Children categories

94. Education and Training Services (7)

94. Education and Training Services

Chapter Editor: Michael McCann

Table of Contents

Tables and Figures

Tables

Click a link below to view table in article context.

1. Diseases affecting day-care workers & teachers

2. Hazards & precautions for particular classes

3. Summary of hazards in colleges & universities

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

95. Emergency and Security Services (9)

95. Emergency and Security Services

Chapter Editor: Tee L. Guidotti

Table of Contents

Tables and Figures

Tables

Click a link below to view table in article context.

1. Recommendations & criteria for compensation

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

96. Entertainment and the Arts (31)

96. Entertainment and the Arts

Chapter Editor: Michael McCann

Table of Contents

Tables and Figures

Arts and Crafts

Performing and Media Arts

Entertainment

Tables

Click a link below to view table in article context.

1. Precautions associated with hazards

2. Hazards of art techniques

3. Hazards of common stones

4. Main risks associated with sculpture material

5. Description of fibre & textile crafts

6. Description of fibre & textile processes

7. Ingredients of ceramic bodies & glazes

8. Hazards & precautions of collection management

9. Hazards of collection objects

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

97. Health Care Facilities and Services (25)

97. Health Care Facilities and Services

Chapter Editor: Annelee Yassi

Table of Contents

Tables and Figures

Health Care: Its Nature and Its Occupational Health Problems

Annalee Yassi and Leon J. Warshaw

Social Services

Susan Nobel

Home Care Workers: The New York City Experience

Lenora Colbert

Occupational Health and Safety Practice: The Russian Experience

Valery P. Kaptsov and Lyudmila P. Korotich

Ergonomics and Health Care

Hospital Ergonomics: A Review

Madeleine R. Estryn-Béhar

Strain in Health Care Work

Madeleine R. Estryn-Béhar

Case Study: Human Error and Critical Tasks: Approaches for Improved System Performance

Work Schedules and Night Work in Health Care

Madeleine R. Estryn-Béhar

The Physical Environment and Health Care

Exposure to Physical Agents

Robert M. Lewy

Ergonomics of the Physical Work Environment

Madeleine R. Estryn-Béhar

Prevention and Management of Back Pain in Nurses

Ulrich Stössel

Case Study: Treatment of Back Pain

Leon J. Warshaw

Health Care Workers and Infectious Disease

Overview of Infectious Diseases

Friedrich Hofmann

Prevention of Occupational Transmission of Bloodborne Pathogens

Linda S. Martin, Robert J. Mullan and David M. Bell

Tuberculosis Prevention, Control and Surveillance

Robert J. Mullan

Chemicals in the Health Care Environment

Overview of Chemical Hazards in Health Care

Jeanne Mager Stellman

Managing Chemical Hazards in Hospitals

Annalee Yassi

Waste Anaesthetic Gases

Xavier Guardino Solá

Health Care Workers and Latex Allergy

Leon J. Warshaw

The Hospital Environment

Buildings for Health Care Facilities

Cesare Catananti, Gianfranco Damiani and Giovanni Capelli

Hospitals: Environmental and Public Health Issues

M.P. Arias

Hospital Waste Management

M.P. Arias

Managing Hazardous Waste Disposal Under ISO 14000

Jerry Spiegel and John Reimer

Tables

Click a link below to view table in article context.

1. Examples of health care functions

2. 1995 integrated sound levels

3. Ergonomic noise reduction options

4. Total number of injuries (one hospital)

5. Distribution of nurses’ time

6. Number of separate nursing tasks

7. Distribution of nurses' time

8. Cognitive & affective strain & burn-out

9. Prevalence of work complaints by shift

10. Congenital abnormalities following rubella

11. Indications for vaccinations

12. Post-exposure prophylaxis

13. US Public Health Service recommendations

14. Chemicals’ categories used in health care

15. Chemicals cited HSDB

16. Properties of inhaled anaesthetics

17. Choice of materials: criteria & variables

18. Ventilation requirements

19. Infectious diseases & Group III wastes

20. HSC EMS documentation hierarchy

21. Role & responsibilities

22. Process inputs

23. List of activities

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

98. Hotels and Restaurants (4)

98. Hotels and Restaurants

Chapter Editor: Pam Tau Lee

Table of Contents

99. Office and Retail Trades (7)

99. Office and Retail Trades

Chapter Editor: Jonathan Rosen

Table of Contents

Tables and Figures

The Nature of Office and Clerical Work

Charles Levenstein, Beth Rosenberg and Ninica Howard

Professionals and Managers

Nona McQuay

Offices: A Hazard Summary

Wendy Hord

Bank Teller Safety: The Situation in Germany

Manfred Fischer

Telework

Jamie Tessler

The Retail Industry

Adrienne Markowitz

Case Study: Outdoor Markets

John G. Rodwan, Jr.

Tables

Click a link below to view table in article context.

1. Standard professional jobs

2. Standard clerical jobs

3. Indoor air pollutants in office buildings

4. Labour statistics in the retail industry

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

100. Personal and Community Services (6)

100. Personal and Community Services

Chapter Editor: Angela Babin

Table of Contents

Tables and Figures

Indoor Cleaning Services

Karen Messing

Barbering and Cosmetology

Laura Stock and James Cone

Laundries, Garment and Dry Cleaning

Gary S. Earnest, Lynda M. Ewers and Avima M. Ruder

Funeral Services

Mary O. Brophy and Jonathan T. Haney

Domestic Workers

Angela Babin

Case Study: Environmental Issues

Michael McCann

Click a link below to view table in article context.

1. Postures observed during dusting in a hospital

2. Dangerous chemicals used in cleaning

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

101. Public and Government Services (12)

101. Public and Government Services

Chapter Editor: David LeGrande

Table of Contents

Tables and Figurs

Occupational Health and Safety Hazards in Public and Governmental Services

David LeGrande

Case Report: Violence and Urban Park Rangers in Ireland

Daniel Murphy

Inspection Services

Jonathan Rosen

Postal Services

Roxanne Cabral

Telecommunications

David LeGrande

Hazards in Sewage (Waste) Treatment Plants

Mary O. Brophy

Domestic Waste Collection

Madeleine Bourdouxhe

Street Cleaning

J.C. Gunther, Jr.

Sewage Treatment

M. Agamennone

Municipal Recycling Industry

David E. Malter

Waste Disposal Operations

James W. Platner

The Generation and Transport of Hazardous Wastes: Social and Ethical Issues

Colin L. Soskolne

Tables

Click a link below to view table in article context.

1. Hazards of inspection services

2. Hazardous objects found in domestic waste

3. Accidents in domestic waste collection (Canada)

4. Injuries in the recycling industry

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

102. Transport Industry and Warehousing (18)

102. Transport Industry and Warehousing

Chapter Editor: LaMont Byrd

Table of Contents

Tables and Figures

General Profile

LaMont Byrd

Case Study: Challenges to Workers’ Health and Safety in the Transportation and Warehousing Industry

Leon J. Warshaw

Air Transport

Airport and Flight Control Operations

Christine Proctor, Edward A. Olmsted and E. Evrard

Case Studies of Air Traffic Controllers in the United States and Italy

Paul A. Landsbergis

Aircraft Maintenance Operations

Buck Cameron

Aircraft Flight Operations

Nancy Garcia and H. Gartmann

Aerospace Medicine: Effects of Gravity, Acceleration and Microgravity in the Aerospace Environment

Relford Patterson and Russell B. Rayman

Helicopters

David L. Huntzinger

Road Transport

Truck and Bus Driving

Bruce A. Millies

Ergonomics of Bus Driving

Alfons Grösbrink and Andreas Mahr

Motor Vehicle Fuelling and Servicing Operations

Richard S. Kraus

Case Study: Violence in Gasoline Stations

Leon J. Warshaw

Rail Transport

Rail Operations

Neil McManus

Case Study: Subways

George J. McDonald

Water Transport

Water Transportation and the Maritime Industries

Timothy J. Ungs and Michael Adess

Storage

Storage and Transportation of Crude Oil, Natural Gas, Liquid Petroleum Products and Other Chemicals

Richard S. Kraus

Warehousing

John Lund

Case Study: US NIOSH Studies of Injuries among Grocery Order Selectors

Tables

Click a link below to view table in article context.

