Children categories

94. Education and Training Services (7)

94. Education and Training Services

Chapter Editor: Michael McCann

Table of Contents

Tables and Figures

Tables

Click a link below to view table in article context.

1. Diseases affecting day-care workers & teachers

2. Hazards & precautions for particular classes

3. Summary of hazards in colleges & universities

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

95. Emergency and Security Services (9)

95. Emergency and Security Services

Chapter Editor: Tee L. Guidotti

Table of Contents

Tables and Figures

Tables

Click a link below to view table in article context.

1. Recommendations & criteria for compensation

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

96. Entertainment and the Arts (31)

96. Entertainment and the Arts

Chapter Editor: Michael McCann

Table of Contents

Tables and Figures

Arts and Crafts

Performing and Media Arts

Entertainment

Tables

Click a link below to view table in article context.

1. Precautions associated with hazards

2. Hazards of art techniques

3. Hazards of common stones

4. Main risks associated with sculpture material

5. Description of fibre & textile crafts

6. Description of fibre & textile processes

7. Ingredients of ceramic bodies & glazes

8. Hazards & precautions of collection management

9. Hazards of collection objects

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

97. Health Care Facilities and Services (25)

97. Health Care Facilities and Services

Chapter Editor: Annelee Yassi

Table of Contents

Tables and Figures

Health Care: Its Nature and Its Occupational Health Problems

Annalee Yassi and Leon J. Warshaw

Social Services

Susan Nobel

Home Care Workers: The New York City Experience

Lenora Colbert

Occupational Health and Safety Practice: The Russian Experience

Valery P. Kaptsov and Lyudmila P. Korotich

Ergonomics and Health Care

Hospital Ergonomics: A Review

Madeleine R. Estryn-Béhar

Strain in Health Care Work

Madeleine R. Estryn-Béhar

Case Study: Human Error and Critical Tasks: Approaches for Improved System Performance

Work Schedules and Night Work in Health Care

Madeleine R. Estryn-Béhar

The Physical Environment and Health Care

Exposure to Physical Agents

Robert M. Lewy

Ergonomics of the Physical Work Environment

Madeleine R. Estryn-Béhar

Prevention and Management of Back Pain in Nurses

Ulrich Stössel

Case Study: Treatment of Back Pain

Leon J. Warshaw

Health Care Workers and Infectious Disease

Overview of Infectious Diseases

Friedrich Hofmann

Prevention of Occupational Transmission of Bloodborne Pathogens

Linda S. Martin, Robert J. Mullan and David M. Bell

Tuberculosis Prevention, Control and Surveillance

Robert J. Mullan

Chemicals in the Health Care Environment

Overview of Chemical Hazards in Health Care

Jeanne Mager Stellman

Managing Chemical Hazards in Hospitals

Annalee Yassi

Waste Anaesthetic Gases

Xavier Guardino Solá

Health Care Workers and Latex Allergy

Leon J. Warshaw

The Hospital Environment

Buildings for Health Care Facilities

Cesare Catananti, Gianfranco Damiani and Giovanni Capelli

Hospitals: Environmental and Public Health Issues

M.P. Arias

Hospital Waste Management

M.P. Arias

Managing Hazardous Waste Disposal Under ISO 14000

Jerry Spiegel and John Reimer

Tables

Click a link below to view table in article context.

1. Examples of health care functions

2. 1995 integrated sound levels

3. Ergonomic noise reduction options

4. Total number of injuries (one hospital)

5. Distribution of nurses’ time

6. Number of separate nursing tasks

7. Distribution of nurses' time

8. Cognitive & affective strain & burn-out

9. Prevalence of work complaints by shift

10. Congenital abnormalities following rubella

11. Indications for vaccinations

12. Post-exposure prophylaxis

13. US Public Health Service recommendations

14. Chemicals’ categories used in health care

15. Chemicals cited HSDB

16. Properties of inhaled anaesthetics

17. Choice of materials: criteria & variables

18. Ventilation requirements

19. Infectious diseases & Group III wastes

20. HSC EMS documentation hierarchy

21. Role & responsibilities

22. Process inputs

23. List of activities

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

98. Hotels and Restaurants (4)

98. Hotels and Restaurants

Chapter Editor: Pam Tau Lee

Table of Contents

99. Office and Retail Trades (7)

99. Office and Retail Trades

Chapter Editor: Jonathan Rosen

Table of Contents

Tables and Figures

The Nature of Office and Clerical Work

Charles Levenstein, Beth Rosenberg and Ninica Howard

Professionals and Managers

Nona McQuay

Offices: A Hazard Summary

Wendy Hord

Bank Teller Safety: The Situation in Germany

Manfred Fischer

Telework

Jamie Tessler

The Retail Industry

Adrienne Markowitz

Case Study: Outdoor Markets

John G. Rodwan, Jr.

Tables

Click a link below to view table in article context.

1. Standard professional jobs

2. Standard clerical jobs

3. Indoor air pollutants in office buildings

4. Labour statistics in the retail industry

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

100. Personal and Community Services (6)

100. Personal and Community Services

Chapter Editor: Angela Babin

Table of Contents

Tables and Figures

Indoor Cleaning Services

Karen Messing

Barbering and Cosmetology

Laura Stock and James Cone

Laundries, Garment and Dry Cleaning

Gary S. Earnest, Lynda M. Ewers and Avima M. Ruder

Funeral Services

Mary O. Brophy and Jonathan T. Haney

Domestic Workers

Angela Babin

Case Study: Environmental Issues

Michael McCann

Click a link below to view table in article context.

1. Postures observed during dusting in a hospital

2. Dangerous chemicals used in cleaning

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

101. Public and Government Services (12)

101. Public and Government Services

Chapter Editor: David LeGrande

Table of Contents

Tables and Figurs

Occupational Health and Safety Hazards in Public and Governmental Services

David LeGrande

Case Report: Violence and Urban Park Rangers in Ireland

Daniel Murphy

Inspection Services

Jonathan Rosen

Postal Services

Roxanne Cabral

Telecommunications

David LeGrande

Hazards in Sewage (Waste) Treatment Plants

Mary O. Brophy

Domestic Waste Collection

Madeleine Bourdouxhe

Street Cleaning

J.C. Gunther, Jr.

Sewage Treatment

M. Agamennone

Municipal Recycling Industry

David E. Malter

Waste Disposal Operations

James W. Platner

The Generation and Transport of Hazardous Wastes: Social and Ethical Issues

Colin L. Soskolne

Tables

Click a link below to view table in article context.

1. Hazards of inspection services

2. Hazardous objects found in domestic waste

3. Accidents in domestic waste collection (Canada)

4. Injuries in the recycling industry

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

102. Transport Industry and Warehousing (18)

102. Transport Industry and Warehousing

Chapter Editor: LaMont Byrd

Table of Contents

Tables and Figures

General Profile

LaMont Byrd

Case Study: Challenges to Workers’ Health and Safety in the Transportation and Warehousing Industry

Leon J. Warshaw

Air Transport

Airport and Flight Control Operations

Christine Proctor, Edward A. Olmsted and E. Evrard

Case Studies of Air Traffic Controllers in the United States and Italy

Paul A. Landsbergis

Aircraft Maintenance Operations

Buck Cameron

Aircraft Flight Operations

Nancy Garcia and H. Gartmann

Aerospace Medicine: Effects of Gravity, Acceleration and Microgravity in the Aerospace Environment

Relford Patterson and Russell B. Rayman

Helicopters

David L. Huntzinger

Road Transport

Truck and Bus Driving

Bruce A. Millies

Ergonomics of Bus Driving

Alfons Grösbrink and Andreas Mahr

Motor Vehicle Fuelling and Servicing Operations

Richard S. Kraus

Case Study: Violence in Gasoline Stations

Leon J. Warshaw

Rail Transport

Rail Operations

Neil McManus

Case Study: Subways

George J. McDonald

Water Transport

Water Transportation and the Maritime Industries

Timothy J. Ungs and Michael Adess

Storage

Storage and Transportation of Crude Oil, Natural Gas, Liquid Petroleum Products and Other Chemicals

Richard S. Kraus

Warehousing

John Lund

Case Study: US NIOSH Studies of Injuries among Grocery Order Selectors

Tables

Click a link below to view table in article context.

