Actors

Acting involves placing your mind in the world of fantasy and bringing forth a character for a performance. Actors are involved in many arts and entertainment areas, including theatre, film, television, amusement and theme parks and so on. Hazards faced by actors include stress, physical hazards and chemical hazards. Stage fright (performance anxiety) is considered in a separate article.

Stress

Causes of stress include the fierce competition for scarce jobs, the pressure of performing shows daily or even more frequently (e.g., theme parks and matinee days), working at night, touring shows, filming deadlines, frequent retakes (especially while filming television commercials) and so on. There are also psychological pressures involved in adopting and maintaining a character role, including the pressure to express certain emotions upon demand, and the tactics often used by directors to obtain a given reaction from an actor. As a result, actors have higher rates of alcoholism and suicide. The solution to many of these causes of stress involves improved working and living conditions, especially when touring and on location. In addition, personal measures such as therapy and relaxation techniques can also help.

Costumes

Many costumes are a fire hazard near open flames or other ignition sources. Special effects costumes and masks can create problems of heat stress and excess weight.

The costumes of all actors working near open flames must be treated with an approved fire retardant. Actors wearing heavy costumes or costumes not suitable to the climate should be given adequate work breaks. With heavy metal or wood framework costumes, supplying cool air inside the costume might be necessary. Provision should also be made for easy escape from such costumes in case of emergency.

Theatrical Makeup

Theatrical makeup can cause allergic skin and eye reactions and irritation in some people. The widespread practice of sharing makeup or applying it to many people from the same container can create risks of transmitting bacterial infections. According to medical experts, transmission of the HIV and other viruses is not likely through shared makeup. The use of hair sprays and other spray products in unventilated dressing rooms is also a problem. Special effects makeup can involve the use of more hazardous materials such as polyurethane and silicone rubber resins and a variety of solvents.

Basic precautions when applying makeup include washing hands before and after; not using old makeup; no smoking, eating or drinking during application; using potable water and not saliva for moistening brushes; avoiding creation of airborne dust; and using pump sprays instead of aerosol sprays. Each performer should have his or her own makeup kit when practical. When applying makeup to several individuals, disposable sponges, brushes and individual applicators, individual lipsticks (or sliced and labelled lipsticks) and so on should be used. The least toxic materials possible should be used for special effects makeup. The dressing room should have a mirror, good lighting and comfortable chairs.

Stunts

A stunt can be defined as any action sequence that involves a greater than normal risk of injury to performers or others on the set. In many such situations, actors are doubled by stunt performers who have extensive experience and training in carrying out such action sequences. Examples of potentially hazardous stunts include falls, fights, helicopter scenes, car chases, fires and explosions. Careful preplanning and written safety procedures are necessary. See the article “Motion picture and television production” for detailed information on stunts.

Other Hazards

Other hazards to actors, especially on location, include environmental conditions (heat, cold, polluted water, etc.), water scenes with possible risk of hypothermia and special effects (fogs and smoke, pyrotechnics, etc.). Special consideration must be given to these factors before filming starts. In theatres, scenes with dirt, gravel, artificial snow and so on can create eye and respiratory irritation problems when hazardous materials are used, or when materials are swept up and reused, resulting in possible biological contamination. An additional hazard is the growing phenomenon of stalking of well-known actors, actresses and other celebrities, with resultant threats or actuality of violence.

Child Actors

The use of children in theatre and motion picture production can lead to exploitation unless careful procedures are enforced to ensure that children do not work long hours, are not placed in hazardous situations and receive adequate education. Concern has also been expressed about the psychological effects on children participating in theatre or motion picture scenes involving simulated violence. Child labour laws in many countries do not adequately protect child actors.

Performance Anxiety

Performance anxiety is, like fear, joy or grief, an emotion which includes physical and psychological components. Motor responses, autonomic reactions, memories, ideas and thoughts continuously interact. Performance anxiety is no longer thought of as an isolated symptom but rather as a syndrome comprising attitudes, traits and unconscious conflicts that become activated in particular circumstances.

Nearly every person must deal with performance anxiety in one form or another at one time or another. By the nature of their profession, however, performing artists, or those for whom public performance is an important part of their profession, have to deal with performance anxiety more frequently and often more intensely than do others. Even those with years of experience may still have a performance anxiety problem.

Performance anxiety is mainly characterized by an irrational situational anxiety accompanied by unwanted physical symptoms which can lead to dysfunction and/or uncontrolled behaviour. It occurs especially in those situations in which a task has to be done that could subject the performer to possible criticism from others. Examples of such situations include public speaking, giving a concert, writing exams, sexual performance, etc. Performance anxiety can cause a broad range of possible physical symptoms of distress, such as trembling hands, trembling lips, diarrhoea, sweating hands and palpitations of the heart. These symptoms can not only affect the quality of a performance but may also negatively influence the sufferer’s future and career.

Some experts believe that the causes of performance anxiety include improper practice and preparation habits, insufficient performance experience, having an inappropriate repertoire and so on. Other theories view performance anxiety as mainly caused by negative thoughts and poor self-esteem. Still others are of the opinion that the stress and fear of performance anxiety is closely related to so-called career stress, which includes feelings of inadequacy, anticipation of punishment or criticism and loss of status. Although there is no agreement as to the cause of performance anxiety, and the explanation cannot be simple, it is clear that the problem is widespread and that even world-famous artists such as Yehudi Menuhin or Pablo Casals are known to have suffered from performance anxiety and fear all their lives.

Personal traits are undoubtedly related to performance anxiety. A challenge for one person can be a catastrophe for another. The experience of performance anxiety depends to a great extent on the personal perception of a fearful situation. Some introverted individuals may, for example, be more prone to stressful events and thus more likely to suffer performance anxiety than others. For some people, success can also cause fear and performance anxiety. This in turn reduces and undermines the communicative and creative aspects of the performer.

To achieve an optimum performance a bit of fear and stress and a certain amount of nervousness may be unavoidable. The margin between the degree of (still) acceptable performance anxiety and the necessity of therapeutic intervention, however, can be set only by the performer.

Performance anxiety is a complex phenomenon; its various components lead to variable and changing reactions depending on the situation. Individual aspects, work situations, social factors, personal development and so on play a considerable role, making it difficult to give general rules.

Methods for diminishing performance anxiety include developing personal coping strategies or learning relaxation techniques such as biofeedback. Such approaches are directed towards transforming task-irrelevant negative thoughts and worrisome anticipations into task-relevant demands and the positive task-orientated self. Medical interventions, such as beta-blockers and tranquillizers are also commonly used (Nubé 1995). The taking of drugs however, remains controversial and should be done only under medical supervision due to possible side effects and contra-indications.

Radiation Biology and Biological Effects

After its discovery by Roentgen in 1895, the x ray was introduced so rapidly into the diagnosis and treatment of disease that injuries from excessive radiation exposure began to be encountered almost immediately in pioneer radiation workers, who had yet to become aware of the dangers (Brown 1933). The first such injuries were predominantly skin reactions on the hands of those working with the early radiation equipment, but within a decade many other types of injury also had been reported, including the first cancers attributed to radiation (Stone 1959).

Throughout the century since these early findings, study of the biological effects of ionizing radiation has received continuing impetus from the growing uses of radiation in medicine, science and industry, as well as from the peaceful and military applications of atomic energy. As a result, the biological effects of radiation have been investigated more thoroughly than those of virtually any other environmental agent. The evolving knowledge of radiation effects has been influential in shaping measures for the protection of human health against many other environmental hazards as well as radiation.

Nature and Mechanisms of the Biological Effects of Radiation

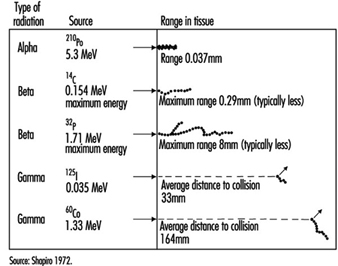

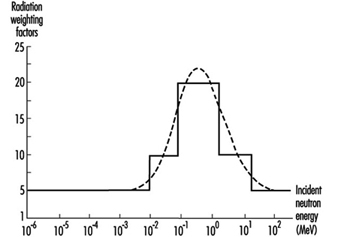

Energy deposition. In contrast to other forms of radiation, ionizing radiation is capable of depositing enough localized energy to dislodge electrons from the atoms with which it interacts. Thus, as radiation collides randomly with atoms and molecules in passing through living cells, it gives rise to ions and free radicals which break chemical bonds and cause other molecular changes that injure the affected cells. The spatial distribution of the ionizing events depends on the radiation weighting factor, w R of the radiation (see table 1 and figure 1).