1. Bus driver seat measurements

2. Illumination levels for service stations

3. Hazardous conditions & administration

4. Hazardous conditions & maintenance

5. Hazardous conditions & right of way

6. Hazard control in the Railway industry

7. Merchant vessel types

8. Health hazards common across vessel types

9. Notable hazards for specific vessel types

10. Vessel hazard control & risk-reduction

11. Typical approximate combustion properties

12. Comparison of compressed & liquified gas

13. Hazards involving order selectors

14. Job safety analysis: Fork-lift operator

15. Job safety analysis: Order selector

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

Indoor Cleaning Services

General Profile

Cleaning consists of dusting, washing and polishing surfaces; washing walls; mopping, sweeping and polishing floors; as well as disposing of waste and waste water. It is done in offices, public and commercial buildings, homes and factories. It may be done in confined spaces with little ventilation and in spaces not designed with cleaning in mind. Cleaners may be independent or be employed by the enterprise which owns the facilities being cleaned, or they may work for private contractors. Those who clean may be called cleaners, housekeepers, chars, custodians or janitors, depending on the spaces cleaned and the details of the assigned tasks. For example, janitors and custodians may combine cleaning with maintenance and repair work.

Cleaners have usually worked relatively autonomously, compared to other employment categories of similar prestige. Inspection is done by supervisors, although the users of the cleaned spaces also comment on the cleaners’ work. Workers tend to order the tasks themselves and develop their own procedures (Messing, Haëntjens and Doniol-Shaw 1993). However, in commercial spaces in North America, cleaners’ routes have increasingly been determined using software programmed to take account of furniture, floor surfaces and crowding. The desired frequency of operations, area to be cleaned and time estimated for the type of area are used to calculate the total time required. Inspection may be done using a computer-programmed spot check procedure. Some of these procedures may severely underestimate the task as performed in shared space, especially if the inventory is not brought regularly up to date (Messing, Chatigny and Courville 1996).

In Canada, cleaning is the eighth most common profession of men and the tenth most common profession of women; women make up 46% of the profession (Armstrong and Armstrong 1994). In France in 1991, 229,000 cleaners worked for 9,000 cleaning companies; about a third were immigrants and 64% were women (Bretin 1994). In Denmark 85% of the 130,000 cleaners are women (Nielsen 1995). In some countries, tasks in factories and services have often been divided into “light” and “heavy”, assigned formally or informally to female and male workers respectively, who may be paid at different rates (Government of Quebec 1994). Women may dust and polish surfaces, clean bathrooms and empty wastebaskets while men sweep, mop and polish floors and carry waste to incinerators (Messing, Haëntjens and Doniol-Shaw 1993; Messing, Doniol-Shaw and Haëntjens 1993; Messing, Chatigny and Courville 1996). In other countries, men and women can be assigned to all cleaning tasks (Nielsen 1995; Hagner and Hagberg 1989). Cleaners are often relatively old compared to other workers (Bretin et al. 1992; Messing 1991; Nielsen 1995).

Risk Factors and Prevention Strategies

Cleaning may be done with hand-held tools such as brushes, brooms, rags and mops, or may be aided by machines. A variety of chemicals are used to dissolve dirt and to make surfaces appear clean and shiny. The difficulty of the task varies according to the type of surface (rough, smooth, pitted), the height and geometry of the objects cleaned, the degree of crowding of spaces and the vocations exercised in the spaces cleaned. In some places, the need for cleaning may be reduced or eliminated by design changes in the object cleaned (such as self-flushing toilets).

Musculoskeletal load

Cleaning, particularly cleaning furniture and bathrooms and emptying wastebaskets, involves rapid postural changes and many awkward and constrained postures (see table 1). Many objects must be cleaned, at a variety of heights; a typical sequence observed for dusting in a hospital room was: table (81 cm), television (196 cm), table (81 cm), telephone (81 cm), lamp (extends to 188 cm), table foot (11 cm), chair (46 cm), screen (81 cm), armchair (46 cm), window ledge (89 cm), wall sphygmomanometer (154 cm), chair legs (floor to 46 cm), oxygen fixture (137 cm) (Messing, Chatigny and Courville 1995).

Table 1. Postures observed during dusting in a hospital.

|

Activity |

Duration |

Extension (%) |

Neutral (%) |

Bending <45º (%) |

Bending ≥45º (%) |

Not observable |

|

Clean nurse station |

3 m, 26 s |

— |

13.6 |

86.4 |

— |

— |

|

Waste-basket (3) |

1 m, 26 s |

— |

19.8 |

71.1 |

9.2 |

— |

|

Bath (2) |

5 m, 17 s |

2.8 |

26.6 |

63.1 |

7.5 |

— |

|

Bathroom corridor (2) |

3 m, 53 s |

6.6 |

18.6 |

71.0 |

3.8 |

0.3 |

|

Clean rooms |

8 m, 45 s |

3.7 |

29.8 |

60.1 |

2.9 |

3.5 |

|

Reception area |

3 m, 13 s |

— |

24.7 |

74.4 |

— |

0.9 |

|

Secretaries’ office |

10 m, 20 s |

3.6 |

32.0 |

59.7 |

0.3 |

4.4 |

|

Overall |

36 m, 20 s |

3.0 |

26.4 |

65.8 |

2.7 |

2.2 |

Source: Messing, Chatigny and Courville 1995.

Floor cleaning requires repeated movements (fundamental cycle time of 1 to 2 seconds in the Sogaard, Fallentin and Nielsen (1996) study) and a sustained moderate bending of the back. Constant pressure is exerted by the hands to push vacuum cleaners or buffers, tasks requiring forces near 10 kg (Messing, Chatigny and Courville 1996). Sogaard, Fallentin and Nielsen (1996) found mean back bending during floor mopping to be 28º and mean neck bending to be 51º. Hagner and Hagberg (1989) also noted static muscular loads especially at the shoulder joint. Nordin et al. (1986) found extensive forward trunk bending in a simulated janitorial task involving floor mopping. Cleaning floors and objects is usually done with repeated movements. Sogaard (1994) suggests that the sustained repetitive motions with infrequent pauses in activity may exhaust the relatively small numbers of muscle fibres involved and result in muscular disorders.

In order to clean, many objects must be moved. During 66 minutes cleaning and polishing floors, 0.7 objects had to be moved per minute, with weights up to 10 kg; during 23 minutes of dusting, 3.7 objects were moved per minute, with weights up to 2 kg (Messing, Chatigny and Courville 1995).

Winkel et al. (1983) and Hagner and Hagberg (1989) note that increasing specialization and standardization have reduced the number of opportunities to vary body movements and postures during cleaning work. It is therefore important to provide adequate break time. Formal or informal division of tasks according to sex may increase the likelihood of musculoskeletal problems by decreasing the variation in movements (Messing, Haëntjens and Doniol-Shaw 1993).

Cardiovascular load

The cardiovascular load can be quite heavy. Johansson and Ljunggren (1989) recorded the heart rate of female cleaners during office or toilet cleaning at 123 beats/minute, 65% of the maximum for their average age of 29.8 years (corresponding to about 35% of their estimated maximal oxygen uptake or VO2 max, close to that of construction workers). Swabbing or mopping resulted in similar heart rates of 122 to 127 beats/minute. Hagner and Hagberg (1989) found a high level of oxygen consumption (up to 40% of the VO2 max) among cleaners doing floor mopping under experimental conditions. Sogaard (1994) found that relative cardiovascular strain of female school cleaners measured in the workplace was 53% of the VO2 max.

To prevent musculoskeletal problems and decrease the cardiovascular load, workload should be appropriate and sufficient rest time should be allowed. Attention should be paid to ease of cleaning when spaces and procedures are being designed and when furnishings are purchased. Vacuuming requires less force if carpets are carefully laid so as not to wrinkle when the vacuum cleaner is passed. The use of adequate tools is important. For example, extendable brushes for dusting can reduce the necessity to reach or climb. Prolonged bending can be minimized if efficient chemicals and tools make it possible to clean quickly, and if cleaning is frequent enough so that dirt does not become hardened.