1. Bus driver seat measurements

2. Illumination levels for service stations

3. Hazardous conditions & administration

4. Hazardous conditions & maintenance

5. Hazardous conditions & right of way

6. Hazard control in the Railway industry

7. Merchant vessel types

8. Health hazards common across vessel types

9. Notable hazards for specific vessel types

10. Vessel hazard control & risk-reduction

11. Typical approximate combustion properties

12. Comparison of compressed & liquified gas

13. Hazards involving order selectors

14. Job safety analysis: Fork-lift operator

15. Job safety analysis: Order selector

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

Street Cleaning

Adapted from 3rd edition, Encyclopaedia of Occupational Health and Safety.

Prevention of dirt-borne disease, prevention of damage to vehicles by harmful objects and the joy of viewing a neat, attractive city are all benefits derived from clean streets. Herded animals or animal-drawn vehicles, which in earlier times caused unsanitary conditions, have generally ceased to be a problem; however, the expansion in world population with the resultant upsurge in waste generated, the increase in the number and size of factories, the growth in the number of vehicles and newspapers and the introduction of disposable containers and products have all contributed to the amount of street refuse and added to the street-cleaning problem.

Organization and Processes

Municipal authorities recognizing the threat to health posed by dirty streets have sought to minimise the danger by organizing street cleaning sections in the public works departments. In these sections, a superintendent responsible for scheduling frequency of cleaning various districts will have forepeople responsible for specific cleaning operations.

Normally, business districts will be swept daily while arterial roads and residential areas will be swept weekly. Frequency will depend upon rain or snowfall, topography and the education of the populace toward prevention of litter.

The superintendent will also decide the most effective means of achieving clean streets. These could be hand sweeping by one worker or a group, hose flushing or machine sweeping or flushing. Generally a combination of methods, depending on the availability of equipment, type of dirt encountered and other factors will be used. In areas of heavy snowfall, special snow-clearing equipment may be used on occasion.

Hand sweeping is generally done in the daytime and confined to cleaning of gutters or spot cleaning of pavements or adjacent areas. The equipment used consists of brooms, scrapers and shovels. One sweeper generally patrols a specified route and cleans about 9 km of curb per shift under favourable conditions; however, this may be reduced in congested business districts.

Dirt collected by one-person sweeping is placed in a cart which he or she pushes ahead and dumps in boxes placed at intervals along his or her route; these boxes are emptied periodically into refuse trucks. In group sweeping, dirt is swept into piles along the gutters and loaded directly into trucks. Normally a group of 8 sweepers will have 2 workers assigned as loaders. Group sweeping is particularly effective for massive clean-up jobs such as after storms, parades or other special events.

Advantages of hand sweeping are: it is easily adjusted to meet changing cleaning loads; it can be used in areas inaccessible to machines; it can be conducted in heavy traffic with minimum interference with vehicle movement; it can be done in freezing weather and it can be used on pavements where surface conditions do not permit machine cleaning. Disadvantages are: the work is dangerous in traffic; it raises dust; dirt piled in gutters may be dispersed by wind or traffic if not collected promptly; and hand sweeping may be costly in labour-expensive areas.

Hose flushing is not considered an economical operation today; however, it is effective where there is a large amount of dirt or mud adhering to the pavement surfaces, where there are large numbers of parked vehicles or in market areas. It is generally done at night by a two-person crew, one of whom handles the hose nozzle and directs the stream and the other connects hose to the hydrant. Equipment consists of hoses, hose nozzles and hydrant wrenches.

Machine sweepers consist of motorized chassis mounted with brushes, conveyors, sprinklers and storage bins. They are generally used in late evening or early morning hours in business districts and during the day in residential areas. Cleaning action is confined to the gutters and adjacent areas where most dirt accumulates.

The machine is operated by one worker and can be expected to clean approximately 36 km of curb during an 8 hour shift. Factors affecting output are: number of times and distance which must be travelled to dump dirt or pick up sprinkling water; traffic density; and amount of dirt collected.

The advantages of machine sweepers are: they clean well, rapidly and raise no dust when sprinklers are used; they pick up the dirt as they clean; they can be used at night; and they are relatively economical. The disadvantages are: they cannot clean under parked cars or in off-pavement areas; they are not effective on rough, wet or muddy streets; the sprinkler cannot be used in freezing weather and dry sweeping raises dust; and they require skilled operators and maintenance personnel.

Flushing machines are essentially water tanks mounted on a motorized chassis which is fitted with a pump and nozzle to provide pressure and direct the stream of water against the pavement surface. The machine can be expected to clean about 36 km of 7 m wide pavement during an 8 hour shift.

The advantages of flushing machines are: they can be used effectively on wet or muddy pavements; they clean rapidly, well and under parked cars without raising dust; and they can operate at night or in light traffic. The disadvantages are: they require additional cleaning to be effective where street, litter or sewer conditions are not favourable; they annoy pedestrians or vehicle operators who are splashed; they cannot be used in freezing weather; and they require skilled operators and maintenance personnel.

Hazards and Their Prevention

Street cleaning is a hazardous occupation due to the fact that it is conducted in traffic and is concerned with dirt and refuse, with the possibility of infection, cuts from broken glass, tins and so on. In crowded areas, hand sweepers may be exposed to a considerable amount of carbon monoxide and to a high level of noise.

Traffic hazards are protected against by training sweepers in ways of avoiding danger, such as arranging work against the traffic flow and providing them with highly visible clothing as well as attaching red flags or other warning devices to their carts. Machine sweepers and flushers are made visible by fitting them with flashing lights, waving flags and painting them distinctively.

Street cleaners, and in particular hand sweepers, are exposed to all the vagaries of weather and occasionally may have to work in very severe conditions. Illness, infection and handling accidents can in part be prevented by the use of PPE and in part by training. Mechanical equipment such as that used for snow cleaning should be operated only by trained workers.

There should be a conveniently accessible central point providing good washing facilities (including showers where practicable), a cloakroom with arrangements for changing and drying clothes, a messroom and a first-aid room. Periodical medical examination is desirable.

Environmental Concerns of Snow Disposal

Snow removal and disposal introduces a set of environmental concerns related to the potential deposition of debris, salts, oil, metals and particulates in local waterbodies. A particular danger exists from the concentration of particulates, such as lead, that originate in atmospheric emissions from industrialized areas and automobiles. The danger of melt-water runoff to aquatic organisms and the risk of soil and groundwater contamination has been countered by the adoption of safe handling practices that protect sensitive areas from exposure. Snow disposal guidelines have been adopted in several Canadian provinces (e.g., Quebec, Ontario, Manitoba).

Municipal Recycling Industry

Overview

Recycling means different things to different people. To consumers, recycling may mean putting out bottles and cans for curbside collection. To a product maker—a manufacturer of raw materials or fabricator of goods—it means including recycled materials in the process. To recycling service providers, recycling can mean providing cost-efficient collection, sorting and shipping services. For scavengers, it means culling recyclable materials from garbage and waste cans and selling them to recycling depots. To public policy makers in all levels of government, it means establishing regulations governing collection and utilization as well as reducing the volume of waste to be disposed of and deriving revenue from the sale of the recycled materials. For recycling to work effectively and safely, these diverse groups must be educated to work together and share responsibility for its success.

