Children categories

94. Education and Training Services (7)

94. Education and Training Services

Chapter Editor: Michael McCann

Table of Contents

Tables and Figures

Tables

Click a link below to view table in article context.

1. Diseases affecting day-care workers & teachers

2. Hazards & precautions for particular classes

3. Summary of hazards in colleges & universities

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

95. Emergency and Security Services (9)

95. Emergency and Security Services

Chapter Editor: Tee L. Guidotti

Table of Contents

Tables and Figures

Tables

Click a link below to view table in article context.

1. Recommendations & criteria for compensation

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

96. Entertainment and the Arts (31)

96. Entertainment and the Arts

Chapter Editor: Michael McCann

Table of Contents

Tables and Figures

Arts and Crafts

Performing and Media Arts

Entertainment

Tables

Click a link below to view table in article context.

1. Precautions associated with hazards

2. Hazards of art techniques

3. Hazards of common stones

4. Main risks associated with sculpture material

5. Description of fibre & textile crafts

6. Description of fibre & textile processes

7. Ingredients of ceramic bodies & glazes

8. Hazards & precautions of collection management

9. Hazards of collection objects

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

97. Health Care Facilities and Services (25)

97. Health Care Facilities and Services

Chapter Editor: Annelee Yassi

Table of Contents

Tables and Figures

Health Care: Its Nature and Its Occupational Health Problems

Annalee Yassi and Leon J. Warshaw

Social Services

Susan Nobel

Home Care Workers: The New York City Experience

Lenora Colbert

Occupational Health and Safety Practice: The Russian Experience

Valery P. Kaptsov and Lyudmila P. Korotich

Ergonomics and Health Care

Hospital Ergonomics: A Review

Madeleine R. Estryn-Béhar

Strain in Health Care Work

Madeleine R. Estryn-Béhar

Case Study: Human Error and Critical Tasks: Approaches for Improved System Performance

Work Schedules and Night Work in Health Care

Madeleine R. Estryn-Béhar

The Physical Environment and Health Care

Exposure to Physical Agents

Robert M. Lewy

Ergonomics of the Physical Work Environment

Madeleine R. Estryn-Béhar

Prevention and Management of Back Pain in Nurses

Ulrich Stössel

Case Study: Treatment of Back Pain

Leon J. Warshaw

Health Care Workers and Infectious Disease

Overview of Infectious Diseases

Friedrich Hofmann

Prevention of Occupational Transmission of Bloodborne Pathogens

Linda S. Martin, Robert J. Mullan and David M. Bell

Tuberculosis Prevention, Control and Surveillance

Robert J. Mullan

Chemicals in the Health Care Environment

Overview of Chemical Hazards in Health Care

Jeanne Mager Stellman

Managing Chemical Hazards in Hospitals

Annalee Yassi

Waste Anaesthetic Gases

Xavier Guardino Solá

Health Care Workers and Latex Allergy

Leon J. Warshaw

The Hospital Environment

Buildings for Health Care Facilities

Cesare Catananti, Gianfranco Damiani and Giovanni Capelli

Hospitals: Environmental and Public Health Issues

M.P. Arias

Hospital Waste Management

M.P. Arias

Managing Hazardous Waste Disposal Under ISO 14000

Jerry Spiegel and John Reimer

Tables

Click a link below to view table in article context.

1. Examples of health care functions

2. 1995 integrated sound levels

3. Ergonomic noise reduction options

4. Total number of injuries (one hospital)

5. Distribution of nurses’ time

6. Number of separate nursing tasks

7. Distribution of nurses' time

8. Cognitive & affective strain & burn-out

9. Prevalence of work complaints by shift

10. Congenital abnormalities following rubella

11. Indications for vaccinations

12. Post-exposure prophylaxis

13. US Public Health Service recommendations

14. Chemicals’ categories used in health care

15. Chemicals cited HSDB

16. Properties of inhaled anaesthetics

17. Choice of materials: criteria & variables

18. Ventilation requirements

19. Infectious diseases & Group III wastes

20. HSC EMS documentation hierarchy

21. Role & responsibilities

22. Process inputs

23. List of activities

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

98. Hotels and Restaurants (4)

98. Hotels and Restaurants

Chapter Editor: Pam Tau Lee

Table of Contents

99. Office and Retail Trades (7)

99. Office and Retail Trades

Chapter Editor: Jonathan Rosen

Table of Contents

Tables and Figures

The Nature of Office and Clerical Work

Charles Levenstein, Beth Rosenberg and Ninica Howard

Professionals and Managers

Nona McQuay

Offices: A Hazard Summary

Wendy Hord

Bank Teller Safety: The Situation in Germany

Manfred Fischer

Telework

Jamie Tessler

The Retail Industry

Adrienne Markowitz

Case Study: Outdoor Markets

John G. Rodwan, Jr.

Tables

Click a link below to view table in article context.

1. Standard professional jobs

2. Standard clerical jobs

3. Indoor air pollutants in office buildings

4. Labour statistics in the retail industry

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

100. Personal and Community Services (6)

100. Personal and Community Services

Chapter Editor: Angela Babin

Table of Contents

Tables and Figures

Indoor Cleaning Services

Karen Messing

Barbering and Cosmetology

Laura Stock and James Cone

Laundries, Garment and Dry Cleaning

Gary S. Earnest, Lynda M. Ewers and Avima M. Ruder

Funeral Services

Mary O. Brophy and Jonathan T. Haney

Domestic Workers

Angela Babin

Case Study: Environmental Issues

Michael McCann

Click a link below to view table in article context.

1. Postures observed during dusting in a hospital

2. Dangerous chemicals used in cleaning

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

101. Public and Government Services (12)

101. Public and Government Services

Chapter Editor: David LeGrande

Table of Contents

Tables and Figurs

Occupational Health and Safety Hazards in Public and Governmental Services

David LeGrande

Case Report: Violence and Urban Park Rangers in Ireland

Daniel Murphy

Inspection Services

Jonathan Rosen

Postal Services

Roxanne Cabral

Telecommunications

David LeGrande

Hazards in Sewage (Waste) Treatment Plants

Mary O. Brophy

Domestic Waste Collection

Madeleine Bourdouxhe

Street Cleaning

J.C. Gunther, Jr.

Sewage Treatment

M. Agamennone

Municipal Recycling Industry

David E. Malter

Waste Disposal Operations

James W. Platner

The Generation and Transport of Hazardous Wastes: Social and Ethical Issues

Colin L. Soskolne

Tables

Click a link below to view table in article context.

1. Hazards of inspection services

2. Hazardous objects found in domestic waste

3. Accidents in domestic waste collection (Canada)

4. Injuries in the recycling industry

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

102. Transport Industry and Warehousing (18)

102. Transport Industry and Warehousing

Chapter Editor: LaMont Byrd

Table of Contents

Tables and Figures

General Profile

LaMont Byrd

Case Study: Challenges to Workers’ Health and Safety in the Transportation and Warehousing Industry

Leon J. Warshaw

Air Transport

Airport and Flight Control Operations

Christine Proctor, Edward A. Olmsted and E. Evrard

Case Studies of Air Traffic Controllers in the United States and Italy

Paul A. Landsbergis

Aircraft Maintenance Operations

Buck Cameron

Aircraft Flight Operations

Nancy Garcia and H. Gartmann

Aerospace Medicine: Effects of Gravity, Acceleration and Microgravity in the Aerospace Environment

Relford Patterson and Russell B. Rayman

Helicopters

David L. Huntzinger

Road Transport

Truck and Bus Driving

Bruce A. Millies

Ergonomics of Bus Driving

Alfons Grösbrink and Andreas Mahr

Motor Vehicle Fuelling and Servicing Operations

Richard S. Kraus

Case Study: Violence in Gasoline Stations

Leon J. Warshaw

Rail Transport

Rail Operations

Neil McManus

Case Study: Subways

George J. McDonald

Water Transport

Water Transportation and the Maritime Industries

Timothy J. Ungs and Michael Adess

Storage

Storage and Transportation of Crude Oil, Natural Gas, Liquid Petroleum Products and Other Chemicals

Richard S. Kraus

Warehousing

John Lund

Case Study: US NIOSH Studies of Injuries among Grocery Order Selectors

Tables

Click a link below to view table in article context.