The common practice of reducing the rate of ventilation in buildings during the evening or night hours, when cleaning is done, reduces air quality for cleaning workers who work during these times and should be avoided. To prevent overwork in the case where cleaning is planned using purchased software, careful observation and verification should be done in order to make sure that times allotted are realistic and take into account multiple use of spaces cleaned. Inventories of rooms and objects cleaned should be updated frequently.

Procedures and apparatus for emptying wastebaskets into bins, and bins into incinerators, have been developed so that manual lifting can be avoided.

Chemicals

Chemicals can be classed as soaps, detergents, disinfectants, porcelain cleaners, scouring powders, wax removers and strippers, solvents, pesticides and drain cleaners. They may contain other ingredients such as fragrances and colouring agents. There may be surface skin contact or they may be inhaled or absorbed through the skin into the system. Damage to the skin, eyes, throat or lungs can result. The risk of exposure depends on the concentration of the chemical and how it is used. Sprays volatilize chemicals and increase exposure. Some chemicals are irritants at low concentration and corrosive at high concentration (acids, oxidizing agents or bases). Others are effective solvents or detergents which may damage the skin barrier and make it more vulnerable to other chemical agents. Still others contain metals (nickel, cobalt, chrome) or other substances which can act as allergens.

Cleaning agents are often sold at high concentrations and diluted on site for use. The common practice of using chemicals at a higher concentration than recommended, in the hope of cleaning more quickly or more efficiently, is a source of overexposure and should be remedied by proper education and by adjusting the workload. Mixing different chemicals can cause accidental intoxication or burns. Work with strong chemicals in poorly ventilated spaces can be a hazard for cleaners and should be avoided.

The Danish Product Register Data Base PROBAS contains information on 2,567 washing and cleaning agents. Of these, 70 are considered to be potentially harmful agents causing chronic or acute health damage, such as corrosives, carcinogens, reproductive toxicants, allergens and neurotoxic agents (Borglum and Hansen 1994). These agents are presented in table 2. A study of the PROBAS register found 33 contact allergens in cleaning agents (Flyvholm 1993).

Table 2. Dangerous chemicals used in cleaning.†

|

Chemical |

Health damage codes |

Other hazards |

|

Solvents |

||

|

Butylglycol |

N* |

|

|

Isopropyl benzene |

N |

|

|

Naphtha, white spirit, Stoddard solvent |

N,R |

|

|

Toluene |

N,R |

Flammable |

|

Ethanol |

R |

Flammable |

|

2-Ethoxyethanol |

N,R |

|

|

2-Methoxyethanol |

R |

|

|

1-Methyl-2-pyrrolido |

R |

|

|

Base oil, crude oil |

N |

|

|

Tetrachloroethylene |

N,R |

|

|

1,1,1-Trichloroethane |

N |

|

|

Xylene |

N,R* |

Flammable |

|

Butyldiglycol |

I |

|

|

Acids and bases |

||

|

Acetic acid |

C |

|

|

Ammonium hydroxide |

I |

Reacts with chlorine bleaches to liberate toxic gas |

|

Potassium hydroxide |

C |

|

|

Sodium carbonate |

I |

|

|

Sodium hydroxide |

C |

|

|

Phosphoric acid |

C |

|

|

Sulphuric acid |

C |

|

|

Residual monomers and impurities |

||

|

Formaldehyde |

A,K* |

|

|

Phenol |

N* |

|

|

Benzene |

K,R,N |

|

|

Acrylonitrile |

A,K |

|

|

Butylacrylate |

A |

|

|

Methylmethacrylate |

A,R |

|

|

Styrene |

R |

Flammable |

|

1-Propanol |

N |

Flammable |

|

Ethyl acrylate |

A,K* |

|

|

1,2-Ethylene diamine |

A |

|

|

Ethylene oxide |

A,K,R |

Flammable |

|

Propylene oxide |

K |

Flammable |

|

2-Methylaniline |

K |

|

|

2-Propyn-1-ol |

N |

|

|

Chelators |

||

|

Sodium EDTA (ethylene diamine tetraacetic acid) |

R |

|

|

Sodium NTA (nitrilotriacetic acid) |

K |

|

|

Anti-rusts |

||

|

2-Aminoethanol |

N |

|

|

Triethanolamine |

A |

|

|

Hexamethylene tetramine |

A |

|

|

2-Butyn-1,4-diol |

C,T |

|

|

Disodium metasilicate |

C,I |

|

|

2-(3H)-Benzothiazolethione |

A |

|

|

Disinfectants |

||

|

Borax |

R |

|

|

Disodium tetraborate |

R |

|

|

Morpholine |

N |

|

|

Benzalkonium chloride |

C |

|

|

Sodium dichloroisocyanurate |

I |

Reacts with acid to liberate toxic gas |

|

Sodium hypochlorite |

C |

Reacts with acid or ammonia to release toxic gases |

|

Preserving agents |

||

|

1,2-Bensisothiazol-3(2H)-one |

A |

|

|

5-Chlor-2-methyl-3-isothiazolone |

A |

|

|

2-Methyl-3-isothiazolone |

A |

|

|

2-Chloracetamide |

A |

|

|

p-Chlor-m-cresol |

A |

|

|

Hexahydro-1,3,5-tris- (2-hydroxyethyl)1,3,5-triazine |

A |

|

|

1,5-Pentadiol |

A |

|

|

2-Bromo-2-nitro-1,3-propanediol |

T |

|

|

Fillers |

||

|

Quartz |

K |

|

|

Silicon dioxide |

K |

|

|

Sodium hydrogen sulphate |

C |

|

|

Others |

||

|

Subtilisin (Enzyme) |

A |

|

|

Sodium saccharine |

K |

|

|

Ammonium peroxodisulphate (bleaching agent) |

A |

|

A = allergen; C = corrosive; I = irritant; K = carcinogen; N = neurotoxic agent; R = reproductive toxic agent; T = toxic if swallowed; * = danger dependent on concentration.

