Children categories

73. Iron and Steel (4)

73. Iron and Steel

Chapter Editor: Augustine Moffit

Table of Contents

Figures and Tables

Iron and Steel Industry

John Masaitis

Rolling Mills

H. Schneider

Health and Safety Problems and Patterns

Environmental and Public Health Issues

Tables

Click a link below to view table in article context.

1. Recoverable by-products of coke ovens

2. Waste generated & recycled in steel production in Japan

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

74. Mining and Quarrying (17)

74. Mining and Quarrying

Chapter Editors: James R. Armstrong and Raji Menon

Table of Contents

Figures and Tables

Mining: An Overview

Norman S. Jennings

Exploration

William S. Mitchell and Courtney S. Mitchell

Types of Coal Mining

Fred W. Hermann

Techniques in Underground Mining

Hans Hamrin

Underground Coal Mining

Simon Walker

Surface Mining Methods

Thomas A. Hethmon and Kyle B. Dotson

Surface Coal Mining Management

Paul Westcott

Processing Ore

Sydney Allison

Coal Preparation

Anthony D. Walters

Ground Control in Underground Mines

Luc Beauchamp

Ventilation and Cooling in Underground Mines

M.J. Howes

Lighting in Underground Mines

Don Trotter

Personal Protective Equipment in Mining

Peter W. Pickerill

Fires and Explosions in Mines

Casey C. Grant

Detection of Gases

Paul MacKenzie-Wood

Emergency Preparedness

Gary A. Gibson

Health Hazards of Mining and Quarrying

James L. Weeks

Tables

Click a link below to view table in article context.

1. Design air quantity factors

2. Clothing-corrected air cooling powers

3. Comparison of mine light sources

4. Heating of coal-hierarchy of temperatures

5. Critical elements/sub-elements of emergency preparedness

6. Emergency facilities, equipment & materials

7. Emergency preparedness training matrix

8. Examples of horizontal auditing of emergency plans

9. Common names & health effects of hazardous gases

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

75. Oil Exploration and Distribution (1)

75. Oil Exploration and Distribution

Chapter Editor: Richard S. Kraus

Table of Contents

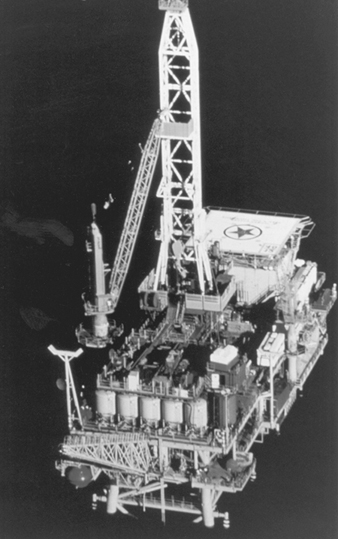

Exploration, Drilling and Production of Oil and Natural Gas

Richard S. Kraus

Tables

Click a link below to view table in article context.

1. Properties & gasoline potential of crude oils

2. Composition of crude oil & natural gas

3. Composition of natural & oil processing gases

4. Platform types for underwater drilling

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

76. Power Generation and Distribution (7)

76. Power Generation and Distribution

Chapter Editor: Michael Crane

Table of Contents

Figures and Tables

General Profile

Michael Crane

Hydroelectric Power Generation

Neil McManus

Fossil Fuel Power Generation

Anthony W. Jackson

Nuclear Power Generation

W.G. Morison

Electric Power Generation, Transmission and Distribution Safety: A US Example

Janet Fox

Hazards

Michael Crane

Environmental and Public Health Issues

Alexander C. Pittman, Jr.

Tables

Click a link below to view table in article context.

1. Controlling chemical & biological hazards

2. Controlling physical & safety hazards

3. Nuclear power station characteristics (1997)

4. Major potential environmental hazards

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

Ventilation and Cooling in Underground Mines

The main objective of mine ventilation is the provision of sufficient quantities of air to all the working places and travel ways in an underground mine to dilute to an acceptable level those contaminants which cannot be controlled by any other means. Where depth and rock temperatures are such that air temperatures are excessive, mechanical refrigeration systems may be used to supplement the beneficial effects of ventilation.

The Mine Atmosphere

The composition of the gaseous envelope encircling the earth varies by less than 0.01% from place to place and the constitution of “dry” air is usually taken as 78.09% nitrogen, 20.95% oxygen, 0.93% argon and 0.03% carbon dioxide. Water vapour is also present in varying amounts depending on the air temperature and pressure and the availability of free water surfaces. As ventilation air flows through a mine, the concentration of water vapour may change significantly and this variation is the subject of the separate study of psychrometry. To define the state of a water vapour and dry air mixture at a particular point requires the three measurable independent properties of barometric pressure, dry bulb and wet bulb temperatures.

Ventilation Requirements

The contaminants to be controlled by dilution ventilation are primarily gases and dust, although ionizing radiations associated with naturally occurring radon may present problems, especially in uranium mines and where the background uranium concentrations of the host or adjacent rocks are elevated. The amount of air required for dilution control will depend on both the strength of the contaminant source and the effectiveness of other control measures such as water for dust suppression or methane drainage systems in coal mines. The minimum dilution air flow rate is determined by the contaminant requiring the greatest dilution quantity with due cognizance of the possible additive effects of mixtures and synergism where one contaminant can increase the effect of another. Overriding this value could be a minimum air velocity requirement which is typically 0.25 m/s and increasing as air temperatures also increase.

Diesel-powered equipment ventilation

In mechanized mines using diesel-powered mobile equipment and in the absence of continuous gas monitoring, exhaust gas dilution is used to determine the minimum ventilation air requirements where they operate. The amount of air required normally ranges between 0.03 and 0.06 m3/s per kW of rated power at the point of operation depending on the type of the engine and whether any exhaust gas conditioning is being used. Continuing developments in both fuel and engine technology are providing lower engine emissions while catalytic converters, wet scrubbers and ceramic filters may further reduce the leaving concentrations of carbon monoxide/aldehydes, oxides of nitrogen and diesel particulates respectively. This helps in meeting increasingly stringent contaminant limits without significantly increasing exhaust dilution rates. The minimum possible dilution limit of 0.02 m3/s per kW is determined by the carbon dioxide emissions which are proportional to engine power and unaffected by exhaust gas conditioning.

Diesel engines are about one-third efficient at converting the energy available in the fuel to useful power and most of this is then used to overcome friction resulting in a heat output which is about three times the power output. Even when hauling rock up a decline in a truck, the useful work done is only about 10% of energy available in the fuel. Higher diesel engine powers are used in larger mobile equipment which require bigger excavations to operate safely. Allowing for normal vehicle clearances and a typical diesel exhaust gas dilution rate of

0.04 m3/s per kW, the minimum air velocities where diesels operate average about 0.5 m/s.

Ventilation of different mining methods

Although the setting of general air quantity requirements is not appropriate where detailed mine and ventilation planning information is available or possible, they are supportive of the criteria being used for design. Deviations from normal values generally can be explained and justified, for instance, in mines with heat or radon problems. The general relationship is:

Mine quantity = αt + β

where t is the annual production rate in million tonnes per annum (Mtpa), α is a variable air quantity factor which is directly related to production rate and β is the constant air quantity required to ventilate the mine infrastructure such as the ore handling system. Typical values of α are given in table 1.

