Software and Computers: Hybrid Automated Systems

A hybrid automated system (HAS) aims to integrate the capabilities of artificially intelligent machines (based on computer technology) with the capacities of the people who interact with these machines in the course of their work activities. The principal concerns of HAS utilization relate to how the human and machine subsystems should be designed in order to make the best use of the knowledge and skills of both parts of the hybrid system, and how the human operators and machine components should interact with each other to assure their functions complement one another. Many hybrid automated systems have evolved as the products of applications of modern information- and control-based methodologies to automate and integrate different functions of often complex technological systems. HAS was originally identified with the introduction of computer-based systems used in the design and operation of real-time control systems for nuclear power reactors, for chemical processing plants and for discrete parts-manufacturing technology. HAS can now also be found in many service industries, such as air traffic control and aircraft navigation procedures in the civil aviation area, and in the design and use of intelligent vehicle and highway navigation systems in road transportation.

With continuing progress in computer-based automation, the nature of human tasks in modern technological systems shifts from those that require perceptual-motor skills to those calling for cognitive activities, which are needed for problem solving, for decision making in system monitoring, and for supervisory control tasks. For example, the human operators in computer-integrated manufacturing systems primarily act as system monitors, problem solvers and decision makers. The cognitive activities of the human supervisor in any HAS environment are (1) planning what should be done for a given period of time, (2) devising procedures (or steps) to achieve the set of planned goals, (3) monitoring the progress of (technological) processes, (4) “teaching” the system through a human-interactive computer, (5) intervening if the system behaves abnormally or if the control priorities change and (6) learning through feedback from the system about the impact of supervisory actions (Sheridan 1987).

Hybrid System Design

The human-machine interactions in a HAS involve utilization of dynamic communication loops between the human operators and intelligent machines—a process that includes information sensing and processing and the initiation and execution of control tasks and decision making—within a given structure of function allocation between humans and machines. At a minimum, the interactions between people and automation should reflect the high complexity of hybrid automated systems, as well as relevant characteristics of the human operators and task requirements. Therefore, the hybrid automated system can be formally defined as a quintuple in the following formula:

HAS = (T, U, C, E, I)

where T = task requirements (physical and cognitive); U = user characteristics (physical and cognitive); C = the automation characteristics (hardware and software, including computer interfaces); E = the system’s environment; I = a set of interactions among the above elements.

The set of interactions I embodies all possible interactions between T, U and C in E regardless of their nature or strength of association. For example, one of the possible interactions might involve the relation of the data stored in the computer memory to the corresponding knowledge, if any, of the human operator. The interactions I can be elemental (i.e., limited to a one-to-one association), or complex, such as would involve interactions between the human operator, the particular software used to achieve the desired task, and the available physical interface with the computer.

Designers of many hybrid automated systems focus primarily on the computer-aided integration of sophisticated machines and other equipment as parts of computer-based technology, rarely paying much attention to the paramount need for effective human integration within such systems. Therefore, at present, many of the computer-integrated (technological) systems are not fully compatible with the inherent capabilities of the human operators as expressed by the skills and knowledge necessary for the effective control and monitoring of these systems. Such incompatibility arises at all levels of human, machine and human-machine functioning, and can be defined within a framework of the individual and the entire organization or facility. For example, the problems of integrating people and technology in advanced manufacturing enterprises occur early in the HAS design stage. These problems can be conceptualized using the following system integration model of the complexity of interactions, I, between the system designers, D, human operators, H, or potential system users and technology, T:

I (H, T) = F [ I (H, D), I (D, T)]

where I stands for relevant interactions taking place in a given HAS’s structure, while F indicates functional relationships between designers, human operators and technology.

The above system integration model highlights the fact that the interactions between the users and technology are determined by the outcome of the integration of the two earlier interactions—namely, (1) those between HAS designers and potential users and (2) those between the designers and the HAS technology (at the level of machines and their integration). It should be noted that even though strong interactions typically exist between the designers and technology, only very few examples of equally strong interrelationships between designers and human operators can be found.

It can be argued that even in the most automated systems, the human role remains critical to successful system performance at the operational level. Bainbridge (1983) identified a set of problems relevant to the operation of the HAS which are due to the nature of automation itself, as follows:

- Operators “out of the control loop”. The human operators are present in the system to exercise control when needed, but by being “out of the control loop” they fail to maintain the manual skills and long-term system knowledge that are often required in case of an emergency.

- Outdated “mental picture”. The human operators may not be able to respond quickly to changes in the system behaviour if they have not been following the events of its operation very closely. Furthermore, the operators’ knowledge or mental picture of the system functioning may be inadequate to initiate or exercise required responses.

- Disappearing generations of skills. New operators may not be able to acquire sufficient knowledge about the computerized system achieved through experience and, therefore, will be unable to exercise effective control when needed.

- Authority of automatics. If the computerized system has been implemented because it can perform the required tasks better than the human operator, the question arises, “On what basis should the operator decide that correct or incorrect decisions are being made by the automated systems?”

- Emergence of the new types of “human errors” due to automation. Automated systems lead to new types of errors and, consequently, accidents which cannot be analysed within the framework of traditional techniques of analysis.

Task Allocation

One of the important issues for HAS design is to determine how many and which functions or responsibilities should be allocated to the human operators, and which and how many to the computers. Generally, there are three basic classes of task allocation problems that should be considered: (1) the human supervisor–computer task allocation, (2) the human–human task allocation and (3) the supervisory computer–computer task allocation. Ideally, the allocation decisions should be made through some structured allocation procedure before the basic system design is begun. Unfortunately such a systematic process is seldom possible, as the functions to be allocated may either need further examination or must be carried out interactively between the human and machine system components—that is, through application of the supervisory control paradigm. Task allocation in hybrid automated systems should focus on the extent of the human and computer supervisory responsibilities, and should consider the nature of interactions between the human operator and computerized decision support systems. The means of information transfer between machines and the human input-output interfaces and the compatibility of software with human cognitive problem-solving abilities should also be considered.

In traditional approaches to the design and management of hybrid automated systems, workers were considered as deterministic input-output systems, and there was a tendency to disregard the teleological nature of human behaviour—that is, the goal-oriented behaviour relying on the acquisition of relevant information and the selection of goals (Goodstein et al. 1988). To be successful, the design and management of advanced hybrid automated systems must be based on a description of the human mental functions needed for a specific task. The “cognitive engineering” approach (described further below) proposes that human-machine (hybrid) systems need to be conceived, designed, analysed and evaluated in terms of human mental processes (i.e., the operator’s mental model of the adaptive systems is taken into account). The following are the requirements of the human-centred approach to HAS design and operation as formulated by Corbett (1988):

- Compatibility. System operation should not require skills unrelated to existing skills, but should allow existing skills to evolve. The human operator should input and receive information which is compatible with conventional practice in order that the interface conform to the user’s prior knowledge and skill.

- Transparency. One cannot control a system without understanding it. Therefore, the human operator must be able to “see” the internal processes of the system’s control software if learning is to be facilitated. A transparent system makes it easy for users to build up an internal model of the decision-making and control functions that the system can perform.

- Minimum shock. The system should not do anything which operators find unexpected in the light of the information available to them, detailing the present state of the system.

- Disturbance control. Uncertain tasks (as defined by the choice structure analysis) should be under human operator control with computer decision-making support.

- Fallibility. The implicit skills and knowledge of the human operators should not be designed out of the system. The operators should never be put in a position where they helplessly watch the software direct an incorrect operation.

- Error reversibility. Software should supply sufficient feedforward of information to inform the human operator of the likely consequences of a particular operation or strategy.

- Operating flexibility. The system should offer human operators the freedom to trade off requirements and resource limits by shifting operating strategies without losing the control software support.

Cognitive Human Factors Engineering

Cognitive human factors engineering focuses on how human operators make decisions at the workplace, solve problems, formulate plans and learn new skills (Hollnagel and Woods 1983). The roles of the human operators functioning in any HAS can be classified using Rasmussen’s scheme (1983) into three major categories:

- Skill-based behaviour is the sensory-motor performance executed during acts or activities which take place without conscious control as smooth, automated and highly integrated patterns of behaviour. Human activities that fall under this category are considered to be a sequence of skilled acts composed for a given situation. Skill-based behaviour is thus the expression of more or less stored patterns of behaviours or pre-programmed instructions in a space-time domain.

- Rule-based behaviour is a goal-oriented category of performance structured by feedforward control through a stored rule or procedure—that is, an ordered performance allowing a sequence of subroutines in a familiar work situation to be composed. The rule is typically selected from previous experiences and reflects the functional properties which constrain the behaviour of the environment. Rule-based performance is based on explicit know-how as regards employing the relevant rules. The decision data set consists of references for recognition and identification of states, events or situations.