Determination of toxicity was done by the Danish Institute of Occupational Health. †Note that not all cleaning agents have been tested for all toxic properties, so that this list is not necessarily complete or comprehensive. Source: Summarized from Borglum and Hansen 1994. Cleaners who work in factories or hospitals may be exposed to chemicals (or biohazards) associated with the ongoing activities in the spaces they clean. If cleaners are not integrated into the training programmes and social network of the regular workforce, they may be less aware of these hazards than other workers. For example, one study showed that cleaners were the group most often exposed to harmful chemicals of all categories of hospital workers (Weaver et al. 1993). There is some controversy about the use of gloves for cleaning work. Gloves play an important role in protecting the skin from hazardous agents if they fit correctly and are made of impermeable and resistant materials. But wearing gloves constantly can keep perspiration from evaporating. The resulting damp area is a favourable growth medium for infectious agents. Wearing gloves was associated with skin problems in a large sample of Danish cleaners (Nielsen 1996). It is therefore best to wear gloves the minimum time compatible with protection. The necessity for wearing gloves can often be obviated by using tools with long handles, or by other changes in methods. Wearing cotton gloves under rubber or plastic gloves may reduce humidity and protect against allergies to some glove materials (Foussereau et al. 1982). Some hand creams may contain irritants and should be avoided (Hansen 1983). Several other practices diminish exposure to chemicals. When cleaning solutions are stored or prepared, there should be good ventilation, and procedures should permit preparation without any danger of touching or breathing the chemicals. The temptation to work with undiluted chemicals will diminish if workers have adequate time and implements. Also, cleaners may use undiluted chemicals or chemicals that have allergenic fragrances in order to signal to others that they have done their job. This can be done by other means, such as clear inspection procedures and communication links with other workers and with clients of cleaning services. Useful information on prevention of exposure to chemicals can be found in a handbook published by the City of New York (Michaels, undated). Other health risks Cleaners often work evening or night shifts, so as not to interfere with the other activities being carried out in the same spaces. They may therefore suffer the usual effects of shift work on biorhythms. In addition, they may risk violence if they work alone in isolated areas. Cleaners, particularly those who work outside regular building hours and/or who are not part of the regular personnel, may be ignored and excluded from the social network in their workplaces (Messing in press). They may not be given access to the appropriate facilities for breaks and meals. Aside from the psychological effects of exclusion, cleaners may be deprived of information on hazards routinely given to other workers, despite legal requirements in many jurisdictions to provide this information. Also, despite the importance of surface textures and design for their work, they and their supervisors may not be consulted when relevant purchasing and planning decisions are made. This is especially true if cleaning is contracted out. It is therefore important that a special effort be made to include cleaners in occupational health and safety promotion activities in the workplace. Information on characteristics of chemicals, on work procedures and on safety should be discussed with cleaners and clearly posted in the workplace. Health Effects and Disease Patterns Cleaners as a profession have poorer health than others (Nielsen 1995; ASSTSAS 1993; Sogaard 1994). Comparing cleaners with other workers, an analysis of the Quebec Health Survey found, after controlling for age, that women cleaners had the highest prevalence of chronic back problems and cardiopathies of all categories of women workers and that male cleaners had the highest prevalence of musculoskeletal problems and cardiopathies (Gervais 1993). Pregnant cleaners have an increased likelihood of miscarriage (McDonald et al. 1986), giving birth prematurely (McDonald et al. 1988) or bearing children with low birth weight (McDonald et al. 1987). Some large population-based epidemiological studies have found high cancer rates among cleaners. Rates of some brain tumours among US White men have been found to be especially high for cleaning service workers (Demers, Vaughan and Schommer 1991). Among women, invasive cervical cancer is almost five times more common among cleaners than other women (Savitz, Andrews and Brinton 1995). These results are attributed to chemical exposures, particularly solvents. Musculoskeletal problems are often encountered. In Denmark, Nielsen (1995) found that those who left cleaning had a reduced frequency of musculoskeletal symptoms compared to those who stayed in the profession. Cleaning was one of the five trades reporting the most shoulder/neck pain, tendovaginitis and low back pain (Sogaard, Fallentin and Nielsen 1996). A population-based epidemiological study found female cleaners to be particularly likely to have osteoarthritis of the knee, compared to other Swedish workers (Vingard et al. 1991). Cleaners in Quebec hospitals suffer almost twice as many occupational accidents and illnesses as the average Quebec health care worker: 23.8 compared to 13.9 per 100 full-time equivalent workers per year (ASSTSAS 1993). Most lesions involved the trunk or upper limbs (ASSTSAS 1993). Comparing male with female cleaners, a survey of cleaners in the Paris region in France found that men had more back pain and women had more joint pain (Opatowski et al. 1995). These differences are probably attributable to specificities in the tasks assigned to women and men cleaners (Messing, Haëntjens and Doniol-Shaw 1993; Messing, Doniol-Shaw and Haëntjens 1993; Messing, Chatigny and Courville 1996). Cleaners have a high level of skin problems, including dermatitis and eczema (Gawkrodger, Lloyd and Hunter 1986; Singgih et al. 1986). Point prevalences of skin diseases of 15 to 18%and a duration of employment prevalence of 39%have been found among large samples of hospital cleaners (Hansen 1983; Delaporte et al. 1990). Cleaners who spend more time with wet hands have more skin problems (Nielsen 1996). Cleaners may also be injured or infected by broken glass, needles or other sharp objects while handling waste (ASSTSAS 1993). Recently, occupational health specialists have noted symptoms of stress related to work among hospital cleaners, for which they suggest re-examination of the work process (Toivanen, Helin and Hänninen 1993). Low prestige of the profession may be a cause of distress for cleaners (Messing, in press). Accidents, infection and environmental contamination may be prevented by clear and well-publicized guidelines for disposal of dangerous waste in factories, hospitals, offices and public buildings. Since constraints placed on other workers may prevent them from paying full attention to prevention of hazards for cleaners, consultations between cleaners and other workers should be arranged, in order to decide on the appropriate size and placement of wastebaskets, waste separation and labelling. Cleaners should be included whenever waste disposal practices are being planned or reviewed so that realistic methods can be proposed.

Barbering and Cosmetology

General Profile

It has been estimated that over a million people work in approximately 150,000 salons and barber shops in the United States. These men and women, barbers and cosmetologists (also referred to as “technicians”), perform a wide range of services, including shaving; cutting and styling hair; giving manicures and pedicures; applying artificial nails; and performing a variety of chemical hair processes including bleaching, colouring, hair relaxing and permanent waving. In addition, some technicians provide facial treatments and removal of body hair.

Technicians may be exposed to a variety of potential health and safety hazards on the job, including:

Chemicals. According to an analysis conducted by the US National Institute for Occupational Safety and Health (NIOSH), 30% of the nearly 3,000 chemicals used in cosmetology are classified by the US government as toxic substances. Ventilation in many shops is often inadequate to eliminate chemical exposure.

Diseases. Because of their close contact with clients, technicians may be exposed to a variety of infectious diseases, ranging from colds and flu to impetigo, chicken pox and hepatitis.

Ergonomic hazards. Barbers and cosmetologists also suffer from a range of musculoskeletal disorders associated with repetitive motion, prolonged standing, cramped work spaces and poorly designed tools and equipment.

Scheduling. Working hours may be irregular and extended. Many technicians work in “split shifts”, splitting their work day to cover 12 to 14 hours of client services.

Other problems. These include poor housekeeping and electrical and fire hazards.

As a result of exposure to these and other hazards, an increasing number of people are being forced to leave their chosen profession. A recent study by Nellie Brown, director of the Chemical Hazards Information Program at Cornell University, found that 20% of US hair stylists leave their jobs because of work-related illness (New York Times Magazine, 7 March 1993).

Despite increasing evidence of risk, there are few regulations protecting barbers and cosmetologists. In the United States, cosmetic products are regulated by the Food and Drug Administration (FDA), which is oriented towards consumer protection and has a limited ability to address worker health and safety issues. Like regulatory agencies in many countries, the FDA does not require product manufacturers to conduct safety tests before public marketing, to list ingredients on the labels of products sold for professional use only or to give the FDA information on consumer complaints. Nor does the FDA routinely test products on its own initiative; any testing done by the FDA focuses on risks to consumers, not workers, although workers may be at greater risk due to their daily and prolonged use of cosmetic chemicals.

Attempts to regulate this industry are further complicated by the differing local, national and international definitions of the tasks barbers and cosmetologists perform. In the United States, licensing requirements vary from state to state. Many countries have no licensing requirements at all.

Major Processes and Hazards

Chemical hazards

Barbers and cosmetologists are exposed to a wide variety of chemicals during the course of a working day. Technicians are at risk for absorbing chemicals through the skin or eyes, inhaling dangerous vapours or particulates and ingesting toxins that have contaminated food, drink or cigarettes. Some guidelines for reducing hazardous exposure are given in figure 1 .

Figure 1. Reducing exposure to chemical hazards.

Chemicals can affect the body in different ways depending on the concentration of the chemical in a product; how toxic the chemical is; the route by which it enters the body (inhalation, skin contact, ingestion); and the length of time of the exposure. Individual characteristics, such as general health status, pregnancy and smoking, can also affect a person’s risk.

There are thousands of different chemicals associated with cosmetology processes. In order to determine the specific chemicals contained in a product and their effects, it is important that technicians have access to, and understand, product labels and material safety data sheets (MSDSs).

Common chemical processes

Colouring hair. Hair colouring solutions are applied manually to the hair with an applicator bottle or brush. It also is becoming very common for clients to request an eyebrow or eyelash tints.

Chemicals used in hair colouring include synthetic organic colorants, complex metallic colorants and vegetable dyes. Synthetic hair colorants often include permanent oxidative dyes which use hydrogen peroxide to oxidize aromatic diamines. These chemicals are eye, nose and throat irritants. Synthetic organic hair dyes containing an amine group are also among the most frequent causes of allergic sensitization. Metallic dyes may include lead-containing compounds.

Coal tar-based hair dyes may contain mutagens. Hair dyes which have been found to be mutagenic in in vitro testing pose uncertain human health risks. However, the production of non-mutagenic hair dyes appears to be possible and should be encouraged. For example, henna, a vegetable dye, is one of the oldest hair dyes and is not known to be either a mutagen or a carcinogen.

Bleaching hair. Bleaching solutions are applied manually with an applicator bottle or brush. These solutions may contain hydrogen peroxide, sodium peroxide, ammonium hydroxide, ammonium persulphate or potassium persulphate. These chemicals can cause skin, eye, nose, throat or lung irritation. Persulphate bleach powders have also been associated with asthma among cosmetologists (Blainey et al. 1986).

