that identify work-related hazards and minimize the risks—either through modification or by developing better equipment. A reasonable means to that end is job rotation, which reduces employee exposure to high-risk tasks.

The use of machine guarding is another critical component of safe beverage manufacturing. Equipment such as fillers and conveyors move at high speeds and, if left unguarded, could snag employee clothing or body parts, causing potentially severe injuries. Conveyors, pulleys, gears and spindles must have appropriate covers to prevent employee contact. Overhead conveyors can create an additional hazard of falling cases. Netting or wire-mesh screens should be installed to protect against this danger. Maintenance programmes should dictate that all guarding which is removed for repair be replaced as soon as repair work is completed.

Since wet conditions are prevalent in the filling room, adequate drainage is necessary to keep liquid from accumulating on nearby walkways. In order to avoid slip-and-fall injuries, proper efforts must be made to keep floors as dry as possible. While steel-toed shoes usually are not required in the filling room, slip-resistant soles are highly recommended. Shoes should be selected based on the slip coefficient of the sole. Additionally, all electrical equipment should be properly grounded and protected from any moisture. Employees must take precautions to dry the areas around equipment before any electrical work begins.

Good housekeeping practices and routine inspections also are beneficial in keeping the workplace hazard-free. By taking these comparatively simple steps, management can be sure that all equipment is in good operating condition and properly stored. Emergency equipment such as fire extinguishers and eyewash stations also should be inspected for proper operation.

Although most of the chemicals present in bottling plants are not extremely hazardous, every operation uses flammable substances, acids, caustics, corrosives and oxidants. Appropriate work practices should be developed so employees know how to work safely with these chemicals. They must be taught how properly to store, handle and dispose of the chemicals and how to wear protective gear. Training should cover the location and operation of emergency response equipment. Eyewash stations and showers can minimize injury to anyone who is accidentally exposed to a hazardous chemical.

It also is necessary to install equipment such as chemical booms and dykes, as well as absorbent material, to be used in the event of a spill. Properly designed hazardous chemical storage facilities will minimize the risk of employee injury, too. Flammables should be separated from corrosives and oxidants.

The large tanks used for mixing ingredients, which need to be entered and cleaned routinely, are considered confined spaces. See the box on confined spaces in this chapter for information on the related hazards and precautions.

Mechanized equipment has become increasingly complex, often controlled by remote computers, pneumatic lines or even gravity. Employees must be sure that this equipment has been de-energized before it is serviced. Proper de-energizing procedures must be developed to guarantee the safety of those who maintain and repair this equipment. Energy must be shut off and locked out at its source so that the unit being serviced cannot be accidentally energized, causing potentially fatal injuries to service employees or nearby line operators.

Safety training and written de-energizing procedures are critical for each piece of equipment. Emergency stop switches should be strategically placed on all equipment. Interlocked safety devices are used to stop the equipment automatically when doors are opened or light beams are interrupted. Employees must be informed, however, that these devices cannot be relied upon to completely de-energize the equipment, but only to stop it in an emergency. Emergency stop switches cannot take the place of a proven de-energizing procedure for equipment maintenance.

Chlorine, which is used in the water treatment area, could be hazardous in the event of an accidental release. Chlorine typically comes in steel cylinders, which should be stored in an isolated, well-ventilated area and secured from tipping. Employees should be trained to follow safe cylinder-changing procedures. They also should be taught how to take quick, decisive action if an accidental release of chlorine occurs. In the late 1990s new chlorine compounds are gradually replacing the need for chlorine gas. Although still hazardous, these compounds are much safer to handle than gas.

Ammonia is used as a refrigerant in bottling operations. Typically, large ammonia systems can create a health hazard in the event of a leak or a spill. Bottling facilities should develop emergency response procedures to identify the responsibilities of involved employees. Those who are required to respond to such an emergency must be trained in spill response and respirator use. In the event of a leak or spill, respirators should be immediately available, and all non-essential personnel evacuated to safe areas until the situation is controlled.

CO2, which is used in the filling operation, also can create health concerns. If filling rooms and adjacent work areas are not adequately ventilated, CO2 accumulation can displace oxygen in employees’ breathing zones. Facilities should be monitored regularly for elevated CO2 levels and, if they are detected, ventilation systems should be inspected to determine the cause for this occurence. Additional ventilation may be required to correct the situation.

Technological advances have made available better sound-absorption material for insulating or muffling motors and gears in most equipment. Still, given the function and size of filling equipment, noise levels generally exceed 90 dBA in this area. Employees who are exposed to this level of noise for an 8-hour weighted average must be protected. Good hearing protection programmes should include research on better ways to control noise; employee education on related health effects; personal noise protection; and training on how to use hearing protection devices, the wearing of which must be enforced in high-noise areas. Employee hearing must be routinely checked.

Fork-lifts are operated throughout the bottling plant and their safe use is imperative. In addition to demonstrating their driving skills, potential operators must understand fork-lift safety principles. Licenses are commonly issued to show that a minimum level of competency has been achieved. Fork-lift safety programmes should include a pre-use inspection process, whereby the vehicles are checked to ensure that all safety equipment is in place and working. Any deficient conditions should be immediately reported and corrected. Gas or liquid petroleum (LP) fork-lifts generate carbon monoxide as a by-product of combustion. Such emissions can be minimized by keeping the fork-lift engines tuned to manufacturers’ specifications.

Personal protective equipment (PPE) is common throughout the bottling facility. Filling-room employees wear eye and ear protection. Sanitation crews wear face, hand and foot protection that is appropriate for the chemicals they are exposed to. While slip-resistant shoes are recommended throughout the plant, maintenance employees should also have the added protection of steel-toed shoes. The key to a good PPE programme is to identify and evaluate the potential hazards associated with each job and to determine whether those hazards can be eliminated through engineering changes. If not, PPE must be selected to address the specific hazard at hand.

Management’s role is critical in identifying hazards and developing practices and procedures to minimize them in the workplace. Once developed, these practices and procedures must be communicated to employees so that they can perform their jobs safely.

As plant technology continues to advance—providing better equipment, new guards and protective devices—soft drink bottlers will have even more ways to maintain the safety of their workforce.

Soft Drink Concentrate Manufacturing

Process Overview

The making of the concentrate is the first step in the production of a carbonated soft drink. At the beginnings of the industry, in the nineteenth century, both concentrate and soft drink were manufactured in the same facility. Sometimes the concentrate was sold to the consumers, who would make their own soft drinks. As the carbonated soft drink business has grown, the concentrate and the soft drink manufacturing have become specialized. Today, a concentrate manufacturing plant sells its product to various bottling companies.