Table 1. Design air quantity factors

|

Mining method |

α (air quantity factor m3/s/Mtpa) |

|

Block-caving |

50 |

|

Room-and-pillar (Potash) |

75 |

|

Sub-level caving |

120 |

|

Open stoping |

|

|

Mechanized cut-and-fill |

320 |

|

Non-mechanized mining |

400 |

The constant air quantity β is mainly dependent on the ore handling system and, to a certain extent, on the overall mine production rate. For mines where rock is transported through a decline using diesel powered truck haulage or there is no crushing of the mined rock, a suitable value of β is 50 m3/s. This typically increases to 100 m3/s when using underground crushers and skip hoisting with underground maintenance areas. As the ore handling system become more extensive (i.e., using conveyors or other ore transfer systems), β can further increase by up to 50%. On very large mines where multiple shaft systems are used, the constant air quantity β is also a multiple of the number of shaft systems required.

Cooling Requirements

Design thermal conditions

The provision of suitable thermal conditions to minimize the dangers and adverse effects of heat stress may require mechanical cooling in addition to the ventilation necessary to control contaminants. Although the applied heat stress is a complex function of climatic variables and physiological responses to them, in practical mining terms it is the air velocity and wet bulb temperature that have the greatest influence. This is illustrated by the clothing-corrected air cooling powers (W/m2) given in table 2. Underground the radiant temperature is taken to be equal to the dry bulb temperature and 10 °C higher than the wet bulb temperature. The barometric pressure and the clothing regime are typical for underground work (i.e., 110 kPa and 0.52 clothing units).

Table 2. Clothing-corrected air cooling powers (W/m2)

|

Air velocity (m/s) |

Wet bulb temperature (°C) |

|||||

|

20.0 |

22.5 |

25.0 |

27.5 |

30.0 |

32.5 |

|

|

0.1 |

176 |

153 |

128 |

100 |

70 |

37 |

|

0.25 |

238 |

210 |

179 |

145 |

107 |

64 |

|

0.5 |

284 |

254 |

220 |

181 |

137 |

87 |

|

1.0 |

321 |

290 |

254 |

212 |

163 |

104 |

An air velocity of 0.1 m/s reflects the effect of natural convection (i.e., no perceivable airflow at all). An air velocity of 0.25 m/s is the minimum normally allowed in mining and 0.5 m/s would be required where the wet bulb temperature exceeds 25 °C. With respect to achieving thermal equilibrium, the metabolic heat resulting from typical work rates are: rest, 50 W/m2; light work, 115 to 125 W/m2, medium work, 150 to 175 W/m2; and hard work, 200 to 300 W/m2. Design conditions for a specific mine application would be determined from a detailed optimization study. Generally, optimum wet bulb temperatures are between 27.5 °C and 28.5 °C with the lower temperatures applicable to less mechanized operations. Work performance decreases and the risk of heat-related illness increases significantly when the wet bulb temperature exceeds 30.0 °C, and work should not normally continue when the wet bulb temperature is greater than 32.5 °C.

Mine heat loads

The mine refrigeration load is the mine heat load less the cooling capacity of the ventilation air. The mine heat load includes the effects of auto-compression of the air in the intake airways (the conversion of potential energy to enthalpy as the air flows down into the mine), heat flow into the mine from the surrounding rock, heat removed from the rock broken or any fissure water before they are removed from the intakes or working sections of the mine, and the heat resulting from the operation of any equipment used in the ore breaking and transportation processes. The cooling capacity of the ventilation air depends on both the design thermal environmental conditions in the working places and the actual climatic conditions on surface.

Although the relative contributions of each heat source to the total is site specific, auto-compression is usually the main contributor at between 35 and 50% of the total. As the depth of mining increases, auto-compression can cause the cooling capacity of the air to become negative and the effect of supplying more air is to increase the mine refrigeration load. In this case, the amount of ventilation supplied should be the minimum consistent with meeting contaminant control and increasing amounts of refrigeration are required to provide productive and safe working conditions. The depth of mining at which refrigeration becomes necessary will depend primarily on the surface climatic conditions, the distance the air travels through the intake airways before it is used and the extent to which large equipment (diesel or electric powered) is used.

Primary Ventilation Systems

Networks

Primary ventilation systems or networks are concerned with ensuring the flow of air through interconnected mine openings. The overall ventilation network has junctions where three or more airways meet, branches that are airways between junctions and meshes which are closed paths traversed through the network. Although most mine ventilation networks are ramified with hundreds or even thousands of branches, the number of main intake (branch between surface and the mine workings) and return or exhaust (branch between the workings and surface) airways is usually limited to less than ten.

With large numbers of branches in a network, determining a flow pattern and establishing the overall pressure loss is not straightforward. Although many are in simple series or parallel arrangement which can be solved algebraically and precisely, there will be some compound sections requiring iterative methods with convergence to an acceptable tolerance. Analogue computers have been successfully used for network analysis; however, these have been superseded by less time-consuming digital methods based on the Hardy Cross approximation technique developed to solve water flow networks.

Airway resistance and shock losses

The resistance to airflow of a tunnel or mine opening is a function of its size and surface roughness and the resultant pressure loss depends on this resistance and the square of the air velocity. By adding energy to the system, a pressure can be generated which then overcomes the pressure loss. This may occur naturally where the energy is provided by heat from the rock and other sources (natural ventilation). Although this used to be the main method of providing ventilation, only 2 to 3% of the energy is converted and, during hot summers, the rock may actually cool the intake air resulting in flow reversals. In modern mines a fan is normally used to provide energy to the air stream which then overcomes the pressure loss although the effects of natural ventilation can either assist or retard it depending on the time of year.

When air flows over a surface, the air molecules immediately next to the surface are at a standstill and those adjacent slip over those at rest with a resistance which is dependent on the viscosity of the air. A velocity gradient is formed where the velocity increases with increasing distance from the surface. The boundary layer created as a result of this phenomenon and the laminar sub-layer also formed as the boundary layer develops have a profound effect on the energy required to promote flow. Generally, the roughness of the surface of mine airways is large enough for the “bumps” to extend through the boundary sub-layer. The airway is then hydraulically rough and the resistance is a function of the relative roughness, i.e., the ratio of the roughness height to the diameter of the airway.

Most airways mined by conventional drill and blast techniques have roughness heights between 100 and 200 mm and even in very “blocky” ground, the average roughness height would not exceed 300 mm. Where airways are driven using boring machines, the roughness height is between 5 and 10 mm and still considered to be hydraulically rough. The roughness of airways can be reduced by lining them, although the justification is more usually ground support rather than a reduction in power required to circulate the ventilation air. For example, a large concrete-lined shaft with a roughness of 1 mm would be transitionally rough and the Reynolds number, which is the ratio of inertial to viscous forces, would also affect the resistance to airflow.

In practice, the difficulties in smooth concrete lining such a large shaft from the top down as it is being sunk results in increased roughness and resistances about 50% higher than the smooth values.

With a limited number of intake and return airways between the workings and surface, a large proportion (70 to 90%) of the total mine pressure loss occurs in them. Airway pressure losses also depend on whether there are any discontinuities causing shock losses such as bends, contractions, expansions or any obstructions in the airway. The losses resulting from these discontinuities such as bends into and out of airways, when expressed in terms of the losses which would be produced in an equivalent length of straight airway, can be a significant proportion of the total and need to be assessed carefully, particularly when considering the main intakes and exhausts. The losses in discontinuities depend on the amount of boundary layer separation; this is minimized by avoiding sudden changes in area.

Resistance of airways with obstructions

The effect of an obstruction on pressure losses depends on its drag coefficient and the fill coefficient, which is the ratio of the blockage area of the object and the cross-sectional area of the airway. The losses caused by obstructions can be reduced by minimizing boundary-layer separation and the extent of any turbulent wake by streamlining the object. Drag coefficients are affected by their shape and arrangement in the shaft; comparative values would be: I beam, 2.7; square, 2.0; cylinder, 1.2; elongated hexagon, 0.6; and fully streamlined, 0.4.