Permanent waving. Permanent waves usually involve several steps: washing the hair; rolling the hair in curlers; applying a thioglycolate or similar solution; and rinsing and neutralizing with an oxidizing agent. Water sprays may also be used.

Permanent-wave solutions may contain alcohol, bromates, sodium hydroxide, boric acid (perborate or borate), ammonium thioglycolate or glycerol monothioglycolate. Some of these chemicals may cause central nervous system effects (headache, dizziness, nausea, drowsiness); eye, nose and throat irritation; lung problems (breathing difficulty or coughing); skin irritation; burns; or allergic reactions (stuffy or runny nose, sneezing, asthma or allergic dermatitis).

Manicures, pedicures and artificial nails. Nail care involves soaking the cuticles in softening agents, using nail clippers, using emery boards or nail files to file the nails, using hand lotions and applying and removing polish. Artificial nails (acrylics, gels, fibreglass, porcelains and fabric wraps and tips) may be brushed onto the nail or attached to it with glue. They are allowed to harden and then filed to the desired shape.

The many chemicals found in nail products include acetone, ethyl methacrylate and other acrylates, methyl ethyl ketone, ethyl acetate, lanolin and dimethyl-p-toluidine. These can cause skin, eye, nose, throat and lung irritation, as well as central nervous system effects. Some nail products also contain formaldehyde, associated with allergies as well as cancer with long term use. Some products contain glycol ethers, xylene and toluene, all linked to reproductive problems in laboratory animals.

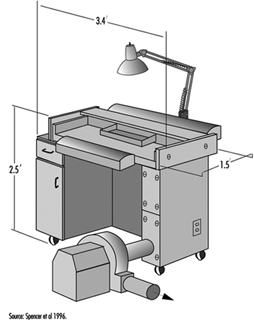

The use of methyl methacrylate (MMA) in artificial nail products was banned in the United States in 1974. Despite the ban, this chemical continues to be used. A 1982 study found that methyl methacrylate was present in 8 of 29 artificial nail products, and a 1986 study found measurable levels of MMA in the air of some nail salons. This chemical, if in contact with the skin, can cause tingling, numbness and whitening of the fingers. It also causes skin allergy in many people. An allergy to MMA can result in cross-sensitivity to other more commonly used methacrylates. In some products MMA has been replaced by other acrylates that may also be sensitizers. Figure 2 shows a downdraft table designed to minimize a manicurist’s exposure to the chemicals.

Figure 2. A modified commercial downdraft manicure table for application of artificial fingernails.

Washing and styling hair. Hair washing involves shampooing and rinsing with water. During this service, conditioners and other hair treatment products may also be applied. Hair drying is done in many ways: drying manually with towels, using a hand-held dryer or having the client sit under a fixed dryer. Styling generally involves the use of gels, creams or aerosol sprays. Washing the hair is often the first step for other services such as setting the hair, hair colouring and permanent waving. In large salons, one person may be assigned the job of washing clients’ hair, and do nothing other than that.

Shampoos and conditioners may contain alcohol, petroleum distillates and formaldehyde. All have been linked to dermatitis and allergies, including asthma. Long-term use of formaldehyde has also been linked to cancer.

Aerosol hair sprays may contain polyvinylpyrrolidone, which has been associated with lung and other respiratory diseases, including thesaurosis. They also contain a variety of solvents.

Straightening hair. Hair-straightening or hair-relaxing solutions are applied to the hair with a brush; then the hair is stretched to relax the natural curl. Hair straightener may contain sodium hydroxide, hydrogen peroxide, bromates, ammonium, thioglycolate and glycerol monothioglycolate. These chemicals may cause eye, nose and throat irritation, central nervous system effects and dermatitis.

Other chemical processes. A variety of cosmetics, including face creams and powders, mascara, eye liners, lipsticks and other products, may also be applied by cosmetologists. These can contain a wide variety of solvents, dyes, pigments, preservatives, oils, waxes and other chemicals that can cause skin allergies and/or irritation.

Cosmetologists may also remove body hair. Hair removal treatments can involve the application of hot wax and use of chemical depilatory products. These products often contain alkaline ingredients that can cause dermatitis.

Ergonomic hazards

Barbers and cosmetologists are at risk for musculoskeletal disorders due to the physical demands of their work and to poorly designed equipment, tools and work spaces. Such disorders can include:

- Wrist and hand problems, such as tendinitis and carpal tunnel syndrome. Risk factors include bending and twisting of the wrist while cutting and styling hair, holding hair dryers and using a round brush or curling iron. These disorders are also linked to forceful gripping or pinching caused by cutting with dull and/or poorly fitting shears.

- Shoulder problems, including tendinitis and bursitis. These are associated with constant reaching for supplies, or holding arms above shoulder height while cutting or styling hair. See figure 3.

- Neck and back problems, ranging from common aches and pains to serious conditions such as pinched nerves and ruptured discs. These are associated with frequent bending or twisting during activities such as shampooing, cutting hair below ear level, and performing manicures and pedicures.

- Foot and leg problems, including swelling, calluses and varicose veins. These may occur as a result of long periods of standing on hard floors in shoes with poor arch support.

Figure 3. Working with arms above shoulder level in a hairdressing salon in Zimbabwe.

Preventing musculoskeletal disorders

To prevent musculoskeletal disorders, it is important to apply ergonomic principles to the design of tasks, tools and workstations. Ergonomics is the science of adapting the workplace to the needs of the human body. It suggests ways to minimize awkward postures and repetitive motions, as well as the use of excessive force. It maximizes safety, health and comfort.

Ergonomic solutions may include:

- Adjustable furniture. For example, client chairs are available that can be raised, lowered and swiveled. Manicurist chairs are available with back support, armrests and seat pans that can be tilted to accommodate forward bending.

- Shears that are sharp, well-lubricated and designed to fit the individual’s hand.

- Curling irons and hair dryers with flexible handles. These can be used without excessive bending or twisting of the wrist.

- Free-standing sinks that allow technicians to wash hair without twisting and bending their backs.

- Rolling seats or stools that allow technicians to perform many procedures while seated, or to alternate between sitting and standing.

- Proper workstation designs such as storing commonly used supplies within easy reach; providing cushioned floor mats; and ensuring that cabinets are at the correct height to minimize reaching or bending.

- Client scheduling that varies the tasks and processes that a technician performs throughout the day.

- Training for technicians in good body mechanics and work practices such as proper lifting methods; bending at the hips instead of the waist; and using hair-cutting techniques that minimize reaching and bending of the wrist.

Infectious diseases

Work performed by barbers and cosmetologists involves close contact with clients. Understanding how infectious diseases are transmitted will help technicians prevent infection. Infectious diseases may be spread in the salon in the following ways:

- Through the air (e.g., upper respiratory illnesses such as colds and flu)

- Through contaminated water or food (e.g., hepatitis A, salmonella and giardia)

- Through insect or animal bites (e.g., lice)

- Through direct skin contact with infected persons (e.g., scabies, lice, ringworm, impetigo, herpes simplex, colds and chickenpox)

- Rarely, through exposure to the blood of an infected person (e.g., hepatitis B and HIV/AIDS)

While there is no recorded case of a barber or cosmetologist becoming infected with HIV/AIDS on the job, and work-related hepatitis B infection is extremely rare in these occupations, exposure to these bloodborne pathogens could possibly occur in rare instances of blood contact. Possible sources of exposure could include puncturing the skin with tools that carry infected blood (razors, tweezers, tattoo needles or clippers), or infected blood entering the body through an open wound, sore or skin rash.

This is one reason that shaving clients with razors has become uncommon in many countries. In addition to the risk to technicians, there is the possibility of skin and other infections being transferred from one client to another through unsterilized equipment.

Exposure to harmful organisms can be prevented by taking simple precautions:

- Hands should be washed frequently with soap and water.

- Latex gloves should be worn to protect technician and client if either has sores, lesions or skin rashes.

- Sharp instruments should be handled carefully and disposed of in approved puncture-proof containers.

- All tools, equipment and surfaces should be disinfected properly.

- Towels should be sanitized.