Concentrate plants are constantly optimizing their operation through systems automation. As the demand for concentrate increases, automation has allowed the manufacturer to satisfy the demand without expanding the size of the manufacturing plant. Packaging size has increased too. Early in the industry, 1/2-, 1- and 5-gallon containers were the most common. Today 40- and 50-gallon drums and even tank trucks with capacities of 3,000 to 4,000 gallons are used.

Operations in a concentrate manufacturing plant can be divided into five basic processes:

- treating water

- receiving raw materials

- concentrate manufacturing

- concentrate and additives filling

- shipping finished products.

Each of these processes has safety hazards that must be evaluated and controlled. Water is a very important ingredient in the concentrate and it must have excellent quality. Each concentrate plant treats water until it reaches the desired quality and is free from micro-organisms. Water treatment is monitored during all stages.

When the plant receives the compounding ingredients, inspection, sampling and analysing of the ingredients in the quality-control department are begun. Only materials that have passed the tests will be used in the concentrate manufacturing process. Some of the raw materials are received in tank trucks and require special handling. Also, packaging material is received, evaluated and analysed in the same way as the raw materials.

During the manufacturing of concentrate, treated water and liquid and solid ingredients are pumped into stainless-steel tanks, where they are mixed, homogenized and/or extracted in accordance with the manufacturing instructions. The tanks have capacities of 50 gallons, 10,000 gallons and even more. These tanks are completely clean and sanitized at the time of mixing.

Once the concentrate is manufactured, the filling stage is started. All the products are piped into the filling room. Filling machines are strictly cleaned and sanitized before the filling process starts. Most of the filling machines are dedicated to specific container sizes. The product is kept inside pipes and tanks at times during the filling process in order to avoid contamination. Each container should be labelled with the product name and handling hazards (if necessary). Full containers are moved by conveyors to the packaging area. Containers are placed on pallets and wrapped in plastic or tied before they are stored. Besides the concentrates, additives to be used in the preparation of carbonated soft drinks are packed. Many of these additives are packed in plastic bags and placed in boxes.

Once at the warehouse, the products are divided and prepared to be sent to the different bottling companies. These products should be labelled following all government regulations. If products are going to another country, the product must be labelled in accordance with the other country’s labelling requirements.

Production of fruit juices

Fruit juices are made from a wide variety of fruits, including oranges and other citrus fruits, apples, grapes, cranberries, pineapples, mangoes and so forth. In many cases, various fruit juices are blended. Usually, the fruit is processed into a concentrate near where it is grown, then shipped to a fruit juice packager. Fruit juices can be sold as concentrates, frozen concentrates (especially orange juice) and as the diluted juice. Often sugar and preservatives are added.

Once received at the processing plant, the oranges are washed, graded to remove damaged fruit, separated according to size and sent to the juice extractors. There the oils are extracted from the peel, and then the juice extracted by crushing. The pulpy juice is screened to remove seeds and pulp, which often end up as cattle feed. If the orange juice is intended for sale as “not from concentrate”, it is then pasteurized. Otherwise the juice is sent to evaporators, which remove most of the water by heat and vacuum, then chilled, to produce the frozen, concentrated orange juice. This process also removes many oils and essences which are blended back into the concentrate before shipping to the juice packager.

The frozen concentrate is shipped to the packager in refrigerated trucks or tankers. Many dairies package orange juice using the same equipment used to package milk. (See the article “Dairy products industry” elsewhere in this volume.) The concentrate is diluted with filtered water, pasteurized and packaged under sterile conditions. Depending on the amount of water added, the final product can be cans of frozen orange juice concentrate or ready-to-serve orange juice.

Michael McCann

Hazard Prevention

Hazards in a concentrate manufacturing plant vary depending on the products manufactured and the size of the plant.

Concentrate plants have a low injury rate due to a high degree of automation and mechanized handling. Materials are handled by fork-lifts, and full containers are placed on pallets by automatic palletizers. Although, employees generally do not have to use excessive force to get the job done, lifting related injuries remain a concern. Major hazards include engines and equipment in motion, objects falling from overhead containers, energy hazards in repair and maintenance, confined space hazards in cleaning mixing tanks, noise, fork-lift accidents and hazardous chemical cleaning agents. See the article “Soft drink bottling and canning” for more information on hazards and precautions.

Production of Fruit Juices

Fruit juices are made from a wide variety of fruits, including oranges and other citrus fruits, apples, grapes, cranberries, pineapples, mangoes and so forth. In many cases, various fruit juices are blended. Usually, the fruit is processed into a concentrate near where it is grown, then shipped to a fruit juice packager. Fruit juices can be sold as concentrates, frozen concentrates (especially orange juice) and as the diluted juice. Often sugar and preservatives are added.

Once received at the processing plant, the oranges are washed, graded to remove damaged fruit, separated according to size and sent to the juice extractors. There the oils are extracted from the peel, and then the juice extracted by crushing. The pulpy juice is screened to remove seeds and pulp, which often end up as cattle feed. If the orange juice is intended for sale as “not from concentrate”, it is then pasteurized. Otherwise the juice is sent to evaporators, which remove most of the water by heat and vacuum, then chilled, to produce the frozen, concentrated orange juice. This process also removes many oils and essences which are blended back into the concentrate before shipping to the juice packager.

The frozen concentrate is shipped to the packager in refrigerated trucks or tankers. Many dairies package orange juice using the same equipment used to package milk. (See the article “Dairy products industry” elsewhere in this volume.) The concentrate is diluted with filtered water, pasteurized and packaged under sterile conditions. Depending on the amount of water added, the final product can be cans of frozen orange juice concentrate or ready-to-serve orange juice.

General Profile

Overview of the Sector

The beverage industry consists of two major categories and eight sub-groups. The non-alcoholic category is comprised of soft drink syrup manufacture; soft drink and water bottling and canning; fruit juices bottling, canning and boxing; the coffee industry and the tea industry. Alcoholic beverage categories include distilled spirits, wine and brewing.

Evolution of the industry

Although many of these beverages, including beer, wine and tea, have been around for thousands of years, the industry has developed only over the past few centuries.

The beverage products industry, viewed as an aggregate group, is highly fragmented. This is evident by the number of manufacturers, methods of packaging, production processes and final products. The soft drink industry is the exception to the rule, as it is quite concentrated. Although the beverage industry is fragmented, ongoing consolidation since the 1970s is changing that.