- Knowledge-based behaviour is a category of goal-controlled performance, in which the goal is explicitly formulated based on knowledge of the environment and the aims of the person. The internal structure of the system is represented by a “mental model”. This kind of behaviour allows the development and testing of different plans under unfamiliar and, therefore, uncertain control conditions, and is needed when skills or rules are either unavailable or inadequate so that problem solving and planning must be called upon instead.

In the design and management of a HAS, one should consider the cognitive characteristics of the workers in order to assure the compatibility of system operation with the worker’s internal model that describes its functions. Consequently, the system’s description level should be shifted from the skill-based to the rule-based and knowledge-based aspects of human functioning, and appropriate methods of cognitive task analysis should be used to identify the operator’s model of a system. A related issue in the development of a HAS is the design of means of information transmission between the human operator and automated system components, at both the physical and the cognitive levels. Such information transfer should be compatible with the modes of information utilized at different levels of system operation—that is, visual, verbal, tactile or hybrid. This informational compatibility ensures that different forms of information transfer will require minimal incompatibility between the medium and the nature of the information. For example, a visual display is best for transmission of spatial information, while auditory input may be used to convey textual information.

Quite often the human operator develops an internal model that describes the operation and function of the system according to his or her experience, training and instructions in connection with the given type of human-machine interface. In light of this reality, the designers of a HAS should attempt to build into the machines (or other artificial systems) a model of the human operator’s physical and cognitive characteristics—that is, the system’s image of the operator (Hollnagel and Woods 1983). The designers of a HAS must also take into consideration the level of abstraction in the system description as well as various relevant categories of the human operator’s behaviour. These levels of abstraction for modelling human functioning in the working environment are as follows (Rasmussen 1983): (1) physical form (anatomical structure), (2) physical functions (physiological functions), (3) generalized functions (psychological mechanisms and cognitive and affective processes), (4) abstract functions (information processing) and (5) functional purpose (value structures, myths, religions, human interactions). These five levels must be considered simultaneously by the designers in order to ensure effective HAS performance.

System Software Design

Since the computer software is a primary component of any HAS environment, software development, including design, testing, operation and modification, and software reliability issues must also be considered at the early stages of HAS development. By this means, one should be able to lower the cost of software error detection and elimination. It is difficult, however, to estimate the reliability of the human components of a HAS, on account of limitations in our ability to model human task performance, the related workload and potential errors. Excessive or insufficient mental workload may lead to information overload and boredom, respectively, and may result in degraded human performance, leading to errors and the increasing probability of accidents. The designers of a HAS should employ adaptive interfaces, which utilize artificial intelligence techniques, to solve these problems. In addition to human-machine compatibility, the issue of human-machine adaptability to each other must be considered in order to reduce the stress levels that come about when human capabilities may be exceeded.

Due to the high level of complexity of many hybrid automated systems, identification of any potential hazards related to the hardware, software, operational procedures and human-machine interactions of these systems becomes critical to the success of efforts aimed at reduction of injuries and equipment damage. Safety and health hazards associated with complex hybrid automated systems, such as computer-integrated manufacturing technology (CIM), is clearly one of the most critical aspects of system design and operation.

System Safety Issues

Hybrid automated environments, with their significant potential for erratic behaviour of the control software under system disturbance conditions, create a new generation of accident risks. As hybrid automated systems become more versatile and complex, system disturbances, including start-up and shut-down problems and deviations in system control, can significantly increase the possibility of serious danger to the human operators. Ironically, in many abnormal situations, operators usually rely on the proper functioning of the automated safety subsystems, a practice which may increase the risk of severe injury. For example, a study of accidents related to malfunctions of technical control systems showed that about one-third of the accident sequences included human intervention in the control loop of the disturbed system.

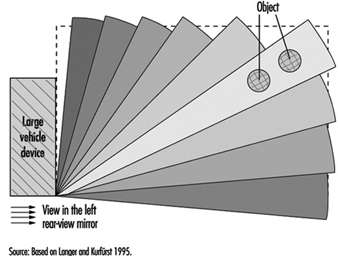

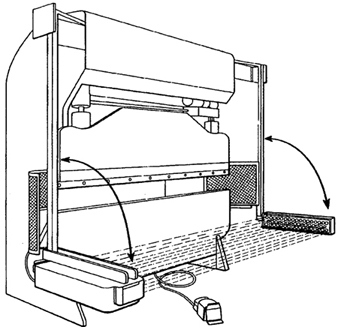

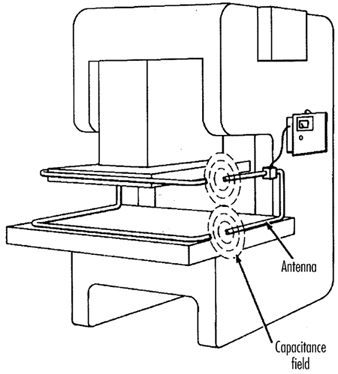

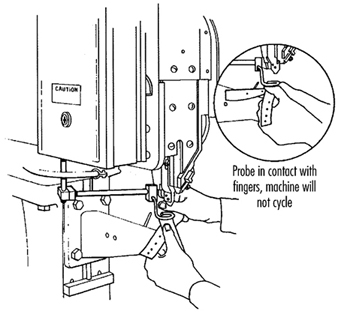

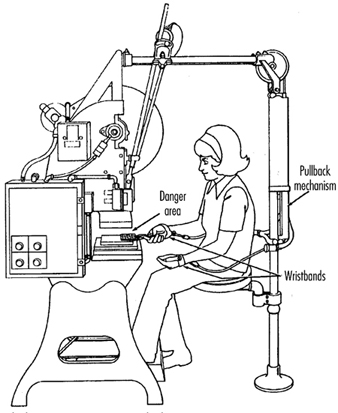

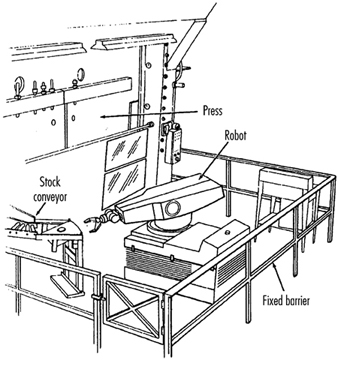

Since traditional safety measures cannot be easily adapted to the needs of HAS environments, injury control and accident prevention strategies need to be reconsidered in view of the inherent characteristics of these systems. For example, in the area of advanced manufacturing technology, many processes are characterized by the existence of substantial amounts of energy flows which cannot be easily anticipated by the human operators. Furthermore, safety problems typically emerge at the interfaces between subsystems, or when system disturbances progress from one subsystem to another. According to the International Organization for Standardization (ISO 1991), the risks associated with hazards due to industrial automation vary with the types of industrial machines incorporated into the specific manufacturing system and with the ways in which the system is installed, programmed, operated, maintained and repaired. For example, a comparison of robot-related accidents in Sweden to other types of accidents showed that robots may be the most hazardous industrial machines used in advanced manufacturing industry. The estimated accident rate for industrial robots was one serious accident per 45 robot-years, a higher rate than that for industrial presses, which was reported to be one accident per 50 machine-years. It should be noted here that industrial presses in the United States accounted for about 23% of all metalworking machine-related fatalities for the 1980–1985 period, with power presses ranked first with respect to the severity-frequency product for non-fatal injuries.

In the domain of advanced manufacturing technology, there are many moving parts which are hazardous to workers as they change their position in a complex manner outside the visual field of the human operators. Rapid technological developments in computer-integrated manufacturing created a critical need to study the effects of advanced manufacturing technology on the workers. In order to identify the hazards caused by various components of such a HAS environment, past accidents need to be carefully analysed. Unfortunately, accidents involving robot use are difficult to isolate from reports of human operated machine-related accidents, and, therefore, there may be a high percentage of unrecorded accidents. The occupational health and safety rules of Japan state that “industrial robots do not at present have reliable means of safety and workers cannot be protected from them unless their use is regulated”. For example, the results of the survey conducted by the Labour Ministry of Japan (Sugimoto 1987) of accidents related to industrial robots across the 190 factories surveyed (with 4,341 working robots) showed that there were 300 robot-related disturbances, of which 37 cases of unsafe acts resulted in some near accidents, 9 were injury-producing accidents, and 2 were fatal accidents. The results of other studies indicate that computer-based automation does not necessarily increase the overall level of safety, as the system hardware cannot be made fail-safe by safety functions in the computer software alone, and system controllers are not always highly reliable. Furthermore, in a complex HAS, one cannot depend exclusively on safety-sensing devices to detect hazardous conditions and undertake appropriate hazard-avoidance strategies.