1. Bus driver seat measurements

2. Illumination levels for service stations

3. Hazardous conditions & administration

4. Hazardous conditions & maintenance

5. Hazardous conditions & right of way

6. Hazard control in the Railway industry

7. Merchant vessel types

8. Health hazards common across vessel types

9. Notable hazards for specific vessel types

10. Vessel hazard control & risk-reduction

11. Typical approximate combustion properties

12. Comparison of compressed & liquified gas

13. Hazards involving order selectors

14. Job safety analysis: Fork-lift operator

15. Job safety analysis: Order selector

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

Aircraft Flight Operations

Adapted from the 3rd edition Encyclopaedia article “Aviation - flying personnel” authored by H. Gartmann.

This article deals with the occupational safety and health of the crew members of civil aviation aircraft; see also the articles “Airport and flight control operations”, “Aircraft maintenance operations” and “Helicopters” for additional information.

Technical Crew Members

The technical personnel, or flight crew members, are responsible for the operation of the aircraft. Depending on aircraft type, the technical crew includes the pilot-in-command (PIC), the co-pilot (or first officer), and the flight engineer or a second officer (a pilot).

The PIC (or captain) has the responsibility for the safety of the aircraft, the passengers and the other crew members. The captain is the legal representative of the air carrier and is vested by the air carrier and the national aviation authority with the authority to carry out all actions necessary to fulfil this mandate. The PIC directs all duties on the flight deck and is in command of the entire aircraft.

The co-pilot takes his or her orders directly from the PIC and acts as the captain’s deputy upon delegation or in the latter’s absence. The co-pilot is the primary assistant to the PIC in a flight crew; in newer generation, two-person flight deck operations and in older two-engine aircraft, he or she is the only assistant.

Many older generation aircraft carry a third technical crew member. This person may be a flight engineer or a third pilot (usually called the second officer). The flight engineer, when present, is responsible for the mechanical condition of the aircraft and its equipment. New generation aircraft have automated many of the functions of the flight engineer; in these two-person operations, the pilots perform such duties as a flight engineer might otherwise perform that have not been automated by design.

On certain long-distance flights, the crew may be supplemented by a pilot with the qualifications of the PIC, an additional first officer and, when required, an additional flight engineer.

National and international laws stipulate that aircraft technical personnel may operate aircraft only when in possession of a valid licence issued by the national authority. In order to maintain their licences, technical crew members are given ground school training once every year; they are also tested in a flight simulator (a device that simulates real flight and flight emergency conditions) twice a year and in actual operations at least once a year.

Another condition for the receipt and renewal of a valid licence is a medical examination every 6 months for airline transport and commercial pilots over 40 years old, or every 12 months for commercial pilots under 40 years old and for flight engineers. The minimum requirements for these examinations are specified by the ICAO and by national regulations. A certain number of physicians experienced in aviation medicine may be authorized to provide such examinations by the national authorities concerned. These may include air ministry physicians, airforce flight surgeons, airline medical officers or private practitioners designated by the national authority.

Cabin Crew Members

The cabin crew (or flight attendants) are primarily responsible for passenger safety. Flight attendants perform routine safety duties; in addition, they are responsible for monitoring the aircraft cabin for security and safety hazards. In the event of an emergency, the cabin crew members are responsible for the organization of emergency procedures and for the safe evacuation of the passengers. In flight, cabin crew may need to respond to emergencies such as smoke and fire in the cabin, turbulence, medical trauma, aircraft decompressions, and hijackings or other terrorist threats. In addition to their emergency responsibilities, flight attendants also provide passenger service.

The minimum cabin crew ranges from 1 to 14 flight attendants, depending on the type of aircraft, the aircraft’s passenger capacity and national regulations. Additional staffing requirements may be determined by labour agreements. The cabin crew may be supplemented by a purser or service manager. The cabin crew is usually under the supervision of a lead or “in-charge” flight attendant, who, in turn, is responsible and reports directly to the PIC.

National regulations do not usually stipulate that the cabin crew should hold licences in the same way as the technical crew; however, cabin crew are required by all national regulations to have received appropriate instruction and training in emergency procedures. Periodic medical examinations are not usually required by law, but some air carriers require medical examinations for the purposes of health maintenance.

Hazards and Their Prevention

All air crew members are exposed to a wide variety of stress factors, both physical and psychological, to the hazards of an aircraft accident or other flight incident and to the possible contraction of a number of diseases.

Physical stress

Lack of oxygen, one of the main concerns of aviation medicine in the early days of flying, had until recently become a minor consideration in modern air transport. In the case of a jet aircraft flying at 12,000 m altitude, the equivalent altitude in the pressurized cabin is only 2,300 m and, consequently, symptoms of oxygen deficiency or hypoxia will not normally be encountered in healthy persons. Oxygen deficiency tolerance varies from individual to individual, but for a healthy, non-trained subject the presumed altitude threshold at which the first symptoms of hypoxia occur is 3,000 m.

With the advent of new generation aircraft, however, concerns about cabin air quality have resurfaced. Aircraft cabin air consists of air drawn from compressors in the engine and often also contains recirculated air from within the cabin. The flow rate of outside air within an aircraft cabin can vary from as little as 0.2 m3 per minute per person to 1.42 m3 per minute per person, depending upon aircraft type and age, and depending on location within the cabin. New aircraft use recirculated cabin air to a much greater degree than do older models. This air quality issue is specific to the cabin environment. The flight deck compartment air flow rates are often as high as 4.25 m3 per minute per crew member. These higher air flow rates are provided on the flight deck to meet the cooling requirements of the avionic and electronic equipment.

Complaints of poor cabin air quality from cabin crew and passengers have increased in recent years, prompting some national authorities to investigate. Minimal ventilation rates for aircraft cabins are not defined in national regulations. Actual cabin airflow is seldom measured once an aircraft is put into service, since there is no requirement to do so. Minimal air flow and the use of recirculated air, combined with other issues of air quality, such as the presence of chemical contaminants, micro-organisms, other allergens, tobacco smoke and ozone, require further evaluation and study.

Maintaining a comfortable air temperature in the cabin does not represent a problem in modern aircraft; however, the humidity of this air cannot be raised to a comfortable level, due to the large temperature difference between the aircraft interior and exterior. Consequently, both crew and passengers are exposed to extremely dry air, especially on long-distance flights. Cabin humidity depends on the cabin ventilation rate, passenger load, temperature and pressure. The relative humidity found on aircraft today varies from about 25% to less than 2%. Some passengers and crew members experience discomfort, such as dryness of the eyes, nose and throat, on flights that exceed 3 or 4 hours. There is no conclusive evidence of extensive or serious adverse health effects of low relative humidity on flight personnel. However, precautions should be taken to avoid dehydration; adequate intake of liquids such as water and juices should be sufficient to prevent discomfort.

Motion sickness (dizziness, malaise and vomiting due to the abnormal movements and altitudes of the aircraft) was a problem for civil aviation crews and passengers for many decades; the problem still exists today in the case of small sports aircraft, military aircraft and aerial acrobatics. In modern jet transport aircraft, it is much less serious and occurs less frequently due to higher aircraft speeds and take-off weights, higher cruising altitudes (which take the aircraft above the turbulence zones) and the use of airborne radar (which enables squalls and storms to be located and circumnavigated). Additionally, the lack of motion sickness also may be attributed to the more spacious, open design of today’s aircraft cabin, which provides a greater feeling of security, stability and comfort.

Other physical and chemical hazards

Aircraft noise, while a significant problem for ground personnel, is less serious for the crew members of a modern jet aircraft than was the case with the piston-engined plane. The efficiency of noise control measures such as insulation in modern aircraft have helped to eliminate this hazard in most flight environments. Additionally, improvements in communications equipment have minimized background noise levels from these sources.