The recycling industry had been growing steadily since its inception a century ago. Until the 1970s, it remained basically unchanged as a voluntary private sector effort conducted largely by scrap dealers. With the advent of incineration in the 1970s, it became desirable to separate out certain materials before putting waste into the furnaces. This concept was introduced to address the emission problems created by metals, batteries, plastics and other materials discarded in urban wastes which were causing many old incinerators to be shut down as environmental polluters. The increasing concern about the environment provided the primary impetus for the organized separation of plastics, aluminium, tin, paper and cardboard from the residential waste stream. Initially, the recycling industry was not economically viable as a self-sustaining business, but by the mid 1980s, the need for the materials and the increase in their prices led to the development of many new material recycling facilities (MRFs) to handle commingled recyclable materials across the US and Europe.

Work Force

The broad range of skills and expertise makes the range of employment for a MRF very wide. Whether it is a full-service MRF or a single sorting-line operation, the following groups of workers are generally employed:

- Operators of heavy equipment (front end loaders, grapples, bull-dozers, etc.) work on the tipping floor, coordinating the movement of waste from the staging area of the tipping floor to the area where the materials are sorted.

- Material sorters, the majority of the workforce, segregate and sort recyclable materials by product and/or colour. This may be done entirely by hand or with the assistance of equipment. The sorted materials are then baled or crated.

- Forklift operators are responsible for moving finished bales from the throat of the baler to the storage area and from there to the trucks or other means of transportation.

- Maintenance workers are becoming increasingly important as the technology advances and the machines and equipment become more complicated.

Processes and Facilities

The recycling industry has been growing very rapidly and has evolved many different processes and procedures as the technology of sorting recyclable materials has advanced. The most common types of installation include full-service MRFs, non-waste stream MRFs and simple sorting and processing systems.

Full-service MRFs

The full-service MRF receives recyclable materials mixed in the residential waste streams. Typically, the resident places the recyclables in coloured plastic bags which are then placed in the residential waste container. This allows the community to combine recyclable materials with other residential wastes, eliminating the need for separate collection vehicles and containers. A typical sequence of operations includes the following procedures:

- The waste and recyclables bags are dropped from the collection vehicle onto the tipping/collection floor.

- The mixture of waste and recyclables is moved either by a grapple or a front-end loader to an in-floor conveyer.

- The conveyer moves the material into the sorting area where a rotating trommel (a cylindrical sieve) opens the bags and allows the very small particles of dirt, sand and gravel to pass through the openings to a collection container for discarding.

- The remaining materials are semi-automatically sorted by screens or disks according to weight and bulkiness. Glass is sorted by its heavier weight, plastics by their lighter weight and paper fibre materials by their bulk.

- Employees hand sort materials, typically from an elevated position above bunkers into which the materials can be stored. Materials are sorted according to the grade of paper, the colour of glass, the physical properties of plastic and so on.

- Refuse and other wastes are collected and removed by tractor-trailer loads.

- The separated materials are moved from the bunkers by forklift or by a “walking floor” (i.e., a conveyer) to a baler or a shredding and baling operation.

- The formed bale is discharged from the baler and moved to the storage area by a forklift.

- Collected bales are shipped either by rail or a tractor-trailer. Instead of baling, some MRFs loose load the materials into a rail car or a tractor trailer.

Non-waste stream MRF

In this system, only the recyclables are delivered to the MRF; the residential wastes go elsewhere. It involves an advanced, semi-automated sorting and processing process system in which all of the steps are the same as those described above. Because of the smaller volume, fewer employees are involved.

Simple sorting/processing system

This is a labour-intensive system in which the sorting is performed manually. Typically, a conveyer belt is used to move material from one work station to another with each sorter removing one type of material as the belt passes his station. A typical sequence for such a simple, inexpensive processing system would include these processes:

- Mixed recyclables are received on a tipping floor and are moved by a front-end loader to the main sorting conveyor belt.

- Glass bottles are separated manually by colour (flint, amber, green and so forth).

- Plastic containers are sorted by grade and accumulated for baling.

- Aluminium cans are removed manually and fed to either a compactor or baler.

- The remaining materials are discharged into a residue pile or container for disposal.

Equipment and machinery

The machinery and equipment used in a MRF is determined by the type of process and the volumes of materials handled. In a typical semi-automated MRF, it would include:

- bag openers

- magnetic separators

- screens (disks, shakers or trommel)

- material classification equipment (mechanical or pneumatic)

- glass crushers

- balers and compactors

- eddy current separators (for non-ferrous metal separation)

- conveyer belts

- rolling stock.

Health and safety hazards

MRF workers face a large variety of environmental and work hazards, many of which are unpredictable since the content of the waste changes continually. Prominent among them are:

- infectious disease from biological and medical wastes

- acute and chronic toxicity from household chemicals, solvents and other chemicals being discarded. This risk is not very great (except when industrial wastes find their way into the residential stream) since household chemicals are usually not very toxic and only relatively small amounts are present.

- solvents and fuel and exhaust fumes (especially vehicle operators and maintenance workers)

- exposures to heat, cold and bad weather since many MRFs are exposed to the elements

- noise at harmful levels when heavy machines operate in confined spaces

- physical hazards such as slips and falls, puncture wounds, lacerations and abrasions, muscular strains, sprains and repetitive motion injuries. Sorters usually stand continuously, while vehicle operators must sometimes contend with poorly designed seats and operating controls.

- airborne dust and particles.

Table 1 lists the most common types of injury in the recycling industry.

Table 1. Most frequent injuries in the recycling industry.

|

Injury type |

Cause of injury |

Body part affected |

|

Cuts, abrasions and lacerations |

Contact with sharp materials |

Hands and forearms |

|

Strain |

Lifting |

Lower back |

|

Particles in eye |

Airborne dust and flying objects |

Eye |

|

Repetitive motion |

Manual sorting |

Upper extremities |

Prevention

MRF workers have the potential to be exposed to whatever wastes are delivered to it, as well as the ever-changing environment in which they work. The management of the facility must constantly be aware of the content of the material being delivered, the training and supervision of the workers and their compliance with safety rules and regulations, the proper use of PPE and the maintenance of machinery and equipment. The following safety considerations deserve constant close attention:

- lockout/tagout precautions

- general housekeeping

- egress maintenance

- emergency preparedness and, when needed, access to first-aid and medical assistance

- hearing conservation programmes

- protection against blood-borne pathogens

- preventive maintenance of machines and equipment

- traffic patterns and danger to pedestrians from the rolling stock

- confined spaces

- fire prevention and training and equipment for fire-fighting

- household hazardous waste management

- availability and use of high-quality, properly-sized PPE.

Conclusion

Municipal recycling is a relatively new industry that is changing rapidly as it grows and its technology advances. The health and safety of its workforce depend on proper design of processes and equipment and the proper training and supervision of its workers.

Waste Disposal Operations

Workers involved in municipal waste disposal and handling face occupational health and safety hazards which are as diverse as the materials they are handling. Workers’ primary complaints relate to odour and upper respiratory tract irritation usually related to dust. However, actual occupational health and safety concerns vary with the work process and the waste stream characteristics (mixed municipal solid waste (MSW), sanitary and biological waste, recycled wastes, agricultural and food wastes, ash, construction debris and industrial wastes). Biological agents such as bacteria, endotoxins and fungi may present hazards, particularly for immune system-compromised and hypersensitive workers. In addition to safety concerns, health impacts have involved predominantly respiratory health problems among workers, including symptoms of organic dust toxic syndrome (ODTS), irritation of the skin, eyes and upper airways and cases of more severe pulmonary diseases such as asthma, alveolitis and bronchitis.