Since the early 1900s beverage companies have evolved from regional firms that mainly produced goods for local markets, to today’s corporate giants that make products for international markets. This shift began when companies in this manufacturing sector adopted mass production techniques that let them expand. Also during this time period there were advances in product packaging and processes that greatly increased product shelf life. Air-tight containers for tea prevented absorption of moisture, which is the principle cause of loss of flavour. In addition, the advent of refrigeration equipment enabled lager beers to be brewed during the summer months.

Economic importance

The beverage industry employs several million people worldwide, and each type of beverage grosses billions of dollars in revenue each year. Indeed, in several small, developing countries, the production of coffee is the major support of the entire economy.

Characteristics of the Workforce

Though the ingredients and production of beverages vary, generally the characteristics of those employed in this industry have many commonalties. The process of harvesting raw materials, whether they be coffee beans, barley, hops or grapes, employs low-income, unskilled individuals or families. In addition to being their main source of income, the harvest determines a large part of their culture and lifestyle.

In contrast, the processing of the product involves automated and mechanized operations, usually employing a semi-skilled, blue-collar workforce. In the production facility and warehouse areas, some of the common jobs include packaging and filling machine operator, fork-lift operator, mechanic and manual labourer. The training for these positions is completed onsite with extensive on-the-job instruction. As technology and automation evolve, the workforce diminishes in number and technical training becomes more important. This semi-skilled manufacturing workforce is usually supported by a highly skilled technical group consisting of industrial engineers, manufacturing managers, cost accountants and quality assurance/food safety technicians.

The beverage industry for the most part distributes its products to wholesalers using common carriers. However, soft drink manufacturers usually employ drivers to deliver their products directly to individual retailers. These drivers-salesworkers account for about one-seventh of the workers in the soft drink industry.

The more health-conscious atmosphere in Europe and North America in the 1990s has led to a flat market in the alcoholic beverage industry, with demand shifting to non-alcoholic beverages. Both alcoholic and non-alcoholic beverages, however, are expanding considerably in developing nations in Asia, South America and to some extent Africa. Because of this expansion, numerous local jobs are being created to meet production and distribution needs.

Moving Parts of Machines

This article discusses situations and chains of events leading to accidents attributable to contact with the moving part of machines. People who operate and maintain machinery run the risk of being involved in serious accidents. US statistics suggest that 18,000 amputations and over 800 fatalities in the United States each year are assignable to such causes. According to the US National Institute for Occupational Safety and Health (NIOSH), the “caught in, under, or between” category of injuries in their classification ranked highest among the most important kinds of occupational injuries in 1979. Such injuries generally involved machines (Etherton and Myers 1990). “Contact with moving machine part” has been reported as the principal injury event in just over 10% of occupational accidents ever since this category was introduced into Swedish occupational-injury statistics in 1979.

Most machines have moving parts that can cause injury. Such moving parts may be found at the point of operation where work is performed on the material, such as where cutting, shaping, boring or deforming takes place. They may be found in the apparatus which transmits energy to the parts of the machine carrying out the work, such as flywheels, pulleys, connecting rods, couplers, cams, spindles, chains, cranks and gears. They may be found in other moving parts of the machine such as wheels on mobile equipment, gear motors, pumps, compressors and so forth. Hazardous machine movements can also be found among other sorts of machinery, especially in the auxiliary pieces of equipment which handle and transport such loads as work pieces, materials, waste or tools.

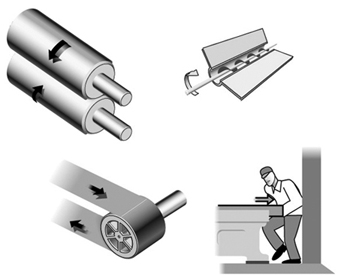

All parts of a machine that move in the course of the performance of work may contribute to accidents causing injury and damages. Both rotating and linear machine movements, as well as their sources of power, can be dangerous:

Rotating motion. Even smooth rotating shafts can grip an item of clothing and, for example, draw a person’s arm into a hazardous position. The danger in a rotating shaft increases if it has projecting parts or uneven or sharp surfaces, such as adjusting screws, bolts, slits, notches or cutting edges. Rotating machine parts give rise to “nip points” in three different ways:

- There are the points between two rotating parts that rotate in opposite directions and have parallel axes, such as gears or cog-wheels, carriage rollers or mangles.

- There are the points of contact between rotating parts and parts in linear movement, such as found between a power-transmission belt and its pulley, a chain and a sprocket, or a rack and pinion.

- Rotating machine movements can give rise to the risk of cuts and crushing injuries when they take place in close proximity to stationary objects—this sort of condition exists between a worm conveyor and its housing, between the spokes of a wheel and the machine bed, or between a grinding wheel and a tool jig.

Linear movements. Vertical, horizontal and reciprocating motion can cause injury in several ways: a person may receive a shove or blow from a machine part, and may be caught between the machine part and some other object, or may be cut by a sharp edge, or sustain a nip injury by being trapped between the moving part and another object (figure 1).

Figure 1. Examples of mechanical movements that can injure a person

Power sources. Frequently, external sources of power are employed to run a machine which may involve considerable quantities of energy. These include electric, steam, hydraulic, pneumatic and mechanical power systems, all of which, if released or uncontrolled, can give rise to serious injuries or damage. A study of accidents that occurred over one year (1987 to 1988) among farmers in nine villages in northern India showed that fodder-cutting machines, all otherwise of the same design, are more dangerous when powered by a motor or tractor. The relative frequency of accidents involving more than a minor injury (per machine) was 5.1 per thousand for manual cutters and 8.6 per thousand for powered cutters (Mohan and Patel 1992).

Injuries Associated with Machine Movements

Since the forces associated with machine movements are often quite large, it can be presumed that the injuries to which they give rise will be serious. This presumption is confirmed by several sources. “Contact with moving machinery or material being machined” accounted for only 5% of all occupational accidents but for as much as 10% of fatal and major accidents (fractures, amputations and so on) according to British statistics (HSE 1989). Studies of two vehicle-manufacturing workplaces in Sweden point in the same direction. Accidents caused by machine movements gave rise to twice the number of days of sick leave, as measured by median values, compared to non-machine-related accidents. Machine-related accidents also differed from other accidents with regard to part of the body injured: The results indicated that 80% of the injuries sustained in “machine” accidents were to the hands and fingers, while the corresponding proportion for “other” accidents was 40% (Backström and Döös 1995).