Even with small fill coefficients and low drag coefficients, if the obstruction is repeated regularly, such as with the beams separating hoisting compartments in a shaft, the cumulative effect on pressure losses is significant. For example, the resistance of a shaft equipped with semi-streamlined elongated hexagon beams and a fill coefficient of 0.08 would be about four times that of the concrete lined shaft alone. Although the material costs of the more readily available rectangular hollow structural steel sections are more than I beams, the drag coefficients are about one-third and easily justify their application.

Main and booster fans

Both axial and centrifugal fans are used to provide air circulation in mine ventilation systems, with fan efficiencies of over 80% being achievable. The selection between axial flow or centrifugal for main mine fans depends on cost, size, pressure, robustness, efficiency and any performance variation. In mines where a fan failure may result in dangerous methane accumulations, additional fan capacity is installed to ensure continuity of ventilation. Where this is not so critical and with a twin fan installation, about two-thirds of the mine airflow will continue if one fan stops. Vertical axial flow fans installed over the airways have low costs but are limited to about 300 m3/s. For larger air quantities, multiple fans are required and they are connected to the exhaust with ducting and a bend.

To obtain the highest efficiencies at reasonable cost, axial flow fans are used for low pressure (less than 1.0 kPa) applications and centrifugal fans for high pressure (greater than 3.0 kPa) systems. Either selection is suitable for the intermediate pressures. Where robustness is required, such as with exhausts with air velocities above the critical range, and water droplets are carried up and out of the system, a centrifugal fan will provide a more reliable selection. The critical air velocity range is between 7.5 m/s and 12.5 m/s where the water droplets may stay in suspension depending on their size. Within this range, the amount of suspended water can build up and increase the system pressure until the fan stalls. This is the region where some of the air recirculates around the blades and fan operation becomes unstable. Although not desirable for any type of fan, the possibility of a centrifugal fan blade failure is significantly less than an axial blade failure in this region of flow fluctuation.

It is rare that a main fan is required to operate at the same duty point over the life of the mine, and effective methods of varying fan performance are desirable. Although variable speed results in the most efficient operation for both axial and centrifugal fans, the costs, particularly for large fans, is high. The performance of an axial flow fan can be varied by adjusting the blade angle and this can be carried out either when the fan is stopped or, at a significantly higher cost, when it is rotating. By imparting a swirl to the air entering a fan using variable inlet vanes, the performance of a centrifugal fan can be varied while it is running.

The efficiency of the centrifugal fan away from its design point falls off more rapidly than that of an axial flow fan and, if a high performance is required over a wide range of operating points and the pressures are suitable, the axial flow fan is selected.

Ventilation systems

The position of the main fan in the overall system is normally on surface at the exhaust airway. The main reasons for this are simplicity where the intake is often a hoisting shaft and the exhaust is a separate single purpose airway and minimization of the heat load by excluding fans from intake airways. Fans can be installed at hoisting shafts either in forcing or exhausting mode by providing a sealed headframe. However, where workers, materials or rock also enter or leave the shaft, there is a potential for air leakage.

Push-pull systems where both intake and exhaust fans are installed are used either to reduce the maximum pressure in the system by sharing or to provide a very small pressure difference between the workings and surface. This is pertinent in mines using caving methods where leakage through the caved area may be undesirable. With large pressure differences, although air leakage through a caved zone is normally small, it may introduce heat, radiation or oxidation problems into the working places.

Underground booster fans, because of space limitations, are almost always axial flow and they are used to boost flow in the deeper or more distant sections of a mine. Their main drawback is the possibility of recirculation between the booster fan exhaust and the intake airways. By only providing a boost to the smaller airflows where they are required, they can result in a lower main fan pressure for the full mine airflow and a consequent reduction in total fan power required.

Secondary Ventilation

Auxiliary systems

Secondary ventilation systems are required where through ventilation is not possible, such as in development headings. Four arrangements are possible, each having its own advantages and disadvantages.

The forcing system results in the coolest and freshest air reaching the face and allows cheaper flexible duct to be used. The high velocity of the air issuing from the end of the supply duct creates a jet which entrains additional air and helps sweep the face of contaminants and provide an acceptable face velocity. Its main drawback is that the rest of the heading is ventilated with air that is contaminated with the gases and dust produced by mining operations in the face. This is particularly a problem after blasting, where safe re-entry times are increased.

An exhausting system allows all the face contaminants to be removed and maintains the rest of the heading in intake air. The drawbacks are that heat flow from the surrounding rock and moisture evaporation will result in higher face delivery air temperatures; operations in the heading back from the face, such as rock removal using diesel-powered equipment, will contaminate the intake air; there is no air jet produced to sweep the face; and more costly duct which is capable of sustaining a negative pressure is required.

In an exhaust-overlap system the problem of clearing the face with an air jet is overcome by installing a smaller fan and duct (the overlap). In addition to the extra cost, a disadvantage is that the overlap needs to be advanced with the face.

In a reversing system, the forcing ventilation mode is used, except during blasting and the re-entry period after blasting, when the airflow is reversed. Its main application is in shaft sinking, where re-entry times for deep shafts can be prohibitive if a forcing only system was used. The air reversal can be obtained by either using dampers at the fan inlet and outlet or, by taking advantage of a feature of axial flow fans, where changing the direction of blade rotation results in a flow reversal with about 60% of the normal flow being delivered.

Fans and ducts

The fans used for secondary ventilation are almost exclusively axial flow. To achieve the high pressures necessary to cause the air to flow through long lengths of duct, multiple fans with either contra-rotating or co-rotating impeller arrangements may be used. Air leakage is the greatest problem in auxiliary fan and duct systems, particularly over long distances. Rigid ducts fabricated from galvanized steel or fibreglass, when installed with gaskets, have suitably low leakage and may be used to develop headings up to several kilometres in length.

Flexible ducts are considerably cheaper to purchase and easier to install; however, leakage at the couplings and the ease with which they are ripped by contact with mobile equipment results in much higher air losses. Practical development limits using flexible duct rarely exceed 1.0 km, although they can be extended by using longer duct lengths and ensuring ample clearances between the duct and mobile equipment.

Ventilation Controls

Both through ventilation and auxiliary fan and duct systems are used to provide ventilation air to locations where personnel may work. Ventilation controls are used to direct the air to the working place and to minimize the short circuiting or loss of air between intake and exhaust airways.

A bulkhead is used to stop air flowing through a connecting tunnel. The materials of construction will depend on the pressure difference and whether it will be subject to shock waves from blasting. Flexible curtains attached to the surrounding rock surfaces are suitable for low pressure applications such as separating the intake and return airways in a room-and-pillar panel mined with a continuous miner. Timber and concrete bulkheads are suitable for higher pressure applications and may incorporate a heavy rubber flap which can open to minimize any blast damage.

A ventilation door is needed where pedestrian or vehicular passage is required. The materials of construction, opening mechanism and degree of automation are influenced by the pressure difference and the frequency of opening and closing. For high pressure applications, two or even three doors may be installed to create air locks and reduce leakage and the loss of intake air. To assist in opening air lock doors, they usually contain a small sliding section which is opened first to allow equalization of the pressure on both sides of the door to be opened.

A regulator is used where the amount of air flowing through a tunnel is to be reduced rather than stopped completely and also where access is not required. The regulator is a variable orifice and by changing the area, the air quantity flowing through it can also be changed. A drop board is one of the simplest types where a concrete frame supports channels into which timber boards can be placed (dropped) and the open area varied. Other types, such as butterfly louvres, can be automated and remotely controlled. On the upper levels in some open stoping systems, infrequent access through the regulators may be required and horizontally stiffened, flexible panels can be simply raised or lowered to provide access while minimizing blast damage. Even piles of broken rock have been used to increase the resistance in sections of a level where there is temporarily no mining activity.