Effects of Automation on Human Health

As discussed above, worker activities in many HAS environments are basically those of supervisory control, monitoring, system support and maintenance. These activities may also be classified into four basic groups as follows: (1) programming tasks i.e., encoding the information that guides and directs machinery operation, (2) monitoring of HAS production and control components, (3) maintenance of HAS components to prevent or alleviate machinery malfunctions, and (4) performing a variety of support tasks, etc. Many recent reviews of the impact of the HAS on worker well-being concluded that although the utilization of a HAS in the manufacturing area may eliminate heavy and dangerous tasks, working in a HAS environment may be dissatisfying and stressful for the workers. Sources of stress included the constant monitoring required in many HAS applications, the limited scope of the allocated activities, the low level of worker interaction permitted by the system design, and safety hazards associated with the unpredictable and uncontrollable nature of the equipment. Even though some workers who are involved in programming and maintenance activities feel the elements of challenge, which may have positive effects on their well-being, these effects are often offset by the complex and demanding nature of these activities, as well as by the pressure exerted by management to complete these activities quickly.

Although in some HAS environments the human operators are removed from traditional energy sources (the flow of work and movement of the machine) during normal operating conditions, many tasks in automated systems still need to be carried out in direct contact with other energy sources. Since the number of different HAS components is continually increasing, special emphasis must be placed on workers’ comfort and safety and on the development of effective injury control provisions, especially in view of the fact that the workers are no longer able to keep up with the sophistication and complexity of such systems.

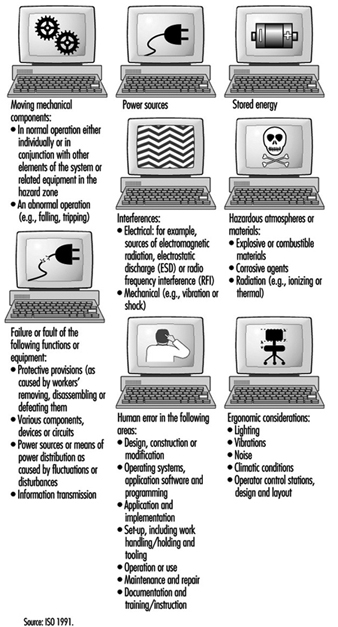

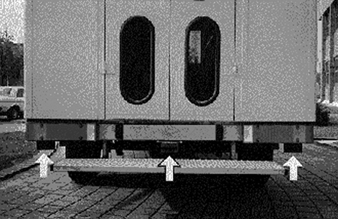

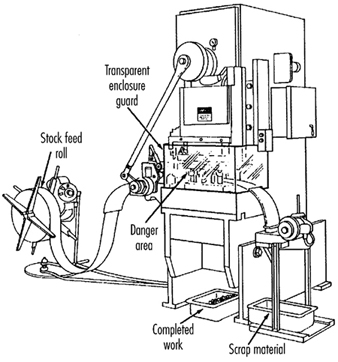

In order to meet the current needs for injury control and worker safety in computer integrated manufacturing systems, the ISO Committee on Industrial Automation Systems has proposed a new safety standard entitled “Safety of Integrated Manufacturing Systems” (1991). This new international standard, which was developed in recognition of the particular hazards which exist in integrated manufacturing systems incorporating industrial machines and associated equipment, aims to minimize the possibilities of injuries to personnel while working on or adjacent to an integrated manufacturing system. The main sources of potential hazards to the human operators in CIM identified by this standard are shown in figure 1.

Figure 1. Main source of hazards in computer-intergrated manufacturing (CIM) (after ISO 1991)

Human and System Errors

In general, hazards in a HAS can arise from the system itself, from its association with other equipment present in the physical environment, or from interactions of human personnel with the system. An accident is only one of the several outcomes of human-machine interactions that may emerge under hazardous conditions; near accidents and damage incidents are much more common (Zimolong and Duda 1992). The occurrence of an error can lead to one of these consequences: (1) the error remains unnoticed, (2) the system can compensate for the error, (3) the error leads to a machine breakdown and/or system stoppage or (4) the error leads to an accident.

Since not every human error that results in a critical incident will cause an actual accident, it is appropriate to distinguish further among outcome categories as follows: (1) an unsafe incident (i.e., any unintentional occurrence regardless whether it results in injury, damage or loss), (2) an accident (i.e., an unsafe event resulting in injury, damage or loss), (3) a damage incident (i.e., an unsafe event which results only in some kind of material damage), (4) a near accident or “near miss” (i.e., an unsafe event in which injury, damage or loss was fortuitously avoided by a narrow margin) and (5) the existence of accident potential (i.e., unsafe events which could have resulted in injury, damage, or loss, but, owing to circumstances, did not result in even a near accident).

One can distinguish three basic types of human error in a HAS:

- skill-based slips and lapses

- rule-based mistakes

- knowledge-based mistakes.

This taxonomy, devised by Reason (1990), is based on a modification of Rasmussen’s skill-rule-knowledge classification of human performance as described above. At the skill-based level, human performance is governed by stored patterns of pre-programmed instructions represented as analogue structures in a space-time domain. The rule-based level is applicable to tackling familiar problems in which solutions are governed by stored rules (called “productions”, since they are accessed, or produced, at need). These rules require certain diagnoses (or judgements) to be made, or certain remedial actions to be taken, given that certain conditions have arisen that demand an appropriate response. At this level, human errors are typically associated with the misclassification of situations, leading either to the application of the wrong rule or to the incorrect recall of consequent judgements or procedures. Knowledge-based errors occur in novel situations for which actions must be planned “on-line” (at a given moment), using conscious analytical processes and stored knowledge. Errors at this level arise from resource limitations and incomplete or incorrect knowledge.

The generic error-modelling systems (GEMS) proposed by Reason (1990), which attempts to locate the origins of the basic human error types, can be used to derive the overall taxonomy of human behaviour in a HAS. GEMS seeks to integrate two distinct areas of error research: (1) slips and lapses, in which actions deviate from current intention due to execution failures and/or storage failures and (2) mistakes, in which the actions may run according to plan, but the plan is inadequate to achieve its desired outcome.

Risk Assessment and Prevention in CIM

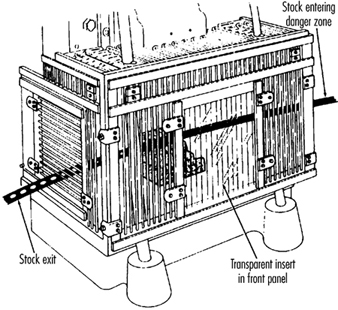

According to the ISO (1991), risk assessment in CIM should be performed so as to minimize all risks and to serve as a basis for determining safety objectives and measures in the development of programmes or plans both to create a safe working environment and to ensure the safety and health of personnel as well. For example, work hazards in manufacturing-based HAS environments can be characterized as follows: (1) the human operator may need to enter the danger zone during disturbance recovery, service and maintenance tasks, (2) the danger zone is difficult to determine, to perceive and to control, (3) the work may be monotonous and (4) the accidents occurring within computer-integrated manufacturing systems are often serious. Each identified hazard should be assessed for its risk, and appropriate safety measures should be determined and implemented to minimize that risk. Hazards should also be ascertained with respect to all of the following aspects of any given process: the single unit itself; the interaction between single units; the operating sections of the system; and the operation of the complete system for all intended operating modes and conditions, including conditions under which normal safeguarding means are suspended for such operations as programming, verification, troubleshooting, maintenance or repair.

The design phase of the ISO (1991) safety strategy for CIM includes:

- specification of the limits of system parameters

- application of a safety strategy

- identification of hazards

- assessment of the associated risks

- removal of the hazards or diminution of the risks as much as practicable.

The system safety specification should include:

- a description of system functions

- a system layout and/or model

- the results of a survey undertaken to investigate the interaction of different working processes and manual activities

- an analysis of process sequences, including manual interaction

- a description of the interfaces with conveyor or transport lines

- process flow charts

- foundation plans

- plans for supply and disposal devices

- determination of the space required for supply and disposal of material

- available accident records.

In accordance with the ISO (1991), all necessary requirements for ensuring a safe CIM system operation need to be considered in the design of systematic safety-planning procedures. This includes all protective measures to effectively reduce hazards and requires:

- integration of the human-machine interface

- early definition of the position of those working on the system (in time and space)

- early consideration of ways of cutting down on isolated work

- consideration of environmental aspects.