The World Bank (Beede and Bloom 1995) estimates that 1.3 billion tonnes of MSW were generated in 1990 which represents an average of two-thirds of a kilogram per person per day. In the US alone, an estimated 343,000 workers were involved in MSW collection, transport and disposal according to 1991 US Census Bureau statistics. In industrialized countries waste streams are increasingly distinct and work processes are increasingly complex. Efforts to segregate and better define the compositions of waste streams are often critical for identifying occupational hazards and appropriate controls and for controlling environmental impacts. Most waste disposal workers continue to face unpredictable exposures and risks from mixed wastes in dispersed open dumps, often with open burning.

The economics of waste disposal, reuse and recycling, as well as public health concerns, are driving rapid changes in waste handling globally to maximize recovery of resources and reduce dispersion of refuse into the environment. Depending on local economic factors this results in the adoption of either increasingly labour-intensive or capital-intensive work processes. Labour-intensive practices draw an increasing number of workers into hazardous work environments and commonly involve informal sector scavengers who sort mixed refuse by hand and sell recyclable and reusable materials. Increased capitalization has not automatically led to improvements in working conditions as increased work within confined spaces (e.g., in drum composting operations or incinerators), and increased mechanical processing of wastes can result in increased exposure to both airborne contaminants and mechanical hazards, unless proper controls are implemented.

Waste Disposal Processes

A variety of waste disposal processes are used, and as waste collection, transportation and disposal costs increase to meet increasingly stringent environmental and community standards, an increasing diversity of processes can be cost-justified. These processes break down into four basic approaches which may be used in combination or in parallel for various waste streams. The four basic processes are dispersal (land or water dumping, evaporation), storage/isolation (sanitary and hazardous waste landfills), oxidation (incineration, composting) and reduction (hydrogenation, anaerobic digestion). These processes share some general occupational hazards associated with waste handling, but also involve work-process-specific occupational hazards.

General Occupational Hazards in Waste Handling

Regardless of the specific disposal process being utilized, simply processing MSW and other wastes involves common defined hazards (Colombi 1991; Desbaumes 1968; Malmros and Jonsson 1994; Malmros, Sigsgaard and Bach 1992; Maxey 1978; Mozzon, Brown and Smith 1987; Rahkonen, Ettala and Loikkanen 1987; Robazzi et al. 1994).

Unidentified, highly hazardous materials are often intermixed with normal waste. Pesticides, flammable solvents, paints, industrial chemicals, and biohazardous waste, may all be intermixed with household waste. This hazard can be handled primarily through segregation of the waste stream and in particular separation of industrial and household waste.

Odours and exposure to mixed volatile organic compounds (VOCs) can induce nausea but are typically well below American Conference of Governmental Industrial Hygenists (ACGIH) threshold limit values (TLVs), even within enclosed spaces (ACGIH 1989; Wilkins 1994). Control typically involves isolation of the process, as in sealed anaerobic digesters or drum composters, minimizing worker contact through daily soil cover or transfer station cleanup and controlling biological degradation processes, particularly minimizing anaerobic degradation by controlling moisture content and aeration.

Insect- and rodent-borne pathogens can be controlled through daily cover of waste with soil. Botros et al. (1989) reported that 19% of garbage workers in Cairo had antibodies to Rickettsia Typhi (from fleas) which causes human rickettsial disease.

Injection or blood contact with infectious waste, such as needles and blood soiled waste, is best controlled at the generator by segregation and sterilization of such waste prior to disposal and disposal in puncture resistant containers. Tetanus is also a real concern should skin damage occur. Up-to-date immunization is required.

Ingestion of Giardia sp. and other gastrointestinal pathogens can be controlled by minimizing handling, reducing hand-to-mouth contact (including tobacco use), supplying safe drinking water, providing toilet and clean up facilities for workers and maintaining appropriate temperature in composting operations in order to destroy pathogens prior to dry handling and bagging. Precautions are particularly appropriate for Giardia found in sewage sludge and disposable baby diapers in MSW, as well as for tape and round worms from poultry and slaughterhouse wastes.

Inhalation of airborne bacteria and fungi is of particular concern when mechanical processing increases (Lundholm and Rylander 1980) with compactors (Emery et al. 1992), macerators or shredders, aeration, bagging operations and when moisture content is allowed to drop. This results in increased respiratory disorders (Nersting et al. 1990), bronchial obstruction (Spinaci et al. 1981) and chronic bronchitis (Ducel et al. 1976). Although there are no formal guidelines, the Dutch Occupational Health Association (1989) recommended that total bacteria and fungal counts should be kept below 10,000 colony forming units per cubic metre (cfu/m3) and below 500 cfu/m3 for any single pathogenic organism (outdoor air levels are about 500 cfu/m3 for total bacteria, indoor air is typically less). These levels may be regularly exceeded in composting operations.

Biotoxins are formed by fungi and bacteria including endotoxins formed by gram-negative bacteria. Inhaling or ingesting an endotoxin, even after killing the bacteria which produced it, can cause fever and flu-like symptoms without infection. The Dutch Working Group on Research Methods in Biological Indoor Air Pollution recommends that airborne gram-negative bacteria be kept below 1000 cfu/m3 to avoid endotoxin effects. Bacteria and fungi can produce a variety of other potent toxins which may also present occupational hazards.

Heat exhaustion and heat stroke can be serious concerns particularly where safe drinking water is limited and where PPE is utilized in sites known to contain hazardous wastes. Simple PVC-Tyvek suits show a heat stress equivalent of adding 6 to 11°C (11 to 20°F) to the ambient wet bulb globe temperature (WBGT) index (Paull and Rosenthal 1987). When the WBGT exceeds 27.7°C (82°F) conditions are considered hazardous.

Skin damage or disease are common complaints in waste handling operations (Gellin and Zavon 1970). Direct skin damage from caustic ash and other irritating waste contaminants, combined with high exposures to pathogenic organisms, frequent skin lacerations and punctures and, typically, poor availability of washing facilities result in a high incidence of skin problems.

Wastes contain a variety of materials that can cause lacerations or punctures. These are of particular concern in labour intensive operations such as waste sorting for recycling or manual turning of MSW compost and where mechanical processes such as compacting, crushing or shredding can create projectiles. The most critical control measures are safety glasses and puncture and slash resistant footwear and gloves.

Vehicular-use hazards include both operator hazards such as rollover and engulfment hazards and collision hazards with workers on the ground. Any vehicle that works on unsound or irregular surfaces should be equipped with rollover cages that will support the vehicle and allow the operator to survive. Pedestrian and vehicular traffic should be separated to the extent possible into distinct traffic areas, particularly where visibility is limited such as during open burning, at night and in composting yards where dense ground fogs may develop in cold weather.

Reports of increased atopic bronchopulmonary reactions such as asthma (Sigsgaard, Bach and Malmros 1990) and skin reactions can occur in waste workers, particularly where organic dust exposure levels are high.

Process-specific Hazards

Dispersion

Dispersion includes dumping waste into bodies of water, evaporation into the air or dumping with no effort at containment. Ocean dumping of MSW and hazardous wastes is rapidly declining. However, an estimated 30 to 50% of MSW is not collected in the cities of developing countries (Cointreau-Levine 1994) and is commonly burned or dumped in canals and streets, where it presents a significant public health threat.

Evaporation, sometimes with active heating at low temperatures, is used as a cost-saving alternative to incinerators or kilns, especially for volatile liquid organic contaminants such as solvents or fuel which are mixed with non-combustible wastes such as soil. Workers may face confined-space entry hazards and explosive atmospheres, especially in maintenance operations. Such operations should incorporate appropriate air emissions controls.