The risk situation at automated installations has turned out to be both different (in terms of type of accident, sequence of events and degree of injury severity) and more complicated (both in technical terms and with regard to the need for specialized skills) than at installations where conventional machinery is used. The term automated is herein meant to refer to equipment which, without the direct intervention of a human being, can either initiate a machine movement or change its direction or function. Such equipment requires sensor devices (e.g., position sensors or microswitches) and/or some form of sequential controls (e.g., a computer program) to direct and monitor their activities. Over recent decades, a programmable logic controller (PLC) has been increasingly employed as the control unit in production systems. Small computers are now the most common means used for controlling production equipment in the industrialized world, while other means of control, such as electro-mechanical units, are becoming less and less common. In the Swedish manufacturing industry, the use of numerically controlled (NC) machines increased by 11 to 12% per year over the 1980s (Hörte and Lindberg 1989). In modern industrial production, being injured by “moving parts of machines” is increasingly becoming equivalent to being injured by “computer-controlled machine movements”.

Automated installations are found in more and more sectors of industry, and they have an increasing number of functions. Stores management, materials handling, processing, assembly and packaging are all being automated. Series production has come to resemble process production. If the feeding, machining and ejection of work pieces are mechanized, the operator no longer needs to be in the risk zone during the course of regular, undisturbed production. Research studies of automated manufacturing have shown that accidents occur primarily in the handling of disturbances affecting production. However, people can also get in the way of machine movements in performing other tasks, such as cleaning, adjusting, resetting, controlling and repairing.

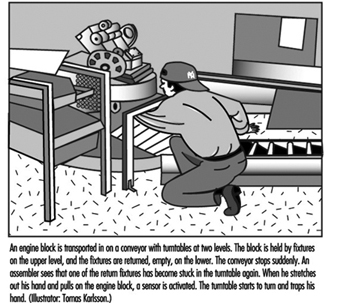

When production is automated and the process is no longer under the direct control of the human being, the risk of unexpected machine movements increases. Most operators who work with groups or lines of inter-linked machines have experienced such unexpected machine movements. Many automation accidents occur as a result of just such movements. An automation accident is an accident in which the automatic equipment controlled (or should have controlled) the energy giving rise to the injury. This means that the force which injures the person comes from the machine itself (e.g., the energy of a machine movement). In a study of 177 automation accidents in Sweden, it was found that injury was caused by the “unexpected start” of a part of a machine in 84% of cases (Backström and Harms-Ringdahl 1984). A typical example of an injury caused by a computer-controlled machine movement is shown in figure 2.

Figure 2. A typical example of an injury caused by a computer-controlled machine movement

One of the studies referred to above (Backström and Döös 1995) showed that automatically controlled machine movements were causally linked to longer periods of sick leave than injuries due to other kinds of machine movements, the median value being four times higher at one of the workplaces. The injury pattern of automation accidents was similar to that for other machine accidents (mainly involving hands and fingers), but the tendency was for the former kind of injuries to be more serious (amputations, crushes and fractures).

Computer control, like manual, has weaknesses from the perspective of reliability. There is no guarantee that a computer program will operate without error. The electronics, with their low signal levels, may be sensitive to interference if not properly protected, and the consequences of resultant failures are not always possible to predict. Furthermore, programming changes are often left undocumented. One method used to compensate for this weakness is, for example, by operating “double” systems in which there are two independent chains of functional components and a method for monitoring such that both chains display the same value. If the systems display different values, this indicates a failure in one of them. But there is a possibility that both chains of components may suffer from the same fault and that they both can be put out of order by the same disturbance, thereby giving a false positive reading (as both systems agree). However, in only a few of the cases investigated has it been possible to trace an accident to computer failure (see below), despite the fact that it is common for a single computer to control all the functions of an installation (even the stopping of a machine as a result of the activation of a safety device). As an alternate, consideration may be given to providing a tried-and-tested system with electro-mechanical components for safety functions.

Technical Problems

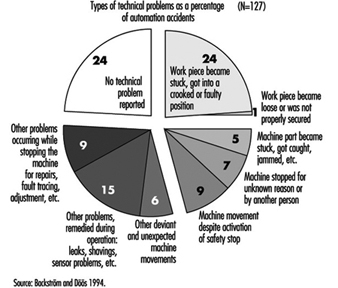

In general, it can be said that a single accident has many causes, including technical, individual, environmental and organizational ones. For preventive purposes, an accident is best looked at not as an isolated event, but as a sequence of events or a process (Backström 1996). In the case of automation accidents, it has been shown that technical problems are frequently part of such a sequence and occur either at one of the early stages of the process or close to the injury event of the accident. Studies in which technical problems involved in automation accidents have been examined suggest that these lie behind 75 to 85% of the accidents. At the same time, in any specific case, there are usually other causes, such as those of an organizational nature. Only in one-tenth of cases has it been found that the direct source of the energy giving rise to an injury could be attributed to technical failure—for example, a machine movement taking place despite the machine’s being in the stop position. Similar figures have been reported in other studies. Usually, a technical problem led to trouble with the equipment, so that the operator had to switch tasks (e.g., to re-position a part that was in a crooked position). The accident then occurred during the implementation of the task, prompted by the technical failure. A quarter of the automation accidents were preceded by a disturbance in the materials flow such as a part becoming stuck or getting into a crooked or otherwise faulty position (see figure 3).

Figure 3. Types of technical problems involved in automation accidents (number of accidents =127)

In a study of 127 accidents involving automation, 28 of these accidents, described in figure 4, were further investigated to determine the types of technical problems which were involved as causal factors (Backström and Döös, in press). The problems specified in the accident investigations were most frequently caused by jammed, defective or worn-out components. In two cases, a problem was caused by a computer-program error, and in one by electromagnetic interference. In more than half of the cases (17 out of 28), faults had been present for some time but not remedied. Only in 5 of the 28 cases where a technical failure or deviation was referred to, had the defect not manifested itself previously. Some faults had been repaired only to reappear later. Certain defects had been present right from the time of installation, while others resulted from wear and the impact of the environment.