- Workers should be vaccinated against hepatitis B.

Other hazards

Fire hazards

Some products used in the salon may contain flammable or combustible chemicals. Sources of ignition can include flame from a cigarette, match or burner; a spark from a light switch, electric plug or frayed cord; or a hot object such as a curling iron, stove, light bulb or hotplate. To prevent accidents, it should be made sure that chemicals are used and stored properly. Flammables and combustibles should be kept away from flames, sparks or hot objects, and electrical equipment should be checked for broken or frayed cords that might spark or get hot. Each shop should also have a fire-prevention and evacuation plan, and appropriate and functioning fire extinguishers.

General housekeeping

Salons are often cramped and crowded work environments. Overstocked shelves may be unstable. Technicians may be at risk for slips and falls as a result of spilled liquids, poorly stored equipment or poorly positioned cords or wires. Narrow, crowded aisles limit workers’ ability to move freely without obstruction. All shops should practice good housekeeping, including: keeping aisles clear, cleaning up spills immediately, storing heavy objects on low shelves and making sure people can move freely through their workspace.

Electrical hazards

Electrical devices in the salon can include hair clippers, hair dryers, facial machines and electrolysis equipment and they should be checked for frayed wires and proper grounding. Since electrical equipment and outlets are often within splash range of water, red ground fault circuit interrupters to prevent shock should be used.

Health Problems and Disease Patterns

Skin diseases

Irritant and allergic dermatitis of the hands alone, or of hands and face together, is a common problem, experienced by 10 to 20% of cosmetologists (van der Walle and Brunsveld 1994). It often produces a characteristic rash in the spaces between the fingers. Signs of dermatitis generally include redness, drying and cracking on the skin of the hands. Eczema of the tips of the fingers may also occur, with ridging of the nail folds. Younger workers appear to be at highest risk, possibly because those with lower seniority tend to be assigned most often to shampooing and permanent-waving jobs. Most frequent causes of allergic skin rash in cosmetologists include glycerol thioglycolate, ammonium thioglycolate, nickel sulphate, ammonium persulphate preservatives and hair dyes (p-phenylenediamine or resorcinol) (Villaplana, Romaguera and Grimalt 1991).

In most cases, once an allergic dermatitis develops it does not improve, even with the wearing of gloves. Rubber latex glove use may itself be a significant risk factor for allergic responses, and vinyl gloves may need to be substituted if latex allergy develops. If one worker in a salon develops latex allergy, the entire salon may need to become latex-free to protect that worker from repeated allergic responses.

Other skin diseases of hairdressers include granuloma from hair implantation, and hot water burns. Also, varicose veins may result from the prolonged standing common to this occupation. Sharp tools such as scissors, shaving equipment and electric hair-cutting tools can cause skin lacerations. Such cuts may predispose the cosmetologist to dermatitis due to chemical exposures.

Lung problems

Allergic rhinitis (“hay fever”) and asthma have been associated with exposure to permanent-wave solution (Schwartz, Arnold and Strohl 1990), and in particular to ammonium persulphate (Gamboa et al. 1989). Hair bleach as well as henna (Starr, Yunginger and Brahser 1982) have been associated with occupational asthma in cosmetologists.

Reproductive health

A recent study found a moderately increased risk of spontaneous abortion among cosmetologists who worked full time and performed a large number of chemical services. The use of formaldehyde and exposure to manicuring and nail-sculpting chemicals were specifically associated with an increased risk of spontaneous abortion (John, Savitz and Shy 1994).

Cancer

Cosmetologists have been found to have a possible increased risk of developing certain types of cancer, including non-Hodgkin’s lymphoma (Zahm et al. 1992; Pearce 1992), bladder/urothelial cancer (Steineck et al. 1990) and breast cancer (Koenig 1994).

Laundries, Garment and Dry Cleaning

General Profile

Commercial laundries began as domestic enterprises, but have developed into businesses with many unique health and safety concerns. Laundries specializing in services for hospitals must deal with possible biological hazards, and those laundering work clothes for manufacturing or service workers may risk exposure to specific chemical hazards.

Dry cleaning reputedly originated in France in 1825 when a worker in a dye and cleaning factory spilled lamp oil on a soiled tablecloth (IARC 1995a). After the tablecloth dried, the spots had disappeared. Lamp oil is a hydrocarbon. Similar hydrocarbon solvents - turpentine, kerosene, benzene and gasoline - were used in the fledgling dry-cleaning industry. All these solvents had one major disadvantage: they were flammable, often resulting in fires and explosions (Wentz 1995). In 1928, W.J. Stoddard introduced a nearly odourless, petroleum-based solvent with a higher flashpoint, which reduced the risk of fire. Stoddard solvent gained widespread acceptance in the industry and is still used today.

At the turn of the century, advances in the synthesis of chlorinated hydrocarbons permitted development of nonflammable solvents for dry cleaning. Initially, carbon tetrachloride was preferred, but because of its toxicity and aggressiveness to metals, textiles and dyes, it was gradually replaced in the 1940s and 1950s by trichloroethylene and tetrachloroethylene (also commonly known as perchloroethylene, or PERC) (Wentz 1995). PERC (C2Cl4) is a colourless, clear, heavy liquid with an ethereal odour. Today, approximately 90% of US dry cleaners use PERC (EPA 1991a).

Although cleaning practices vary from country to country and from shop to shop, laundries and dry-cleaning shops are usually small businesses; about 70% of US dry-cleaning shops have fewer than four employees, who usually perform the cleaning at the same location as the shop. The employees of such a small business, many of whom typically labour more than eight hours per day, may be members of one family, sometimes including children. In many countries, the dry-cleaning family lives in the same building as the shop. An increasing trend among larger corporations is to operate multiple “drop” shops where customers leave soiled garments. The garments are transported to a central facility for cleaning, and later returned to the drop shops for customer pick-up. This arrangement confines hazardous waste to one site and reduces the solvent exposure of drop shop workers.

The Laundry and Dry-Cleaning Process

The dry-cleaning or laundry process usually begins when a customer brings soiled garments to a shop. Modern clothing is made from many different fibres and fabrics. Garments are inspected and sorted according to weight, colour, finish and fabric type prior to machine loading. Visible stains are treated at a spotting station with various chemicals, before or after cleaning, depending on the type of stain.

Cleaning is a three-step process: washing, extracting and drying (figure 1). Wet-process washing (laundering) uses detergent, water and possibly steam. In dry cleaning, detergent and water are added to the solvent to aid in soil removal. Clothes are manually loaded into the machine, and the cleaning solution is automatically injected. Machine contents are agitated for a period, then spun at high speed to extract the water or solvent and tumbled dry. Once garments have been removed from the dryer, they are pressed to remove wrinkles and restore their shape.

Figure 1. The dry cleaning process flow diagram.

Many countries have recently imposed stringent regulations for the control of PERC exposures and emissions because of associated health effects and environmental problems. In response to these regulations, dry-cleaning processes are changing. Improved solvent purification and vapour-recovery systems are available, alternative solvents are being developed, and wet methods using water immersion are being refined to clean garments traditionally cleaned in solvent. These processes are described below.

Transfer versus dry-to-dry equipment

Two basic types of machines used in dry cleaning are transfer and dry-to-dry. Transfer machines, older and less expensive, require manual transfer of solvent-laden clothing from the washer to the dryer. The transfer activity causes excessive worker exposure to PERC. Because of high solvent usage rates, emissions and exposures during transfer, PERC transfer machines are no longer manufactured in the United States; however, older used or reconditioned ones can still be purchased.

In 1994, at least 70% of PERC machines in the United States, for example, were dry-to-dry machines, using a one-step process that eliminates clothing transfer. Many shops are replacing or have replaced transfer machines with dry-to-dry machines because of the trend towards stricter environmental regulations; however, some shops still use transfer equipment for increased productivity and to avoid the capital expenditure required for new machines. In the United States, petroleum machines are primarily transfer units.

Dry-to-dry machines may be vented or ventless. Vented dry-to-dry machines vent residual solvent vapours directly to the atmosphere or through some form of vapour-recovery system during the aeration process. Ventless dry-to-dry machines are essentially closed systems, open to the atmosphere only when the machine door is opened. They recirculate the heated drying air through a vapour-recovery system and back to the drying drum. There is no aeration step.