Refrigeration and Cooling Systems

The first mine refrigeration system was installed at Morro Velho, Brazil, in 1919. Since that date, the growth in worldwide capacity has been linear at about 3 megawatts of refrigeration (MWR) per year until 1965, when the total capacity reached about 100 MWR. Since 1965 the growth in capacity has been exponential, with a doubling every six or seven years. The development of mine refrigeration has been influenced both by the air conditioning industry and the difficulties of dealing with a dynamic mining system in which the fouling of heat exchanger surfaces may have profound effects on the amount of cooling provided.

Initially, the refrigeration plants were installed on surface and the mine intake air was cooled. As the distance underground from the surface plant increased, the cooling effect was reduced and the refrigeration plants were moved underground closer to the workings.

Limitations in underground heat rejection capacity and the simplicity of surface plants has resulted in a move back to the surface location. However, in addition to the intake air being cooled, chilled water is now also supplied underground. This may be used in air-cooling devices adjacent to the working areas or as the service water used in drills and for dust suppression.

Refrigeration plant equipment

Vapour compression refrigeration systems are exclusively used for mines, and the central element of the surface plant is the compressor. Individual plant capacities may vary between 5 MWR and over 100 MWR and generally require multiple compressor systems which are either of the centrifugal or positive displacement screw design. Ammonia is normally the refrigerant selected for a surface plant and a suitable halocarbon is used underground.

The heat required to condense the refrigerant after compression is rejected to the atmosphere and, to minimize the power required to provide the mine cooling, this is kept as low as practical. The wet bulb temperature is always less than or equal to the dry bulb temperature and consequently wet-heat rejection systems are invariably selected. The refrigerant may be condensed in a shell and tube or plate and frame heat exchanger using water and the heat extracted and then rejected to the atmosphere in a cooling tower. Alternatively, the two processes can be combined by using an evaporative condenser where the refrigerant circulates in tubes over which air is drawn and water is sprayed. If the refrigeration plant is installed underground, mine exhaust air is used for heat rejection unless the condenser water is pumped to surface. Operation of the underground plant is limited by the amount of air available and higher underground wet bulb temperatures relative to those on surface.

After passing the condensed refrigerant through an expansion valve, the evaporation of the low temperature liquid and gas mixture is completed in another heat exchanger that cools and provides the chilled water. In turn, this is used both to cool the intake air and as cold service water supplied to the mine. The contact between water, ventilation air and the mine reduces water quality and increases heat exchanger fouling. This increases the resistance to heat flow. Where possible, this effect is minimized by selecting equipment having large water side surface areas that are easy to clean. On surface and underground, spray chambers and cooling towers are used to provide the more effective direct contact heat exchange between the air being cooled and the chilled water. Cooling coils which separate the air and water streams become clogged with dust and diesel particulate and their effectiveness rapidly declines.

Energy recovery systems can be used to offset the costs of pumping the water back out of the mine and pelton wheels are well suited to this application. The use of cold water as service water has helped to ensure that cooling is available wherever there is mining activity; its use has significantly improved the effectiveness of mine cooling systems.

Ice systems and spot coolers

The cooling capacity of 1.0 l/s of chilled water supplied underground is 100 to 120 kWR. On mines where large amounts of refrigeration are required underground at depths greater than 2,500 m, the costs of circulating the chilled water can justify replacing it with ice. When the latent heat of fusion of the ice is taken into account, the cooling capacity of each 1.0 l/s is increased approximately fourfold, thus reducing the mass of water that needs to be pumped from the mine back to surface. The reduction in pump power resulting from the use of ice to transport the coolness offsets the increased refrigeration plant power required to produce the ice and the impracticability of energy recovery.

Development is usually the mining activity with the highest heat loads relative to the amount of air available for ventilation. This often results in worksite temperatures significantly higher than those found with other mining activities in the same mine. Where the application of refrigeration is a borderline issue for a mine, spot coolers specifically targeted at development ventilation can defer its general application. A spot cooler is essentially a miniature underground refrigeration plant where the heat is rejected into the return air from the development and typically provides 250 to 500 kWR of cooling.

Monitoring and Emergencies

Ventilation surveys which include airflow, contaminant and temperature measurements are undertaken on a routine basis to meet both statutory requirements and to provide a continuing measure of the effectiveness of the ventilation control methods used. Where practical, important parameters such as main fan operation are monitored continuously. Some degree of automatic control is possible where a critical contaminant is monitored continuously and, if a pre-set limit is exceeded, corrective action can be prompted.

More detailed surveys of barometric pressure and temperatures are undertaken less frequently and are used to confirm airway resistances and to assist in planning extensions of existing operations. This information can be used to adjust the network simulation resistances and reflect the actual airflow distribution. Refrigeration systems can also be modelled and flow and temperature measurements analysed to determine actual equipment performance and to monitor any changes.

The emergencies that may affect or be affected by the ventilation system are mine fires, sudden gas outbursts and power failures. Fires and outbursts are dealt with elsewhere in this chapter and power failures are only a problem in deep mines where the air temperatures may increase to dangerous levels. It is common to provide a diesel-powered backup fan to ensure a small airflow through the mine under these conditions. Generally, when an emergency such as a fire occurs underground, it is better not to interfere with the ventilation while personnel who are familiar with the normal flow patterns are still underground.

Lighting in Underground Mines

Light Sources in Mining

In 1879 a practical incandescent filament lamp was patented. As a result light no longer depended on a fuel source. Many startling breakthroughs have been made in lighting knowledge since Edison’s discovery, including some with applications in underground mines. Each has inherent advantages and disadvantages. Table 1 lists the light source types and compares some parameters.

Table 1. Comparison of mine light sources

|

Type of light source |

Approximate luminance |

Average rated life (h) |

DC source |

Approximate initial efficacy lm·W–1 |

Colour rendition |

|

Tungsten filament |

105 to 107 |

750 to 1,000 |

Yes |

5 to 30 |

Excellent |

|

Incandescent |

2 × 107 |

5 to 2,000 |

Yes |

28 |

Excellent |

|

Fluorescent |

5 × 104 to 2 × 105 |

500 to 30,000 |

Yes |

100 |

Excellent |

|

Mercury vapour |

105 to 106 |

16,000 to 24,000 |

Yes with limitations |

63 |

Average |

|

Metal halide |

5 × 106 |

10,000 to 20,000 |

Yes with limitations |

125 |

Good |

|

High-pressure sodium |

107 |

12,000 to 24,000 |

Not advised |

140 |

Fair |

|

Low-pressure sodium |

105 |

10,000 to 18,000 |

Not advised |

183 |

Poor |

cd = candela, DC = direct current; lm = lumens.

Current to energize the light sources may be either alternating (AC) or direct (DC). Fixed light sources almost always use alternating current whereas portable sources such as cap lamps and underground vehicle headlights use a DC battery. Not all light source types are suitable for direct current.

Fixed light sources

Tungsten filament lamps are most common, often with a frosted bulb and a shield to reduce glare. The fluorescent lamp is the second most common light source and is easily distinguishable by its tubular design. Circular and U-shaped designs are compact and have mining applications as mining areas are often in cramped spaces. Tungsten filament and fluorescent sources are used to light such diverse underground openings as shaft stations, conveyors, travelways, lunchrooms, charging stations, fuel bays, repair depots, warehouses, tool rooms and crusher stations.