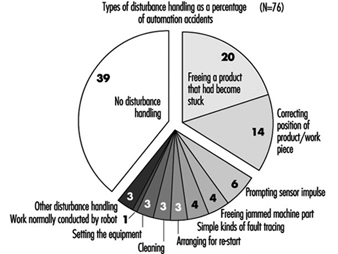

The proportion of automation accidents occurring in the course of the correction of a disturbance to production comes to between one-third and two-thirds of all cases, according to most studies. In other words, there is general agreement that handling production disturbances is a hazardous occupational task. The variation in the extent to which such accidents occur has many explanations, among them those related to the type of production and to how occupational tasks are classified. In some studies of disturbances, only problems and machine stops in the course of regular production have been considered; in others, a wider range of problems have been treated—for example, those involved in the setting up of work.

A very important measure in the prevention of automation accidents is to prepare procedures for removing the causes of production disturbances so that they are not repeated. In a specialized study of production disturbances at time of accident (Döös and Backström 1994), it was found that the most common task to which disturbances gave rise was the freeing or the correcting of the position of a work piece that had become stuck or wrongly placed. This type of problem initiated one of two rather similar sequences of events: (1) the part was freed and came into its correct position, the machine received an automatic signal to start, and the person was injured by the machine movement initiated, (2) there was not time for the part to be freed or repositioned before the person was injured by a machine movement that came unexpectedly, more quickly or was of greater force than the operator expected. Other disturbance-handling involved prompting a sensor impulse, freeing a jammed machine part, carrying out simple kinds of fault tracing, and arranging for restart (see figure 4).

Figure 4. Type of disturbance handling at time of accident (number of accidents =76)

Worker Safety

The categories of personnel which tend to be injured in automation accidents depend on how work is organized—that is, on which occupational group performs the hazardous tasks. In practice, this is a matter of which person at the workplace is assigned to deal with problems and disturbances on a routine basis. In modern Swedish industry, active interventions are usually demanded from the persons operating the machine. This is why, in the previously mentioned vehicle-manufacturing workplace study in Sweden (Backström and Döös, accepted for publication), it was found that 82% of the people who sustained injuries from automated machines were production workers or operators. Operators also had a higher relative accident frequency (15 automation accidents per 1,000 operators per year) than maintenance workers (6 per 1,000). The findings of studies which indicate that maintenance workers are more affected are at least partly to be explained by the fact that operators are not allowed to enter machining areas in some companies. In organizations with a different type of task distribution, other categories of personnel—setters, for example—may be given the task of solving any production problems that arise.

The most common corrective measure taken in this connection in order to raise the level of personal safety is to protect the person from hazardous machine movements by using some kind of safety device, such as machine guarding. The main principle here is that of “passive” safety—that is, the provision of protection that does not require action on the part of the worker. It is, however, impossible to judge the effectiveness of protective devices without very good acquaintance with the actual work requirements at the machine in question, a form of knowledge which is normally possessed only by machine operators themselves.

There are many factors that can put even what is apparently good machine protection out of action. In order to perform their work, operators may need to disengage or circumvent a safety device. In one study (Döös and Backström 1993), it was found that such disengagement or circumvention had taken place in 12 out of 75 of the automation accidents covered. It is often a matter of the operator’s being ambitious, and no longer willing to accept either production problems or the delay to the production process involved in correcting disturbances in accordance with instructions. One way of avoiding this problem is to make the protective device imperceptible, so that it does not affect the pace of production, product quality or task performance. But this is not always possible; and where there are repeated disturbances to production, even minor inconveniences can prompt people not to utilize safety devices. Again, routines should be made available to remove the causes of production disturbances so that these are not repeated. A lack of a means of confirming that safety devices really function according to specifications is a further significant risk factor. Faulty connections, start signals that remain in the system and later give rise to unexpected starts, build-up in air pressure, and sensors that have come loose may all cause failure of protective equipment.

Summary

As has been shown, technical solutions to problems may give rise to new problems. Although injuries are caused by machine movements, which are essentially technical by nature, this does not automatically mean that the potential for their eradication lies in purely technical factors. Technical systems will continue to malfunction, and people will fail to handle the situations to which these malfunctions give rise. The risks will continue to exist, and can be held in check only by a wide variety of means. Legislation and control, organizational measures at individual companies (in the form of training, safety rounds, risk analysis and the reporting of disturbances and near accidents), and an emphasis on steady, ongoing improvements are all needed as complements to purely technical development.

Hand and Portable Power Tool Safety

Tools are such a common part of our lives that it is sometimes difficult to remember that they may pose hazards. All tools are manufactured with safety in mind, but occasionally an accident may occur before tool-related hazards are recognized. Workers must learn to recognize the hazards associated with the different types of tools and the safety precautions required to prevent those hazards. Appropriate personal protective equipment, such as safety goggles or gloves, should be worn for protection from potential hazards that may be encountered while using portable power tools and hand tools.

Hand Tools

Hand tools are non-powered and include everything from axes to wrenches. The greatest hazards posed by hand tools result from misuse, use of the wrong tool for the job, and improper maintenance. Some of the hazards associated with the use of hand tools include but are not limited to the following:

- Using a screwdriver as a chisel may cause the tip of the screwdriver to break off and fly, hitting the user or other employees.

- If a wooden handle on a tool such as a hammer or an axe is loose, splintered or cracked, the head of the tool may fly off and strike the user or another worker.

- A wrench must not be used if its jaws are sprung, because it might slip.

- Impact tools such as chisels, wedges or drift pins are unsafe if they have mushroomed heads which might shatter on impact, sending sharp fragments flying.

The employer is responsible for the safe condition of tools and equipment provided to employees, but the employees have the responsibility to use and maintain the tools properly. Workers should direct saw blades, knives or other tools away from aisle areas and other employees working in close proximity. Knives and scissors must be kept sharp, as dull tools can be more hazardous than sharp ones. (See figure 1.)

Figure 1. A screwdriver

Safety requires that floors be kept as clean and dry as possible to prevent accidental slips when working with or around dangerous hand tools. Although sparks produced by iron and steel hand tools are not normally hot enough to be sources of ignition, when working with or around flammable materials, spark-resistant tools made from brass, plastic, aluminium or wood may be used to prevent spark formation.

Power Tools

Power tools are hazardous when improperly used. There are several types of power tools, usually categorized according to the power source (electric, pneumatic, liquid fuel, hydraulic, steam and explosive powder actuated). Employees should be qualified or trained in the use of all power tools used in their work. They should understand the potential hazards associated with the use of power tools, and observe the following general safety precautions to prevent those hazards from occurring:

- Never carry a tool by the cord or hose.

- Never yank the cord or the hose to disconnect it from the receptacle.

- Keep cords and hoses away from heat, oil and sharp edges.