Ozone exposure is a known but poorly monitored hazard for air crew and passengers. Ozone is present in the upper atmosphere as a result of the photochemical conversion of oxygen by solar ultraviolet radiation at altitudes used by commercial jet aircraft. The mean ambient ozone concentration increases with increasing latitude and is most prevalent during spring. It can also vary with weather systems, with the result of high ozone plumes descending down to lower altitudes.

Symptoms of ozone exposure include cough, upper airway irritation, tickle in the throat, chest discomfort, substantial pain or soreness, difficulty or pain in taking a deep breath, shortness of breath, wheezing, headache, fatigue, nasal congestion and eye irritation. Most people can detect ozone at 0.02 ppm, and studies have shown that ozone exposure at 0.5 ppm or more causes significant decrements in pulmonary function. The effects of ozone contamination are felt more readily by persons engaged in moderate to heavy activity than those who are at rest or engaged in light activity. Thus flight attendants (who are physically active in flight) have experienced the effects of ozone earlier and more frequently than technical crew or passengers on the same flight when ozone contamination was present.

In one study conducted in the late 1970s by the aviation authority in the United States (Rogers 1980), several flights (mostly at 9,150 to 12,200 m) were monitored for ozone contamination. Eleven per cent of the flights monitored were found to exceed that authority’s permissible ozone concentration limits. Methods of minimizing ozone exposure include choice of routes and altitudes that avoid areas of high ozone concentration and the use of air treatment equipment (usually a catalytic converter). The catalytic converters, however, are subject to contamination and loss of efficiency. Regulations (when they exist) do not require their periodic removal for efficiency testing, nor do they require monitoring of ozone levels in actual flight operations. Crew members, especially cabin crew, have requested that better monitoring and control of ozone contamination be implemented.

Another serious concern for technical and cabin crew members is cosmic radiation, which includes radiation forms that are transmitted through space from the sun and other sources in the universe. Most cosmic radiation that travels through space is absorbed by the earth’s atmosphere; however, the higher the altitude, the less the protection. The earth’s magnetic field also provides some shielding, which is greatest near the equator and decreases at the higher latitudes. Air crew members are exposed to cosmic radiation levels inflight that are higher than those received on the ground.

The amount of radiation exposure depends on the type and the amount of flying; for example, a crew member who flies many hours at high altitudes and high latitudes (e.g., polar routes) will receive the greatest amount of radiation exposure. The civil aviation authority in the United States (the FAA) has estimated that the long-term average cosmic radiation dose for air crew members ranges from 0.025 to 0.93 millisieverts (mSv) per 100 block hours (Friedberg et al. 1992). Based on FAA estimates, a crew member flying 960 block hours per year (or an average of 80 hours/month) would receive an estimated annual radiation dose of between 0.24 and 8.928 mSv. These levels of exposure are lower than the recommended occupational limit of 20 millisieverts per year (5-year average) established by the International Commission on Radiological Protection (ICRP).

The ICRP, however, recommends that occupational exposure to ionizing radiation should not exceed 2 mSv during pregnancy. In addition, the US National Council on Radiation Protection and Measurements (NCRP) recommends that exposure not exceed 0.5 mSv in any month once a pregnancy is known. If a crew member worked an entire month on flights with the highest exposures, the monthly dose rate could exceed the recommended limit. Such a pattern of flying over 5 or 6 months could result in an exposure which also would exceed the recommended pregnancy limit of 2 mSv.

The health effects of low-level radiation exposure over a period of years include cancer, genetic defects and birth defects to a child exposed in the womb. The FAA estimates that the added risk of fatal cancer resulting from exposure to inflight radiation would range from 1 in 1,500 to 1 in 94, depending on the type of routes and number of hours flown; the level of added risk of a serious genetic defect resulting from one parent’s exposure to cosmic radiation ranges from 1 in 220,000 live births to 1 in 4,600 live births; and the risk of mental retardation and childhood cancer in a child exposed in utero to cosmic radiation would range between 1 in 20,000 to 1 in 680, depending upon the type and amount of flying the mother did while pregnant.

The FAA report concludes that “radiation exposure is not likely to be a factor that would limit flying for a non-pregnant crew member” because even the largest amount of radiation received annually by a crew member working as much as 1,000 block hours a year is less than half the ICRP recommended average annual limit. However, for a pregnant crew member, the situation is different. The FAA calculates that a pregnant crew member working 70 block hours per month would exceed the recommended 5-month limit on about one-third of the flights they studied (Friedberg et al. 1992).

It should be stressed that these exposure and risk estimates are not universally accepted. Estimates are dependent upon assumptions about the types and mix of radioactive particles encountered at altitude and the weight or quality factor used to determine dose estimates for some of these forms of radiation. Some scientists believe that the actual radiation hazard to air crew members may be greater than described above. Additional monitoring of the flight environment with reliable instrumentation is needed to more clearly determine the extent of inflight radiation exposure.

Until more is known about exposure levels, air crew members should keep their exposure to all types of radiation as low as possible. With respect to inflight radiation exposure, minimizing the amount of flight time and maximizing the distance from the source of radiation can have a direct effect on the dose received. Reducing monthly and yearly flight time and/or selecting flights which fly at lower altitudes and latitudes will reduce exposure. An air crew member who has the ability to control his or her flight assignments might choose to fly fewer hours per month, to bid for a mix of domestic and international flights or to request leaves periodically. A pregnant air crew member might choose to take a leave for the duration of the pregnancy. Since the first trimester is the most crucial time to guard against radiation exposure, an air crew member planning a pregnancy also may want to consider a leave especially if she is flying long-distance polar routes on a regular basis and has no control over her flight assignments.

Ergonomic problems

The main ergonomic problem for technical crew is the need to work for many hours in a sitting but unsettled position and in a very limited working area. In this position (restrained by lap and shoulder harness), it is necessary to carry out a variety of tasks such as movements of the arms, legs and head in different directions, consulting instruments at a distance of about 1 m above, below, to the front and to the side, scanning the far distance, reading a map or manual at close distance (30 cm), listening through earphones or talking through a microphone. Seating, instrumentation, lighting, cockpit microclimate and radio communications equipment comfort have been and still remain the object of continuous improvement. Today’s modern flight deck, often referred to as the “glass cockpit”, has created yet another challenge with its use of leading-edge technology and automation; maintaining vigilance and situational awareness under these conditions has created new concerns for both the designers of aircraft and the technical personnel who fly them.

Cabin crew have an entirely different set of ergonomic problems. One main problem is that of standing and moving around during flight. During climb and descent, and in turbulence, the cabin crew is required to walk on an inclined floor; in some aircraft the cabin incline may remain at approximately 3% during cruise as well. Also, many cabin floors are designed in a manner that creates a rebound effect while walking, putting an additional stress on the flight attendants who are constantly moving about during a flight. Another important ergonomic problem for flight attendants has been the use of mobile carts. These carts can weigh up to 100 to 140 kg and must be pushed and pulled up and down the length of the cabin. Additionally, the poor design and maintenance of the braking mechanisms on many of these carts have caused an increase in repetitive-strain injuries (RSIs) among flight attendants. Air carriers and cart manufacturers are now taking a more serious look at this equipment, and new designs have resulted in ergonomic improvements. Additional ergonomic problems result from the need to lift and carry heavy or bulky items in restricted spaces or while maintaining uncomfortable body posture.

Workload

The workload for air crew members depends on the task, the ergonomic layout, the hours of work/duty and many other factors. The additional factors affecting the technical crew include:

- duration of rest time between present and last flight and the duration of sleep time during the rest period

- the pre-flight briefing and problems encountered during the pre-flight briefing

- delays preceding departure

- timing of flights

- meteorological conditions at the point of departure, en route and at the destination

- number of flight segments

- type of equipment being flown

- quality and quantity of radio communications

- visibility during descent, glare and protection from the sun

- turbulence

- technical problems with the aircraft

- experience of other crew members

- air traffic (especially at point of departure and destination)

- presence of air carrier or national authority personnel for purposes of checking crew competency.