Storage/isolation

Isolation involves a combination of remote locations and physical containment in increasingly secure landfills. Typical sanitary landfills involve excavation with earth moving equipment, dumping of waste, compaction and daily cover with soil or compost to reduce pest infestations, odours and dispersion. Clay or impervious plastic caps and/or liners may be installed to limit water infiltration and leachate into groundwater. Test wells may be used to evaluate off-site leachate migration and to allow monitoring of leachate within the landfill. Workers include heavy equipment operators, truck drivers, spotters who may be responsible for rejecting hazardous waste and directing vehicle traffic flows and informal sector scavengers who may sort the waste and remove recyclables.

In areas dependent on coal or wood for fuel, ash can constitute a significant portion of the waste. Quenching prior to dumping, or segregation into ash monofills, may be necessary to avoid fires. Ash can cause skin irritation and caustic burns. Fly ash presents a variety of health hazards including respiratory and mucosal irritation as well as acute respiratory distress (Shrivastava et al. 1994). Low density fly ash can also constitute an engulfment hazard and can be unstable under heavy equipment and in excavations.

In many nations waste disposal continues to consist of simple dumping with open burning, which may be combined with informal scavenging of reusable or recyclable components with value. These informal sector workers face serious safety and health hazards. It is estimated that in Manila, Philippines, 7,000 scavengers work at the MSW dump, 8,000 in Jakarta and 10,000 in Mexico City (Cointreau-Levine 1994). Because of the difficulties in controlling work practices in informal work, an important step in controlling these hazards is to move separation of recyclables and reusables into the formal waste collection process. This may be performed by the waste generators, including consumers or household workers, by collection/sorting workers (e.g., in Mexico City collection workers officially spend 10% of their time sorting waste for sale of recyclables, and in Bangkok 40% (Beede and Bloom 1995)) or in pre-disposal waste separation operations (e.g., magnetic separation of metallic waste).

Open burning exposes workers to a potentially toxic mix of degradation products as discussed below. Because open burning can be used by informal scavengers to assist in separating metal and glass from combustible waste, it may be necessary to recover materials with salvage value prior to dumping in order to eliminate such open burning.

As hazardous wastes are successfully segregated from the waste stream, risks of MSW workers are reduced while quantities handled by hazardous waste site workers increase. Highly secure hazardous waste treatment and disposal sites depend on detailed manifesting of waste composition, high levels of worker PPE, and extensive worker training to control hazards. Secure landfills have unique hazards including slip and fall hazards where excavations are lined with plastic or polymer gels to reduce migration of leachate, potentially serious dermatological problems, heat stress related to work for extended periods in impermeable suits and supplied air quality control. Heavy equipment operators, labourers and technicians depend largely on PPE to minimize their exposures.

Oxidation (incineration and composting)

Open burning, incineration and waste-derived fuel are the most obvious examples of oxidation. Where the moisture content is low enough and the combustible content is high enough, increasing effort is made to utilize the fuel value in MSW either through the generation of waste-derived fuel as compressed briquettes or by incorporating electrical cogeneration or steam plants into municipal waste incinerators. Such operations can involve high levels of dry dusts due to efforts to produce a fuel with consistent heat value. Residual ash must still be disposed of, usually in landfills.

MSW incinerators involve a variety of safety hazards (Knop 1975). Swedish MSW incinerator workers showed increased ischemic heart disease (Gustavsson 1989), while a study of US incinerator workers in Philadelphia, Pennsylvania, failed to show a correlation between health outcomes and exposure groups (Bresnitz et al. 1992). Somewhat elevated blood lead levels have been identified in incinerator workers, primarily related to exposures to electrostatic precipitator ash (Malkin et al. 1992).

Ash exposures (e.g., crystalline silica, radioisotopes, heavy metals) can be significant not only in incinerator operations, but also at landfills and lightweight concrete plants where ash is used as aggregate. Although crystalline silica and heavy metal content vary with the fuel, this may present serious silicosis risk. Schilling (1988) observed lung function and respiratory symptom effects in ash exposed workers, but no changes observable by x ray.

Thermal degradation on pyrolysis products resulting from incomplete oxidation of many waste products can pose significant health risks. These products can include hydrogen chloride, phosgene, dioxins and dibenzofurans from chlorinated wastes, such as polyvinyl chloride (PVC) plastics and solvents. Non-halogenated wastes also can produce hazardous degradation products, including polyaromatic hydrocarbons, acrolein, cyanide from wools and silk, isocyanates from polyurethane and organotin compounds from a variety of plastics. These complex mixtures of degradation products can vary tremendously with waste composition, feed rates, temperature and available oxygen during combustion. While these degradation products are a significant concern in open burning, exposures in MSW incinerator workers appear to be relatively low (Angerer et al. 1992).

In MSW and hazardous waste incinerators and rotary kilns, control of combustion parameters and the residence time for waste vapours and solids at high temperatures is critical in destruction of wastes while minimizing the generation of more hazardous degradation products. Workers are involved in incinerator operation, loading and waste transfer into the incinerator, waste delivery and unloading from trucks, equipment maintenance, housekeeping and ash and slag removal. While incinerator design can limit necessary manual labour and worker exposures, with less capital-intensive designs there may be significant worker exposures and a need for regular confined space entry (e.g., chipping for removal of slag from glass waste from incinerator grates).

Composting

In aerobic biological processes the temperature and speed of oxidation are lower than incineration, but it is nevertheless oxidation. Composting of agricultural and yard wastes, sewage sludge, MSW and food wastes is increasingly common in city-scale operations. Rapidly developing technologies for biological remediation of hazardous and industrial wastes often involve a sequence of aerobic and anaerobic digestion processes.

Composting usually occurs either in wind rows (long piles) or in large vessels which provide aeration and mixing. The objective of composting operations is to create a mix of waste with optimum ratios of carbon and nitrogen (30:1) and then maintain moisture at 40 to 60% by weight, greater than 5% oxygen and temperature levels 32 to 60oC so that aerobic bacteria and other organisms can grow (Cobb and Rosenfield 1991). Following separation of recyclables and hazardous wastes (which typically involves hand sorting), MSW is shredded to create more surface area for biological action. Shredding can produce high noise and dust levels and significant mechanical guarding concerns. Some operations use ganged hammer-mills to allow reduced front-end sorting.

In-vessel or drum composting operations are capital intensive but allow more effective odour and process control. Confined space entry is a significant hazard for maintenance workers as high levels of CO2 may be released causing oxygen deficiency. Lockout of equipment prior to maintenance is also critical as mechanisms include internal screw-drives and conveyors.

In less capital intensive wind row composting operations, waste is shredded and placed in long piles which are mechanically aerated through perforated pipes or simply by turning, either with front-end loaders or manually. Wind rows may be covered or roofed to facilitate maintenance of constant moisture content. Where specialized wind row turning equipment is used, chain mixing-flails rotate at high speed through the compost and should be well guarded from human contact. As these flails rotate through the wind row, they eject objects which can become dangerous projectiles. Operators must assure safe clearance distances around and behind the equipment.

Regular temperature measurements with probes allow monitoring the progress of composting and assure high enough temperatures to kill pathogens while allowing adequate survival of beneficial organisms. At moisture contents of 20 to 45% when the temperature exceeds 93oC there can also be a spontaneous combustion fire hazard (much like a silo fire). This is most likely to occur when piles exceed 4 m in height. Fires can be avoided by keeping pile heights below 3 m, and turning when the temperature exceeds 60°C. Facilities should provide water hydrants and adequate access between wind rows for control of fires.