Table 1. Radiation weighting factors wR

|

Type and energy range |

wR 1 |

|

Photons, all energies |

1 |

|

Electrons and muons, all energies2 |

1 |

|

Neutrons, energy <10 keV |

5 |

|

10 keV to 100 keV |

10 |

|

>100 keV to 2 MeV |

20 |

|

>2 MeV to 20 MeV |

10 |

|

>20 MeV |

5 |

|

Protons, other than recoil protons, energy >2 MeV |

5 |

|

Alpha particles, fission fragments, heavy nuclei |

20 |

1 All values relate to the radiation incident on the body or, for internal sources, emitted from the source.

2 Excluding Auger electrons emitted from nuclei bound to DNA.

Figure 1. Differences among various types of ionizing radiation in penetrating power in tissue

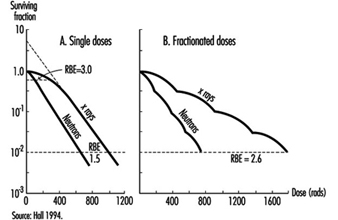

Effects on DNA. Any molecule in the cell may be altered by radiation, but DNA is the most critical biological target because of the limited redundancy of the genetic information it contains. An absorbed dose of radiation large enough to kill the average dividing cell—2 gray (Gy)—suffices to cause hundreds of lesions in its DNA molecules (Ward 1988). Most such lesions are reparable, but those produced by a densely ionizing radiation (for example, a proton or an alpha particle) are generally less reparable than those produced by a sparsely ionizing radiation (for example, an x ray or a gamma ray) (Goodhead 1988). Densely ionizing (high LET) radiations, therefore, typically have a higher relative biological effectiveness (RBE) than sparsely ionizing (low LET) radiations for most forms of injury (ICRP 1991).

Effects on genes. Damage to DNA that remains unrepaired or is misrepaired may be expressed in the form of mutations, the frequency of which appears to increase as a linear, non-threshold function of the dose, approximately 10–5 to 10–6 per locus per Gy (NAS 1990). The fact that the mutation rate appears to be proportional to the dose is interpreted to signify that traversal of the DNA by a single ionizing particle may, in principle, suffice to cause a mutation (NAS 1990). In Chernobyl accident victims, the dose-response relationship for glycophorin mutations in bone marrow cells closely resembles that observed in atomic bomb survivors (Jensen, Langlois and Bigbee 1995).

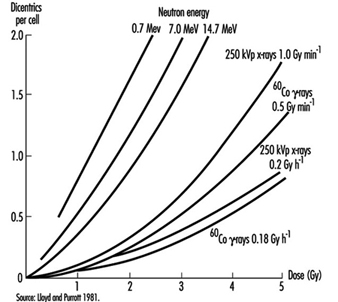

Effects on chromosomes. Radiation damage to the genetic apparatus may also cause changes in chromosome number and structure, the frequency of which has been observed to increase with the dose in radiation workers, atomic bomb survivors, and others exposed to ionizing radiation. The dose-response relationship for chromosome aberrations in human blood lymphocytes (figure 2) has been characterized well enough so that the frequency of aberrations in such cells can serve as a useful biological dosimeter (IAEA 1986).

Figure 2. Frequency of dicentric chromosome aberrations in human lymphocytes in relation to dose, dose rate, and quality of irradiation in vitro

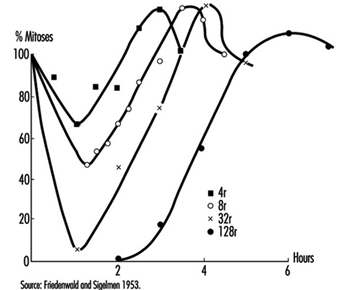

Effects on cell survival. Among the earliest reactions to irradiation is the inhibition of cell division, which appears promptly after exposure, varying both in degree and duration with the dose (figure 3). Although the inhibition of mitosis is characteristically transitory, radiation damage to genes and chromosomes may be lethal to dividing cells, which are highly radiosensitive as a class (ICRP 1984). Measured in terms of proliferative capacity, the survival of dividing cells tends to decrease exponentially with increasing dose, 1 to 2 Gy generally sufficing to reduce the surviving population by about 50% (figure 4).

Figure 3. Mitotic inhibition induced by x rays in rat corneal epithelial cells

Figure 4. Typical dose-survival curves for mammalian cells exposed to x rays and fast neutrons

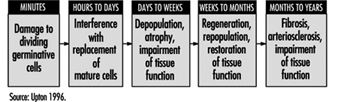

Effects on tissues. Mature, non-dividing cells are relatively radioresistant, but the dividing cells in a tissue are radiosensitive and may be killed in sufficient numbers by intensive irradiation to cause the tissue to become atrophic (figure 5). The rapidity of such atrophy depends on cell population dynamics within the affected tissue; that is, in organs characterized by slow cell turnover, such as the liver and vascular endothelium, the process is typically much slower than in organs characterized by rapid cell turnover, such as the bone marrow, epidermis and intestinal mucosa (ICRP 1984). It is noteworthy, moreover, that if the volume of tissue irradiated is sufficiently small, or if the dose is accumulated gradually enough, the severity of injury may be greatly reduced by the compensatory proliferation of surviving cells.

Figure 5. Characteristic sequence of events in the pathogenesis of nonstochastic effects of ionizing radiation

Clinical Manifestations of Injury

Types of effects. Radiation effects encompass a wide variety of reactions, varying markedly in their dose-response relationships, clinical manifestations, timing and prognosis (Mettler and Upton 1995). The effects are often subdivided, for convenience, into two broad categories: (1) heritable effects, which are expressed in the descendants of exposed individuals, and (2) somatic effects, which are expressed in exposed individuals themselves. The latter include acute effects, which occur relatively soon after irradiation, as well as late (or chronic) effects, such as cancer, which may not appear until months, years or decades later.

Acute effects. The acute effects of radiation result predominantly from the depletion of progenitor cells in affected tissues (figure 5) and can be elicited only by doses that are large enough to kill many such cells (for example, table 2). For this reason, such effects are viewed as nonstochastic, or deterministic, in nature (ICRP 1984 and 1991), in contradistinction to the mutagenic and carcinogenic effects of radiation, which are viewed as stochastic phenomena resulting from random molecular alterations in individual cells that increase as linear-nonthreshold functions of the dose (NAS 1990; ICRP 1991).

Table 2. Approximate threshold doses of conventionally fractionated therapeutic x-radiation for clinically detrimental nonstochastic effects in various tissues