Certain of these factors may be equally important for the cabin crew. In addition, the latter are subject to the following specific factors:

- pressure of time due to short duration of flight, high number of passengers and extensive service requirements

- extra services demanded by passengers, the character of certain passengers and, occasionally, verbal or physical abuse by passengers

- passengers requiring special care and attention (e.g., children, the disabled, the elderly, a medical emergency)

- extent of preparatory work

- lack of necessary service items (e.g., insufficient meals, beverages and so on) and equipment.

The measures taken by air carrier managements and government administrations to keep crew workload within reasonable limits include: improvement and extension of air-traffic control; reasonable limits on hours of duty and requirements for minimum rest provisions; execution of preparatory work by dispatchers, maintenance, catering and cleaning personnel; automation of cockpit equipment and tasks; the standardization of service procedures; adequate staffing; and the provision of efficient and easy-to-handle equipment.

Hours of work

One of the most important factors affecting both technical and cabin crew member occupational health and safety (and certainly the most widely discussed and controversial) is the issue of flight fatigue and recovery. This issue covers the broad spectrum of activity encompassing crew scheduling practices—length of duty periods, amount of flight time (daily, monthly and yearly), reserve or standby duty periods and availability of time for rest both while on flight assignment and at domicile. Circadian rhythms, especially sleep intervals and duration, with all their physiological and psychological implications, are especially significant for air crew members. Time shifts due either to night flights or to east/west or west/east travel across a number of time zones create the greatest problems. Newer generation aircraft, which have the capability of remaining aloft for up to 15 to 16 hours at a time, have exacerbated the conflict between airline schedules and human limitations.

National regulations to limit duty and flight periods and to provide minimum rest limitations exist on a nation by nation basis. In some instances, these regulations have not kept pace with technology or science, nor do they necessarily guarantee flight safety. Until recently there has been little attempt to standardize these regulations. Current attempts at harmonization have given rise to concerns among air crew members that those countries with more protective regulations may be required to accept lower and less adequate standards. In addition to national regulations, many air crew members have been able to negotiate more protective hours of service requirements in their labour agreements. While these negotiated agreements are important, most crew members feel that hours of service standards are essential to their health and safety (and to that of the flying public), and thus minimum standards should be adequately regulated by the national authorities.

Psychological stress

In recent years, aircraft crew have been confronted with a serious mental stress factor: the likelihood of hijacking, bombs and armed attacks on aircraft. Although security measures in civil aviation worldwide have been considerably increased and upgraded, the sophistication of terrorists has likewise increased. Air piracy, terrorism and other criminal acts remain a real threat to all air crew members. The commitment and cooperation of all national authorities as well as the force of worldwide public opinion are needed to prevent these acts. Additionally, air crew members must continue to receive special training and information on security measures and must be informed on a timely basis of suspected threats of air piracy and terrorism.

Air crew members understand the importance of starting flight duty in a sufficiently good mental and physical state to ensure that the fatigue and stresses occasioned by the flight itself will not affect safety. Fitness for flight duty may occasionally be impaired by psychological and physical stress, and it is the responsibility of the crew member to recognize whether or not he or she is fit for duty. Sometimes, however, these effects may not be readily apparent to the person under duress. For this reason, most airlines and air crew member associations and labour unions have professional standards committees to assist crew members in this area.

Accidents

Fortunately, catastrophic aircraft accidents are rare events; nonetheless, they do represent a hazard for air crew members. An aircraft accident is practically never a hazard resulting from a single, well-defined cause; in almost every instance, a number of technical and human factors coincide in the causal process.

Defective equipment design or equipment failure, especially as a result of inadequate maintenance, are two mechanical causes of aircraft accidents. One important, although relatively rare, type of human failure is sudden death due, for example, to myocardial infarction; other failures include sudden loss of consciousness (e.g., epileptic fit, cardiac syncope and fainting due to food poisoning or other intoxication). Human failure may also result from the slow deterioration of certain functions such as hearing or vision, although no major aircraft accident has been attributed to such a cause. Preventing accidents from medical causes is one of the most important tasks of aviation medicine. Careful personnel selection, regular medical examinations, surveys of absence due to illness and accidents, continuous medical contact with working conditions and industrial hygiene surveys can considerably decrease the danger of sudden incapacitation or slow deterioration in technical crew. Medical personnel should also routinely monitor flight scheduling practices to prevent fatigue-related incidents and accidents. A well-operated, modern airline of significant size should have its own medical service for these purposes.

Advances in aircraft accident prevention are often made as a result of careful investigation of accidents and incidents. Systematic screening of all, even minor, accidents and incidents by an accident investigation board comprising technical, operational, structural, medical and other experts is essential to determine all causal factors in an accident or incident and to make recommendations for preventing future occurrences.

A number of strict regulations exist in aviation to prevent accidents caused by use of alcohol or other drugs. Crew members should not consume quantities of alcohol in excess of what is compatible with professional requirements, and no alcohol at all should be consumed during and for at least 8 hours prior to flight duty. Illegal drug use is strictly prohibited. Drug use for medicinal purposes is strictly controlled; such drugs are generally not allowed during or immediately preceding flight, although exceptions may be allowed by a recognized flight physician.

The transport of hazardous materials by air is yet another cause of aircraft accident and incidents. A recent survey covering a 2-year period (1992 to 1993) identified over 1,000 aircraft incidents involving hazardous materials on passenger and cargo air carriers in one nation alone. More recently, an accident in the United States which resulted in the deaths of 110 passengers and crew involved the carriage of hazardous cargo. Hazardous materials incidents in air transportation occur for a number of reasons. Shippers and passengers may be unaware of the dangers presented by the materials they bring aboard aircraft in their baggage or offer for transport. Occasionally, unscrupulous persons may choose to illegally ship forbidden hazardous materials. Additional restrictions on the carriage of hazardous materials by air and improved training for air crew members, passengers, shippers and loaders may help to prevent future incidents. Other accident prevention regulations deal with oxygen supply, crew meals and procedures in case of illness.

Diseases

Specific occupational disease of crew members are not known or documented. However, certain diseases may be more prevalent among crew members than among persons in other occupations. Common colds and upper respiratory system infections are frequent; this may be due in part to the low humidity during flight, irregularities of schedules, exposure to att large number of people in a confined space and so on. A common cold, especially with upper respiratory congestion, that is not significant for an office worker may incapacitate a crew member if it prevents the clearing of pressure on the middle ear during ascent and, particularly, during descent. Additionally, illnesses that require some form of drug therapy may also preclude the crew member from engaging in work for a period of time. Frequent travel to tropical areas may also entail increased exposure to infectious diseases, the most important being malaria and infections of the digestive system.

The close confines of an aircraft for extended periods of time also carry an excess risk of airborne infectious diseases like tuberculosis, if a passenger or crew member has such a disease in its contagious stage.

Art Teaching

Health and safety problems in art programmes can be similar in educational institutions ranging from junior high schools to universities. Arts programmes are a special problem because their hazards are not often recognized and, especially at the college level, can be semi-industrial in scale. Hazards can include inhalation of airborne contaminants; ingestion or dermal absorption of toxins; injury from machinery and tools; slips, trips and falls; and repetitive strain and other musculoskeletal injuries. Precautions include the provision of adequate ventilation (both dilution and local exhaust), the safe handling and storage of chemicals, machine-guarding and competent maintenance of machinery, efficient clean-up, good housekeeping and adjustable work stations. A key precaution in avoiding occupational safety and health problems of all kinds is adequate and mandatory training.

Elementary and Secondary School Teachers

Hazards at the elementary and secondary school levels include practices such as spraying and unsafe use of solvents and other chemicals and poor ventilation of processes. There is frequently a lack of proper equipment and sufficient knowledge of materials to ensure a safe workplace. Precautions include efficient engineering controls, better knowledge of materials, the elimination of hazardous art supplies from schools and substitution with safer ones (see table 1). This will help protect not only teachers, technicians, maintenance workers and administrators, but also students.