Hazards in composting operations include vehicle and mechanical hazards resulting from tractors and trucks involved in turning wind-rows of waste to maintain aeration and moisture content. In cooler climates the elevated temperatures of compost can produce dense ground fogs in a work area occupied by heavy equipment operators and pedestrian workers. Compost workers report more nausea, headache and diarrhoea than their counterparts in a drinking water plant (Lundholm and Rylander 1980). Odour problems can occur as a result of poor control of the moisture and air required for the composting to progress. If anaerobic conditions are allowed to occur, hydrogen sulphide, amines and other odorous materials are generated. In addition to typical disposal worker concerns, composting involving actively growing organisms can raise MSW temperatures high enough to kill pathogens, but can also produce exposures to moulds and fungi and their spores and toxins, especially in compost bagging operations and where compost is allowed to dry. Several studies have evaluated airborne fungi, bacteria, endotoxins and other contaminants (Belin 1985; Clark, Rylander and Larsson 1983; Heida, Bartman and van der Zee 1975; Lacey et al. 1990; Millner et al. 1994; van der Werf 1996; Weber et al. 1993) in composting operations. There is some indication of increased respiratory disorders and hypersensitivity reactions in compost workers (Brown et al. 1995; Sigsgaard et al. 1994). Certainly bacterial and fungal respiratory infections (Kramer, Kurup and Fink 1989) are a concern for immune-suppressed workers such as those with AIDS and those receiving cancer chemotherapy.

Reduction (hydrogenation and anaerobic digestion)

Anaerobic digestion for sewage and agricultural waste involves closed tanks, often with rotating brush contacts if nutrients are dilute, which can pose serious confined space entry concerns for maintenance workers. Anaerobic digesters are also commonly used in many countries as methane generators which may be fuelled with agricultural, sanitary or food wastes. Methane collection from MSW landfills and burning or compression for use is now required in many countries when methane generation exceeds specified thresholds, but most landfills have inadequate moisture for anaerobic digestion to proceed efficiently. Hydrogen sulphide generation is also a common result of anaerobic digestion and can cause eye irritation and olfactory fatigue at low levels.

More recently, high temperature reduction/hydrogenation has become a treatment option for organic chemical wastes. This can involve smaller, and therefore potentially mobile, installations with less energy input than a high temperature incinerator because metallic catalysts allow hydrogenation to proceed at lower temperatures. Organic wastes can be converted into methane and used as fuel to continue the process. Critical worker safety concerns include explosive atmospheres and confined space entry for cleaning, sludge removal and maintenance, hazards of transporting and loading the liquid feed wastes and spill response.

Summary

As wastes are viewed as resources for recycling and reuse, waste processing increases, resulting in rapid change in the waste disposal industry globally. Occupational health and safety risks of waste disposal operations often go beyond obvious safety hazards to a variety of chronic and acute health concerns. These hazards are often faced with minimal PPE and inadequate sanitary and wash-up facilities. Industrial waste reduction and pollution prevention efforts are increasingly shifting recycling and reuse processes away from contracted or external waste disposal operations and into production work areas.

Top priorities in controlling occupational safety and health hazards in this rapidly changing industry sector should include:

- integrating informal sector work into the formal work process

- providing adequate toilet and wash-up facilities and safe drinking water

- eliminating open burning and waste dispersion into the environment

- segregating waste streams to facilitate characterization of wastes and identification of appropriate control measures and work practices

- minimizing mixed vehicular and pedestrian traffic in work areas

- following appropriate excavation practices for soil and waste characteristics

- anticipating and controlling hazards prior to entry into confined spaces

- minimizing respirable dust exposures in high dust operations

- using safety glasses and slash and puncture resistant shoes and gloves

- integrating occupational safety and health concerns when introducing process change plans, particularly during transitions from open dumping and landfills to more complex and potentially more hazardous enclosed operations such as composting, mechanical or manual separation for recycling, waste to energy operations or incinerators.

In this period of rapid change in the industry, significant improvements in worker health and safety can be made at low cost.

The Generation and Transport of Hazardous Wastes: Social and Ethical Issues

Adapted from Soskolne 1997, with permission.

Hazardous wastes include, among other things, radioactive materials and chemicals. The movement of these substances from their source to other locations has been termed “toxic trade”. It was in the late 1980s that concern was raised about toxic trade, in particular with Africa (Vir 1989). This set the stage for the recently recognized issue of environmental justice, in some situations also known as environmental racism (Coughlin 1996).

Vir (1989) pointed out that as environmental safety laws became increasingly stringent in Europe and in the United States, and as the cost of disposal increased, “dumpers” or “waste merchants” began to turn their attention to poorer nations as potential and willing recipients of their waste products, providing a much needed source of revenue to these poorer countries. Some of these countries had been willing to take such waste at a fraction of the cost that developed nations would otherwise have had to pay for their disposal. To “nations that are drowning economically, this is an attractive deal” (Vir 1989).

Asante-Duah, Saccomanno and Shortreed (1992) show the exponential growth in the United States in the production of hazardous wastes since 1970, with the costs associated with treatment and disposal similarly increasing. They argue in favour of a controlled hazardous waste trade, one that is “regulated and informed”. They note that “countries generating small quantities of hazardous wastes should view the waste trade as an important economic option, as long as the waste recipients do not compromise their environmental sustainability”. Hazardous wastes will continue to be generated and there are countries for which an increase in some of these substances would not increase the risk to health of either present or future generations. It might therefore be economically efficient for such countries to accept waste.

There are others who argue that waste should be disposed of only at the source and not be transported at all (Puckett and Fogel 1994; Cray 1991; Southam News 1994). The latter argue from the position that science is incapable of providing any guarantees about the absence of risk.

One ethical principle that emerges from the foregoing argument is that of respect for autonomy (i.e., respect for persons), which also includes questions of national autonomy. The crucial question is one of the ability of a recipient country to adequately assess the level of risk associated with a shipment of hazardous waste. Assessment presupposes full disclosure of the contents of a shipment from the originating country and a level of local expertise to assess any potential impacts on the recipient country.

Because communities in developing countries are less likely to be informed about the potential risks associated with waste shipments, the NIMBY phenomenon (i.e., not in my backyard) so evident in the more affluent regions of the world is less likely to manifest in poorer regions. Furthermore, workers in developing regions of the world tend not to have the infrastructure related to worker protection, including information concerning the labelling of products with which they come into contact. Hence, workers in poorer nations involved in the management, storage and disposal of hazardous waste would lack the training to know how to protect themselves. Regardless of these ethical considerations, in the final analysis the economic benefits to be derived from accepting such waste shipments would need to be weighed against any potential harms that could arise in the short, medium and longer terms.

A second ethical principle emerging from the preceding argument is that of distributive justice, which involves question regarding who takes risks and who derives benefits. When there is an imbalance between those who take risks and those who derive benefits, the principle of distributive justice is not being honoured. It has often been financially poor labourers who have been exposed to hazards without any ability to enjoy the fruits of their efforts. This has occurred in the context of production of relatively expensive merchandise in the developing world for the benefit of first world markets. Another example related to the testing of new vaccines or drugs on people in developing countries who could never afford access to them in their own countries.

Towards Controlling the Transport of Hazardous Wastes

Because of the recognized need to better control the dumping of hazardous wastes, the Basel Convention was entered into by ministers of 33 countries in March 1989 (Asante-Duah, Saccomanno and Shortreed 1992). The Basel Convention addressed the transboundary movements of hazardous wastes and required the notification and consent of recipient countries before any waste shipments could take place.

Subsequently, the United Nations Environment Programme (UNEP) launched its Cleaner Production Programme, in close cooperation with governments and industry, to advocate low- and non-waste technologies (Rummel-Bulska 1993). In March 1994, a full ban was introduced on all transboundary movements of hazardous wastes from the 24 rich industrialized countries of the Organization for Economic Cooperation and Development (OECD) to other states that are not members of the OECD. The ban was immediate for wastes bound for final disposal and enters into force at the beginning of 1998 for all hazardous wastes that are said to be destined for recycling or recovery operations (Puckett and Fogel 1994). The countries most opposed to the introduction of a total ban were Australia, Canada, Japan and the United States. Despite this opposition from a handful of powerful industrial governments through the penultimate vote, the ban was finally agreed to by consensus (Puckett and Fogel 1994).