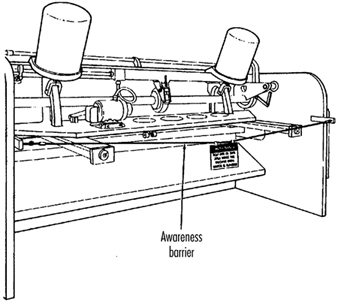

The safety planning procedure should address, among others, the following safety issues of CIM:

- Selection of the operating modes of the system. The control equipment should have provisions for at least the following operating modes:(1) normal or production mode (i.e., with all normal safeguards connected and operating), (2) operation with some of the normal safeguards suspended and (3) operation in which system or remote manual initiation of hazardous situations is prevented (e.g., in the case of local operation or of isolation of power to or mechanical blockage of hazardous conditions).

- Training, installation, commissioning and functional testing. When personnel are required to be in the hazard zone, the following safety measures should be provided in the control system: (1) hold to run, (2) enabling device, (3) reduced speed, (4) reduced power and (5) moveable emergency stop.

- Safety in system programming, maintenance and repair. During programming, only the programmer should be allowed in the safeguarded space. The system should have inspection and maintenance procedures in place to ensure continued intended operation of the system. The inspection and maintenance programme should take into account the recommendations of the system supplier and those of suppliers of various elements of the systems. It scarcely needs mentioning that personnel who perform maintenance or repairs on the system should be trained in the procedures necessary to perform the required tasks.

- Fault elimination. Where fault elimination is necessary from inside the safeguarded space, it should be performed after safe disconnection (or, if possible, after a lockout mechanism has been actuated). Additional measures against erroneous initiation of hazardous situations should be taken. Where hazards can occur during fault elimination at sections of the system or at the machines of adjoining systems or machines, these should also be taken out of operation and protected against unexpected starting. By means of instruction and warning signs, attention should be drawn to fault elimination in system components which cannot be observed completely.

System Disturbance Control

In many HAS installations utilized in the computer-integrated manufacturing area, human operators are typically needed for the purpose of controlling, programming, maintaining, pre-setting, servicing or troubleshooting tasks. Disturbances in the system lead to situations that make it necessary for workers to enter the hazardous areas. In this respect, it can be assumed that disturbances remain the most important reason for human interference in CIM, because the systems will more often than not be programmed from outside the restricted areas. One of the most important issues for CIM safety is to prevent disturbances, since most risks occur in the troubleshooting phase of the system. The avoidance of disturbances is the common aim as regards both safety and cost-effectiveness.

A disturbance in a CIM system is a state or function of a system that deviates from the planned or desired state. In addition to productivity, disturbances during the operation of a CIM have a direct effect on the safety of the people involved in operating the system. A Finnish study (Kuivanen 1990) showed that about one-half of the disturbances in automated manufacturing decrease the safety of the workers. The main causes for disturbances were errors in system design (34%), system component failures (31%), human error (20%) and external factors (15%). Most machine failures were caused by the control system, and, in the control system, most failures occurred in sensors. An effective way to increase the level of safety of CIM installations is to reduce the number of disturbances. Although human actions in disturbed systems prevent the occurrence of accidents in the HAS environment, they also contribute to them. For example, a study of accidents related to malfunctions of technical control systems showed that about one-third of the accident sequences included human intervention in the control loop of the disturbed system.

The main research issues in CIM disturbance prevention concern (1) major causes of disturbances, (2) unreliable components and functions, (3) the impact of disturbances on safety, (4) the impact of disturbances on the function of the system, (5) material damage and (6) repairs. The safety of HAS should be planned early at the system design stage, with due consideration of technology, people and organization, and be an integral part of the overall HAS technical planning process.

HAS Design: Future Challenges

To assure the fullest benefit of hybrid automated systems as discussed above, a much broader vision of system development, one which is based on integration of people, organization and technology, is needed. Three main types of system integration should be applied here:

- integration of people, by assuring effective communication between them

- human-computer integration, by designing suitable interfaces and interaction between people and computers

- technological integration, by assuring effective interfacing and interactions between machines.

The minimum design requirements for hybrid automated systems should include the following: (1) flexibility, (2) dynamic adaptation, (3) improved responsiveness, and (4) the need to motivate people and make better use of their skills, judgement and experience. The above also requires that HAS organizational structures, work practices and technologies be developed to allow people at all levels of the system to adapt their work strategies to the variety of systems control situations. Therefore, the organizations, work practices and technologies of HAS will have to be designed and developed as open systems (Kidd 1994).

An open hybrid automated system (OHAS) is a system that receives inputs from and sends outputs to its environment. The idea of an open system can be applied not only to system architectures and organizational structures, but also to work practices, human-computer interfaces, and the relationship between people and technologies: one may mention, for example, scheduling systems, control systems and decision support systems. An open system is also an adaptive one when it allows people a large degree of freedom to define the mode of operating the system. For example, in the area of advanced manufacturing, the requirements of an open hybrid automated system can be realized through the concept of human and computer-integrated manufacturing (HCIM). In this view, the design of technology should address the overall HCIM system architecture, including the following: (1) considerations of the network of groups, (2) the structure of each group, (3) the interaction between groups, (4) the nature of the supporting software and (5) technical communication and integration needs between supporting software modules.

The adaptive hybrid automated system, as opposed to the closed system, does not restrict what the human operators can do. The role of the designer of a HAS is to create a system that will satisfy the user’s personal preferences and allow its users to work in a way that they find most appropriate. A prerequisite for permitting user input is the development of an adaptive design methodology—that is, an OHAS that allows enabling, computer-supported technology for its implementation in the design process. The need to develop a methodology for adaptive design is one of the immediate requirements to realize the OHAS concept in practice. A new level of adaptive human supervisory control technology needs also to be developed. Such technology should allow the human operator to “see through” the otherwise invisible control system of HAS functioning—for example, by application of an interactive, high-speed video system at each point of system control and operation. Finally, a methodology for development of an intelligent and highly adaptive, computer-based support of human roles and human functioning in the hybrid automated systems is also very much needed.

Safety-Related Applications

In the last few years microprocessors have played an ever-increasing role in the field of safety technology. Because entire computers (i.e., central processing unit, memory and peripheral components) are now available in a single component as “single-chip computers”, microprocessor technology is being employed not only in complex machine control, but also in safeguards of relatively simple design (e.g., light grids, two-hand control devices and safety edges). The software controlling these systems comprises between one thousand and several tens of thousands of single commands and usually consists of several hundred program branches. The programs operate in real time and are mostly written in the programmers’ assembly language.

The introduction of computer-controlled systems in the sphere of safety technology has been accompanied in all large-scale technical equipment not only by expensive research and development projects but also by significant restrictions designed to enhance safety. (Aerospace technology, military technology and atomic power technology may here be cited as examples of large-scale applications.) The collective field of industrial mass production has up to now been treated only in a very limited fashion. This is partly for the reason that the rapid cycles of innovation characteristic of industrial machine design make it difficult to carry over, in any but a very restricted manner, such knowledge as may be derived from research projects concerned with the final testing of large-scale safety devices. This makes the development of rapid and low-cost assessment procedures a desideratum (Reinert and Reuss 1991).

This article first examines machines and facilities in which computer systems presently perform safety tasks, using examples of accidents occurring preponderantly in the area of machine safeguards to depict the particular role which computers play in safety technology. These accidents give some indication as to which precautions must be taken so that the computer-controlled safety equipment currently coming into increasingly wide use will not lead to a rise in the number of accidents. The final section of the article sketches out a procedure which will enable even small computer systems to be brought to an appropriate level of technical safety at justifiable expense and within an acceptable period of time. The principles indicated in this final part are currently being introduced into international standardization procedures and will have implications for all areas of safety technology in which computers find application.

Examples of the Use of Software and Computers in the Field of Machine Safeguards

The following four examples make it clear that software and computers are currently entering more and more into safety-related applications in the commercial domain.

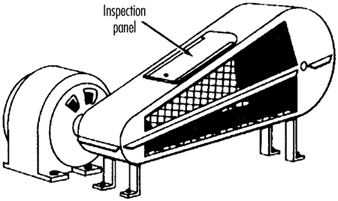

Personal-emergency signal installations consist, as a rule, of a central receiving station and a number of personal emergency signalling devices. The devices are carried by persons working onsite by themselves. If any of these persons working alone find themselves in an emergency situation, they can use the device to trip an alarm by radio signal in the central receiving station. Such a will-dependent alarm trigger may also be supplemented by a will-independent triggering mechanism activated by sensors built into the personal emergency devices. Both the individual devices and the central receiving station are frequently controlled by microcomputers. It is conceivable that failure of specific single functions of the built-in computer could lead, in an emergency situation, to a failure to trip the alarm. Precautions must therefore be taken to perceive and to repair such loss of function in time.