Table 1. Hazards and precautions for particular classes.

|

Class |

Activity/Subject |

Hazards |

Precautions |

||||||

|

Elementary Classes |

|||||||||

|

Science |

Animal handling

Plants

Chemicals

Equipment

|

Bites and scratches, zoonoses, parasites

Allergies, poisonous plants

Skin and eye problems, toxic reactions, allergies

Electrical hazards, safety hazards |

Allow only live, healthy animals. Handle animals with heavy gloves. Avoid animals which can carry disease-transmitting insects and parasites.

Avoid plants which are known to be poisonous or cause allergic reaction.

Avoid using toxic chemicals with children. Wear proper personal protective equipment when doing teacher demonstrations with toxic chemicals.

Follow standard electrical safety procedures. Ensure all equipment is properly guarded. Store all equipment, tools, etc., properly. |

||||||

|

Art |

Painting and drawing

Photography

Textile and fibre arts

Printmaking

Woodworking

Ceramics |

Pigments, solvents

Photochemicals

Dyes

Acids, solvents

Cutting tools

Tools

Glues

Silica, toxic metals, heat, kiln fumes |

Use only non-toxic art materials. Avoid solvents, acids, alkalis, spray cans, chemical dyes, etc.

Use only children’s paints. Do not use pastels, dry pigments.

Do not do photoprocessing. Send out film for developing or use Polaroid cameras or blueprint paper and sunlight.

Avoid synthetic dyes; use natural dyes such as onion skins, tea, spinach, etc.

Use water-based block printing inks.

Use linoleum cuts instead of woodcuts.

Use soft woods and hand tools only.

Use water-based glues.

Use wet clay only, and wet mop. Paint pottery rather than using ceramic glazes. Do not fire kiln inside classroom.

|

||||||

|

Secondary Classes |

|||||||||

|

Chemistry |

General

Organic chemistry

Inorganic chemistry

Analytical chemistry

Storage |

Solvents

Peroxides and explosives

Acids and bases

Hydrogen sulphide

Incompatibilities

Flammability |

All school laboratories should have the following: laboratory hood if toxic, volatile chemicals are used; eyewash fountains; emergency showers (if concentrated acids, bases or other corrosive chemicals are present); first aid kits; proper fire extinguishers; protective goggles, gloves and lab coats; proper disposal receptacles and procedures; spill control kit. Avoid carcinogens, mutagens and highly toxic chemicals like mercury, lead, cadmium, chlorine gas, etc.

Use only in laboratory hood. Use least toxic solvents. Do semi-micro- or microscale experiments.

Do not use explosives or chemicals such as ether, which can form explosive peroxides.

Avoid concentrated acids and bases when possible.

Do not use hydrogen sulphide. Use substitutes.

Avoid alphabetical storage, which can place incompatible chemicals in close proximity. Store chemicals by compatible groups.

Store flammable and combustible liquids in approved flammable-storage cabinets. |

||||||

|

Biology |

Dissection

Anaesthetizing insects

Drawing of blood

Microscopy

Culturing bacteria |

Formaldehyde

Ether, cyanide

HIV, Hepatitis B

Stains

Pathogens |

Do not dissect specimens preserved in formaldehyde. Use smaller, freeze-dried animals, training films and videotapes, etc.

Use ethyl alcohol for anaesthetization of insects. Refrigerate insects for counting.

Avoid if possible. Use sterile lancets for blood typing under close supervision.

Avoid skin contact with iodine and gentian violet.

Use sterile technique with all bacteria, assuming there could be contamination by pathogenic bacteria. |

||||||

|

Physical sciences |

Radioisotopes

Electricity and magnetism

Lasers |

Ionizing radiation

Electrical hazards

Eye and skin damage, electrical hazards |

Use radioisotopes only in “exempt” quantities not requiring a license. Only trained teachers should use these. Develop a radiation safety programme.

Follow standard electrical safety procedures.

Use only low-power (Class I) lasers. Never look directly into a laser beam or pass the beam across face or body. Lasers should have a key lock. |

||||||

|

Earth sciences |

Geology

Water pollution

Atmosphere

Volcanoes

Solar observation |

Flying chips

Infection, toxic chemicals

Mercury manometers

Ammonium dichromate

Infrared radiation |

Crush rocks in canvas bag to prevent flying chips. Wear protective goggles.

Do not take sewage samples because of infection risk. Avoid hazardous chemicals in field testing of water pollution.

Use oil or water manometers. If mercury manometers are used for demonstration, have mercury spill control kit.

Do not use ammonium dichromate and magnesium to simulate volcanoes.

Never view sun directly with eyes or through lenses. |

||||||

|

Art and Industrial Arts |

All

Painting and drawing

Photography

Textile and fibre arts |

General

Pigments, solvents

Photochemicals, acids, sulphur dioxide

Dyes, dyeing assistants, wax fumes |

Avoid most dangerous chemicals and processes. Have proper ventilation. See also precautions under Chemistry

Avoid lead and cadmium pigments. Avoid oil paints unless cleanup is done with vegetable oil. Use spray fixatives outside.

Avoid colour processing and toning. Have dilution ventilation for darkroom. Have eyewash fountain. Use water instead of acetic acid for stop bath.

Use aqueous liquid dyes or mix dyes in glove box. Avoid dichromate mordants. Do not use solvents to remove wax in batik. Have ventilation if ironing out wax. |

||||||

|

|

Papermaking

Printmaking

Woodworking

Ceramics

Sculpture

Jewelry

|

Alkali, beaters

Solvents

Acids, potassium chlorate

Dichromates

Woods and wood dust

Machinery and tools

Noise

Glues

Paints and finishes

Lead, silica, toxic metals, kiln fumes

Silica, plastics resins, dust

Soldering fumes, acids |

Do not boil lye. Use rotten or mulched plant materials, or recycle paper and cardboard. Use large blender instead of more dangerous industrial beaters to prepare paper pulp.

Use water-based instead of solvent-based silk screen inks. Clean intaglio press beds nd inking slabs with vegetable oil and dishwashing liquid instead of solvents. Use cut paper stencils instead of lacquer stencils for silk screen printing.

Use ferric chloride to etch copper plates instead of Dutch mordant or nitric acid on zinc plates. If using nitric acid etching, have emergency shower and eyewash fountain and local exhaust ventilation.

Use diazo instead of dichromate photoemulsions. Use citric acid fountain solutions in lithography to replace dichromates.

Have dust collection system for woodworking machines. Avoid irritating and allergenic hardwoods, preserved woods (e.g., chromated copper arsenate treated).Clean up wood dust to remove fire hazards.

Have machine guards. Have key locks and panic button.

Reduce noise levels or wear hearing protectors.

Use water-based glues when possible. Avoid formaldehyde/resorcinol glues, solvent-based glues.

Use water-based paints and finishes. Use shellac based on ethyl alcohol rather than methyl alcohol.

Purchase wet clay. Do not use lead glazes. Buy prepared glazes rather than mixing dry glazes. Spray glazes only in spray booth. Fire kiln outside or have local exhaust ventilation. Wear infrared goggles when looking into hot kiln.

Use only hand tools for stone sculpture to reduce dust levels. Do not use sandstone, granite or soapstone, which might contain silica or asbestos. Do not use highly toxic polyester, epoxy or polyurethane resins. Have ventilation if heating plastics to remove decomposition products. Wet mop or vacuum dusts.

Avoid cadmium silver solders and fluoride fluxes. Use sodium hydrogen sulphate rather than sulphuric acid for pickling. Have local exhaust ventilation. |

||||||

|

|

Enameling

Lost wax casting

Stained glass

Welding

Commercial art |

Lead, burns, infrared radiation

Metal fumes, silica, infrared radiation, heat

Lead, acid fluxes

Metal fumes, ozone, nitrogen dioxide, electrical and fire hazards

Solvents, photochemicals, video display terminals |

Use only lead-free enamels. Ventilate enameling kiln. Have heat-protective gloves and clothing, and infrared goggles.