The trend in mine lighting is to use more efficient light sources. These are the four high-intensity discharge (HID) sources called mercury vapour, metal halide, high-pressure sodium and low-pressure sodium. Each requires a few minutes (one to seven) to come up to full light output. Also, if power to the lamp is lost or turned off, the arc tube must be cooled before the arc can be struck and the lamp relit. (However, in the case of low-pressure sodium (Sox) lamps, restrike is almost instantaneous.) Their spectral energy distributions differ from that of natural light. Mercury vapour lamps produce a bluish white light whereas high-pressure sodium lamps produce a yellowish light. If colour differentiation is important in underground work (e.g., for using colour-coded gas bottles for welding, reading colour-coded signs, electrical wiring hook-ups or sorting ore by colour), care must be taken in the colour rendition properties of the source. Objects will have their surface colours distorted when lit by a low-pressure sodium lamp. Table 1 gives colour rendition comparisons.

Mobile light sources

With working places spread out often both laterally and vertically, and with continual blasting in these working places, permanent installations are often deemed impractical because of the costs of installation and upkeep. In many mines the battery-operated cap lamp is the most important single source of light. Although fluorescent cap lamps are in use, by far the majority of cap lamps use tungsten filament battery-operated cap lamps. Batteries are lead acid or nickel cadmium. A miniature tungsten-halogen lamp bulb is often used for the miner’s cap lamp. The small bulb allows the beam to be easily focused. The halogen gas surrounding the filament prevents the tungsten filament material from boiling off, which keeps lamp walls from blackening. The bulb can also be burned hotter and hence brighter.

For mobile vehicle lighting, incandescent lamps are most commonly used. They require no special equipment, are inexpensive and are easy to replace. Parabolic aluminized reflector (PAR) lamps are used as headlights on vehicles.

Standards for Mine Lighting

Countries with a well-established underground mining industry are usually quite specific in their requirements regarding what constitutes a safe mine lighting system. This is particularly true for mines which have methane gas given off from the workings, usually coal mines. Methane gas can ignite and cause an underground explosion with devastating results. Consequently any lights must be designed to be either “intrinsically safe” or “explosion proof”. An intrinsically safe light source is one in which the current feeding the light has very little energy so that any short in the circuit would not produce a spark which could ignite the methane gas. For a lamp to be explosion proof, any explosion triggered by the lamp’s electrical activity is contained within the device. In addition, the device itself will not become hot enough to cause an explosion. The lamp is more expensive, heavier, with metal parts usually made of castings. Governments usually have test facilities to certify whether lamps can be classified for use in a gassy mine. A low-pressure sodium lamp could not be so certified as the sodium in the lamp could ignite if the lamp were to break and the sodium came in contact with water.

Countries also legislate standards for the amount of light required for various tasks but legislation varies greatly in the amount of light that should be placed in the various working places.

Guidelines for mine lighting are also provided by international bodies concerned with lighting, such as the Illumination Engineering Society (IES) and the Commission internationale de l’éclairage (CIE). The CIE stresses that the quality of light being received by the eye is as important as the quantity and provides formulas to ascertain whether glare may be a factor in visual performance.

Effects of Lighting on Accidents, Production and Health

One would expect that better lighting would reduce accidents, increase production and reduce health hazards, but it is not easy to substantiate this. The direct effect of lighting on underground efficiency and safety is hard to measure because lighting is only one of many variables that affect production and safety. There is well-documented evidence that shows highway accidents decrease with improved illumination. A similar correlation has been noted in factories. The very nature of mining, however, dictates that the work area is constantly changing, so that very few reports relating mine accidents to lighting can be found in the literature and it remains an area of research that has been largely unexplored. Accident investigations show that poor lighting is rarely the primary cause of underground accidents but is often a contributing factor. While lighting conditions play some role in many mine accidents, they have special significance in accidents involving falls of ground, since poor lighting makes it easy to miss dangerous conditions that could otherwise be corrected.

Until the beginning of the twentieth century, miners commonly suffered from the eye disease nystagmus, for which there was no known cure. Nystagmus produced uncontrollable oscillation of the eyeballs, headaches, dizziness and loss of night vision. It was caused by working under very low light levels over long periods of time. Coal miners were particularly susceptible, since very little of the light that strikes the coal is reflected. These miners often had to lie on their sides when working in low coal and this may also have contributed to the disease. With the introduction of the electric cap lamp in mines, miner’s nystagmus has disappeared, eliminating the most important health hazard associated with underground lighting.

With recent technological advances in new light sources, the interest in lighting and health has been revived. It is now possible to have lighting levels in mines that would have been extremely difficult to achieve previously. The main concern is glare, but concern has also been expressed about the radiometric energy given off by the lights. Radiometric energy can affect workers either by acting directly on cells on or near the surface of the skin or by triggering certain responses, such as biological rhythms on which physical and mental health depends. An HID light source can still operate even though the glass envelope containing the source is cracked or broken. Workers can then be in danger of receiving doses beyond threshold limit values, particularly since these light sources often cannot be mounted very high.

Personal Protective Equipment in Mining

Head Protection

In most countries miners must be provided with, and must wear, safety caps or hats which are approved in the jurisdiction in which the mine operates. Hats differ from caps in that they have a full brim rather than just a front peak. This has the advantage of shedding water in mines which are very wet. It does, however, preclude the incorporation of side slots for mounting of hearing protection, flashlights and face shields for welding, cutting, grinding, chipping and scaling or other accessories. Hats represent a very small percentage of the head protection worn in mines.

The cap or hat would in most cases be equipped with a lamp bracket and cord holder to permit mounting of a miner’s cap lamp.

The traditional miner’s cap has a very low profile which significantly reduces the propensity for the miner to bump his or her head in low seam coal mines. However, in mines where head room is adequate the low profile serves no useful purpose. Furthermore, it is achieved by reducing the clearance between the crown of the cap and the wearer’s skull so that these types of cap rarely meet the top impact standards for industrial head protection. In jurisdictions where the standards are enforced, the traditional miner’s cap is giving way to conventional industrial head protection.

Standards for industrial head protection have changed very little since the 1960s. However, in the 1990s, the boom in recreational head protection, such as hockey helmets, cycle helmets and so on, has highlighted what are perceived to be inadequacies in industrial head protection, most notably lack of lateral impact protection and lack of retention capabilities in the event of an impact. Thus, there has been pressure to upgrade the standards for industrial head protection and in some jurisdictions this has already happened. Safety caps with foam liners and, possibly, ratchet suspensions and/or chin straps are now appearing in the industrial marketplace. They have not been widely accepted by users because of the higher cost and weight and their lesser comfort. However, as the new standards become more widely entrenched in labour legislation the new style of cap is likely to appear in the mining industry.

Cap Lamps

In areas of the mine where permanent lighting is not installed, the miner’s cap lamp is essential to permit the miner to move and work effectively and safely. The key requirements for a cap lamp are that it be rugged, easy to operate with gloved hands, provide sufficient light output for the full duration of a work shift (to illumination levels required by local regulation) and that it be as light as possible without sacrificing any of the above performance parameters.

Halogen bulbs have largely replaced the incandescent tungsten filament bulb in recent years. This has resulted in three- or fourfold improvement in illumination levels, making it feasible to meet the minimum standards of illumination required by legislation even at the end of an extended work-shift. Battery technology also plays a major part in lamp performance. The lead acid battery still predominates in most mining applications, although some manufacturers have successfully introduced nickel-cadmium (nicad) batteries, which can achieve the same performance with a lower weight. Reliability, longevity and maintenance issues, however, still favour the lead acid battery and probably account for its continued dominance.