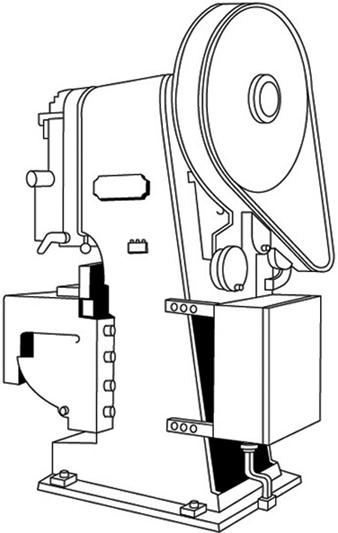

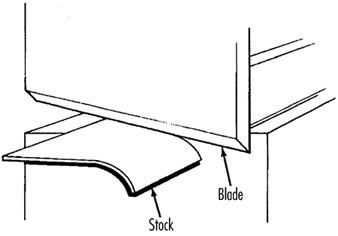

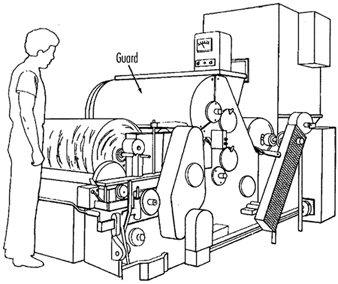

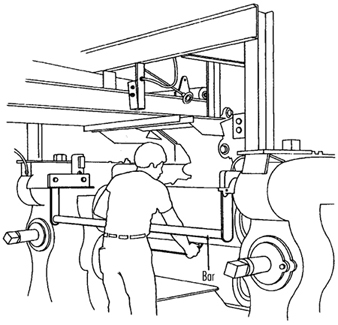

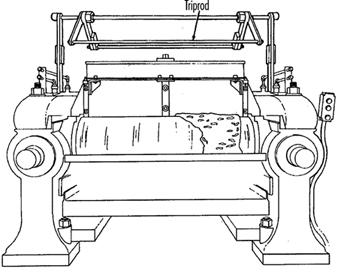

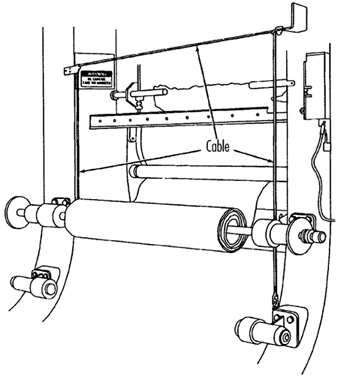

Printing presses used today to print magazines are large machines. The paper webs are normally prepared by a separate machine in such a way as to enable a seamless transition to a new paper roll. The printed pages are folded by a folding machine and subsequently worked through a chain of further machines. This results in pallets loaded with fully sewn magazines. Although such plants are automated, there are two points at which manual interventions must be made: (1) in the threading of the paper paths, and (2) in clearing obstructions caused by paper tears at danger spots on the rotating rollers. For this reason, a reduced speed of operation or a path- or time-limited jogging mode must be ensured by the control technology while the presses are being adjusted. On account of the complex steering procedures involved, every single printing station must be equipped with its own programmable logic controller. Any failure occurring in the control of a printing plant while guard grids are open must be kept from leading either to the unexpected start-up of a stopped machine or to operation in excess of appropriately reduced speeds.

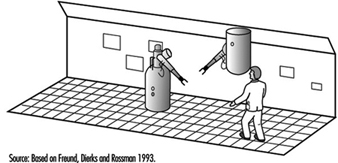

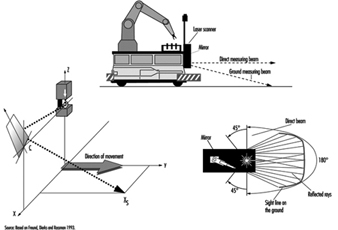

In large factories and warehouses, driverless, automated guided robot vehicles move about on specially marked tracks. These tracks can be walked upon at any time by persons, or materials and equipment may be inadvertently left on the tracks, since they are not separated structurally from other lines of traffic. For this reason, some sort of collision-prevention equipment must be used to ensure that the vehicle will be brought to a halt before any dangerous collision with a person or object occurs. In more recent applications, collision prevention is effected by means of ultrasonic or laser light scanners used in combination with a safety bumper. Since these systems work under computer control, it is possible to configure several permanent detection zones so that a vehicle can modify its reaction depending on the specific detection zone in which a person is located. Failures in the protective device must not lead to a dangerous collision with a person.

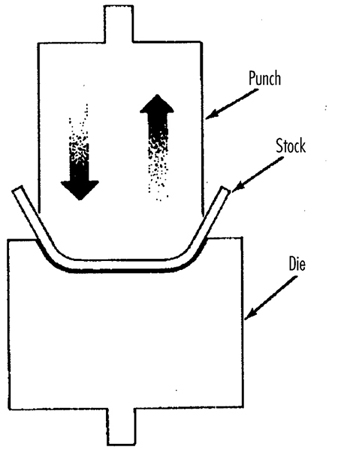

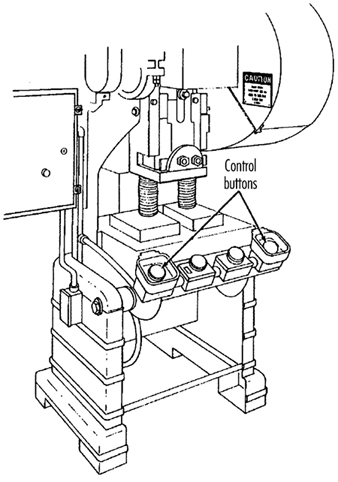

Paper-cutting control device guillotines are used to press and then cut thick stacks of paper. They are triggered by a two-hand control device. The user must reach into the danger zone of the machine after each cut is made. An immaterial safeguard, usually a light grid, is used in conjunction with both the two-hand control device and a safe machine-control system to prevent injuries when paper is fed during the cutting operation. Nearly all the larger, more modern guillotines in use today are controlled by multichannel microcomputer systems. Both the two-hand operation and the light grid must also be guaranteed to function safely.

Accidents with Computer-Controlled Systems

In nearly all fields of industrial application, accidents with software and computers are reported (Neumann 1994). In most cases, computer failures do not lead to injury to persons. Such failures are in any case made public only when they are of general public interest. This means that the instances of malfunction or accident related to computers and software in which injury to persons is involved make up a relatively high proportion of all publicized cases. Unfortunately, accidents which do not cause much of a public sensation are not investigated as to their causes with quite the same intensity as are more prominent accidents, typically in large-scale plants. For this reason, the examples which follow refer to four descriptions of malfunctions or accidents typical of computer-controlled systems outside the field of machine safeguards, which are used to suggest what has to be taken into account when judgements concerning safety technology are made.

Accidents caused by random failures in hardware

The following mishap was caused by a concentration of random failures in the hardware combined with programming failure: A reactor overheated in a chemical plant, whereupon relief valves were opened, allowing the contents of the reactor to be discharged into the atmosphere. This mishap occurred a short time after a warning had been given that the oil level in a gearbox was too low. Careful investigation of the mishap showed that shortly after the catalyst had initiated the reaction in the reactor—in consequence of which the reactor would have required more cooling—the computer, on the basis of the report of low oil levels in the gearbox, froze all magnitudes under its control at a fixed value. This kept the cold water flow at too low a level and the reactor overheated as a result. Further investigation showed that the indication of low oil levels had been signalled by a faulty component.

The software had responded according to the specification with the tripping of an alarm and the fixing of all operative variables. This was a consequence of the HAZOP (hazards and operability analysis) study (Knowlton 1986) done prior to the event, which required that all controlled variables not be modified in the event of a failure. Since the programmer was not acquainted with the procedure in detail, this requirement was interpreted to mean that the controlled actuators (control valves in this case) were not to be modified; no attention was paid to the possibility of a rise in temperature. The programmer did not take into consideration that after having received an erroneous signal the system might find itself in a dynamic situation of a type requiring the active intervention of the computer to prevent a mishap. The situation which led to the mishap was so unlikely, moreover, that it had not been analysed in detail in the HAZOP study (Levenson 1986). This example provides a transition to a second category of causes of software and computer accidents. These are the systematic failures which are in the system from the beginning, but which manifest themselves only in certain very specific situations which the developer has not taken into account.

Accidents caused by operating failures

In field testing during the final inspection of robots, one technician borrowed the cassette of a neighbouring robot and substituted a different one without informing his colleague that he had done so. Upon returning to his workplace, the colleague inserted the wrong cassette. Since he stood next to the robot and expected a particular sequence of movements from it—a sequence which came out differently on account of the exchanged program—a collision occurred between robot and human. This accident describes the classical example of an operating failure. The role of such failures in malfunctions and accidents is currently increasing due to increasing complexity in the application of computer-controlled safety mechanisms.