Use 50/50 30-mesh sand/plaster instead of cristobalite investments. Have local exhaust ventilation for wax burnout kiln and casting operation. Wear heat-pro tective clothing and gloves.

Use copper foil technique rather than lead came. Use lead- and antimony-free solders. Avoid lead glass paints. Use acid- and rosin-free soldering fluxes.

Do not weld metals coated with zinc, lead paints, or alloys with hazardous metals (nickel, chromium, etc.). Weld only metals of known composition.

Use double-sided tape instead of rubber cement. Use heptane-based, not hexane rubber cements. Have spray booths for air brushing. Use water-based or alcohol- based permanent markers instead of xylene types. See Photography section for photoprocesses. Have proper ergonomic chairs, lighting, etc., for computers. |

||||||

|

Performing Arts |

Theatre

Dance

Music |

Solvents, paints, welding fumes, isocyanates, safety, fire

Acute injuries Repetitive strain injuries

Musculoskeletal injuries (e.g., carpal tunnel syndrome)

Noise

Vocal strain |

Use water-based paints and dyes. Do not use polyurethane spray foams. Separate welding from other areas. Have safe rigging procedures. Avoid pyrotechnics, firearms, fog and smoke, and other hazardous special effects. Fireproof all stage scenery. Mark all trap doors, pits and elevations.

Have a proper dance floor. Avoid full schedules after period of inactivity. Assure proper warm-up before and cool-down after dance activity. Allow sufficient recovery time after injuries.

Use proper sized instruments. Have adequate instrument supports. Allow sufficient recovery time after injuries.

Keep sound levels at acceptable levels. Wear musician’s ear plugs if needed. Position speakers to minimize noise levels. Use sound-absorbing materials on walls.

Assure adequate warm-up. Provide proper vocal training and conditioning. |

||||||

|

Automotive Mechanics |

Brake drums

Degreasing

Car motors

Welding

Painting |

Asbestos

Solvents

Carbon monoxide

Solvents, pigments |

Do not clean brake drums unless approved equipment is used.

Use water-based detergents. Use parts cleaner

Have tailpipe exhaust.

See above.

Spray paint only in spray booth, or outdoors with respiratory protection.

|

||||||

|

Home Economics |

Food and nutrition |

Electrical hazards

Knives and other sharp utensils

Fire and burns

Cleaning products |

Follow standard electrical safety rules.

Always cut away from body. Keep knives sharpened.

Have stove hoods with grease filters that exhaust to outside. Wear protective gloves with hot objects.

Wear goggles, gloves and apron with acidic or basic cleaning products. |

||||||

College and University Teachers

Hazards at the college and university levels include, in addition to those mentioned above, the fact that students, teachers and technicians tend to be more experimental and tend to use more potentially dangerous materials and machinery. They also often work on a larger scale and for longer periods of time. Precautions must include education and training, the provision of engineering controls and personal protective equipment, written safety policies and procedures and insistence on compliance with these.

Artistic Freedom

Many art teachers and technicians are artists in their own right, resulting in multiple exposures to the hazards of art materials and processes which can significantly increase their health risks. When confronted with hazards in their field about which they have not known or which they have ignored, many teachers become defensive. Artists are experimental and frequently belong to an anti-establishment culture which encourages defiance of institutional rules. It is important, however, for the school administration to realize that the quest for artistic freedom is not a valid argument against working safely.

Liability and Training

In many jurisdictions teachers will be subject to both a personal and a school liability for the safety of their students, particularly the younger ones. “Because of the age, maturity, and experience limitations of most students, and because teachers stand in loco parentis (in the place of a parent), schools are expected to provide a safe environment and establish reasonable behaviour for the protection of students” (Qualley 1986).

Health and Safety Programmes

It is important that schools take the responsibility for training both art teachers and school administrators in the potential hazards of art materials and processes and in how to protect their students and themselves. A prudent school administration will ensure that there are in place written health and safety policies, procedures and programmes, compliance with these, regular safety training and a real interest in teaching how to create art safely.

Metalworking

Metalworking involves casting, welding, brazing, forging, soldering, fabrication and surface treatment of metal. Metalworking is becoming even more common as artists in developing countries are also starting to use metal as a basic sculptural material. While many art foundries are commercially run, art foundries are also often part of college art programmes.

Hazards and Precautions

Casting and foundry

Artists either send work out to commercial foundries, or can cast metal in their own studios. The lost wax process is often used for casting small pieces. Common metals and alloys used are bronze, aluminium, brass, pewter, iron and stainless steel. Gold, silver and sometimes platinum are used for casting small pieces, particularly for jewellery.

The lost wax process involves several steps:

- making the positive form

- making the investment mould

- burning out of the wax

- melting the metal

- slagging

- pouring the molten metal into the mould

- removing the mould

The positive form can be made directly in wax; it can also be made in plaster or other materials, a negative mould made in rubber and then the final positive form cast in wax. Heating the wax can result in fire hazards and in decomposition of the wax from overheating.

The mould is commonly made by applying an investment containing the cristobalite form of silica, creating the risk of silicosis. A 50/50 mixture of plaster and 30-mesh sand is a safer substitute. Moulds can also be made using sand and oil, formaldehyde resins and other resins as binders. Many of these resins are toxic by skin contact and inhalation, requiring skin protection and ventilation.

The wax form is burnt out in a kiln. This requires local exhaust ventilation to remove the acrolein and other irritating wax decomposition products.

Melting the metal is usually done in a gas-fired crucible furnace. A canopy hood exhausted to the outside is needed to remove carbon monoxide and metal fumes, including zinc, copper, lead, aluminium and so on.

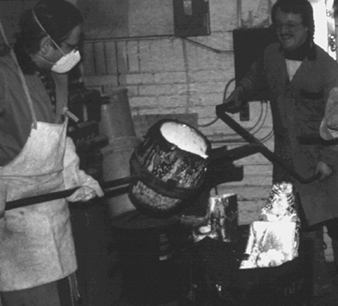

The crucible containing the molten metal is then removed from the furnace, the slag on the surface removed and the molten metal poured into the moulds (figure 1). For weights under 80 pounds of metal, manual lifting is normal; for greater weights, lifting equipment is needed. Ventilation is needed for the slagging and pouring operations to remove metal fumes. Resin sand moulds can also produce hazardous decomposition products from the heat. Face shields protecting against infrared radiation and heat, and personal protective clothing resistant to heat and molten metal splashes are essential. Cement floors must be protected against molten metal splashes by a layer of sand.

Figure 1. Pouring molten metal in art foundry.

Ted Rickard

Breaking away the mould can result in exposure to silica. Local exhaust ventilation or respiratory protection is needed. A variation of the lost wax process called the foam vaporization process involves using polystyrene or polyurethane foam instead of wax, and vaporizing the foam during pouring of the molten metal. This can release hazardous decomposition products, including hydrogen cyanide from polyurethane foam. Artists often use scrap metal from a variety of sources. This practice can be dangerous due to possible presence of lead- and mercury-containing paints, and to the possible presence of metals like cadmium, chromium, nickel and so on in the metals.

Fabrication

Metal can be cut, drilled and filed using saws, drills, snips and metal files. The metal filings can irritate the skin and eyes. Electric tools can cause electric shock. Improper handling of these tools can result in accidents. Goggles are needed to protect the eyes from flying chips and filings. All electrical equipment should be properly grounded. All tools should be carefully handled and stored. Metal to be fabricated should be securely clamped to prevent accidents.

Forging

Cold forging utilizes hammers, mallets, anvils and similar tools to change the shape of metal. Hot forging involves additionally heating the metal. Forging can create great amounts of noise, which can cause hearing loss. Small metal splinters may damage the skin or eyes if precautions are not taken. Burns are also a hazard with hot forging. Precautions include good tools, eye protection, routine clean-up, proper work clothing, isolation of the forging area and wearing ear plugs or ear muffs.