- Disconnect tools when they are not in use, before servicing, and when changing accessories such as blades, bits and cutters.

- All observers should stay a safe distance away from the work area.

- Secure work with clamps or a vise, freeing both hands to operate the tool.

- Avoid accidental starting. The worker should not hold a finger on the switch button while carrying a plugged-in tool. Tools which have lock-on controls should be disengaged when power is interrupted so that they do not start up automatically upon restoration of power.

- Tools should be maintained with care and kept sharp and clean for best performance. Instructions in the user’s manual should be followed for lubrication and changing accessories.

- Workers should assure they have good footing and balance when using power tools. Appropriate apparel should be worn, as loose clothing, ties or jewellery can become caught in moving parts.

- All portable electric tools that are damaged shall be removed from use and tagged “Do Not Use” to prevent electrical shock.

Protective Guards

Hazardous moving parts of power tools need to be safeguarded. For example, belts, gears, shafts, pulleys, sprockets, spindles, drums, flywheels, chains or other reciprocating, rotating or moving parts of equipment must be guarded if such parts are exposed to contact by workers. Where necessary, guards should be provided to protect the operator and others with respect to hazards associated with:

- the point of operation

- in-running nip points

- rotating and reciprocating parts

- flying chips and sparks, and mist or spray from metal-working fluids.

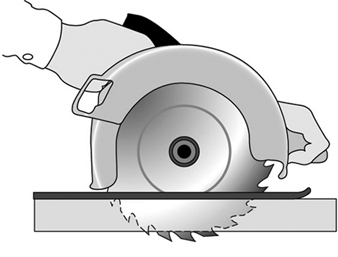

Safety guards must never be removed when a tool is being used. For example, portable circular saws must be equipped with guards. An upper guard must cover the entire blade of the saw. A retractable lower guard must cover the teeth of the saw, except when it makes contact with the work material. The lower guard must automatically return to the covering position when the tool is withdrawn from the work. Note the blade guards in the illustration of a power saw (figure 2).

Figure 2. A circular saw with guard

Safety Switches and Controls

The following are examples of hand-held power tools which must be equipped with a momentary contact “on-off” control switch:

- drills, tappers and fastener drivers

- horizontal, vertical and angle grinders with wheels larger than 2 inches (5.1 cm) in diameter

- disc and belt sanders

- reciprocating and sabre saws.

These tools also may be equipped with a lock-on control, provided that turnoff can be accomplished by a single motion of the same finger or fingers that turn it on.

The following hand-held power tools may be equipped with only a positive “on-off” control switch:

- platen sanders

- disc sanders with discs 2 inches (5.1 cm) or less in diameter

- grinders with wheels 2 inches (5.1 cm) or less in diameter

- routers and planers

- laminate trimmers, nibblers and shears

- scroll saws and jigsaws with blade shanks ¼ inch (0.64 cm) wide or less.

Other hand-held power tools which must be equipped with a constant pressure switch that will shut off the power when the pressure is released include:

- circular saws having a blade diameter greater than 2 inches (5.1 cm)

- chain-saws

- percussion tools without positive accessory-holding means.

Electric Tools

Workers using electric tools must be aware of several dangers. The most serious of these is the possibility of electrocution, followed by burns and slight shocks. Under certain conditions, even a small amount of current can result in fibrillation of the heart which may result in death. A shock also may cause a worker to fall off a ladder or other elevated work surfaces.

To reduce the potential of injury to workers from shock, tools must be protected by at least one of the following means:

- Grounded by a three-wire cord (with a ground wire). Three-wire cords contain two current-carrying conductors and a grounding conductor. One end of the grounding conductor connects to the tool’s metal housing. The other end is grounded through a prong on the plug. Any time an adapter is used to accommodate a two-hole receptacle, the adapter wire must be attached to a known ground. The third prong should never be removed from the plug. (See figure 3.)

- Double insulated. The worker and the tools are protected in two ways: (1) by normal insulation on the wires inside, and (2) by a housing that cannot conduct electricity to the operator in the event of a malfunction.

- Powered by a low-voltage isolation transformer.

- Connected through ground fault circuit interrupters. These are permanent and portable devices which instantaneously disconnect a circuit when it seeks ground through a worker’s body or through grounded objects.

These general safety practices should be followed in using electric tools:

- Electric tools should be operated within their design limitations.

- Gloves and safety footwear are recommended during use of electric tools.

- When not in use, tools should be stored in a dry place.

- Tools should not be used if wires or connectors are frayed, bent or damaged.

- Electric tools should not be used in damp or wet locations.

- Work areas should be well lighted.

Powered Abrasive Wheels

Powered abrasive grinding, cutting, polishing and wire buffing wheels create special safety problems because the wheels may disintegrate and throw off flying fragments.

Before abrasive wheels are mounted, they should be inspected closely and sound (or ring) tested by tapping gently with a light non-metallic instrument to be sure that they are free from cracks or defects. If wheels are cracked or sound dead, they could fly apart in operation and must not be used. A sound and undamaged wheel will give a clear metallic tone or “ring”.

To prevent the wheel from cracking, the user should be sure it fits freely on the spindle. The spindle nut must be tightened enough to hold the wheel in place without distorting the flange. Follow the manufacturer’s recommendations. Care must be taken to assure that the spindle wheel will not exceed the abrasive wheel specifications. Due to the possibility of a wheel disintegrating (exploding) during start-up, the worker should never stand directly in front of the wheel as it accelerates to full operating speed. Portable grinding tools need to be equipped with safety guards to protect workers not only from the moving wheel surface, but also from flying fragments in case of breakage. In addition, when using a powered grinder, these precautions should be observed:

- Always use eye protection.

- Turn off the power when tool is not in use.

- Never clamp a hand-held grinder in a vise.

Pneumatic Tools

Pneumatic tools are powered by compressed air and include chippers, drills, hammers and sanders. Although there are several potential dangers encountered in the use of pneumatic tools, the main one is the danger of getting hit by one of the tool’s attachments or by some kind of fastener the worker is using with the tool. Eye protection is required and face protection is recommended when working with pneumatic tools. Noise is another hazard. Working with noisy tools such as jackhammers requires proper, effective use of appropriate hearing protection.

When using a pneumatic tool, the worker must check to assure that it is fastened securely to the hose to prevent a disconnection. A short wire or positive locking device attaching the air hose to the tool will serve as an added safeguard. If an air hose is more than½ inch (1.27 cm) in diameter, a safety excess flow valve should be installed at the source of the air supply to shut off the air automatically in case the hose breaks. In general, the same precautions should be taken with an air hose that are recommended for electric cords, because the hose is subject to the same kind of damage or accidental striking, and it also presents a tripping hazard.