|

Organ |

Injury at 5 years |

Threshold |

Irradiation |

|

Skin |

Ulcer, severe fibrosis |

55 |

100 cm2 |

|

Oral mucosa |

Ulcer, severe fibrosis |

60 |

50 cm2 |

|

Oesophagus |

Ulcer, stricture |

60 |

75 cm2 |

|

Stomach |

Ulcer, perforation |

45 |

100 cm2 |

|

Small intestine |

Ulcer, stricture |

45 |

100 cm2 |

|

Colon |

Ulcer, stricture |

45 |

100 cm2 |

|

Rectum |

Ulcer, stricture |

55 |

100 cm2 |

|

Salivary glands |

Xerostomia |

50 |

50 cm2 |

|

Liver |

Liver failure, ascites |

35 |

whole |

|

Kidney |

Nephrosclerosis |

23 |

whole |

|

Urinary bladder |

Ulcer, contracture |

60 |

whole |

|

Testes |

Permanent sterility |

5-15 |

whole |

|

Ovary |

Permanent sterility |

2-3 |

whole |

|

Uterus |

Necrosis, perforation |

>100 |

whole |

|

Vagina |

Ulcer, fistula |

90 |

5 cm2 |

|

Breast, child |

Hypoplasia |

10 |

5 cm2 |

|

Breast, adult |

Atrophy, necrosis |

>50 |

whole |

|

Lung |

Pneumonitis, fibrosis |

40 |

lobe |

|

Capillaries |

Telangiectasis, fibrosis |

50-60 |

s |

|

Heart |

Pericarditis, pancarditis |

40 |

whole |

|

Bone, child |

Arrested growth |

20 |

10 cm2 |

|

Bone, adult |

Necrosis, fracture |

60 |

10 cm2 |

|

Cartilage, child |

Arrested growth |

10 |

whole |

|

Cartilage, adult |

Necrosis |

60 |

whole |

|

Central nervous system (brain) |

Necrosis |

50 |

whole |

|

Spinal cord |

Necrosis, transection |

50 |

5 cm2 |

|

Eye |

Panophthalmitis, haemorrhage |

55 |

whole |

|

Cornea |

Keratitis |

50 |

whole |

|

Lens |

Cataract |

5 |

whole |

|

Ear (inner) |

Deafness |

>60 |

whole |

|

Thyroid |

Hypothyroidism |

45 |

whole |

|

Adrenal |

Hypoadrenalism |

>60 |

whole |

|

Pituitary |

Hypopituitarism |

45 |

whole |

|

Muscle, child |

Hypoplasia |

20-30 |

whole |

|

Muscle, adult |

Atrophy |

>100 |

whole |

|

Bone marrow |

Hypoplasia |

2 |

whole |

|

Bone marrow |

Hypoplasia, fibrosis |

20 |

localized |

|

Lymph nodes |

Atrophy |

33-45 |

s |

|

Lymphatics |

Sclerosis |

50 |

s |

|

Foetus |

Death |

2 |

whole |

* Dose causing effect in 1-5 per cent of exposed persons.

Source: Rubin and Casarett 1972.

Acute injuries of the types that were prevalent in pioneer radiation workers and early radiotherapy patients have been largely eliminated by improvements in safety precautions and treatment methods. Nevertheless, most patients treated with radiation today still experience some injury of the normal tissue that is irradiated. In addition, serious radiation accidents continue to occur. For example, some 285 nuclear reactor accidents (excluding the Chernobyl accident) were reported in various countries between 1945 and 1987, irradiating more than 1,350 persons, 33 of them fatally (Lushbaugh, Fry and Ricks 1987). The Chernobyl accident alone released enough radioactive material to require the evacuation of tens of thousands of people and farm animals from the surrounding area, and it caused radiation sickness and burns in more than 200 emergency personnel and fire-fighters, injuring 31 fatally (UNSCEAR 1988). The long-term health effects of the radioactive material released cannot be predicted with certainty, but estimates of the resulting risks of carcinogenic effects, based on nonthreshold dose-incidence models (discussed below), imply that up to 30,000 additional cancer deaths may occur in the population of the northern hemisphere during the next 70 years as a result of the accident, although the additional cancers in any given country are likely to be too few to be detectable epidemiologically (USDOE 1987).

Less catastrophic, but far more numerous, than reactor accidents have been accidents involving medical and industrial gamma ray sources, which also have caused injuries and loss of life. For example, the improper disposal of a caesium-137 radiotherapy source in Goiânia, Brazil, in 1987, resulted in the irradiation of dozens of unsuspecting victims, four of them fatally (UNSCEAR 1993).

A comprehensive discussion of radiation injuries is beyond the scope of this review, but acute reactions of the more radiosensitive tissues are of widespread interest and are, therefore, described briefly in the following sections.

Skin. Cells in the germinal layer of the epidermis are highly radiosensitive. As a result, rapid exposure of the skin to a dose of 6 Sv or more causes erythema (reddening) in the exposed area, which appears within a day or so, typically lasts a few hours, and is followed two to four weeks later by one or more waves of deeper and more prolonged erythema, as well as by epilation (hair loss). If the dose exceeds 10 to 20 Sv, blistering, necrosis and ulceration may ensue within two to four weeks, followed by fibrosis of the underlying dermis and vasculature, which may lead to atrophy and a second wave of ulceration months or years later (ICRP 1984).

Bone marrow and lymphoid tissue. Lymphocytes also are highly radiosensitive; a dose of 2 to 3 Sv delivered rapidly to the whole body can kill enough of them to depress the peripheral lymphocyte count and impair the immune response within hours (UNSCEAR 1988). Haemopoietic cells in the bone marrow are similarly radiosensitive and are depleted sufficiently by a comparable dose to cause granulocytopenia and thrombocytopenia to ensue within three to five weeks. Such reductions in granulocyte and platelet counts may be severe enough after a larger dose to result in haemorrhage or fatal infection (table 3).

Table 3. Major forms and features of the acute radiation syndrome

|

Time after |

Cerebral form |

Gastro- |

Hemopoietic form |

Pulmonary form |

|

First day |

nausea |

nausea |

nausea |

nausea |

|

Second week |

nausea |

|||

|

Third to sixth |

weakness |

|||

|

Second to eighth |

cough |

Source: UNSCEAR 1988.

Intestine. Stem cells in the epithelium lining the small bowel also are extremely radiosensitive, acute exposure to 10 Sv depleting their numbers sufficiently to cause the overlying intestinal villi to become denuded within days (ICRP 1984; UNSCEAR 1988). Denudation of a large area of the mucosa can result in a fulminating, rapidly fatal dysentery-like syndrome (table 3).

Gonads. Mature spermatozoa can survive large doses (100 Sv), but spermatogonia are so radiosensitive that as little as 0.15 Sv delivered rapidly to both testes suffices to cause oligospermia, and a dose of 2 to 4 Sv can cause permanent sterility. Oocytes, likewise, are radiosensitive, a dose of 1.5 to 2.0 Sv delivered rapidly to both ovaries causing temporary sterility, and a larger dose, permanent sterility, depending on the age of the woman at the time of exposure (ICRP 1984).

Respiratory tract. The lung is not highly radiosensitive, but rapid exposure to a dose of 6 to 10 Sv can cause acute pneumonitis to develop in the exposed area within one to three months. If a large volume of lung tissue is affected, the process may result in respiratory failure within weeks, or may lead to pulmonary fibrosis and cor pulmonale months or years later (ICRP 1984; UNSCEAR 1988).

Lens of the eye. Cells of the anterior epithelium of the lens, which continue to divide throughout life, are relatively radiosensitive. As a result, rapid exposure of the lens to a dose exceeding 1 Sv may lead within months to the formation of a microscopic posterior polar opacity; and 2 to 3 Sv received in a single brief exposure—or 5.5 to 14 Sv accumulated over a period of months—may produce a vision-impairing cataract (ICRP 1984).

Other tissues. In comparison with the tissues mentioned above, other tissues of the body are generally appreciably less radiosensitive (for example, table 2); however, the embryo constitutes a notable exception, as discussed below. Noteworthy also is the fact that the radiosensitivity of every tissue is increased when it is in a rapidly growing state (ICRP 1984).

Whole-body radiation injury. Rapid exposure of a major part of the body to a dose in excess of 1 Gy can cause the acute radiation syndrome. This syndrome includes: (1) an initial prodromal stage, characterized by malaise, anorexia, nausea and vomiting, (2) an ensuing latent period, (3) a second (main) phase of illness and (4) ultimately, either recovery or death (table 3). The main phase of the illness typically takes one of the following forms, depending on the predominant locus of radiation injury: (1) haematological, (2) gastro-intestinal, (3) cerebral or (4) pulmonary (table 3).

Localized radiation injury. Unlike the clinical manifestations of acute whole-body radiation injury, which typically are dramatic and prompt, the reaction to sharply localized irradiation, whether from an external radiation source or from an internally deposited radionuclide, tends to evolve slowly and to produce few symptoms or signs unless the volume of tissue irradiated and/or the dose are relatively large (for example, table 3).

Effects of radionuclides. Some radionuclides - for example, tritium (3H), carbon-14 (14C) and cesium-137 (137Cs) - tend to be distributed systemically and to irradiate the body as a whole, whereas other radionuclides are characteristically taken up and concentrated in specific organs, producing injuries that are correspondingly localized. Radium (Ra) and strontium-90

(90Sr), for example, are deposited predominantly in bone and thus injure skeletal tissues primarily, whereas radioactive iodine concentrates in the thyroid gland, the primary site of any resulting injury (Stannard 1988; Mettler and Upton 1995).