Hot forging involves the burning of gas, coke or other fuels. A canopy hood for ventilation is needed to exhaust carbon monoxide and possible polycyclic aromatic hydrocarbon emissions, and to reduce heat build-up. Infrared goggles should be worn for protection against infrared radiation.

Surface treatment

Mechanical treatment (chasing, repousse) is done with hammers, engraving with sharp tools, etching with acids, photoetching with acids and photochemicals, electroplating (plating a metallic film onto another metal) and electroforming (plating a metallic film onto a non-metallic object) with acids and cyanide solutions and metal colouring with many chemicals.

Electroplating and electroforming often use cyanide salts, ingestion of which can be fatal. Accidental mixing of acids and the cyanide solution will produce hydrogen cyanide gas. This is hazardous through both skin absorption and inhalation—death can occur within minutes. Disposal and waste management of spent cyanide solutions is strictly regulated in many countries. Electroplating with cyanide solutions should be done in a commercial plant; otherwise use substitutes that do not contain cyanide salts or other cyanide-containing materials.

Acids are corrosive, and skin and eye protection is needed. Local exhaust ventilation with acid-resistant ductwork is recommended.

Anodizing metals such as titanium and tantalum involves oxidizing these at the anode of an electrolytic bath to colour them. Hydrofluoric acid can be used for precleaning. Avoid using hydrofluoric acid or use gloves, goggles and a protective apron.

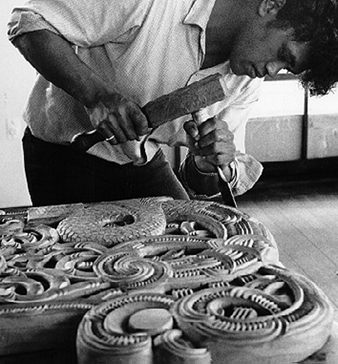

Patinas used to colour metals can be applied cold or hot. Lead and arsenic compounds are very toxic in any form, and others can give off toxic gases when heated. Potassium ferricyanide solutions will give off hydrogen cyanide gas when heated, arsenic acid solutions give off arsine gas and sulphide solutions give off hydrogen sulphide gas. Very good ventilation is needed for metal colouring (figure 2). Arsenic compounds and heating of potassium ferrocyanide solutions should be avoided.

Figure 2. Applying a patina to metal with slot exhaust hood.

Ken Jones

Finishing processes

Cleaning, grinding, filing, sandblasting and polishing are some final treatments for metal. Cleaning involves the use of acids (pickling). This involves the hazards of handling acids and of the gases produced during the pickling process (such as nitrogen dioxide from nitric acid). Grinding can result in the production of fine metal dusts (which can be inhaled) and heavy flying particles (which are eye hazards).

Sandblasting (abrasive blasting) is very hazardous, particularly with actual sand. Inhalation of fine silica dust from sandblasting can cause silicosis in a short time. Sand should be replaced with glass beads, aluminium oxide or silicon carbide. Foundry slags should be used only if chemical analysis shows no silica or dangerous metals such as arsenic or nickel. Good ventilation or respiratory protection is needed.

Polishing with abrasives such as rouge (iron oxide) or tripoli can be hazardous since rouge can be contaminated with large amounts of free silica, and tripoli contains silica. Good ventilation of the polishing wheel is needed.

Welding

Physical hazards in welding include the danger of fire, electric shock from arc-welding equipment, burns caused by molten metal sparks, and injuries caused by excessive exposure to infrared and ultraviolet radiation. Welding sparks can travel 40 feet.

Infrared radiation can cause burns and eye damage. Ultraviolet radiation can cause sunburn; repeated exposure may lead to skin cancer. Electric arc welders in particular are subject to pink eye (conjunctivitis), and some have cornea damage from UV exposure. Skin protection and welding goggles with UV- and IR-protective lenses are needed.

Oxyacetylene torches produce carbon monoxide, nitrogen oxides and unburned acetylene, which is a mild intoxicant. Commercial acetylene contains small amounts of other toxic gases and impurities.

Compressed gas cylinders can be both explosive and fire hazards. All cylinders, connections and hoses must be carefully maintained and inspected. All gas cylinders must be stored in a location which is dry, well ventilated and secure from unauthorized persons. Fuel cylinders must be stored separately from oxygen cylinders.

Arc welding produces enough energy to convert the air’s nitrogen and oxygen to nitrogen oxides and ozone, which are lung irritants. When arc welding is done within 20 feet of chlorinated degreasing solvents, phosgene gas can be produced by the UV radiation.

Metal fumes are generated by the vaporization of metals, metal alloys and the electrodes used in arc welding. Fluoride fluxes produce fluoride fumes.

Ventilation is needed for all welding processes. While dilution ventilation may be adequate for mild steel welding, local exhaust ventilation is necessary for most welding operations. Moveable flanged hoods, or lateral slot hoods should be used. Respiratory protection is needed if ventilation is not available.

Many metal dusts and fumes can cause skin irritation and sensitization. These include brass dust (copper, zinc, lead and tin), cadmium, nickel, titanium and chromium.

In addition, there are problems with welding materials that may be coated with various substances (e.g., lead or mercury paint).

Aerospace Medicine: Effects of Gravity, Acceleration, and Microgravity in the Aerospace Environment

Since the first sustained flight of a powered aircraft at Kitty Hawk, North Carolina (United States), in 1903, aviation has become a major international activity. It is estimated that from 1960 to 1989, the annual number of air passengers of regularly scheduled flights increased from 20 million to over 900 million (Poitrast and deTreville 1994). Military aircraft have become indispensable weapons systems for the armed forces of many nations. Advances in aviation technology, in particular the design of life support systems, have contributed to the rapid development of space programmes with human crews. Orbital space flights occur relatively frequently, and astronauts and cosmonauts work in space vehicles and space stations for extended periods of time.

In the aerospace environment, physical stressors that may affect the health of aircrew, passengers and astronauts to some degree include reduced concentrations of oxygen in the air, decreased barometric pressure, thermal stress, acceleration, weightlessness and a variety of other potential hazards (DeHart 1992). This article describes aeromedical implications of exposure to gravity and acceleration during flight in the atmosphere and the effects of microgravity experienced in space.

Gravity and Acceleration

The combination of gravity and acceleration encountered during flight in the atmosphere produces a variety of physiological effects experienced by aircrew and passengers. At the surface of the earth, the forces of gravity affect virtually all forms of human physical activity. The weight of a person corresponds to the force exerted upon the mass of the human body by the earth’s gravitational field. The symbol used to express the magnitude of the acceleration of an object in free fall when it is dropped near the earth’s surface is referred to as g, which corresponds to an acceleration of approximately 9.8 m/s2 (Glaister 1988a; Leverett and Whinnery 1985).

Acceleration occurs whenever an object in motion increases its velocity. Velocity describes the rate of movement (speed) and direction of motion of an object. Deceleration refers to acceleration that involves a reduction in established velocity. Acceleration (as well as deceleration) is a vector quantity (it has magnitude and direction). There are three types of acceleration: linear acceleration, a change of speed without change in direction; radial acceleration, a change in direction without a change of speed; and angular acceleration, a change in speed and direction. During flight, aircraft are capable of manoeuvring in all three directions, and crew and passengers may experience linear, radial and angular accelerations. In aviation, applied accelerations are commonly expressed as multiples of the acceleration due to gravity. By convention, G is the unit expressing the ratio of an applied acceleration to the gravitational constant (Glaister 1988a; Leverett and Whinnery 1985).