Accidents caused by systematic failures in hardware or software

A torpedo with a warhead was to have been fired for training purposes, from a warship on the high seas. On account of a defect in the drive apparatus the torpedo remained in the torpedo tube. The captain decided to return to the home port in order to salvage the torpedo. Shortly after the ship had begun to make its way back home, the torpedo exploded. An analysis of the accident revealed that the torpedo’s developers had been obliged to build into the torpedo a mechanism designed to prevent its returning to the launching pad after having been fired and thus destroying the ship that had launched it. The mechanism chosen for this was as follows: After the firing of the torpedo a check was made, using the inertial navigation system, to see whether its course had altered by 180°. As soon as the torpedo sensed that it had turned 180°, the torpedo detonated immediately, supposedly at a safe distance from the launching pad. This detection mechanism was actuated in the case of the torpedo which had not been properly launched, with the result that the torpedo exploded after the ship had changed its course by 180°. This is a typical example of an accident occurring on account of a failure in specifications. The requirement in the specifications that the torpedo should not destroy its own ship should its course change was not formulated precisely enough; the precaution was thus programmed erroneously. The error became apparent only in a particular situation, one which the programmer had not taken into account as a possibility.

On 14 September 1993, a Lufthansa Airbus A 320 crashed while landing in Warsaw (figure 1). A careful investigation of the accident showed that modifications in the landing logic of the on-board computer made after an accident with a Lauda Air Boeing 767 in 1991 were partly responsible for this crash landing. What had happened in the 1991 accident was that the thrust deflection, which diverts some part of the motor gases so as to brake the airplane during landing, had engaged while still in the air, thus forcing the machine into an uncontrollable nose-dive. For this reason, an electronic locking of the thrust deflection had been built into the Airbus machines. This mechanism permitted thrust deflection to come into effect only after sensors on both sets of landing gear had signalled the compression of the shock absorbers under the pressure of the wheels touching down. On the basis of incorrect information, the pilots of the plane in Warsaw anticipated a strong side wind.

Figure 1. Lufthansa Airbus after accident in Warsaw 1993

For this reason they brought the machine in at a slight tilt and the Airbus touched down with the right wheel only, leaving the left bearing less than full weight. On account of the electronic locking of the thrust deflection, the on-board computer denied to the pilot for the space of nine seconds such manoeuvers as would have allowed the airplane to land safely despite adverse circumstances. This accident demonstrates very clearly that modifications in computer systems can lead to new and hazardous situations if the range of their possible consequences is not considered in advance.

The following example of a malfunction also demonstrates the disastrous effects which the modification of one single command can have in computer systems. The alcohol content of blood is determined, in chemical tests, using clear blood serum from which the blood corpuscles have been centrifuged out in advance. The alcohol content of serum is therefore higher (by a factor of 1.2) than that of the thicker whole blood. For this reason the alcohol values in serum must be divided by a factor of 1.2 in order to establish the legally and medically critical parts-per-thousand figures. In the inter-laboratory test held in 1984, the blood alcohol values ascertained in identical tests performed at different research institutions using serum were to have been compared with each other. Since it was a question of comparison only, the command to divide by 1.2 was moreover erased from the program at one of the institutions for the duration of the experiment. After the inter-laboratory test had come to an end, a command to multiply by 1.2 was erroneously introduced into the program at this spot. Roughly 1,500 incorrect parts-per-thousand values were calculated between August 1984 and March 1985 as a result. This error was critical for the professional careers of truck drivers with blood alcohol levels between 1.0 and 1.3 per thousand, since a legal penalty entailing confiscation of a driver’s licence for a prolonged period is the consequence of a 1.3 per thousand value.

Accidents caused by influences from operating stresses or from environmental stresses

As a consequence of a disturbance caused by collection of waste in the effective area of a CNC (computer numeric control) punching and nibbling machine, the user put into effect the “programmed stop”. As he was trying to remove the waste with his hands, the push rod of the machine started moving in spite of the programmed stop and severely injured the user. An analysis of the accident revealed that it had not been a question of an error in the program. The unexpected start-up could not be reproduced. Similar irregularities had been observed in the past on other machines of the same type. It seems plausible to deduce from these that the accident must have been caused by electromagnetic interference. Similar accidents with industrial robots are reported from Japan (Neumann 1987).

A malfunction in the Voyager 2 space probe on January 18, 1986, makes even more clear the influence of environmental stresses on computer-controlled systems. Six days before the closest approach to Uranus, large fields of black-and-white lines covered over the pictures from Voyager 2. A precise analysis showed that a single bit in a command word of the flight data subsystem had caused the failure, observed as the pictures were compressed in the probe. This bit had most likely been knocked out of place within the program memory by the impact of a cosmic particle. Error-free transmission of the compressed photographs from the probe was effected only two days later, using a replacement program capable of bypassing the failed memory point (Laeser, McLaughlin and Wolff 1987).

Summary of the accidents presented

The accidents analysed show that certain risks that might be neglected under conditions using simple, electro-mechanical technology, gain in significance when computers are used. Computers permit the processing of complex and situation-specific safety functions. An unambiguous, error-free, complete and testable specification of all safety functions becomes for this reason especially important. Errors in specifications are difficult to discover and are frequently the cause of accidents in complex systems. Freely programmable controls are usually introduced with the intention of being able to react flexibly and quickly to the changing market. Modifications, however—particularly in complex systems—have side effects which are difficult to foresee. All modifications must therefore be subjected to a strictly formal management of change procedure in which a clear separation of safety functions from partial systems not relevant to safety will help keep the consequences of modifications for safety technology easy to survey.

Computers work with low levels of electricity. They are therefore susceptible to interference from external radiation sources. Since the modification of a single signal among millions can lead to a malfunction, it is worth paying special attention to the theme of electromagnetic compatibility in connection with computers.

The servicing of computer-controlled systems is currently becoming more and more complex and thus more unclear. The software ergonomics of user and configuration software is therefore becoming more interesting from the point of view of safety technology.

No computer system is 100% testable. A simple control mechanism with 32 binary input ports and 1,000 different software paths requires 4.3 × 1012 tests for a complete check. At a rate of 100 tests per second executed and evaluated, a complete test would take 1,362 years.

Procedures and Measures for the Improvement of Computer-Controlled Safety Devices

Procedures have been developed within the last 10 years which permit mastery of specific safety-related challenges in connection with computers. These procedures address themselves to the computer failures described in this section. The examples described of software and computers in machine safeguards and the accidents analysed, show that the extent of damage and thus also the risk involved in various applications are extremely variable. It is therefore clear that the requisite precautions for the improvement of computers and software used in safety technology should be established in relation to the risk.

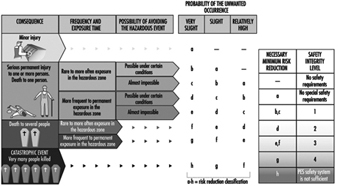

Figure 2 shows a qualitative procedure whereby the necessary risk reduction obtainable using safety systems can be determined independently of the extent to which and the frequency with which damage occurs (Bell and Reinert 1992). The types of failures in computer systems analysed in the section “Accidents with computer-controlled systems” (above) may be brought into relation with the so-called Safety Integrity Levels—that is, the technical facilities for risk reduction.

Figure 2. Qualitative procedure for risk determination

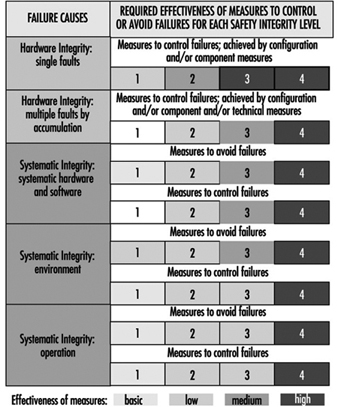

Figure 3 makes it clear that the effectiveness of measures taken, in any given case, to reduce error in software and computers needs to grow with increasing risk (DIN 1994; IEC 1993).

Figure 3, Effectiveness of precautions taken against errors independently of risk

The analysis of the accidents sketched above shows that the failure of computer-controlled safeguards is caused not only by random component faults, but also by particular operating conditions which the programmer has failed to take into account. The not immediately obvious consequences of program modifications made in the course of system maintenance constitute a further source of error. It follows that there can be failures in safety systems controlled by microprocessors which, though made during the development of the system, can lead to a dangerous situation only during operation. Precautions against such failures must therefore be taken while safety-related systems are in the development stage. These so-called failure-avoidance measures must be taken not only during the concept phase, but also in the process of development, installation and modification. Certain failures can be avoided if they are discovered and corrected during this process (DIN 1990).