Carcinogenic Effects

General features. The carcinogenicity of ionizing radiation, first manifested early in this century by the occurrence of skin cancers and leukaemias in pioneer radiation workers (Upton 1986), has since been documented extensively by dose-dependent excesses of many types of neoplasms in radium-dial painters, underground hardrock miners, atomic bomb survivors, radiotherapy patients and experimentally irradiated laboratory animals (Upton 1986; NAS 1990).

The benign and malignant growths induced by irradiation characteristically take years or decades to appear and exhibit no known features by which they can be distinguished from those produced by other causes. With few exceptions, moreover, their induction has been detectable only after relatively large dose equivalents (0.5 Sv), and it has varied with the type of neoplasm as well as the age and sex of those exposed (NAS 1990).

Mechanisms. The molecular mechanisms of radiation carcinogenesis remain to be elucidated in detail, but in laboratory animals and cultured cells the carcinogenic effects of radiation have been observed to include initiating effects, promoting effects, and effects on the progression of neoplasia, depending on the experimental conditions in question (NAS 1990). The effects also appear to involve the activation of oncogenes and/or the inactivation or loss of tumor-suppressor genes in many, if not all, instances. In addition, the carcinogenic effects of radiation resemble those of chemical carcinogens in being similarly modifiable by hormones, nutritional variables and other modifying factors (NAS 1990). It is noteworthy, moreover, that the effects of radiation may be additive, synergistic or mutually antagonistic with those of chemical carcinogens, depending on the specific chemicals and exposure conditions in question (UNSCEAR 1982 and 1986).

Dose-effect relationship. Existing data do not suffice to describe the dose-incidence relationship unambiguously for any type of neoplasm or to define how long after irradiation the risk of the growth may remain elevated in an exposed population. Any risks attributable to low-level irradiation can, therefore, be estimated only by extrapolation, based on models incorporating assumptions about such parameters (NAS 1990). Of various dose-effect models that have been used to estimate the risks of low-level irradiation, the one that has been judged to provide the best fit to the available data is of the form:

![]()

where R0 denotes the age-specific background risk of death from a specific type of cancer, D the radiation dose, f(D) a function of dose that is linear-quadratic for leukaemia and linear for some other types of cancer, and g(b) is a risk function dependent on other parameters, such as sex, age at exposure and time after exposure (NAS 1990).

Non-threshold models of this type have been applied to epidemiological data from the Japanese atomic-bomb survivors and other irradiated populations to derive estimates of the lifetime risks of different forms of radiation-induced cancer (for example, table 4). Such estimates must be interpreted with caution, however, in attempting to predict the risks of cancer attributable to small doses or doses that are accumulated over weeks, months or years, since experiments with laboratory animals have shown the carcinogenic potency of x rays and gamma rays to be reduced by as much as an order of magnitude when the exposure is greatly prolonged. In fact, as has been emphasized elsewhere (NAS 1990), the available data do not exclude the possibility that there may be a threshold in the millisievert (mSv) dose equivalent range, below which radiation may lack carcinogenicity.

Table 4. Estimated lifetime risks of cancer attributable to 0.1 Sv rapid irradiation

|

Type or site of cancer |

Excess cancer deaths per 100,000 |

|

|

(No.) |

(%)* |

|

|

Stomach |

110 |

18 |

|

Lung |

85 |

3 |

|

Colon |

85 |

5 |

|

Leukaemia (excluding CLL) |

50 |

10 |

|

Urinary bladder |

30 |

5 |

|

Oesophagus |

30 |

10 |

|

Breast |

20 |

1 |

|

Liver |

15 |

8 |

|

Gonads |

10 |

2 |

|

Thyroid |

8 |

8 |

|

Osteosarcoma |

5 |

5 |

|

Skin |

2 |

2 |

|

Remainder |

50 |

1 |

|

Total |

500 |

2 |

* Percentage increase in “background” expectation for a non-irradiated population.

Source: ICRP 1991.

It is also noteworthy that the estimates tabulated are based on population averages and are not necessarily applicable to any given individual; that is, susceptibility to certain types of cancer (for example, cancers of the thyroid and breast) is substantially higher in children than in adults, and susceptibility to certain cancers is also increased in association with some hereditary disorders, such as retinoblastoma and the nevoid basal cell carcinoma syndrome (UNSCEAR 1988, 1994; NAS 1990). Such differences in susceptibility notwithstanding, population-based estimates have been proposed for use in compensation cases as a basis for gauging the probability that a cancer arising in a previously irradiated person may have been caused by the exposure in question (NIH 1985).

Low-dose risk assessment. Epidemiological studies to ascertain whether the risks of cancer from low-level exposure to radiation actually vary with dose in the manner predicted by the above estimates have been inconclusive thus far. Populations residing in areas of elevated natural background radiation levels manifest no definitely attributable increases in cancer rates (NAS 1990; UNSCEAR 1994); conversely, a few studies have even suggested an inverse relationship between background radiation levels and cancer rates, which has been interpreted by some observers as evidence for the existence of beneficial (or hormetic) effects of low-level irradiation, in keeping with the adaptive responses of certain cellular systems (UNSCEAR 1994). The inverse relationship is of questionable significance, however, since it has not persisted after controlling for the effects of confounding variables (NAS 1990). Likewise in today’s radiation workers—except for certain cohorts of underground hardrock miners (NAS 1994; Lubin, Boice and Edling 1994)—the rates of cancers other than leukaemia are no longer detectably increased (UNSCEAR 1994), thanks to advances in radiation protection; furthermore, the rates of leukaemia in such workers are consistent with the estimates tabulated above (IARC 1994). In summary, therefore, the data available at present are consistent with the estimates tabulated above (table 4), which imply that less than 3% of cancers in the general population are attributable to natural background radiation (NAS 1990; IARC 1994), although up to 10% of lung cancers may be attributable to indoor radon (NAS 1990; Lubin, Boice and Edling 1994).

High levels of radioactive fallout from a thermonuclear weapons test at Bikini in 1954 have been observed to cause a dose-dependent increase in the frequency of thyroid cancer in Marshall Islanders who received large doses to the thyroid gland in childhood (Robbins and Adams 1989). Similarly, children living in areas of Belarus and the Ukraine contaminated by radionuclides released from the Chernobyl accident have been reported to show an increased incidence of thyroid cancer (Prisyazhuik, Pjatak and Buzanov 1991; Kasakov, Demidchik and Astakhova 1992), but the findings are at variance with those of the International Chernobyl Project, which found no excess of benign or malignant thyroid nodules in children living in the more heavily contaminated areas around Chernobyl (Mettler, Williamson and Royal 1992). The basis for the discrepancy, and whether the reported excesses may have resulted from heightened surveillance alone, remain to be determined. In this connection, it is noteworthy that children of south-western Utah and Nevada who were exposed to fallout from nuclear weapons tests in Nevada during the 1950s have shown increase in the frequency of any type of thyroid cancer (Kerber et al. 1993), and the prevalence of acute leukaemia appears to have been elevated in such children dying between 1952 and 1957, the period of greatest exposure to fallout (Stevens et al. 1990).

The possibility that excesses of leukaemia among children residing in the vicinity of nuclear plants in the United Kingdom may have been caused by radioactivity released from the plants has also been suggested. The releases, however, are estimated to have increased the total radiation dose to such children by less than 2%, from which it is inferred that other explanations are more likely (Doll, Evans and Darby 1994). An ineffective aetiology for the observed clusters of leukaemia is implied by the existence of comparable excesses of childhood leukaemia at sites in the UK that lack nuclear facilities but otherwise resemble nuclear sites in having similarly experienced large influxes of population in recent times (Kinlen 1988; Doll, Evans and Darby 1994). Another hypothesis—namely, that the leukaemias in question may have been caused by occupational irradiation of the fathers of the affected children—also has been suggested by the results of a case-control study (Gardner et al. 1990), but this hypothesis is generally discounted for reasons that are discussed in the section to follow.

Heritable Effects

Heritable effects of irradiation, although well documented in other organisms, have yet to be observed in humans. For example, intensive study of more than 76,000 children of the Japanese atomic-bomb survivors, carried out over four decades, has failed to disclose any heritable effects of radiation in this population, as measured by untoward pregnancy outcomes, neonatal deaths, malignancies, balanced chromosomal rearrangements, sex-chromosome aneuploidy, alterations of serum or erythrocyte protein phenotypes, changes in sex ratio or disturbances in growth and development (Neel, Schull and Awa 1990). Consequently, estimates of the risks of heritable effects of radiation must rely heavily on extrapolation from findings in the laboratory mouse and other experimental animals (NAS 1990; UNSCEAR 1993).