Solvent purification: Filtration and distillation

Dry cleaners use filtration and/or distillation to recover and purify solvents. Filtration removes insoluble soils, non-volatile residues and loose dyes from the solvent. It is also sometimes used, primarily in the United States, to remove soluble soils. Filtration is a continuous process. The solvent passes through an adsorbent powder, cartridge or spin-disc filter, all requiring some level of periodic maintenance. Each filtration system produces contaminated cartridges or powders.

Distillation, used by 90% of US cleaners, removes soluble oils, fatty acids and greases not removed by filtration (International Fabricare Institute 1990). Distillation occurs when PERC is heated to its boiling point so that it vaporizes and later condenses back to liquid form. During this process, non-volatile impurities, which cannot be boiled off, remain in the still and are discarded as hazardous waste. Both filtration and distillation produce some solid wastes containing PERC; however, dry-cleaning machine manufacturers are striving to develop new filtration and distillation technologies that reduce the amount of hazardous waste produced. This ultimately results in important savings to the owner by reducing the cost of hazardous-waste disposal.

Recovery of PERC vapours

Two primary technologies are used to recover PERC vapours: the carbon adsorber and the refrigerated condenser. These two technologies, traditionally separate, are used together in more modern machines. Carbon adsorption is used in about 35% of the controlled machines in the United States, for example. Carbon adsorbers achieve a 95 to 99% vapour reduction by removing PERC from the air. Solvent-laden vapours pass over activated carbon having a high adsorption capacity. The carbon is later desorbed and the PERC recovered, or the carbon is discarded as hazardous waste when it becomes saturated with PERC. Carbon desorption typically occurs with steam or hot air. Desorption can be done automatically after each load, or it can be done at the end of the day. If not performed regularly, the carbon bed will become saturated and be ineffective for PERC recovery. The adsorption system can handle high volumes of air, having relatively low solvent concentrations while maintaining a high PERC removal efficiency, but frequent desorbing is needed and steam regeneration produces contaminated waste water.

Refrigerated condensers cool solvent-laden air below the dew point of the vapour to recover PERC, and operate on the principle that the ability of air to hold a solvent in the vapour state varies with temperature. Refrigerated condensers are used in approximately 65% of controlled machines. The process can achieve 95% vapour control in dry-to-dry machines and 85% control in transfer machines. Condensers require little maintenance and minimize the potential for waste water because steam regeneration is not required. They do require higher solvent concentrations than a carbon adsorber. Water vapour may pose a problem because it can condense and freeze, impeding gas flow and heat transfer (EPA 1991b).

Solvent alternatives to PERC

Alternative dry-cleaning solvents have been substituted for PERC. Flammable, petroleum-based solvents generally have higher exposure limits than PERC. These petroleum-based solvents are less aggressive at removing soils than PERC. Because their vapour pressures are lower than PERC, exposures from inhalation will generally be lower. However, adverse health effects are possible, including asphyxiation, central nervous system depression and skin and mucous membrane irritation. Contamination of aliphatic hydrocarbons with benzene will significantly increase the hazard.

Two different approaches have been taken in Germany to reduce the fire hazard posed by petroleum-based solvents: developing safer solvents and redesigning machines.

Recently developed petroleum-based solvents, widely used in Germany, are either straight-chain, branched or cyclic paraffins with a chain length of between 10 and 12 carbons. These petroleum-based solvents have an atmospheric lifetime of only a few days, are halogen-free, do not lead to ozone depletion and play only a minor role in the greenhouse effect. Some of the German requirements for petroleum-based, dry-cleaning solvents are outlined below (Hohenstein Institute 1995):

- Boiling range between 180° and 210ºC

- Aromatic, benzene, halogen and polycyclic aromatic content less than 0.01 wt%

- Flashpoint higher than 55ºC

- Thermally stable at operating conditions.

Dry-cleaning machines manufactured for petroleum-based solvents in Germany today are much safer than those of the past. Because petroleum-based solvents are combustible, additional safety measures are required on machines using them. Technical advances improve machine safety and greatly reduce the risk of fire/explosion. The following measures can be taken in combination or separately:

- Using an inert gas, such as nitrogen or argon, to displace oxygen in the drum and ensure that oxygen concentration is sufficiently low (approximately 4%) to prevent combustion

- Operating under a vacuum to remove oxygen and lower its concentration to below 4%

- Ensuring that the lower explosive limit (LEL) is not exceeded, or if the LEL is not known, ensuring that operating temperature remains 15ºC below the flashpoint

- Ensuring that vapour concentration remains below 50º of the LEL, by controlling operating temperatures or by providing sufficiently high airflow.

Wet cleaning

Wet cleaning is a developing technology, distinct from traditional laundering in that it is a more gentle process and can be used on many fabrics that were formerly dry cleaned. Four factors play an essential role in soil removal: temperature, time, mechanical action and chemical agents. Only the proper blend of these factors achieves the best cleaning results (Vasquez 1995). There are minor variations of machine wet cleaning, but all techniques use:

- Specially formulated wet-cleaning soaps and spotting agents

- Increased extraction of water prior to drying (extraction speeds as high as approximately 1,000 revolutions per minute)

- Close monitoring of heat and moisture content during the drying process

- Machines having less mechanical action during washing, accomplished by speed reduction and time limits.

Garments are washed with various levels of limited mechanical action, based on garment type and amount of soilage. The greatest risk occurs during drying. Many fibres can be fully dried with little or no difficulty. However, delicate garments or garments susceptible to shrinkage must be dried for only a few minutes before being hung to air dry. Because of these problems, most wet-cleaned garments require more finishing work than solvent-cleaned garments. Long drying times and more finishing work substantially increase processing time (Earnest and Spencer 1996).

Today, wet cleaning use is limited because the technology does not yet completely eliminate the need for solvents. It has been estimated that wet cleaning can safely clean approximately 30 to 70% of garments traditionally cleaned in solvent (Rice and Weinberg 1994). There are still problems with fibre damage, bleeding of dyes and, most importantly, cleaning ability. Inappropriate use of wet cleaning can expose shop owners to liability for damaged clothing. For this reason wet-cleaning advocates are working to persuade garment manufacturers to use fabrics that can be more easily wet cleaned.

Hazards in Laundries and Dry Cleaning Facilities

PERC hazards

In the workplace PERC can enter the human body through both respiratory and dermal exposure (ATSDR 1995). Symptoms associated with respiratory exposure include depression of the central nervous system; damage to the liver and kidneys (RSC 1986); impaired memory; confusion; dizziness; headache; drowsiness; and eye, nose and throat irritation. Repeated dermal exposure may result in dry, scaly and fissured dermatitis (NIOSH 1977).

US National Cancer Institute and National Toxicology Program studies have established a link between PERC exposure and cancer in animals. Human studies show an elevated risk of urinary tract (Duh and Asal 1984; Blair et al. 1990b; Katz and Jowett 1981), oesophageal (Duh and Asal 1984; Ruder, Ward and Brown 1994) and pancreatic cancer (Lin and Kessler 1981) among dry-cleaning workers. The International Agency for Research on Cancer (IARC) recently classified PERC in group 2A (probably carcinogenic to humans) and dry cleaning in group 2B (possibly carcinogenic to humans) (IARC 1995b). The Environmental Protection Agency (EPA) regulates PERC as a hazardous air pollutant.

US Occupational Safety and Health Administration (OSHA) data include numerous personal samples in dry-cleaning shops over the permissible exposure limit (PEL) of 100 ppm, 8-hour time-weighted average (TWA) (OSHA 1993). The machine operator is typically exposed to the greatest concentrations of PERC. US National Institute for Occupational Safety and Health (NIOSH) studies have shown that in many dry-cleaning shops having traditional machines, extremely high operator exposures occur during loading and unloading. Because loading/unloading occurs frequently throughout the day, in many instances exposure during this activity can account for 50 to 75% of the operator’s TWA exposure (Earnest 1996). Occupational exposures can be reduced by using modern dry-cleaning machines, solvent substitution, isolation of the process and effective local and general ventilation near the dry-cleaning machines.