In addition to its primary function of providing lighting, the cap lamp and battery have recently been integrated into mine safety communications systems. Radio receivers and circuitry embedded in the battery cover permit the miners to receive messages, warnings or evacuation instructions through very low frequency (VLF) radio transmission and enable them to be made aware of an incoming message by means of an on/off flashing of the cap lamp.

Such systems are still in their infancy but they do have the potential to provide an advance in early warning capability over traditional stench gas systems in those mines where a VLF radio communication system can be engineered and installed.

Eye and Face Protection

Most mining operations around the world have compulsory eye protection programmes which require the miner to wear safety spectacles, goggles, faceshields or a full facepiece respirator, depending on the operations being performed and the combination of hazards to which the miner is exposed. For the majority of mining operations, safety spectacles with side shields provide suitable protection. The dust and dirt in many mining environments, most notably hard-rock mining, can be highly abrasive. This causes scratching and rapid wear of safety glasses with plastic (polycarbonate) lenses. For this reason, many mines still permit the use of glass lenses, even though they do not provide the resistance to impact and shattering offered by polycarbonates, and even though they may not meet the prevailing standard for protective eye wear in the particular jurisdiction. Progress continues to be made in both anti-fog treatments and surface hardening treatments for plastic lenses. Those treatments which change the molecular structure of the lens surface rather than simply applying a film or coating are typically more effective and longer lasting and have the potential to replace glass as the lens material of choice for abrasive mining environments.

Goggles are not worn frequently below ground unless the particular operation poses a danger of chemical splash.

A faceshield may be worn where the miner requires full-face protection from weld spatter, grinding residues or other large flying particles which could be produced by cutting, chipping or scaling. The faceshield may be of a specialized nature, as in welding, or may be clear acrylic or polycarbonate. Although faceshields can be equipped with their own head harness, in mining they will normally be mounted in the accessory slots in the miner’s safety cap. Faceshields are designed so that they can be quickly and easily hinged upwards for observation of the work and down over the face for protection when performing the work.

A full facepiece respirator may be worn for face protection when there is also a requirement for respiratory protection against a substance which is irritating to the eyes. Such operations are more often encountered in the above ground mine processing than in the below ground mining operation itself.

Respiratory Protection

The most commonly needed respiratory protection in mining operations is dust protection. Coal dust as well as most other ambient dusts can be effectively filtered using an inexpensive quarter facepiece dust mask. The type which uses an elastomer nose/mouth cover and replaceable filters is effective. The moulded throw-away fibre-cup type respirator is not effective.

Welding, flame cutting, use of solvents, handling of fuels, blasting and other operations can produce air-borne contaminants that require the use of twin cartridge respirators to remove combinations of dust, mists, fumes, organic vapours and acid gases. In these cases, the need for protection for the miner will be indicated by measurement of the contaminants, usually performed locally, using detector tubes or portable instruments. The appropriate respirator is worn until the mine ventilation system has cleared the contaminant or reduced it to levels that are acceptable.

Certain types of particulates encountered in mines, such as asbestos fibres found in asbestos mines, coal fines produced in longwall mining and radionuclides found in uranium mining, may require the use of a positive pressure respirator equipped with a high-efficiency particulate absolute (HEPA) filter. Powered air-purifying respirators (PAPRs) which supply the filtered air to a hood, tight-fitting facepiece or integrated helmet facepiece assembly meet this requirement.

Hearing Protection

Underground vehicles, machinery and power tools generate high ambient noise levels which can create long-term damage to human hearing. Protection is normally provided by ear muff type protectors which are slot-mounted on the miner’s cap. Supplementary protection can be provided by wearing closed cell foam ear plugs in conjunction with the ear muffs. Ear plugs, either of the disposable foam cell variety or the reusable elastomeric variety, may be used on their own, either because of preference or because the accessory slot is being used to carry a face shield or other accessory.

Skin Protection

Certain mining operations may cause skin irritation. Work gloves are worn whenever possible in such operations and barrier creams are provided for additional protection, particularly when the gloves cannot be worn.

Foot Protection

The mining work boot may be of either leather or rubber construction, depending on whether the mine is dry or wet. Minimum protective requirements for the boot include a full puncture-proof sole with a composite outer layer to prevent slipping, a steel toe-cap and a metatarsal guard. Although these fundamental requirements have not changed in many years, advances have been made towards meeting them in a boot that is far less cumbersome and far more comfortable than the boots of several years ago. For example, metatarsal guards are now available in moulded fibre, replacing the steel hoops and saddles that were once common. They provide equivalent protection with less weight and less risk of tripping. The lasts (foot forms) have become more anatomically correct and energy absorbing mid-soles, full moisture barriers and modern insulating materials have made their way from the sports/recreation footwear market into the mining boot.

Clothing

Ordinary cotton coveralls or treated flame-resistant cotton coveralls are the normal workwear in mines. Strips of reflective material are usually added to make the miner more visible to drivers of moving underground vehicles. Miners working with jumbo drills or other heavy equipment may also wear rain suits over their coveralls to protect against cutting fluid, hydraulic oil and lubricating oils, which can spray or leak from the equipment.

Work gloves are worn for hand protection. A general purpose work glove would be constructed of cotton canvas reinforced with leather. Other types and styles of glove would be used for special job functions.

Belts and Harnesses

In most jurisdictions, the miners belt is no longer considered suitable or approved for fall protection. A webbing or leather belt is still used, however, with or without suspenders and with or without a lumbar support to carry the lamp battery as well as a filter self-rescuer or self-contained (oxygen generating) self-rescuer, if required.

A full body harness with D-ring attachment between the shoulder blades is now the only recommended device for protecting miners against falls. The harness should be worn with a suitable lanyard and shock absorbing device by miners working in shafts, over crushers or near open sump or pits. Additional D-rings may be added to a harness or a miner’s belt for work positioning or to restrict movement within safe limits.

Protection from Heat and Cold

In open-pit mines in cold climates, miners will have winter clothing including thermal socks, underwear and gloves, wind resistant pants or over-pants, a lined parka with hood and a winter liner to wear with the safety cap.

In underground mines, heat is more of a problem than cold. Ambient temperatures may be high because of the depth of the mine below ground or because it is located in a hot climate. Protection from heat stress and potential heat stroke can be provided by special garments or undergarments which can accommodate frozen gel packs or which are constructed with a network of cooling tubes to circulate cooling fluids over the surface of the body and then through an external heat exchanger. In situations where the rock itself is hot, heat resistant gloves, socks and boots are worn. Drinking water or, preferably, drinking water with added electrolytes must be available and must be consumed to replace lost body fluids.

Other Protective Equipment

Depending on local regulations and the type of mine, miners may be required to carry a self-rescue device. This is a respiratory protection device which will help the miner to escape from the mine in the event of a mine fire or explosion that renders the atmosphere unbreathable because of carbon monoxide, smoke and other toxic contaminants. The self-rescuer may be a filtration type device with a catalyst for carbon monoxide conversion or it may be a self-contained self-rescuer, i.e., a closed-cycle breathing apparatus which chemically regenerates oxygen from exhaled breath.

Portable instruments (including detector tubes and detector tube pumps) for the detection and measurement of toxic and combustible gases are not carried routinely by all miners, but are used by mine safety officers or other designated personnel in accordance with standard operating procedures to test mine atmospheres periodically or before entry.

Improving the ability to communicate with personnel in underground mining operations is proving to have enormous safety benefits and two-way communication systems, personal pagers and personnel locating devices are finding their way into modern mining operations.

Fires and Explosions in Mines

Fires and explosions pose a constant threat to the safety of miners and to the productive capacity of mines. Mine fires and explosions traditionally have ranked among the most devastating industrial disasters.