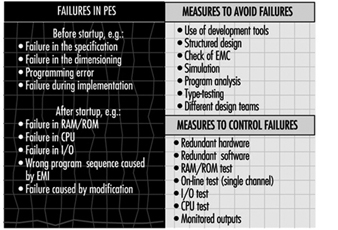

As the last mishap described makes clear, the breakdown of a single transistor can lead to the technical failure of highly complex automated equipment. Since each single circuit is composed of many thousands of transistors and other components, numerous failure-avoidance measures must be taken to recognize such failures as turn up in operation and to initiate an appropriate reaction in the computer system. Figure 4 describes types of failures in programmable electronic systems as well as examples of precautions which may be taken to avoid and control failures in computer systems (DIN 1990; IEC 1992).

Figure 4. Examples of precautions taken to control and avoid errors in computer systems

Possibilities and Prospects of Programmable Electronic Systems in Safety Technology

Modern machines and plants are becoming increasingly complex and must achieve ever more comprehensive tasks in ever shorter periods of time. For this reason, computer systems have taken over nearly all areas of industry since the mid-1970s. This increase in complexity alone has contributed significantly to the rising costs involved in improving safety technology in such systems. Although software and computers pose a great challenge to safety in the workplace, they also make possible the implementation of new error-friendly systems in the field of safety technology.

A droll but instructive verse by Ernst Jandl will help to explain what is meant by the concept error-friendly. “Lichtung: Manche meinen lechts und rinks kann man nicht velwechsern, werch ein Illtum”. (“Dilection: Many berieve light and reft cannot be intelchanged, what an ellol”.) Despite the exchange of the letters r and l, this phrase is easily understood by a normal adult human. Even someone with low fluency in the English language can translate it into English. The task is, however, nearly impossible for a translating computer on its own.

This example shows that a human being can react in a much more error-friendly fashion than a language computer can. This means that humans, like all other living creatures, can tolerate failures by referring them to experience. If one looks at the machines in use today, one can see that the majority of machines penalize user failures not with an accident, but with a decrease in production. This property leads to the manipulation or evasion of safeguards. Modern computer technology places systems at the disposal of work safety which can react intelligently—that is, in a modified way. Such systems thus make possible an error-friendly mode of behaviour in novel machines. They warn users during a wrong operation first of all and shut the machine off only when this is the only way to avoid an accident. The analysis of accidents shows that there exists in this area a considerable potential for reducing accidents (Reinert and Reuss 1991).

Devices for Controlling, Isolating and Switching Energy

Control devices and devices used for isolating and switching must always be discussed in relation to technical systems, a term used in this article to include machines, installations and equipment. Every technical system fulfils a specific and assigned practical task. Appropriate safety control and switching devices are required if this practical task is to be workable or even possible under safe conditions. Such devices are used in order to initiate control, interrupt or retard the current and/or the impulses of electric, hydraulic, pneumatic and also potential energies.

Isolation and Energy Reduction

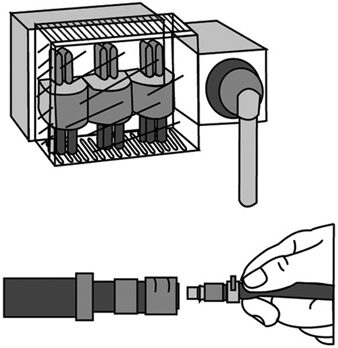

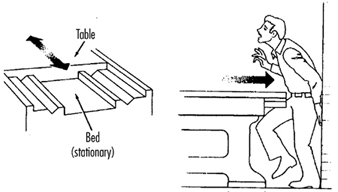

Isolating devices are used to isolate energy by disconnecting the supply line between the energy source and the technical system. The isolating device must normally yield an unequivocally determinable actual disconnection of the energy supply. Disconnection of the energy supply should also always be combined with the reduction of energy stored in all parts of the technical system. If the technical system is fed by several energy sources, all these supply lines must be capable of being reliably isolated. Persons trained to handle the relevant type of energy and who work at the energy end of the technical system, use isolation devices to shield themselves from the hazards of the energy. For safety reasons, these persons will always check to assure that no potentially hazardous energy remains in the technical system—for instance, by ascertaining the absence of electrical potential in the case of electric energy. Risk-free handling of certain isolating devices is possible only for trained specialists; in such cases, the isolating device must be made inaccessible to unauthorized persons. (See figure 1.)

Figure 1. Principles of electric and pneumatic isolating devices

The Master Switch

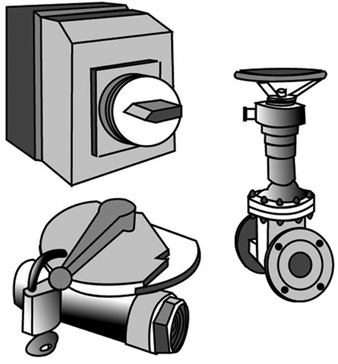

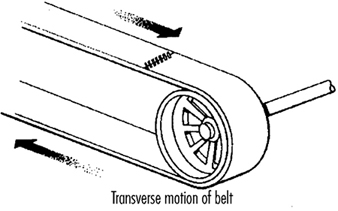

A master-switch device disconnects the technical system from the energy supply. Unlike the isolating device, it can be operated without danger even by “non-energy specialists”. The master- switch device is used to disconnect technical systems not in use at a given moment should, say, their operation be obstructed by unauthorized third persons. It is also used to effect a disconnection for such purposes as maintenance, repair of malfunctions, cleaning, resetting and refitting, provided that such work can be done without energy in the system. Naturally, when a master-switch device also possesses the characteristics of an isolating device, it can also take on and/or share its function. (See figure 2.)

Figure 2. Sample illustration of electric and pneumetic master-switch devices

Safety-disconnection Device

A safety-disconnection device does not disconnect the entire technical system from the energy source; rather, it removes energy from the parts of the system critical to a particular operational subsystem. Interventions of short duration can be designated for operational subsystems—for instance, for the set-up or resetting/refitting of the system, for the repair of malfunctions, for regular cleaning, and for essential and designated movements and function sequences required during the course of set-up, resetting/refitting or test runs. Complex production equipment and plants cannot simply be shut off with a master-switch device in these cases, as the entire technical system could not start up again where it left off after a malfunction has been repaired. Furthermore, the master-switch device is rarely located, in the more extensive technical systems, at the place where the intervention must be made. Thus the safety disconnection device is obliged to fulfil a number of requirements, such as the following:

- It interrupts the energy flow reliably and in such a way that dangerous movements or processes are not triggered by control signals which are either erroneously entered or erroneously generated.

- It is installed precisely where interruptions must be made in danger areas of operational subsystems of the technical system. If necessary, installation can be in several places (for instance, on various floors, in various rooms, or at various access points on machinery or equipment).

- Its control device has a clearly marked “off” position which registers only once after the flow of energy has been reliably cut off.

- Once in the “off” position its control device can be secured against being restarted without authorization (a) if the danger areas in question cannot be reliably overseen from the control area and (b) if persons located in the danger area cannot themselves see the control device readily and constantly, or (c) if lock-out/tag-out is required by regulation or organization procedures.

- It should disconnect only a single functional unit of an extended technical system, if other functional units are able to continue to work on their own without danger to the person intervening.

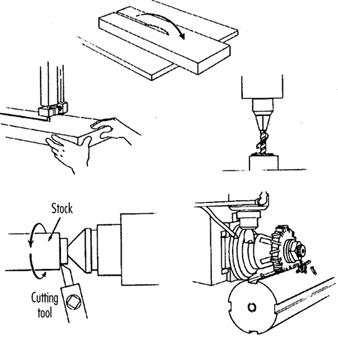

Where the master-switch device used in a given technical system is able to fulfil all the requirements of a safety-disconnection device, it can also take on this function. But that will of course be a reliable expedient only in very simple technical systems. (See figure 3.)

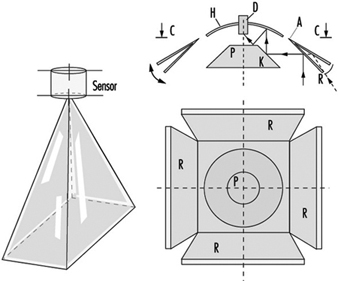

Figure 3. Illustration of elementary principles of a safety disconnection device

Control Gears for Operational Subsystems

Control gears permit movements and functional sequences required for operational subsystems of the technical system to be implemented and controlled safely. Control gears for operational subsystems may be required for set-up (when test runs are to be executed); for regulation (when malfunctions in the operation of the system are to be repaired or when blockages must be cleared); or training purposes (demonstrating operations). In such cases, the normal operation of the system cannot simply be restarted, as the intervening person would be endangered by movements and processes triggered by control signals either erroneously entered or erroneously generated. A control gear for operational subsystems must conform to the following requirements:

- It should permit the safe execution of movements and processes required for operational subsystems of the technical system. For example, certain movements will be executed at reduced speeds, gradually or at lower levels of power (depending on what is appropriate), and processes interrupted immediately, as a rule, if the control panel is no longer attended.