From the available experimental and epidemiological data, it is inferred that the dose required to double the rate of heritable mutations in human germ cells must be at least 1.0 Sv (NAS 1990; UNSCEAR 1993). On this basis, it is estimated that less than 1% of all genetically determined diseases in the human population can be attributed to natural background irradiation (table 5).

Table 5. Estimated frequencies of heritable disorders attributable to natural background ionizing irradiation

|

Type of disorder |

Natural prevalence |

Contribution from natural background |

|

|

First generation |

Equilibrium |

||

|

Autosomal |

180,000 |

20-100 |

300 |

|

X-linked |

400 |

<1 |

<15 |

|

Recessive |

2,500 |

<1 |

very slow increase |

|

Chromosomal |

4,400 |

<20 |

very slow increase |

|

Congenital |

20,000-30,000 |

30 |

30-300 |

|

Other disorders of complex aetiology: |

|||

|

Heart disease |

600,000 |

not estimated4 |

not estimated4 |

|

Cancer |

300,000 |

not estimated4 |

not estimated4 |

|

Selected others |

300,000 |

not estimated4 |

not estimated4 |

1 Equivalent to » 1 mSv per year, or » 30 mSv per generation (30 years).

2 Values rounded.

3 After hundreds of generations, the addition of unfavorable radiation-induced mutations eventually becomes balanced by their loss from the population, resulting in a genetic "equilibrium".

4 Quantitative risk estimates are lacking because of uncertainty about the mutational component of the disease(s) indicated.

Source: National Research Council 1990.

The hypothesis that the excess of leukaemia and non-Hodgkin’s lymphoma in young people residing in the village of Seascale resulted from heritable oncogenic effects caused by the occupational irradiation of the children’s fathers at the Sellafield nuclear installation has been suggested by the results of a case-control study (Gardner et al. 1990), as noted above. Arguments against this hypothesis, however, are:

- the lack of any comparable excess in larger numbers of children born outside Seascale to fathers who had received similar, or even larger, occupational doses at the same nuclear plant (Wakeford et al. 1994a)

- the lack of similar excesses in French (Hill and LaPlanche 1990), Canadian (McLaughlin et al. 1993) or Scottish (Kinlen, Clarke and Balkwill 1993) children born to fathers with comparable occupational exposures

- the lack of excesses in the children of atomic-bomb survivors (Yoshimoto et al. 1990)

- the lack of excesses in US counties containing nuclear plants (Jablon, Hrubec and Boice 1991)

- the fact that the frequency of radiation-induced mutations implied by the interpretation is far higher than established rates (Wakeford et al. 1994b).

On balance, therefore, the available data fail to support the paternal gonadal irradiation hypothesis (Doll, Evans and Darby 1994; Little, Charles and Wakeford 1995).

Effects of Prenatal Irradiation

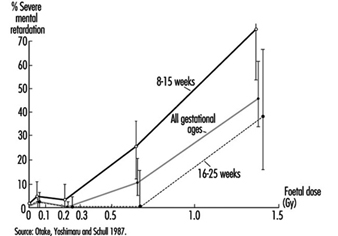

Radiosensitivity is relatively high throughout prenatal life, but the effects of a given dose vary markedly, depending on the developmental stage of the embryo or foetus at the time of exposure (UNSCEAR 1986). During the pre-implantation period, the embryo is most susceptible to killing by irradiation, while during critical stages in organogenesis it is susceptible to the induction of malformations and other disturbances of development (table 6). The latter effects are dramatically exemplified by the dose-dependent increase in the frequency of severe mental retardation (figure 6) and the dose-dependent decrease in IQ test scores in atomic-bomb survivors who were exposed between the eighth and fifteenth weeks (and, to a lesser extent, between the sixteenth and twenty-fifth weeks) (UNSCEAR 1986 and 1993).

Table 6. Major developmental abnormalities produced by prenatal irradiation

|

Brain |

||

|

Anencephaly |

Porencephaly |

Microcephaly* |

|

Encephalocoele |

Mongolism* |

Reduced medulla |

|

Cerebral atrophy |

Mental retardation* |

Neuroblastoma |

|

Narrow aqueduct |

Hydrocephalus* |

Dilatation of ventricles* |

|

Spinal cord anomalies* |

Cranial nerve anomalies |

|

|

Eyes |

||

|

Anophthalmia |

Microphthalmia* |

Microcornia* |

|

Coloboma* |

Deformed iris |

Absence of lens |

|

Absence of retina |

Open eyelids |

Strabismus* |

|

Nystagmus* |

Retinoblastoma |

Hypermetropia |

|

Glaucoma |

Cataract* |

Blindness |

|

Chorioretinitis* |

Partial albinism |

Ankyloblepharon |

|

Skeleton |

||

|

General stunting |

Reduced size of skull |

Skull deformities* |

|

Head ossification defects* |

Vaulted cranium |

Narrow head |

|

Cranial blisters |

Cleft palate* |

Funnel chest |

|

Dislocation of hip |

Spina bifida |

Deformed tail |

|

Deformed feet |

Club foot* |

Digital anomalies* |

|

Calcaneo valgus |

Odontogenesis imperfecta* |

Tibial exostosis |

|

Amelanogenesis* |

Scleratomal necrosis |

|

|

Miscellaneous |

||

|

Situs inversus |

Hydronephrosis |

Hydroureter |

|

Hydrocoele |

Absence of kidney |

Gonadal anomalies* |

|

Congenital heart disease |

Facial deformities |

Pituitary disturbances |

|

Deformities of ears |

Motor disturbances |

Dermatomal necrosis |

|

Myotomal necrosis |

Abnormalities in skinpigmentation |

|

* These abnormalities have been observed in humans exposed prenatally to large doses of radiation and have, therefore, been tentatively attributed to irradiation.

Source: Brill and Forgotson 1964.

Susceptibility to the carcinogenic effects of radiation also appears to be relatively high throughout the prenatal period, judging from the association between childhood cancer (including leukaemia) and prenatal exposure to diagnostic x rays reported in case-control studies (NAS 1990). The results of such studies imply that prenatal irradiation may cause a 4,000% per Sv increase in the risk of leukaemia and other childhood cancers (UNSCEAR 1986; NAS 1990), which is a far larger increase than is attributable to postnatal irradiation (UNSCEAR 1988; NAS 1990). Although, paradoxically, no excess of childhood cancer was recorded in A-bomb survivors irradiated prenatally (Yoshimoto et al. 1990), as noted above, there were too few such survivors to exclude an excess of the magnitude in question.

Figure 6. The frequency of severe mental retardation in relation to radiation dose in prenatally irradiated atomic bomb survivors

Summary and Conclusions

The adverse effects of ionizing radiation on human health are widely diverse, ranging from rapidly fatal injuries to cancers, birth defects, and hereditary disorders that appear months, years or decades later. The nature, frequency and severity of effects depend on the quality of the radiation in question as well as on the dose and conditions of exposure. Most such effects require relatively high levels of exposure and are, therefore, encountered only in accident victims, radiotherapy patients, or other heavily irradiated persons. The genotoxic and carcinogenic effects of ionizing radiation, by contrast, are presumed to increase in frequency as linear non-threshold functions of the dose; hence, although the existence of thresholds for these effects cannot be excluded, their frequency is assumed to increase with any level of exposure. For most effects of radiation, the sensitivity of exposed cells varies with their rate of proliferation and inversely with their degree of differentiation, the embryo and growing child being especially vulnerable to injury.

Singers

The term singer applies to any person whose career, avocation or livelihood relies heavily on the use of his or her voice in a musical context rather than ordinary speech. Unlike percussionists, pianists or violinists, the singer is the instrument. Hence, the well-being of a singer depends not only on the health of his or her larynx (where the sound originates) or vocal tract (where the sound is modified), but also on proper functioning and maximal coordination of most mind and body systems.