Biodynamics

Biodynamics is the science dealing with the force or energy of living matter and is a major area of interest within the field of aerospace medicine. Modern aircraft are highly manoeuvrable and capable of flying at very high speeds, causing accelerative forces upon the occupants. The influence of acceleration upon the human body depends upon the intensity, rate of onset and direction of acceleration. The direction of acceleration is generally described by the use of a three-axis coordinate system (x, y, z) in which the vertical (z) axis is parallel to the long axis of the body, the x axis is oriented from front to back, and the y axis oriented side to side (Glaister 1988a). These accelerations can be categorized into two general types: sustained and transitory.

Sustained acceleration

The occupants of aircraft (and spacecraft operating in the atmosphere under the influence of gravity during launch and re-entry) commonly experience accelerations in response to aerodynamic forces of flight. Prolonged changes in velocity involving accelerations lasting longer than 2 seconds may result from changes in an aircraft’s speed or direction of flight. The physiological effects of sustained acceleration result from the sustained distortion of tissues and organs of the body and changes in the flow of blood and distribution of body fluids (Glaister 1988a).

Positive or headward acceleration along the z axis (+Gz) represents the major physiological concern. In civil air transportation, Gz accelerations are infrequent, but may occasionally occur to a mild degree during some take-offs and landings, and while flying in conditions of air turbulence. Passengers may experience brief sensations of weightlessness when subject to sudden drops (negative Gz accelerations), if unrestrained in their seats. An unexpected abrupt acceleration may cause unrestrained aircrew or passengers to be thrown against internal surfaces of the aircraft cabin, resulting in injuries.

In contrast to civil transport aviation, the operation of high- performance military aircraft and stunt and aerial spray planes may generate significantly higher linear, radial and angular accelerations. Substantial positive accelerations may be generated as a high-performance aircraft changes its flight path during a turn or a pull-up manoeuvre from a steep dive. The +Gz performance characteristics of current combat aircraft may expose occupants to positive accelerations of 5 to 7 G for 10 to 40 seconds (Glaister 1988a). Aircrew may experience an increase in the weight of tissues and of the extremities at relatively low levels of acceleration of only +2 Gz. As an example, a pilot weighing 70 kg who performed an aircraft manoeuvre which generated +2 Gz would experience an increase of body weight from 70 kg to 140 kg.

The cardiovascular system is the most important organ system for determining the overall tolerance and response to +Gz stress (Glaister 1988a). The effects of positive acceleration on vision and mental performance are due to decreases in blood flow and delivery of oxygen to eye and brain. The capability of the heart to pump blood to the eyes and brain is dependent upon its capability to exceed the hydrostatic pressure of blood at any point along the circulatory system and the inertial forces generated by the positive Gz acceleration. The situation may be likened to that of pulling upward a balloon partially full of water and observing the downward distension of the balloon because of the resultant inertial force acting upon the mass of water. Exposure to positive accelerations may cause temporary loss of peripheral vision or complete loss of consciousness. Military pilots of high- performance aircraft may risk development of G-induced blackouts when exposed to rapid onset or extended periods of positive acceleration in the +Gz axis. Benign cardiac arrhythmias frequently occur following exposure to high sustained levels of +Gz acceleration, but usually are of minimal clinical significance unless pre-existing disease is present; –Gz acceleration seldom occurs because of limitations in aircraft design and performance, but may occur during inverted flight, outside loops and spins and other similar manoeuvres. The physiological effects associated with exposure to –Gz acceleration primarily involve increased vascular pressures in the upper body, head and neck (Glaister 1988a).

Accelerations of sustained duration which act at right angles to the long axis of the body are termed transverse accelerations and are relatively uncommon in most aviation situations, with the exception of catapult and jet- or rocket-assisted take-offs from aircraft carriers, and during launch of rocket systems such as the space shuttle. The accelerations encountered in such military operations are relatively small, and usually do not affect the body in a major fashion because the inertial forces act at right angles to the long axis of the body. In general, the effects are less pronounced than in Gz accelerations. Lateral acceleration in ±Gy axis are uncommon, except with experimental aircraft.

Transitory acceleration

The physiological responses of individuals to transitory accelerations of short duration are a major consideration in the science of aircraft accident prevention and crew and passenger protection. Transitory accelerations are of such brief duration (considerably less than 1 second) that the body is unable to attain a steady-state status. The most common cause of injury in aircraft accidents results from the abrupt deceleration that occurs when an aircraft impacts the ground or water (Anton 1988).

When an aircraft impacts the ground, a tremendous amount of kinetic energy applies damaging forces to the aircraft and its occupants. The human body responds to these applied forces by a combination of acceleration and strain. Injuries result from deformation of tissues and organs and trauma to anatomic parts caused by collision with structural components of the aircraft cockpit and/or cabin.

Human tolerance to abrupt deceleration is variable. The nature of injuries will depend on the nature of the applied force (whether it primarily involves penetrating or blunt impact). At impact, the forces which are generated are dependent on the longitudinal and horizontal decelerations which are generally applied to an occupant. Abrupt decelerative forces are often categorized into tolerable, injurious and fatal. Tolerable forces produce traumatic injuries such as abrasions and bruises; injurious forces produce moderate to severe trauma which may not be incapacitating. It is estimated that an acceleration pulse of approximately 25 G maintained for 0.1 second is the limit of tolerability along the +Gz axis, and that about 15 G for 0.1 sec is the limit for the –Gz axis (Anton 1988).

Multiple factors affect human tolerance to short-duration acceleration. These factors include the magnitude and duration of the applied force, the rate of onset of the applied force, its direction and the site of application. It should be noted that people can withstand much greater forces perpendicular to the long axis of the body.

Protective Countermeasures

Physical screening of crew members to identify serious pre- existing diseases which might put them at increased risk in the aerospace environment is a key function of aeromedical programmes. In addition, countermeasures are available to crew of high-performance aircraft to protect against the adverse effects of extreme accelerations during flight. Crew members must be trained to recognize that multiple physiological factors may decrease their tolerance to G stress. These risk factors include fatigue, dehydration, heat stress, hypoglycemia and hypoxia (Glaister 1988b).

Three types of manoeuvres which crew members of high- performance aircraft employ to minimize adverse effects of sustained acceleration during flight are muscle tensing, forced expiration against a closed or partially closed glottis (back of the tongue) and positive-pressure breathing (Glaister 1988b; DeHart 1992). Forced muscle contractions exert increased pressure on blood vessels to decrease venous pooling and increase venous return and cardiac output, resulting in increased blood flow to the heart and upper body. While effective, the procedure requires extreme, active effort and may rapidly result in fatigue. Expiration against a closed glottis, termed the Valsalva manoeuver (or M-1 procedure) can increase pressure in the upper body and raise the intrathoracic pressure (inside the chest); however, the result is short lived and may be detrimental if prolonged, because it reduces venous blood return and cardiac output. Forcibly exhaling against a partially closed glottis is a more effective anti-G straining manoeuver. Breathing under positive pressure represents another method to increase intrathoracic pressure. Positive pressures are transmitted to the small artery system, resulting in increased blood flow to the eyes and brain. Positive-pressure breathing must be combined with the use of anti-G suits to prevent excessive pooling in the lower body and limbs.

Military aircrew practise a variety of training methods to enhance G tolerance. Crews frequently train in a centrifuge consisting of a gondola attached to a rotating arm which spins and generates +Gz acceleration. Aircrew become familiar with the spectrum of physiological symptoms which may develop and learn the proper procedures to control them. Physical fitness training, particularly whole-body strength training, also has been found to be effective. One of the most common mechanical devices used as protective equipment to reduce the effects of +G exposure consists of pneumatically inflated anti-G suits (Glaister 1988b). The typical trouser-like garment consists of bladders over the abdomen, thighs and calves which automatically inflate by means of an anti-G valve in the aircraft. The anti-G valve inflates in reaction to an applied acceleration upon the aircraft. Upon inflation, the anti-G suit produces a rise in the tissue pressures of the lower extremities. This maintains peripheral vascular resistance, reduces the pooling of blood in the abdomen and lower limbs and minimizes downward displacement of the diaphragm to prevent the increase in the vertical distance between the heart and brain that may be caused by positive acceleration (Glaister 1988b).