At the end of the nineteenth century, fires and explosions in mines resulted in loss of life and property damage on a scale unmatched in other industrial sectors. However, clear progress has been achieved in controlling these hazards, as evidenced by the decline in mine fires and explosions reported in recent decades.

This article describes the basic fire and explosion hazards of underground mining and the safeguards needed to minimize them. Fire protection information on surface mines can be found elsewhere in this Encyclopaedia and in standards such as those promulgated by organizations such as the National Fire Protection Association in the United States (e.g., NFPA 1996a).

Permanent Service Areas

By their nature, permanent service areas involve certain hazardous activities, and thus special precautions should be taken. Underground maintenance shops and related facilities are a special hazard in an underground mine.

Mobile equipment in maintenance shops is regularly found to be a frequent source of fires. Fires on diesel-powered mining equipment typically arise from leaking high-pressure hydraulic lines which can spray a heated mist of highly combustible liquid onto an ignition source, such as a hot exhaust manifold or turbocharger (Bickel 1987). Fires on this type of equipment can grow quickly.

Much of the mobile equipment used in underground mines contains not only fuel sources (e.g., diesel fuel and hydraulics) but they also contain ignition sources (e.g., diesel engines and electrical equipment). Thus, this equipment presents an appreciable risk for fires. In addition to this equipment, maintenance shops generally contain a variety of other tools, materials and equipment (e.g., degreasing equipment) that are a hazard in any mechanical shop environment.

Welding and cutting operations are a leading cause of fires in mines. This activity can be expected to occur regularly in a maintenance area. Special precautions need to be taken to ensure that these activities do not create a possible ignition source for a fire or explosion. Fire and explosion protection information relating to safe welding practices can be found elsewhere in this Encyclopaedia and in other documents (e.g., NFPA 1994a).

Consideration should be given to making the entire shop area a completely enclosed structure of fire resistant construction. This is particularly important for shops intended for use longer than 6 months. If such an arrangement is not possible, then the area should be protected throughout by an automatic fire suppression system. This is especially important for coal mines, where it is critical to minimize any potential fire source.

Another important consideration for all shop areas is that they be vented directly to the air return, thus limiting the spread of products of combustion from any fire. Requirements for these type of facilities are clearly outlined in documents such as NFPA 122, Standard for Fire Prevention and Control in Underground Metal and Nonmetal Mines, and NFPA 123, Standard for Fire Prevention and Control in Underground Bituminous Coal Mines (NFPA 1995a, 1995b).

Fuel Bays and Fuel Storage Areas

The storage, handling and use of flammable and combustible liquids pose a special fire hazard for all sectors of the mining industry.

In many underground mines, mobile equipment is typically diesel-powered, and a large percentage of the fires involve the fuel used by these machines. In coal mines, these fire hazards are compounded by the presence of coal, coal dust and methane.

The storage of flammable and combustible liquids is an especially important concern because these materials ignite more easily and propagate fire more rapidly than ordinary combustibles. Both flammable and combustible liquids are often stored underground in most non-coal mines in limited quantities. In some mines, the main storage facility for diesel fuel, lubricating oil and grease, and hydraulic fluid is underground. The potential seriousness of a fire in an underground flammable and combustible liquid storage area requires extreme care in the design of the storage areas, plus the implementation and strict enforcement of safe operating procedures.

All aspects of using flammable and combustible liquids present challenging fire protection concerns, including the transfer to underground, storage, dispensing and ultimate use in equipment. The hazards and protection methods for flammable and combustible liquids in underground mines can be found elsewhere in this Encyclopaedia and in NFPA standards (e.g., NFPA 1995a, 1995b, 1996b).

Fire Prevention

Safety for fires and explosions in underground mines is based on the general principles of preventing fire and explosion. Normally, this involves using common-sense fire safety techniques, such as preventing smoking, as well as providing built-in fire protection measures to prevent fires from growing, such as portable extinguishers or early fire detection systems.

Fire and explosion prevention practices in mines generally fall into three categories: limiting ignition sources, limiting fuel sources and limiting fuel and ignition source contact.

Limiting ignition sources is perhaps the most basic way of preventing a fire or explosion. Ignition sources that are not essential to the mining process should be banned altogether. For example, smoking and any open fires, especially in underground coal mines, should be prohibited. All automated and mechanized equipment that may be subject to unwanted buildup of heat, such as conveyors, should have slippage and sequence switches and thermal cutouts on electric motors. Explosives present an obvious hazard, but they could also be an ignition source for suspended dust of hazardous gas and should be used in strict conformance with special blasting regulations.

Eliminating electrical ignition sources is essential for preventing explosions. Electrical equipment operating where methane, sulphide dust or other fire hazards may be present should be designed, constructed, tested and installed so that its operation will not cause a mine fire or explosion. Explosion proof enclosures, such as plugs, receptacles and circuit interrupting devices, should be used in hazardous areas. The use of intrinsically safe electrical equipment is described in further detail elsewhere in this Encyclopaedia and in documents such as NFPA 70, National Electrical Code (NFPA 1996c).

Limiting fuel sources starts with good housekeeping to prevent unsafe accumulations of trash, oily rags, coal dust and other combustible materials.

When available, less hazardous substitutes should be used for certain combustible materials such as hydraulic fluids, conveyor belting, hydraulic hoses and ventilation tubing (Bureau of Mines 1978). The highly toxic products of combustion that may result from the burning of certain materials often necessitates less hazardous materials. As an example, polyurethane foam had previously been widely used in underground mines for ventilation seals, but more recently has been banned in many countries.

For underground coal mine explosions, coal dust and methane are typically the primary fuels involved. Methane may also be present in non-coal mines and is most commonly handled by dilution with ventilation air and exhaustion from the mine (Timmons, Vinson and Kissell 1979). For coal dust, every attempt is made to minimize the generation of dust in the mining processes, but the tiny amount needed for a coal dust explosion is almost unavoidable. A layer of dust on the floor that is only 0.012 mm thick will cause an explosion if suspended in air. Thus, rock dusting using an inert material such as pulverized limestone, dolomite or gypsum (rock dust) will help to prevent coal dust explosions.

Limiting fuel and ignition source contact depends upon preventing contact between the ignition source and the fuel source. For example, when welding and cutting operations cannot be performed in fire-safe enclosures, it is important that areas be wet down and nearby combustibles covered with fire resistant materials or relocated. Fire extinguishers should be readily available and a fire watch posted for as long as necessary to guard against smouldering fires.

Areas with a high loading of combustible materials, such as timber storage areas, explosives magazines, flammable and combustible liquid storage areas and shops, should be designed to minimize possible ignition sources. Mobile equipment should have hydraulic fluid, fuel and lubricant lines re-routed away from hot surfaces, electrical equipment and other possible ignition sources. Spray shields should be installed to deflect sprays of combustible liquid from broken fluid lines away from potential ignition sources.

Fire and explosion prevention requirements for mines are clearly outlined in NFPA documents (e.g., NFPA 1992a, 1995a, 1995b).

Fire Detection and Warning Systems

The elapsed time between the onset of a fire and its detection is critical since fires may grow rapidly in size and intensity. The most rapid and reliable indication of fire is through advanced fire detection and warning systems using sensitive heat, flame, smoke and gas analysers (Griffin 1979).

The detection of gas or smoke is the most cost-effective approach to providing fire detection coverage over a large area or throughout the entire mine (Morrow and Litton 1992). Thermal fire detection systems are commonly installed for unattended equipment, such as over conveyor belts. Faster-acting fire detection devices are considered appropriate for certain high-hazard areas, such as flammable and combustible liquids storage areas, refuelling areas and shops. Optical flame detectors that sense either ultraviolet or infrared radiation emitted by a fire are often used in these areas.