- Its control panels are to be located in areas where their operation does not endanger the operator, and from which the processes controlled are fully visible.

- If several control panels controlling various processes are present at a single location, then these must be clearly marked and arranged in a distinct and understandable manner.

- The control gear for operational subsystems should become effective only when normal operation has been reliably disengaged; that is, it must be guaranteed that no control command can issue effectively from normal operation and over-ride the control gear.

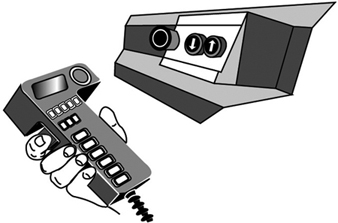

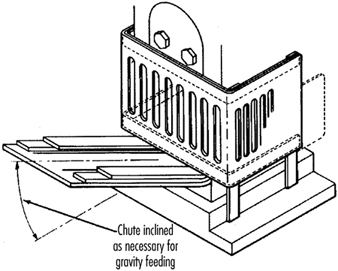

- Unauthorized use of the control gear for operational subsystems should be preventable, for instance, by requiring the use of a special key or code to release the function in question. (See figure 4.)

Figure 4. Actuating devices in the control gears for movable and stationary operational subsystems

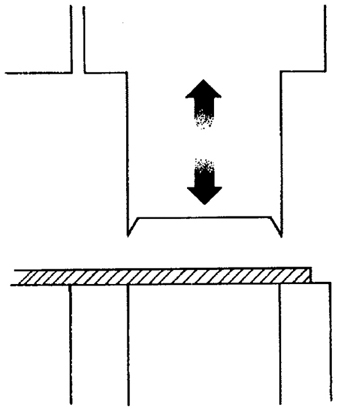

The Emergency Switch

Emergency switches are necessary where the normal operation of technical systems could result in hazards which neither appropriate system design nor the taking of appropriate safety precautions are able to prevent. In operational subsystems, the emergency switch is frequently part of the operational subsystem control gear. When operated in case of danger, the emergency switch implements processes which return the technical system to a safe operating state as quickly as possible. With regard to safety priorities, the protection of persons is of primary concern; prevention of damage to material is secondary, unless the latter is liable to endanger persons as well. The emergency switch must fulfil the following requirements:

- It must bring about a safe operating condition of the technical system as quickly as possible.

- Its control panel must be easily recognizable and placed and designed in such a way that it can be operated without difficulty by the endangered persons and can also be reached by others responding to the emergency.

- The emergency processes it triggers must not bring about new hazards; for example, they must not release clamping devices or disconnect magnetic holding fixtures or block safety devices.

- After an emergency switch process has been triggered, the technical system must not be able to be restarted automatically by the resetting of the emergency switch control panel. Rather, the conscious entry of a new function control command must be required. (See figure 5.)

Figure 5. Illustration of the principles of control panels in emergency switches

Function-switch Control Device

Function-switch control devices are used to switch on the technical system for normal operation and to initiate, implement and interrupt the movements and processes designated for normal operation. The function-switch control device is used exclusively in the course of the normal operation of the technical system—that is, during the undisturbed execution of all assigned functions. It is used accordingly by the persons running the technical system. The function-switch control devices must meet the following requirements:

- Their control panels must be accessible and easy to use without danger.

- Their control panels must be clearly and rationally arranged; for example, control knobs should operate “rationally” with regard to controlled movements up and down, right and left. (“Rational” control movements and corresponding effects may be subject to local variation and are sometimes defined by stipulation.)

- Their control panels are to be clearly and intelligibly labelled, with symbols which are easily understood.

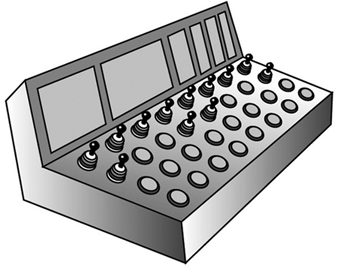

- Processes which require the complete attention of the user for their safe execution must not be able to be triggered either by control signals generated in error or by inadvertent operation of the control devices governing them. Control panel signal processing must be appropriately reliable, and involuntary operation must be prevented by appropriate design of the control device. (See figure 6).

Figure 6. Schematic representation of an operations control panel

Monitoring Switches

Monitoring switches prevent the starting of the technical system as long as the monitored safety conditions are not fulfilled, and they interrupt operation as soon as a safety condition is no longer being fulfilled. They are used, for example, to monitor doors in protective compartments, to check for the correct position of safety guards or to assure that speed or path limits are not exceeded. Monitoring switches must accordingly fulfil the following safety and reliability requirements:

- The switching gear used for monitoring purposes must emit the protective signal in a particularly reliable fashion; for instance, a mechanical monitoring switch might be designed to interrupt the signal flow automatically and with particular reliability.

- The switching tool used for monitoring purposes is to be operated in a particularly reliable fashion when the safety condition is not fulfilled (e.g., when the plunger of a monitoring switch with automatic interruption is forced mechanically and automatically into the interrupt position).

- The monitoring switch must not be able to be improperly turned off, at least not unintentionally and not without some effort; this condition may be fulfilled, for instance, by a mechanical, automatically controlled switch with automatic interruption, when the switch and the operating element are securely mounted. (See figure 7).

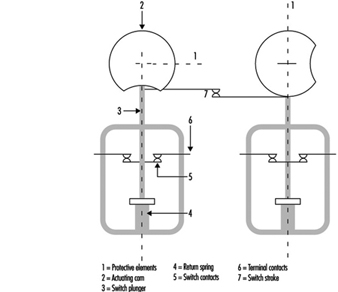

Figure 7. Diagram of a switch with a positive mechanical operation and positive disconnection

Safety Control Circuits

Several of the safety switching devices described above do not execute the safety function directly, but rather by emitting a signal which is then transmitted and processed by a safety control circuit and finally reaches those parts of the technical system which exercise the actual safety function. The safety-disconnection device, for example, frequently causes the disconnection of energy at critical points indirectly, whereas a main switch usually directly disconnects the supply of current to the technical system.

Because safety control circuits must transmit safety signals reliably, the following principles must therefore be taken into consideration:

- Safety should be guaranteed even when outside energy is lacking or insufficient, for example, during disconnects or leaks.

- Protective signals function more reliably by interruption of the signal flow; for example, safety switches with opener contact or an open relay contact.

- The protective function of amplifiers, transformers and the like may be achieved more reliably without outside energy; such mechanisms include, for example, electromagnetic switching devices or vents that are closed when at rest.

- Connections effected in error and leaks in the safety-control circuit must not be allowed to lead to false starts or hindrances to stoppage; particularly in the cases of a short circuit between in- and out-conduits, earth leakage, or grounding.

- Outside influences affecting the system in a measure not exceeding the expectations of the user should not interfere with the safety function of the safety-control circuit.

The components used in safety-control circuits must execute the safety function in an especially reliable way. The functions of components which do not meet this requirement are to be implemented by arranging for as diversified a redundancy as possible and are to be kept under surveillance.

Health and Environmental Concerns

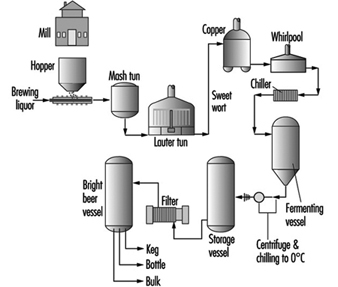

Beverages, both alcoholic and non-alcoholic, are normally produced under strict sanitary guidelines set by governmental regulations. To meet these guidelines, equipment within beverage plants is constantly cleaned and disinfected with harsh cleaning agents. The copious use of cleaning agents can, in itself, pose health problems to the workers exposed to them in their job duties. Skin and eye contact with the caustic cleansers can cause severe dermatitis. Another concern is that inhalation of the fumes or spray produced when using the cleansers may cause damage to the lungs, nose, mouth or throat. Water or other liquids are commonly found in and around production, making slips and falls a common injury and causing many other injuries simply due to poor traction.

Glass containers, high-speed fillers and overhead conveyors result in a combination of elements that can produce serious harm from flying glass. Cuts and eye injuries are common due to glass breakage. Much of the beverage industry has moved to using larger and larger quantities of aluminium cans and plastic containers; this has reduced the incidence of glass-inflicted injuries. However, in certain countries and specific industries, such as wine and spirits, this has not been the case.

Electrical systems in any industry possess a high degree of potential injury. When mixed with the ever present water in beverage manufacturing, the threat of electrocution becomes extreme. Electrical systems within beverage plants are constantly being reworked as the industry rapidly modernizes with new high-speed equipment that results in increasing exposure.