Exposure to chemicals other than PERC

A wide variety of chemicals is present in laundries and dry-cleaning establishments. There is potential exposure through skin or eye contact or inhalation of vapours. Skin damage may occur from chronic or acute exposure. Chemicals that readily vaporize and have a high toxicity may pose a risk from inhalation, although this is generally considered to be of less concern than injury to the eyes or skin. The chemicals commonly used in the United States to treat stains through spotting are trichloroethylene; ketones, especially methyl isobutyl ketone (MIBK); petroleum naphtha; and hydrofluoric acid. Oxidizers, such as chlorine bleaches, may pose a hazard if used in the presence of many common compounds, such as turpentine, ammonia or fuel gases. Detergents containing enzymes may cause immune reactions in many workers. The combined exposures of the dry-cleaning solvent, PERC and various other chemicals is also a concern.

Ergonomic risk factors

Ergonomic hazards in the cleaning industry primarily occur among pressers. Pressing is a dynamic and repetitive task requiring reaching, precision gripping and awkward postures. Ergonomic risk factors are also present during material handling when heavy lifting may occur, especially in commercial laundries.

Fire hazards

The dry-cleaning industry has traditionally had a problem with fires. Part of the reason for this problem has been the widespread use of flammable and combustible liquids as a cleaning medium. The flammability of petroleum-based solvents continues to present an acute health and safety hazard. Approximately 10% of dry-cleaning shops in the United States use traditional, petroleum-based solvents, such as Stoddard solvent or mineral spirits. Even dry-cleaning shops that use non-flammable PERC face important fire hazards. If heated sufficiently, PERC will decompose into hydrogen chloride and phosgene gases. The production of hydrogen cyanide or carbon monoxide is another cause for concern during a fire. Hydrogen cyanide is produced when materials that contain nitrogen, such as many natural and synthetic fibres burn. Carbon monoxide is formed during incomplete combustion. All dry-cleaning shops have a large number of potential fuels and ignition sources.

Dry-cleaning machine designers must avoid conditions that can lead to a fire to occur and must ensure that their machines operate safely. Likewise, shop owners must take appropriate steps to prevent hazardous conditions from developing. Some common causes of fires in all businesses are electrical malfunctions, friction, open flames, sparks, static electricity, hot surfaces and smoking (NIOSH 1975).

Thermal burns

Cleaning facilities have several possible sources of severe burns. In the pressing station, burns may result from contact with the head of a press, lines transporting steam, or the steam itself. Insulation of pipes and surfaces, and use of various guarding techniques, can help prevent burns.

Although modern boilers are of safer design than earlier models, they are still used to produce large quantities of steam and must be operated safely. Many of the needed precautions can be found in the US National Fire Protection Association’s Code 32, Standard for Dry Cleaning Plants, and its Fire Protection Handbook (NFPA 1991). Recommendations in these documents include building code requirements, proper storage and isolation of flammables, fire extinguishers and sprinkler systems. Recommendations concerning the build-up of gases around the boiler address ways to eliminate gas leakage and ensure proper ventilation.

Mechanical hazards

Mechanical hazards are always a concern when powered equipment is used. Presses pose a significant mechanical hazard. Presses designed to be activated by only one hand leave a potential for the worker’s free hand to be caught between the presses. Belts, drive chains, shafts and couplings should be guarded to prevent accidental contact. All moving components of machines should be guarded to prevent body parts from becoming caught in a pinch, nip or shear point. The most common methods of guarding a hazard are enclosing the operation, interlocking devices, moving barriers, removal devices, remote controls, two-hand tripping devices and electronic safety devices.

Electrical hazards

Numerous measures can be taken to limit electrical hazards. Especially important is proper insulation and grounding. Identification and guarding of live parts also helps to prevent injury from electrical current. Electrical hazards can be compounded by the presence of moisture. Ground-fault circuit interrupters are designed to shut off power if high current passes through an unintended path. When selecting electrical equipment, the recommendations of established codes and standards, such as the US National Fire Protection Association 70, the National Electrical Code and the American National Standards Institute’s C2, should be followed. Guidelines for appropriate use of electrical equipment are given elsewhere in this Encyclopaedia.

Heat stress

Heat stress can afflict workers who must labour for extended periods of time in the hot environments that exist in many cleaning facilities. Heat stress may be compounded in the summer months, particularly if the shop is not air conditioned (air conditioning is not common in this industry). Both physical and environmental factors will modify the effects of heat. Acclimatization, body surface area to weight ratio, age and diseases, water and salt balance and physical fitness all play a role in the likelihood an individual will be affected by heat stress.

Slips, trips and falls

The hazard of slips, trips and falls are especially pertinent to cleaning facilities, which are often crowded with people and equipment. Without clearly established aisles and with a large number of containers holding solvents or water, spills can easily occur, resulting in a slippery floor. To control this hazard, regular housekeeping must be emphasized, facility layout must be carefully planned, and floor surfaces should be of non-slip materials. The workplace should be maintained in a clean, orderly, sanitary condition, and any spills should be cleaned up promptly.

Biological hazards

Laundering hospital linens puts sorters at risk from overlooked sharp objects in sheets or uniform pockets. Both dry cleaners and launderers may encounter freshly soiled garments that have been contaminated with human body fluids. Garments that have come from dental and medical offices or labs, blood banks, drug treatment centers, clinics, mortuaries, ambulances and other health-care facilities can be reasonably suspected to contain potentially infectious materials. In many countries, shops that handle garments from these sources must comply with the occupational standards governing exposures, such as the OSHA regulations governing bloodborne pathogens.

Environmental and Public Health Concerns

Environmental and public health concerns have resulted in dramatic changes in environmental regulations affecting the dry-cleaning industry in recent years. Adjacent apartments and businesses can be exposed to PERC vapours by diffusion through walls or ceilings; indoor airflow through holes in ceilings, pipe chases or vents; and through PERC emissions vented outside of the shop that are re-entrained through opened windows or ventilation units. Groundwater or soil contamination can occur through frequent or large solvent spills that might occur during transfer of solvent from a delivery truck to the dry-cleaning machine. Soil contamination might also occur through improper disposal of separator water into the sanitary sewer. Finally, consumers may be exposed from PERC residuals in poorly dried garments. This is of particular concern if the cleaning machine is not functioning properly or the dry cycle is shortened to improve productivity.

Acknowledgement: This article is largely based on materials assembled and published by the US National Institute for Occupational Safety and Health (NIOSH).

Funeral Services

General Profile

Assuming a world population of 5 billion, between one-quarter and one-half of a million people die each day. Many of the dead are infants or children, but eventually everyone who is born will also die. Despite the diversity in culture and religious beliefs surrounding death, the bodily remains of each person must be disposed of. In general, the two main methods of disposing of human remains consist of burial and cremation. Both of these disposal methods often have been applied to the untreated human remains. Many cultures, however, have developed funeral rites that prescribe some treatment of the dead body. Simpler rites may include the washing of the external surface with herbs and spices to slow or mask the onset of decay and the smell associated with dead tissue. More sophisticated rites include intrusive procedures such as embalming and removal of internal organs. Embalming usually involves replacement of blood with an embalming or preserving fluid. The Egyptians were among the first culture to develop and practice embalming of the dead. Embalming has been extensively practiced in the twentieth century throughout Western Europe and North America. Embalming may be followed either by burial or cremation. Outside of Western Europe and North America, burial or cremation is usually not preceded by embalming.

Funeral Processes

The preparation and burial of a deceased person can involve many processes, including:

- washing the surface of the body with various preparations

- dressing the body in burial clothes

- autopsies, in certain circumstances, which involve intrusive procedure, such as dissection and analysis of blood and body tissues

- embalming and removal of internal organs

- application of cosmetics to cover up visible damage if the body is to be viewed

- transporting the body to place of burial or cremation

- lifting of body and casket, and lowering it into the grave

- digging and filling of the grave

- possible exhumation of the body and subsequent autopsy.

Three types of hazard are always associated with the handling of deceased humans: microbial, psychological and ergonomic. A fourth type of hazard - chemical exposure - is introduced when embalming is performed. In the United States many states have enacted laws that require a body to be embalmed if the deceased person will be viewed in a open casket.

Microbial Hazards

Death is often caused by disease. After death the germs that caused the disease may continue to live in the deceased person and can infect the people handling the dead body.