Greenpeace has stressed the primary prevention approach to solving the mounting waste crisis by addressing the root cause of the problem, namely minimizing waste generation through clean production technologies (Greenpeace 1994a). In making this point, Greenpeace identified major countries exporting hazardous wastes (Australia, Canada, Germany, the United Kingdom and the United States) and some countries importing them (Bangladesh, China (including Taiwan), India, Indonesia, Malaysia, Pakistan, the Philippines, the Republic of Korea, Sri Lanka and Thailand). In 1993, Canada, for example, had exported some 3.2 million kilograms of ash containing lead and zinc to India, the Republic of Korea and Taiwan, China, and 5.8 million kilograms of plastic waste to Hong Kong (Southam News 1994). Greenpeace (1993, 1994b) also addresses the extent of the problem in terms of specific substances and approaches to disposal.

Risk Assessment

Epidemiology is at the centre of human health risk assessment, which is invoked when concern is raised by a community about the consequences, if any, of exposure to hazardous and potentially toxic substances. The scientific method that epidemiology brings to the study of the environmental determinants of ill health can be fundamental to protecting unempowered communities, both from environmental hazards and from environmental degradation. Risk assessment conducted in advance of a shipment likely would fall into the legal trade arena; when conducted after a shipment has arrived, risk assessment would be undertaken to determine whether or not any health concerns were justified from what likely would have been an illegal shipment.

Among the concerns to the risk assessor would be hazard assessment, i.e., questions about what hazards, if any, exist and in what quantities and in what form they might be present. In addition, depending on the type of hazard, the risk assessor must make an exposure assessment to establish what possibilities there are for people to be exposed to the hazardous substance(s) through inhalation, skin absorption or ingestion (by contamination of the food chain or directly on foodstuffs).

In terms of trade, autonomy would require the informed consent of the parties in a voluntary and non-coercive milieu. However, it is hardly possible that non-coerciveness could ever pertain in such a circumstance by virtue of the financial need of an importing developing world country. The analogue here is the now accepted ethical guideline which does not permit the coercion of participants in research through payment for anything but direct costs (e.g., lost wages) for the time taken to participate in a study (CIOMS 1993). Other ethical issues involved here would include, on the one hand, truth in the presence of unknowns or in the presence of scientific uncertainty and, on the other hand, the principle of caveat emptor (buyer beware). The ethical principle of non-maleficence requires the doing of more good than harm. Here the short-term economic benefits of any trade agreement to accept toxic wastes must be weighed against the longer term damage to the environment, the public health and possibly also to future generations.

Finally, the principle of distributive justice requires recognition by the parties involved in a trade deal as to who would be deriving the benefits and who would be taking the risks in any trade deal. In the past, general practices for dumping waste and for locating hazardous waste sites in unempowered communities in the United States have led to the recognition of the concern now known as environmental justice or environmental racism (Coughlin 1996). In addition, questions of environmental sustainability and integrity have become central concerns in the public forum.

Acknowledgements: Dr. Margaret-Ann Armour, Department of Chemistry, University of Alberta, provided valuable references on the topic of toxic trade as well as materials from the November 1993 Pacific Basin “Conference on Hazardous Waste” at the University of Hawaii.

The Greenpeace office in Toronto, Ontario, Canada, was most helpful in providing copies of the Greenpeace references cited in this article.

General Profile

The transport sector encompasses industries that are involved in the transportation of goods and passengers throughout the world. This sector is structurally complex and vitally important to economies locally, nationally and globally.

Economic Importance

The transport sector is vitally important to the economic viability of nations. Transportation plays a key role in economically important factors such as employment, utilization of raw and manufactured goods, investment of private and public capital and generation of tax revenues.

In most industrialized countries, transport accounts for 2 to 12% of the paid employment (ILO 1992). In the United States alone, the Department of Transportation reported that in 1993, there were approximately 7.8 million employees in trucking-related firms (DOT 1995). The transport sector’s share in the gross domestic product (GDP) and total employment tends to decrease as the country’s income increases.

The transport sector is also a major consumer of raw materials and finished goods in most industrialized countries. For example, in the United States, the transport sector utilizes approximately 71% of all rubber produced, 66% of all petroleum refined, 24% of all zinc, 23% of all cement, 23% of all steel, 11% of all copper and 16% of all aluminium (Sampson, Farris and Shrock 1990).

Capital investment utilizing public and private funds to purchase trucks, ships, airplanes, terminals and other equipment and facilities easily exceeds hundreds of billions of dollars in industrialized countries.

The transport sector also plays a major role in generating revenues in the form of taxes. In industrialized countries, transport of passengers and freight is often heavily taxed (Sampson, Farris and Shrock 1990; Gentry, Semeijn and Vellenga 1995). Typically these taxes take the form of fuel taxes on gasoline and diesel fuels, and excise taxes on freight bills and passenger tickets, and easily exceed hundreds of billions of dollars annually.

Evolution of the Sector

In the early stages of the transport sector, geography greatly influenced what was the dominant mode of transportation. As advances were made in construction technology, it became possible to overcome many of the geographical barriers that limited the development of the transport sector. As a result, the modes of transport that have dominated the sector evolved in accordance with the technology available.

Initially, water travel over the oceans was the primary mode of transport of freight and passengers. As large rivers were navigated and canals were built, the volume of inland transport over the waterways increased significantly. In the late nineteenth century, transport over railways began to emerge as the dominant mode of transport. Rail transport, because of its ability to overcome natural barriers such as mountains and valleys through the use of tunnels and bridges, offered flexibility that waterways could not provide. Furthermore, unlike transport over waterways, transport over the rails was virtually unaffected by winter conditions.

Many national governments recognized the strategic and economic advantages of rail transport. Consequently, rail companies were awarded governmental financial assistance to facilitate the expansion of rail networks.

In the early twentieth century, the development of the combustion engine combined with the increased use of motor vehicles enabled road transport to become an increasingly popular mode of transport. As the highway and throughway systems were developed, road transport enabled door-to-door deliveries of goods. This flexibility far surpassed that of railways and waterways. Eventually, as advances were made in road construction and improvements were made to the internal combustion engine, in many parts of the world road transport became faster than rail transport. Consequently, road transport has become the most used mode of transport of goods and passengers.

The transport sector continued to evolve with the advent of airplanes. The use of airplanes as a means to transport freight and passengers began during the Second World War. Initially, airplanes were primarily used to transport mail and soldiers. However, as aircraft construction was perfected and an increasing number of persons learned to operate airplanes, air transport grew in popularity. Today, air transport is a very fast, reliable mode of transport. However, in terms of total tonnage, air transport handles only a very small percentage of freight.

Structure of the Sector

Information on the structure of rail systems in industrialized countries is generally reliable and comparable (ILO 1992). Similar information on road systems is somewhat less reliable. Information on the structure of waterways is reliable, having not changed substantially in the past few decades. However, similar information regarding developing countries is scarce and unreliable.

European countries developed economic and political blocs that have had a significant impact on the transport sector. In Europe, road transport dominates the movement of freight and passengers. Trucking, with a heavy emphasis on less-than-trailer-load freight, is conducted by small national and regional carriers. This industry is heavily regulated and highly fractured. Since the early 1970s, the total volume of freight transported by road has increased by 240%. Conversely, rail transport has declined by approximately 8% (Violland 1996). However, several European countries are working diligently to increase the efficiency of rail transport and are promoting intermodal transport.

In the United States, the primary mode of transport is over the roadways. The Department of Transportation, Office of Motor Carriers, reported in 1993 that there were over 335,000 firms operating medium and heavy trucks (DOT 1995). This included large companies that transport their own products, smaller private firms, and for-hire truckload and less-than-truckload common and contract carriers. The majority of these fleets (58%) operate six or fewer trucks. These companies operate a total of 1.7 million combination units, 4.4 million single-unit medium and heavy trucks and 3.8 million trailers. The road system in the United States increased by roughly 2% from 1980 to 1989 (ILO 1992).