Of the many styles of singing documented throughout the world, some reflect a unique liturgical, cultural, linguistic, ethnic or geo-political heritage, while others are more universal in nature. Among the common styles of singing in the United States and Western world are: traditional classical (including oratorio, opera, art songs and so on), barbershop, jazz, musical theatre (Broadway), choral, gospel, folk, country (and western), popular, rhythm and blues, rock ’n’ roll (including heavy metal, alternative rock and so on) and others. Each style of delivery has its typical settings, patterns, habits and associated risk factors.

Vocal Problems

Unlike non-singers, who may not be significantly hindered by vocal problems, for the classical singer, the effect of subtle vocal impairment can be devastating. Even within that category of trained singers, vocal impairment is much more debilitating for the higher voice classifications (sopranos and tenors) than for lower classifications (mezzo sopranos, altos, baritones and basses). On the other hand, some vocal performers (pop, gospel or rock, for example) go to great lengths to achieve a unique trademark and enhance their marketability by inducing vocal pathologies which often yield a breathy, husky, muffled diplophonic (simultaneous multiple pitches) quality. Owing, in part, to their impairment, they tend to sing with great effort, struggling particularly to produce the high notes. To many listeners, this struggle adds a dramatic effect, as if the singer is sacrificing his or her self while engaging in the artistic process.

The prevalence of occupation-related injuries in general, and voice disorders in particular, among singers is not well documented in the literature. This author estimates that on the average, between 10 and 20% of singers in the United States sustain some form of chronic voice disorder. However, the incidence of vocal injury varies significantly with many factors. Because many singers must adhere to specific artistic/aesthetic criteria, performance practices, popular (consumer) demands, financial constraints and social pressures, they often stretch their vocal capabilities and endurance to the limits. Furthermore, singers generally tend to deny, trivialize or ignore warning signs and even diagnoses of vocal injury (Bastian, Keidar and Verdolini-Marston 1990).

The most common problems among singers are benign mucosal disorders. The mucosa is the outer layer, or cover, of the vocal folds (commonly called vocal cords) (Zeitels 1995). Acute problems can include laryngitis and transient vocal fold swelling (oedema). Chronic mucosal lesions include vocal fold swellings, nodules (“calluses”), polyps, cysts, sub-mucosal haemorrhage (bleeding), capillary ectasia (widening), chronic laryngitis, leukoplakia (white spots or patches), mucosal tears and glottic sulci (deep furrows in the tissue). Although these disorders can be exacerbated by smoking and excessive alcohol consumption, it is important to note that these benign mucosal lesions are typically related to the amount and manner of voice use, and are the product of vibratory trauma (Bastian 1993).

Causes of Vocal Problems

In looking at the causes of vocal problems in singers, one should distinguish between intrinsic and extrinsic factors. Intrinsic factors are those related to personality, vocal behaviour (including speaking) on and off stage, vocal technique, and intake habits (primarily if substance abuse, improper medication, malnutrition and/or dehydration is involved). Extrinsic factors are related to environmental pollutants, allergies and so on. Based on clinical experience, intrinsic factors tend to be most important.

Vocal injury is usually a cumulative process of misuse and/or overuse during the singer’s productive (performance-related) and/or non-productive (domestic, social) activities. It is difficult to ascertain how much of the damage is attributable directly to the former versus the latter. Performance risk factors can include unreasonably long dress rehearsals requiring full-voice singing, performing with an upper-respiratory infection in the absence of a replacement and excessive singing. Most vocalists are advised not to sing for more than about 1.5 hours (net) per day. Unfortunately, many singers do not respect the limitations of their apparatus. Some tend to get caught up in the exploratory excitement of new technical skills, new means of artistic expression, new repertoire and so on, and practice 4, 5 or 6 hours daily. Even worse is the beating of the voice into shape when distress signals of injury (such as loss of high notes, inability to sing softly, breathy delay in sound initiation, unstable vibrato and increased phonatory effort) are manifested. The culpability of vocal overtaxing is shared with other taskmasters such as the booking agent who squeezes multiple performances into an impossible time frame, and the recording agent who leases the studio for 12 consecutive hours during which the singer is expected to record a complete CD sound track from start to finish.

Although every singer may encounter acute episodes of voice problems at some point in his or her career, it is generally believed that those singers who are musically literate and can adjust the musical score to their voice limitations, and those who have had proper voice training, are less likely to encounter severe problems of a chronic nature than their untrained peers, who often learn their repertoire by rote, repeatedly imitating or singing along with demo tapes or recordings of other performers. In doing so, they frequently sing in a key, range or style unsuitable for their voices. Singers who lend themselves to periodic tutelage and maintenance by proficient voice experts are less likely to resort to faulty compensatory vocal manoeuvres if confronted by physical impairment, and are more inclined to establish a reasonable balance between artistic demands and vocal longevity. A good teacher is aware of the normal (expected) capabilities of each instrument, can usually distinguish between technical and physical limitations, and often is the first to detect warning signs of vocal impairment.

Sound amplification can also create problems for singers. Many rock groups, for example, amplify not only the singer, but the entire band. When the noise level interferes with auditory feedback, the singer is often unaware that he or she is singing too loudly and using faulty technique. This may contribute significantly to the development and exacerbation of vocal pathology.

Non-performance factors can also be important. Singers must realize that they do not have separate laryngeal mechanisms for singing and speaking. Although most professional singers spend much more time talking than singing, speaking technique is commonly discarded or rejected, which can adversely affect their singing.

Many of today’s singers must travel regularly from one performance venue to another, on trains, tour buses or airplanes. Ongoing touring requires not only psychological adaptation, but also physical adjustments on many levels. In order for singers to function optimally, they must receive adequate quality and quantity of sleep. Radical rapid changes in time zones causes jet lag, which forces singers to remain awake and alert when their internal clock is cueing various body systems to shut down for sleep, and conversely, to sleep when their brain systems are aroused to plan and execute normal daytime activities. Such interruption may result in a host of debilitating symptoms, including chronic insomnia, headaches, sluggishness, dizziness, irritability and forgetfulness (Monk 1994). Aberrant sleep patterns are also a common problem among those singers who perform late at night. These abnormal sleep patterns are all too often mismanaged with alcohol or recreational, prescription or over-the-counter (OTC) drugs (most of which adversely affect the voice). Frequent and/or prolonged confinement to a closed cabin of a motor vehicle, train or aircraft may create additional problems. Inhalation of poorly filtered (often recycled), contaminated, dehumidified (dry) air (Feder 1984), according to many singers, can cause respiratory discomfort, tracheitis, bronchitis or laryngitis that may linger on for hours or even days following a trip.

Owing to environmental instability and hectic scheduling, many singers develop erratic, unhealthful eating habits. In addition to reliance on restaurant food and unpredictable changes in meal times, many singers eat the main meal of the day after their performance, usually late at night. Particularly for the overweight singer, and especially if spicy, greasy or acidic foods, alcohol or coffee were consumed, lying down soon after having filled the stomach is likely to result in gastroesophageal reflux. Reflux is the retrograde flow of acids from the stomach up the oesophagus and into the throat and larynx. The resulting symptoms can be devastating to the singer. Eating disorders are quite common among singers. In the operatic and classical realm, overeating and obesity are quite common. In the musical theatre and pop domain, particularly among young females, reportedly one-fifth of all singers have encountered some form of eating disorder, such as anorexia or bulimia. The latter involves various purging methods, of which vomiting is thought to be particularly hazardous to the voice.

A detrimental factor to voice production is exposure to pollutants, such as formaldehyde, solvents, paints and dusts, and allergens, such as tree, grass or weed pollens, dust, mould spores, animal danders and perfumes (Sataloff 1996). Such exposure may occur on and off stage. In their work milieu, singers can be exposed to these and other pollutants associated with vocal symptoms, including cigarette smoke and theatrical smoke and fog effects. Singers use a greater percentage of their vital capacity than ordinary speakers. Furthermore, during intense aerobic activity (such as dancing), the number of breathing cycles per minute increases, and mouth breathing prevails. This results in the inhalation of larger amounts of cigarette smoke and fogs during performances.