All miners should be warned once a fire has been detected. Telephones and messengers are sometimes used, but miners are often remote from telephones and they are often widely scattered. In coal mines, the most common means of fire warning are shutdown of electric power and subsequent notification by telephone and messengers. This is not an option for non-coal mines, where so little equipment is powered electrically. Stench warning is a common method of emergency communication in non-coal underground mines (Pomroy and Muldoon 1983). Special wireless radio frequency communication systems have also been used successfully in both coal and non-coal mines (Bureau of Mines 1988).

The primary concern during an underground fire is the safety of underground personnel. Early fire detection and warning permit the initiation of an emergency plan in the mine. Such a plan assures that the necessary activities, such as evacuation and fire-fighting will occur. To assure smooth implementation of the emergency plan, miners should be provided with comprehensive training and periodic retraining in emergency procedures. Fire drills, complete with the activation of the mine warning system, should be performed frequently to reinforce the training and to identify weaknesses in the emergency plan.

Further information on fire detection and warning systems can be found elsewhere in this Encyclopaedia and in NFPA documents (e.g., NFPA 1995a, 1995b, 1996d).

Fire Suppression

The most common types of fire suppression equipment used in underground mines are portable hand extinguishers, water hoselines, sprinkler systems, rock dust (applied manually or from a rock dusting machine) and foam generators. The most common type of portable hand extinguishers are typically those using multi-purpose dry chemicals.

Fire suppression systems, either manual or automatic, are becoming more common for mobile equipment, combustible liquids storage areas, conveyor belt drives and electrical installations (Grannes, Ackerson and Green 1990). Automatic fire suppression is especially important for unattended, automated or remote control equipment where personnel are not present to detect a fire, to activate a fire suppression system or to initiate fire-fighting operations.

Explosion suppression is a variation of fire suppression. Some European coal mines use this technology in the form of passive or triggered barriers on a limited basis. Passive barriers consist of rows of large tubs containing water or rock dust that are suspended from the roof of a mine entry. In an explosion, the pressure front that precedes the arrival of the flame front triggers the dumping of the contents of the tubs. The dispersed suppressants quench the flame as it passes through the entry protected by the barrier system. Triggered barriers utilize an electrically or pneumatically operated actuation device that is triggered by the heat, flame or pressure of the explosion to release suppressant agents that are stored in pressurized containers (Hertzberg 1982).

Fires that grow to an advanced stage should be fought only by highly trained and specially equipped fire-fighting teams. Where large areas of coal or timber are burning in an underground mine and fire-fighting is complicated by extensive roof falls, ventilation uncertainties and accumulations of explosive gas, special action should be taken. The only practical alternatives may be inerting with nitrogen, carbon dioxide, the combustion products of an inert gas generator, or by flooding with water or sealing part or all of the mine (Ramaswatny and Katiyar 1988).

Further information on fire suppression can be found elsewhere in this Encyclopaedia and in various NFPA documents (e.g., NFPA 1994b, 1994c, 1994d, 1995a, 1995b, 1996e, 1996f, 1996g).

Fire Containment

Fire containment is a fundamental control mechanism for any type of industrial facility. Means for confining or limiting an underground mine fire can help ensure a safer mine evacuation and lessen the hazards of fire fighting.

For underground coal mines, oil and grease should be stored in closed, fire-resistant containers, and the storage areas should be of fire-resistant construction. Transformer stations, battery charging stations, air compressors, substations, shops and other installations should be housed in fire-resistant areas or in fireproof structures. Unattended electrical equipment should be mounted on non-combustible surfaces and separated from coal and other combustibles or protected by a fire-suppression system.

Materials for building bulkheads and seals, including wood, cloth, saws, nails, hammers, plaster or cement and rock dust, should be readily available to each working section. In underground non-coal mines, oil, grease and diesel fuel should be stored in tightly sealed containers in fire-resistive areas at safe distances from explosives magazines, electrical installations and shaft stations. Ventilation-control barriers and fire doors are required in certain areas to prevent the spread of fire, smoke and toxic gas (Ng and Lazzara 1990).

Reagent Storage (Mills)

Operations that are used to process the ore produced in a mining operations may result in certain hazardous conditions. Among the concerns are certain types of dust explosions and fires involving conveyor operations.

The heat generated by friction between a conveyor belt and a drive roller or idler is a concern and can be addressed by the use of sequence and slippage switches. These switches can be effectively used along with thermal cutouts on electric motors.

Possible explosions can be prevented by eliminating electrical ignition sources. Electrical equipment operating where methane, sulphide dust or other hazardous environments may be present should be designed, constructed, tested and installed such that its operation will not cause a fire or explosion.

Exothermic oxidation reactions can occur in both coal and metal sulphide ores (Smith and Thompson 1991). When the heat generated by these reactions is not dissipated, the temperature of the rock mass or pile increases. If temperatures become high enough, rapid combustion of coal, sulphide minerals and other combustibles can result (Ninteman 1978). Although spontaneous ignition fires occur relatively infrequently, they are generally quite disruptive to operations and difficult to extinguish.

The processing of coal presents special concerns because by its nature it is a fuel source. Fire and explosion protection information relating to the safe handling of coal can be found elsewhere in this Encyclopaedia and in NFPA documents (e.g., NFPA 1992b, 1994e, 1996h).

Detection of Gases

All who work in underground mines should have a sound knowledge of mine gases and be aware of the dangers they may present. A general knowledge of gas detection instruments and systems is also necessary. For those assigned to use these instruments, detailed knowledge of their limitations and the gases they measure is essential.

Even without instruments, the human senses may be able to detect the progressive appearance of the chemical and physical phenomena associated with spontaneous combustion. The heating warms the ventilating air and saturates it with both surface and integral moisture driven off by the heating. When this air meets colder air at the ventilation split, condensation occurs resulting in a haze and the appearance of sweating on surfaces in the returns. A characteristic oily or petrol smell is the next indication, followed eventually by smoke and, finally, visible flames.

Carbon monoxide (CO), which is odourless, appears in measurable concentrations some 50 to 60 °C before the characteristic smell of a spontaneous combustion appears. Consequently, most fire detection systems rely on the detection of a rise in carbon monoxide concentration above the normal background for the particular part of the mine.

Sometimes, a heating is first detected by an individual who notices a faint smell for a fleeting instant. Thorough examination of the area may have to be repeated a number of times before a measurable sustained increase in the concentration of carbon monoxide can be detected. Accordingly, vigilance by all those in the mine should never be relaxed and a prearranged intervention process should be implemented as soon as the presence of an indicator has been suspected or detected and reported. Fortunately, thanks to considerable progress in the technology of fire detection and monitoring made since the 1970s (e.g., detector tubes, pocket-sized electronic detectors, and computerized fixed systems), it is no longer necessary to rely on the human senses alone.

Portable Instruments for Gas Detection

The gas detection instrument is designed to detect and monitor the presence of a wide range of gas types and concentrations that could result in a fire, an explosion and a toxic or oxygen-deficient atmosphere as well as to provide early warning of an outbreak of spontaneous combustion. Gases for which they are used include CO, carbon dioxide (CO2), nitrogen dioxide (NO2), hydrogen sulphide (H2S) and sulphur dioxide (SO2). Different types of instrument are available, but before deciding which to use in a particular situation, the following questions must be answered:

- Why is the detection of a particular gas or gases required?

- What are the properties of these gases?

- Where and in what circumstances do they occur?

- Which gas detecting instrument or device is most suitable for those circumstances?

- How does this instrument work?

- What are its limitations?

- How should the results it provides be interpreted?

Workers must be trained in the correct use of portable gas detectors. Instruments must be maintained according to the manufacturer’s specifications.

Universal detector kits