The rail systems in the United States have declined, due primarily to the loss of Class 1 status of some rail lines, and due to the abandonment of less profitable lines. Canada has increased its rail system by some 40%, due mainly to a change in the classification system. The road system in Canada has decreased by 9% (ILO 1992).

In the industrialized nations of the Pacific Rim, there is great variability of the rail and road systems, due mainly to the different levels of industrialization of the respective countries. For example, rail and road networks in the Republic of Korea are similar to those in Europe, whereas in Malaysia, the rail and road networks are significantly smaller, but experiencing tremendous growth rates (over 53% for roads since 1980) (ILO 1992).

In Japan, the transport sector is heavily dominated by road transport, which accounts for 90.5% of the total Japanese freight transport tonnage. Approximately 8.2% of the tonnage is transported by water and 1.2% by rail (Magnier 1996).

Developing countries in Asia, Africa and Latin America typically suffer from inadequate transport systems. There is significant work underway to improve the systems, but a lack of hard currency, skilled workers and equipment inhibits the growth. Transport systems have grown significantly in Venezuela, Mexico and Brazil.

The Middle East in general has experienced growth in the transport sector, with countries such as Kuwait and Iran leading the way. It should be noted that due to the large size of the countries, sparse populations and arid climatic conditions, unique problems are encountered that limit the development of transport systems in this region.

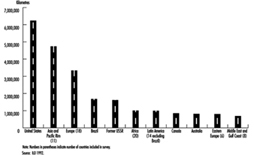

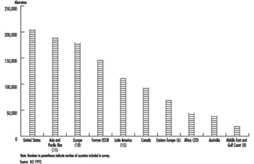

An overview of railroad and road systems for selected countries and world regions is shown in figure 1 and figure 2.

Figure 1. World road network distribution 1988-89, kilometers.

Figure 2. World railroad network distribution, 1988-89, in kilometers.

Workforce Characteristics

The transportation sector contributes significantly to employment in most countries in both the private and public sectors. However, as per capita income increases, the impact of the sector on total employment decreases. The overall number of workers in the transport industries has declined steadily since the 1980s. This loss of workforce in the sector is due to several factors, especially technological advances that have automated many of the jobs related to the construction, maintenance and operation of transport systems. In addition, many countries have passed legislation which deregulated many transport-related industries; this has ultimately resulted in the loss of jobs.

Workers who are currently employed in transport-related industries must be highly skilled and competent. Due to the rapid advances in technology experienced in the transport sector, these workers and prospective workers must receive continual training and retraining.

Challenges to Workers' Health and Safety in the Transportation and Warehousing Industry

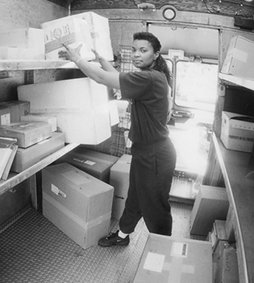

The transportation and warehousing industry is fraught with challenges to worker health and safety. Those involved in loading and unloading of cargo and in storing, stacking and retrieving materials are prone to musculoskeletal injuries, slips and falls due to uncertain, irregular or slippery work surfaces and being struck by falling objects. See figure 1. Those operating and maintaining vehicles and other machinery are not only vulnerable to such injuries but also to the toxic effects of fuels, lubricants and exhaust fumes. If ergonomic principles are not heeded in the design of seats, pedals and instrument panels, drivers of trains, planes and motor vehicles (those used in warehousing as well on roads) will not only be subject to musculoskeletal disorders and undue fatigue, but will also be prone to operating mishaps that can lead to accidents.

Figure 1. Lifting parcels above shoulder height is an ergonomic hazard.

Teamster Union

All workers—and the general public as well—may be exposed to toxic substances in the event of leaks, spills and fires. Since much of the work is done out-of-doors, transportation and warehousing workers are also subject to extremes of weather such as heat, cold, rain, snow and ice, which can not only make the work more arduous but also more dangerous. Aviation crews must adjust to changes in barometric pressure. Noise is a perennial problem for those operating or working near noisy vehicles and machinery.

Stress

Perhaps the most pervasive hazard in this industry is work stress. It has many sources:

Adjusting to work hours. Many workers in this industry are burdened by the necessity of adjusting to changing shifts, while flight crews who travel long east-west or west-east distances must adjust to changes in circadian body rhythms; both of these factors may cause drowsiness and fatigue. The danger of functional impairment due to fatigue has led to laws and regulations stipulating the number of hours or shifts that may be worked without a rest period. These are generally applicable to aviation flight crews, railroad train crews and, in most countries, drivers of road buses and trucks. Many of the last group are independent contractors or work for small enterprises and are frequently forced by economic pressures to flout these regulations. There are always emergencies dictated by problems with traffic, weather or accidents which require exceeding the work hours limits. Led by the airlines, large transportation companies are now using computers to track employees’ work schedules to verify their compliance with the regulations and to minimize the amount of down time for both workers and equipment.

Timetables. Most passenger and a good part of freight transport is guided by timetables stipulating departure and arrival times. The necessity of keeping to schedules which often allow too little leeway is often a very potent stressor for the drivers and their crews.

Dealing with the public. Meeting the sometimes unreasonable and often forcefully expressed demands of the public can be a significant source of stress for those dealing with passengers at terminals and ticket offices and en route. Drivers of road transport must contend with other vehicles, traffic regulations and diligent highway traffic officers.

Accidents. Accidents, whether due to equipment failure, human error or environmental conditions, place the transportation industry at or near the top of listings of occupational fatalities in most countries. Even when a particular worker’s injuries may not be serious, post-traumatic stress disorder (PTSD) can lead to profound and prolonged disability, and in some instances it can prompt changing to another job.

Isolation. Many employees in the transportation industry work alone with little or no human contact (e.g., truck drivers, workers in control rooms and in railroad switch and signal towers). If problems arise, there may be difficulty and delays in getting help. And, if they are not kept busy, boredom may lead to a drop in attentiveness that can presage accidents. Working alone, especially for those driving taxis, limousines and delivery trucks, is an important risk factor for felonious assaults and other forms of violence.

Being away from home. Transportation workers are frequently required to be away from home for periods of days or weeks (in the maritime industry, for months). In addition to the stress of living out of a suitcase, strange food and strange sleeping accommodations, there is the reciprocal stress of separation from family and friends.

Health problems

Most industrialized countries require transportation workers, especially drivers and operating crew members, to take periodic medical examinations to verify that their physical and mental capacities meet the requirements established by regulations. Visual and hearing acuity, colour vision, muscular strength and flexibility and freedom from causes of syncope are some of the factors tested for. Accommodations, however, make it possible for many individuals with chronic disorders or disabilities to work without danger to themselves or others. (In the United States, for example, employers are mandated by the federal Americans With Disabilities Act to provide such accommodations.)

Drugs and alcohol

Prescription and over-the-counter medications taken for a variety of disorders (e.g., hypertension, anxiety and other hyperkinetic conditions, allergies, diabetes, epilepsy, headaches and the common cold) may cause drowsiness and affect alertness, reaction time and coordination, especially when alcoholic beverages are also consumed. Abuse of alcohol and/or illegal drugs is found frequently enough among transportation workers to have led to voluntary or legislatively mandated drug testing programmes.

Summary

The health and safety of workers in the transportation and warehousing industry are critical considerations, not only for the workers themselves but also for the public being transported or involved as bystanders. Safeguarding health and safety, therefore, is the joint responsibility of the employers, the employees and their unions and governments on all levels.

Case Study: US NIOSH Studies of Injuries among Grocery Order Selectors