Treatment of Vocal Problems

Two major issues in the treatment of vocal problems of singers are self-medication and improper treatment by physicians who are not knowledgeable about the voice and its problems. Sataloff (1991, 1995) surveyed the potential side effects associated with medications commonly used by singers. Whether recreational, prescription, over the counter or food supplements, most drugs are likely to have some effect on phonatory function. In an attempt to control “allergies”, “phlegm” or “sinus congestion”, the self-medicating singer will ultimately ingest something that will damage the vocal system. Likewise, the physician who keeps prescribing steroids to reduce chronic inflammation caused by abusive vocal habits and ignores the underlying causes will eventually hurt the singer. Vocal dysfunction resulting from poorly indicated or ill-performed phonosurgery has been documented (Bastian 1996). To avoid injuries secondary to treatment, singers are advised to know their instruments, and consult only with health care professionals who understand and have experience and expertise managing the vocal problems of singers, and who possess the patience to educate and empower singers.

Introduction

Ionizing radiation is everywhere. It arrives from outer space as cosmic rays. It is in the air as emissions from radioactive radon and its progeny. Naturally occurring radioactive isotopes enter and remain in all living things. It is inescapable. Indeed, all species on this planet evolved in the presence of ionizing radiation. While humans exposed to small doses of radiation may not immediately show any apparent biological effects, there is no doubt that ionizing radiation, when given in sufficient amounts, can cause harm. These effects are well known both in kind and in degree.

While ionizing radiation can cause harm, it also has many beneficial uses. Radioactive uranium generates electricity in nuclear power plants in many countries. In medicine, x rays produce radiographs for diagnosis of internal injuries and diseases. Nuclear medicine physicians use radioactive material as tracers to form detailed images of internal structures and to study metabolism. Therapeutic radiopharmaceuticals are available to treat disorders such as hyperthyroidism and cancer. Radiotherapy physicians use gamma rays, pion beams, electron beams, neutrons and other types of radiation to treat cancer. Engineers use radioactive material in oil well logging operations and in soil moisture density gauges. Industrial radiographers use x rays in quality control to look at internal structures of manufactured devices. Exit signs in buildings and aircraft contain radioactive tritium to make them glow in the dark in the event of a power failure. Many smoke detectors in homes and commercial buildings contain radioactive americium.

These many uses of ionizing radiation and radioactive materials enhance the quality of life and help society in many ways. The benefits of each use must always be compared with the risks. The risks may be to workers directly involved in applying the radiation or radioactive material, to the public, to future generations and to the environment or to any combination of these. Beyond political and economic considerations, benefits must always outweigh risks when ionizing radiation is involved.

Ionizing Radiation

Ionizing radiation consists of particles, including photons, which cause the separation of electrons from atoms and molecules. However, some types of radiation of relatively low energy, such as ultraviolet light, can also cause ionization under certain circumstances. To distinguish these types of radiation from radiation that always causes ionization, an arbitrary lower energy limit for ionizing radiation usually is set around 10 kiloelectron volts (keV).

Directly ionizing radiation consists of charged particles. Such particles include energetic electrons (sometimes called negatrons), positrons, protons, alpha particles, charged mesons, muons and heavy ions (ionized atoms). This type of ionizing radiation interacts with matter primarily through the Coulomb force, repelling or attracting electrons from atoms and molecules by virtue of their charges.

Indirectly ionizing radiation consists of uncharged particles. The most common kinds of indirectly ionizing radiation are photons above 10 keV (x rays and gamma rays) and all neutrons.

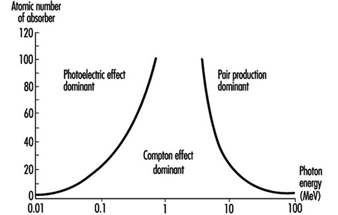

X-ray and gamma-ray photons interact with matter and cause ionization in at least three different ways:

- Lower-energy photons interact mostly via the photoelectric effect, in which the photon gives all of its energy to an electron, which then leaves the atom or molecule. The photon disappears.

- Intermediate-energy photons mostly interact through the Compton effect, in which the photon and an electron essentially collide as particles. The photon continues in a new direction with reduced energy while the released electron goes off with the remainder of the incoming energy (less the electron’s binding energy to the atom or molecule).

- Pair production is possible only for photons with energy in excess of 1.02 MeV. (However, near 1.02 MeV, the Compton effect still dominates. Pair production dominates at higher energies.) The photon disappears and an electron-positron pair appears in its place (this occurs only in the vicinity of a nucleus because of conservation of momentum and energy considerations). The total kinetic energy of the electron-positron pair is equal to the energy of the photon less the sum of the rest-mass energies of the electron and positron (1.02 MeV). These energetic electrons and positrons then proceed as directly ionizing radiation. As it loses kinetic energy, a positron will eventually encounter an electron, and the particles will annihilate each other. Two (usually) 0.511 MeV photons are then emitted from the annihilation site at 180 degrees from each other.

a given photon any of these can occur, except that pair production is possible only for photons with energy greater than 1.022 MeV. The energy of the photon and the material with which it interacts determine which interaction is the most likely to occur.

Figure 1 shows the regions in which each type of photon interaction dominates as a function of photon energy and atomic number of absorber.

Figure 1. Relative importance of the three principal interactions of photons in matter

The most common neutron interactions with matter are inelastic collisions, neutron capture (or activation) and fission. All of these are interactions with nuclei. A nucleus colliding inelastically with a neutron is left at a higher energy level. It can release this energy in the form of a gamma ray or by emitting a beta particle, or both. In neutron capture, an affected nucleus may absorb the neutron and eject energy as gamma or x rays or beta particles, or both. The secondary particles then cause ionization as discussed above. In fission, a heavy nucleus absorbs the neutron and splits into two lighter nuclei that are almost always radioactive.

Quantities, Units and Related Definitions

The International Commission on Radiation Units and Measurements (ICRU) develops internationally accepted formal definitions of quantities and units of radiation and radioactivity. The International Commission on Radiological Protection (ICRP) also sets standards for definition and use of various quantities and units used in radiation safety. A description of some quantities, units and definitions commonly used in radiation safety follows.

Absorbed dose. This is the fundamental dosimetric quantity for ionizing radiation. Basically, it is the energy ionizing radiation imparts to matter per unit mass. Formally,

![]()

where D is the absorbed dose, de is the mean energy imparted to matter of mass dm. Absorbed dose has units of joules per kilogram (J kg–1). The special name for the unit of absorbed dose is the gray (Gy).

Activity. This quantity represents the number of nuclear transformations from a given nuclear energy state per unit time. Formally,

![]()

where A is the activity, dN is the expectation value of the number of spontaneous nuclear transitions from the given energy state in the time interval dt. It is related to the number of radioactive nuclei N by:

![]()

where l is the decay constant. Activity has units of inverse seconds (s–1). The special name for the unit of activity is the becquerel (Bq).

Decay constant (l). This quantity represents the probability per unit time that a nuclear transformation will occur for a given radionuclide. The decay constant has units of inverse seconds (s–1). It is related to the half-life t½ of a radionuclide by:

![]()

The decay constant l is related to the mean lifetime, t, of a radionuclide by:

![]()

The time dependence of activity A(t) and of the number of radioactive nuclei N(t) can be expressed by ![]() and

and ![]() respectively.

respectively.

Deterministic biological effect. This is a biological effect caused by ionizing radiation and whose probability of occurrence is zero at small absorbed doses but will increase steeply to unity (100%) above some level of absorbed dose (the threshold). Cataract induction is an example of a stochastic biological effect.

Effective dose. The effective dose E is the sum of the weighted equivalent doses in all the tissues and organs of the body. It is a radiation safety quantity, so its use is not appropriate for large absorbed doses delivered in a relatively short period of time. It is given by:

![]()

where w T is the tissue weighting factor and HT is the equivalent dose for tissue T. Effective dose has units of J kg–1. The special name for the unit of effective dose is the sievert (Sv).

Equivalent dose. The equivalent dose HT is the absorbed dose averaged over a tissue or organ (rather than at a point) and weighted for the radiation quality that is of interest. It is a radiation safety quantity, so its use is not appropriate for large absorbed doses delivered in a relatively short period of time. The equivalent dose is given by:

![]()

where DT,R is the absorbed dose averaged over the tissue or organ T due to radiation R and w R

is the radiation weighting factor. Equivalent dose has units of J kg–1. The special name for the unit of equivalent dose is the sievert (Sv).