Compressed-air guns should never be pointed toward anyone. Workers should never “dead-end” the nozzle against themselves or anyone else. A safety clip or retainer should be installed to prevent attachments, such as a chisel on a chipping hammer, from being unintentionally shot from the barrel. Screens should be set up to protect nearby workers from being struck by flying fragments around chippers, riveting guns, air hammers, staplers or air drills.

Airless spray guns that atomize paints and fluids at high pressures (1,000 pounds or more per square inch) must be equipped with automatic or manual visual safety devices that will prevent activation until the safety device is manually released. Heavy jackhammers can cause fatigue and strains which may be reduced by the use of heavy rubber grips that provide a secure handhold. A worker operating a jackhammer must wear safety glasses and safety shoes to protect against injury if the hammer slips or falls. A face shield also should be used.

Fuel-Powered Tools

Fuel-powered tools are usually operated using small gasoline-powered internal combustion motors. The most serious potential dangers associated with the use of fuel-powered tools comes from hazardous fuel vapours that can burn or explode and give off dangerous exhaust fumes. The worker must be careful to handle, transport and store the gasoline or fuel only in approved flammable liquid containers, according to proper procedures for flammable liquids. Before the tank for a fuel-powered tool is refilled, the user must shut down the engine and allow it to cool to prevent accidental ignition of hazardous vapours. If a fuel-powered tool is used inside a closed area, effective ventilation and/or protective equipment is necessary to prevent exposure to carbon monoxide. Fire extinguishers must be available in the area.

Explosive Powder-Actuated Tools

Explosive powder-actuated tools operate like a loaded gun and should be treated with the same respect and precautions. In fact, they are so dangerous that they must be operated only by specially trained or qualified employees. Suitable ear, eye and face protection are essential when using a powder-actuated tool. All powder-actuated tools should be designed for varying powder charges so that the user can select a powder level necessary to do the work without excessive force.

The muzzle end of the tool should have a protective shield or guard centred perpendicularly on the barrel to protect the user from any flying fragments or particles that might create a hazard when the tool is fired. The tool must be designed so that it will not fire unless it has this kind of safety device. To prevent the tool from firing accidentally, two separate motions are required for firing: one to bring the tool into position, and another to pull the trigger. The tools must not be able to operate until they are pressed against the work surface with a force at least 5 pounds greater than the total weight of the tool.

If a powder-actuated tool misfires, the user should wait at least 30 seconds before trying to fire it again. If it still will not fire, the user should wait at least another 30 seconds so that the faulty cartridge is less likely to explode, then carefully remove the load. The bad cartridge should be put in water or otherwise safely disposed of in accordance with employer’s procedures.

If a powder-actuated tool develops a defect during use, it should be tagged and taken out of service immediately until it is properly repaired. Precautions for the safe use and handling of powder-actuated tools include the following:

- Powder-actuated tools should not be used in explosive or flammable atmospheres except upon issuance of a hot-work permit by an authorized person.

- Before using the tool, the worker should inspect it to determine that it is clean, that all moving parts operate freely and that the barrel is free from obstructions.

- The tool should never be pointed at anybody.

- The tool should not be loaded unless it is to be used immediately. A loaded tool should not be left unattended, especially where it may be available to unauthorized persons.

- Hands should be kept clear of the barrel end.

In using powder-actuated tools to apply fasteners, the following safety precautions should be considered:

- Do not fire fasteners into material that would let them pass through to the other side.

- Do not drive fasteners into materials like brick or concrete any closer than 3 inches (7.6 cm) to an edge or corner, or into steel any closer than ½ inch (1.27 cm) to a corner or edge.

- Do not drive fasteners into very hard or brittle material that might chip, shatter or make the fasteners ricochet.

- Use an alignment guide when shooting fasteners into existing holes. Do not drive fasteners into a spalled area caused by an unsatisfactory fastening.

Hydraulic Power Tools

The fluid used in hydraulic power tools must be approved for the expected use and must retain its operating characteristics at the most extreme temperatures to which it will be exposed. The manufacturer’s recommended safe operating pressure for hoses, valves, pipes, filters and other fittings must not be exceeded. Where there is a potential for a leak under high pressure in an area where sources of ignition, such as open flames or hot surfaces, may be present, the use of fire-resistant fluids as the hydraulic medium should be considered.

Jacks

All jacks—lever and ratchet jacks, screw jacks and hydraulic jacks—must have a device that stops them from jacking up too high. The manufacturer’s load limit must be permanently marked in a prominent place on the jack and should not be exceeded. Use wooden blocking under the base if necessary to make the jack level and secure. If the lift surface is metal, place a 1-inch-thick (2.54 cm) hardwood block or equivalent between the underside of the surface and the metal jack head to reduce the danger of slippage. A jack should never be used to support a lifted load. Once the load has been lifted, it should immediately be supported by blocks.

To set up a jack, make certain of the following conditions:

- The base rests on a firm level surface.

- The jack is correctly centred.

- The jack head bears against a level surface.

- The lift force is applied evenly.

Proper maintenance of jacks is essential for safety. All jacks must be inspected before each use and lubricated regularly. If a jack is subjected to an abnormal load or shock, it should be thoroughly examined to make sure it has not been damaged. Hydraulic jacks exposed to freezing temperatures must be filled with an adequate antifreeze liquid.

Summary

Workers who use hand and power tools and who are exposed to the hazards of falling, flying, abrasive and splashing objects and materials, or to hazards of harmful dusts, fumes, mists, vapours or gases, must be provided with the appropriate personal equipment necessary to protect them from the hazard. All hazards involved in the use of power tools can be prevented by workers following five basic safety rules:

- Keep all tools in good condition with regular maintenance.

- Use the right tool for the job.

- Examine each tool for damage before use.

- Operate tools according to the manufacturer’s instructions.

- Select and use appropriate protective equipment.

Employees and employers have a responsibility to work together to maintain established safe work practices. If a an unsafe tool or hazardous situation is encountered, it should be brought to the attention of the proper individual immediately.