Half-life. This quantity is the amount of time required for the activity of a radionuclide sample to reduce by a factor of one-half. Equivalently, it is the amount of time required for a given number of nuclei in a given radioactive state to reduce by a factor of one-half. It has fundamental units of seconds (s), but is also commonly expressed in hours, days and years. For a given radionuclide, half-life t½ is related to the decay constant l by:

![]()

Linear energy transfer. This quantity is the energy a charged particle imparts to matter per unit length as it traverses the matter. Formally,

![]()

where L is the linear energy transfer (also called linear collision stopping power) and de is the mean energy lost by the particle in traversing a distance dl. Linear energy transfer (LET) has units of J m–1.

Mean lifetime. This quantity is the average time a nuclear state will survive before it undergoes a transformation to a lower energy state by emitting ionizing radiation. It has fundamental units of seconds (s), but may also be expressed in hours, days or years. It is related to the decay constant by:

![]()

where t is the mean lifetime and l is the decay constant for a given nuclide in a given energy state.

Radiation weighting factor. This is a number w R that, for a given type and energy of radiation R, is representative of values of the relative biological effectiveness of that radiation in inducing stochastic effects at low doses. The values of w R are related to linear energy transfer (LET) and are given in table 1. Figure 2 (overleaf) shows the relationship between w R and LET for neutrons.

Table 1. Radiation weighting factors wR

|

Type and energy range |

wR 1 |

|

Photons, all energies |

1 |

|

Electrons and muons, all energies2 |

1 |

|

Neutrons, energy 10 keV |

5 |

|

10 keV to 100 keV |

10 |

|

>100 keV to 2 MeV |

20 |

|

>2 MeV to 20 MeV |

10 |

|

>20 MeV |

5 |

|

Protons, other than recoil protons, energy >2 MeV |

5 |

|

Alpha particles, fission fragments, heavy nuclei |

20 |

1 All values relate to the radiation incident on the body or, for internal sources, emitted from the source.

2 Excluding Auger electrons emitted from nuclei bound to DNA.

Relative biological effectiveness (RBE). The RBE of one type of radiation compared with another is the inverse ratio of the absorbed doses producing the same degree of a defined biological end point.

Figure 2. Radiation weighting factors for neutrons (the smooth curve is to be treated as an approximation)

Stochastic biological effect. This is a biological effect caused by ionizing radiation whose probability of occurrence increases with increasing absorbed dose, probably with no threshold, but whose severity is independent of absorbed dose. Cancer is an example of a stochastic biological effect.

Tissue weighting factor w T. This represents the contribution of tissue or organ T to the total detriment due to all of the stochastic effects resulting from uniform irradiation of the whole body. It is used because the probability of stochastic effects due to an equivalent dose depends on the tissue or organ irradiated. A uniform equivalent dose over the whole body should give an effective dose numerically equal to the sum of effective doses for all tissues and organs of the body. Therefore, the sum of all tissue weighting factors is normalized to unity. Table 2 gives values for tissue weighting factors.

Table 2. Tissue weighting factors wT

|

Tissue or organ |

wT 1 |

|

Gonads |

0.20 |

|

Bone marrow (red) |

0.12 |

|

Colon |

0.12 |

|

Lung |

0.12 |

|

Stomach |

0.12 |

|

Bladder |

0.05 |

|

Breast |

0.05 |

|

Liver |

0.05 |

|

Oesophagus |

0.05 |

|

Thyroid |

0.05 |

|

Skin |

0.01 |

|

Bone surface |

0.01 |

|

Remainder |

0.052, 3 |

1 The values have been developed from a reference population of equal numbers of both sexes and a wide range of ages. In the definition of effective dose they apply to workers, to the whole population, and to either sex.

2 For purposes of calculation, the remainder is composed of the following additional tissues and organs: adrenals, brain, upper large intestine, small intestine, kidneys, muscle, pancreas, spleen, thymus and uterus. The list includes organs that are likely to be selectively irradiated. Some organs in the list are known to be susceptible to cancer induction.

3 In those exceptional cases in which a single one of the remainder tissues or organs receives an equivalent dose in excess of the highest dose in any of the twelve organs for which a weighting factor is specified, a weighting factor of 0.025 should be applied to that tissue or organ and a weighting factor of 0.025 to the average dose in the rest of the remainder as defined above.

Passive Fire Protection Measures

Confining Fires by Compartmentation

Building and site planning

Fire safety engineering work should begin early in the design phase because the fire safety requirements influence the layout and design of the building considerably. In this way, the designer can incorporate fire safety features into the building much better and more economically. The overall approach includes consideration of both interior building functions and layout, as well as exterior site planning. Prescriptive code requirements are more and more replaced by functionally based requirements, which means there is an increased demand for experts in this field. From the beginning of the construction project, the building designer therefore should contact fire experts to elucidate the following actions:

- to describe the fire problem specific to the building

- to describe different alternatives to obtain the required fire safety level

- to analyse system choice regarding technical solutions and economy

- to create presumptions for technical optimized system choices.

The architect must utilize a given site in designing the building and adapt the functional and engineering considerations to the particular site conditions that are present. In a similar manner, the architect should consider site features in arriving at decisions on fire protection. A particular set of site characteristics may significantly influence the type of active and passive protection suggested by the fire consultant. Design features should consider the local fire-fighting resources that are available and the time to reach the building. The fire service cannot and should not be expected to provide complete protection for building occupants and property; it must be assisted by both active and passive building fire defences, to provide reasonable safety from the effects of fire. Briefly, the operations may be broadly grouped as rescue, fire control and property conservation. The first priority of any fire-fighting operation is to ensure that all occupants are out of the building before critical conditions occur.

Structural design based on classification or calculation

A well-established means of codifying fire protection and fire safety requirements for buildings is to classify them by types of construction, based upon the materials used for the structural elements and the degree of fire resistance afforded by each element. Classification can be based on furnace tests in accordance with ISO 834 (fire exposure is characterized by the standard temperature-time curve), combination of test and calculation or by calculation. These procedures will identify the standard fire resistance (the ability to fulfil required functions during 30, 60, 90 minutes, etc.) of a structural load-bearing and/or separating member. Classification (especially when based on tests) is a simplified and conservative method and is more and more replaced by functionally based calculation methods taking into account the effect of fully developed natural fires. However, fire tests will always be required, but they can be designed in a more optimal way and be combined with computer simulations. In that procedure, the number of tests can be reduced considerably. Usually, in the fire test procedures, load-bearing structural elements are loaded to 100% of the design load, but in real life the load utilization factor is most often less than that. Acceptance criteria are specific for the construction or element tested. Standard fire resistance is the measured time the member can withstand the fire without failure.

Optimum fire engineering design, balanced against anticipated fire severity, is the objective of structural and fire protection requirements in modern performance-based codes. These have opened the way for fire engineering design by calculation with prediction of the temperature and structural effect due to a complete fire process (heating and subsequent cooling is considered) in a compartment. Calculations based on natural fires mean that the structural elements (important for the stability of the building) and the whole structure are not allowed to collapse during the entire fire process, including cool down.

Comprehensive research has been performed during the past 30 years. Various computer models have been developed. These models utilize basic research on mechanical and thermal properties of materials at elevated temperatures. Some computer models are validated against a vast number of experimental data, and a good prediction of structural behaviour in fire is obtained.

Compartmentation

A fire compartment is a space within a building extending over one or several floors which is enclosed by separating members such that the fire spread beyond the compartment is prevented during the relevant fire exposure. Compartmentation is important in preventing the fire to spread into too large spaces or into the whole building. People and property outside the fire compartment can be protected by the fact that the fire is extinguished or burns out by itself or by the delaying effect of the separating members on the spread of fire and smoke until the occupants are rescued to a place of safety.

The fire resistance required by a compartment depends upon its intended purpose and on the expected fire. Either the separating members enclosing the compartment shall resist the maximum expected fire or contain the fire until occupants are evacuated. The load-bearing elements in the compartment must always resist the complete fire process or be classified to a certain resistance measured in terms of periods of time, which is equal or longer than the requirement of the separating members.

Structural integrity during a fire

The requirement for maintaining structural integrity during a fire is the avoidance of structural collapse and the ability of the separating members to prevent ignition and flame spread into adjacent spaces. There are different approaches to provide the design for fire resistance. They are classifications based on standard fire-resistance test as in ISO 834, combination of test and calculation or solely calculation and the performance-based procedure computer prediction based on real fire exposure.

Interior finish