Systems Analysis

A system can be defined as a set of interdependent components combined in such a way as to perform a given function under specified conditions. A machine is a tangible and particularly clear-cut example of a system in this sense, but there are other systems, involving men and women on a team or in a workshop or factory, which are far more complex and not so easy to define. Safety suggests the absence of danger or risk of accident or harm. In order to avoid ambiguity, the general concept of an unwanted occurrence will be employed. Absolute safety, in the sense of the impossibility of a more or less unfortunate incident occurring, is not attainable; realistically one must aim for a very low, rather than a zero probability of unwanted occurrences.

A given system may be looked upon as safe or unsafe only with respect to the performance that is actually expected from it. With this in mind, the safety level of a system can be defined as follows: “For any given set of unwanted occurrences, the level of safety (or unsafeness) of a system is determined by the probability of these occurrences taking place over a given period of time”. Examples of unwanted occurrences that would be of interest in the present connection include: multiple fatalities, death of one or several persons, serious injury, slight injury, damage to the environment, harmful effects on living beings, destruction of plants or buildings, and major or limited material or equipment damage.

Purpose of the Safety System Analysis

The object of a system safety analysis is to ascertain the factors which have a bearing on the probability of the unwanted occurrences, to study the way in which these occurrences take place and, ultimately, to develop preventive measures to reduce their probability.

The analytic phase of the problem can be divided into two main aspects:

- identification and description of the types of dysfunction or maladjustment

- identification of the sequences of dysfunctions that combine one with another (or with more “normal” occurrences) to lead ultimately to the unwanted occurrence itself, and the assessment of their likelihood.

Once the various dysfunctions and their consequences have been studied, the system safety analysts can direct their attention to preventive measures. Research in this area will be based directly on earlier findings. This investigation of preventive means follows the two main aspects of the system safety analysis.

Methods of Analysis

System safety analysis may be conducted before or after the event (a priori or a posteriori); in both instances, the method used may be either direct or reverse. An a priori analysis takes place before the unwanted occurrence. The analyst takes a certain number of such occurrences and sets out to discover the various stages that may lead up to them. By contrast, an a posteriori analysis is carried out after the unwanted occurrence has taken place. Its purpose is to provide guidance for the future and, specifically, to draw any conclusions that may be useful for any subsequent a priori analyses.

Although it may seem that an a priori analysis would be very much more valuable than an a posteriori analysis, since it precedes the incident, the two are in fact complementary. Which method is used depends on the complexity of the system involved and on what is already known about the subject. In the case of tangible systems such as machines or industrial facilities, previous experience can usually serve in preparing a fairly detailed a priori analysis. However, even then the analysis is not necessarily infallible and is sure to benefit from a subsequent a posteriori analysis based essentially on a study of the incidents that occur in the course of operation. As to more complex systems involving persons, such as work shifts, workshops or factories, a posteriori analysis is even more important. In such cases, past experience is not always sufficient to permit detailed and reliable a priori analysis.

An a posteriori analysis may develop into an a priori analysis as the analyst goes beyond the single process that led up to the incident in question and starts to look into the various occurrences that could reasonably lead to such an incident or similar incidents.

Another way in which an a posteriori analysis can become an a priori analysis is when the emphasis is placed not on the occurrence (whose prevention is the main purpose of the current analysis) but on less serious incidents. These incidents, such as technical hitches, material damage and potential or minor accidents, of relatively little significance in themselves, can be identified as warning signs of more serious occurrences. In such cases, although carried out after the occurrence of minor incidents, the analysis will be an a priori analysis as regards more serious occurrences that have not yet taken place.

There are two possible methods of studying the mechanism or logic behind the sequence of two or more events:

- The direct, or inductive, method starts with the causes in order to predict their effects.

- The reverse, or deductive, method looks at the effects and works backwards to the causes.

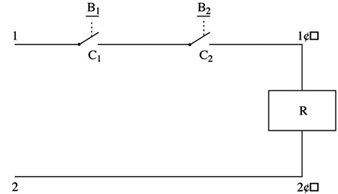

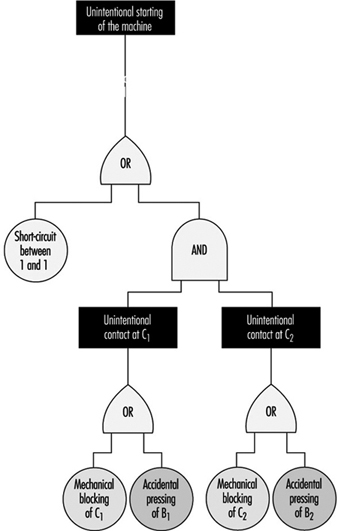

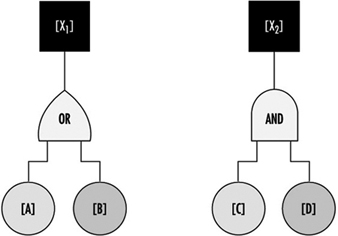

Figure 1 is a diagram of a control circuit requiring two buttons (B1 and B2) to be pressed simultaneously in order to activate the relay coil (R) and start the machine. This example may be used to illustrate, in practical terms, the direct and reverse methods used in system safety analysis.

Figure 1. Two-button control circuit

Direct method

In the direct method, the analyst begins by (1) listing faults, dysfunctions and maladjustments, (2) studying their effects and (3) determining whether or not those effects are a threat to safety. In the case of figure 1, the following faults may occur:

- a break in the wire between 2 and 2´

- unintentional contact at C1 (or C2) as a result of mechanical blocking

- accidental closing of B1 (or B2)

- short circuit between 1 and 1´.

The analyst can then deduce the consequences of these faults, and the findings can be set out in tabular form (table 1).

Table 1. Possible dysfunctions of a two-button control circuit and their consequences

|

Faults |

Consequences |

|

Break in the wire between 2 and 2’ |

Impossible to start the machine* |

|

Accidental closing of B1 (or B2 ) |

No immediate consequence |

|

Contact at C1 (or C2 ) as a result of |

No immediate consequence but possibility of the |

|

Short circuit between 1 and 1’ |

Activation of relay coil R—accidental starting of |

* Occurrence with a direct influence on the reliability of the system

** Occurrence responsible for a serious reduction in the safety level of the system

*** Dangerous occurrence to be avoided

See text and figure 1.

In table 1 consequences which are dangerous or liable to seriously reduce the safety level of the system can be designated by conventional signs such as ***.

Note: In table 1 a break in the wire between 2 and 2´ (shown in figure 1) results in an occurrence that is not considered dangerous. It has no direct effect on the safety of the system; however, the probability of such an incident occurring has a direct bearing on the reliability of the system.