Children categories

64. Agriculture and Natural Resources Based Industries (34)

64. Agriculture and Natural Resources Based Industries

Chapter Editor: Melvin L. Myers

Table of Contents

Tables and Figures

General Profile

Melvin L. Myers

Case Study: Family Farms

Ted Scharf, David E. Baker and Joyce Salg

Farming Systems

Plantations

Melvin L. Myers and I.T. Cabrera

Migrant and Seasonal Farmworkers

Marc B. Schenker

Urban Agriculture

Melvin L. Myers

Greenhouse and Nursery Operations

Mark M. Methner and John A. Miles

Floriculture

Samuel H. Henao

Farmworker Education about Pesticides: A Case Study

Merri Weinger

Planting and Growing Operations

Yuri Kundiev and V.I. Chernyuk

Harvesting Operations

William E. Field

Storing and Transportation Operations

Thomas L. Bean

Manual Operations in Farming

Pranab Kumar Nag

Mechanization

Dennis Murphy

Case Study: Agricultural Machinery

L. W. Knapp, Jr.

Food and Fibre Crops

Rice

Malinee Wongphanich

Agricultural Grains and Oilseeds

Charles Schwab

Sugar Cane Cultivation and Processing

R.A. Munoz, E.A. Suchman, J.M. Baztarrica and Carol J. Lehtola

Potato Harvesting

Steven Johnson

Vegetables and Melons

B.H. Xu and Toshio Matsushita

Tree, Bramble and Vine Crops

Berries and Grapes

William E. Steinke

Orchard Crops

Melvin L. Myers

Tropical Tree and Palm Crops

Melvin L. Myers

Bark and Sap Production

Melvin L. Myers

Bamboo and Cane

Melvin L. Myers and Y.C. Ko

Specialty Crops

Tobacco Cultivation

Gerald F. Peedin

Ginseng, Mint and Other Herbs

Larry J. Chapman

Mushrooms

L.J.L.D. Van Griensven

Aquatic Plants

Melvin L. Myers and J.W.G. Lund

Beverage Crops

Coffee Cultivation

Jorge da Rocha Gomes and Bernardo Bedrikow

Tea Cultivation

L.V.R. Fernando

Hops

Thomas Karsky and William B. Symons

Health and Environmental Issues

Health Problems and Disease Patterns in Agriculture

Melvin L. Myers

Case Study: Agromedicine

Stanley H. Schuman and Jere A. Brittain

Environmental and Public Health Issues in Agriculture

Melvin L. Myers

Tables

Click a link below to view table in article context.

1. Sources of nutrients

2. Ten steps for a plantation work risk survey

3. Farming systems in urban areas

4. Safety advice for lawn & garden equipment

5. Categorization of farm activities

6. Common tractor hazards & how they occur

7. Common machinery hazards & where they occur

8. Safety precautions

9. Tropical & subtropical trees, fruits & palms

10. Palm products

11. Bark & sap products & uses

12. Respiratory hazards

13. Dermatological hazards

14. Toxic & neoplastic hazards

15. Injury hazards

16. Lost time injuries, United States, 1993

17. Mechanical & thermal stress hazards

18. Behavioural hazards

19. Comparison of two agromedicine programmes

20. Genetically engineered crops

21. Illicit drug cultivation, 1987, 1991 & 1995

Figures

Point to a thumbnail to see figure caption, click to see the figure in the article context.

65. Beverage Industry (10)

65. Beverage Industry

Chapter Editor: Lance A. Ward

Table of Contents

Tables and Figures

General Profile

David Franson

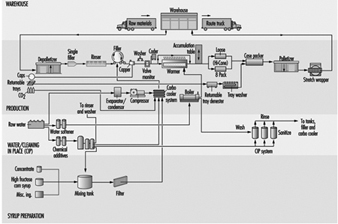

Soft Drink Concentrate Manufacturing

Zaida Colon

Soft Drink Bottling and Canning

Matthew Hirsheimer

Coffee Industry

Jorge da Rocha Gomes and Bernardo Bedrikow

Tea Industry

Lou Piombino

Distilled Spirits Industry

R.G. Aldi and Rita Seguin

Wine Industry

Alvaro Durao

Brewing Industry

J.F. Eustace

Health and Environmental Concerns

Lance A. Ward

Tables

Click a link below to view table in article context.

1. Selected coffee importers (in tonnes)

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

66. Fishing (10)

66. Fishing

Chapter Editors: Hulda Ólafsdóttir and Vilhjálmur Rafnsson

Table of Contents

Tables and Figures

General Profile

Ragnar Arnason

Case Study: Indigenous Divers

David Gold

Major Sectors and Processes

Hjálmar R. Bárdarson

Psychosocial Characteristics of the Workforce at Sea

Eva Munk-Madsen

Psychosocial Characteristics of the Workforce in On-Shore Fish Processing

Marit Husmo

Social Effects of One-Industry Fishery Villages

Barbara Neis

Health Problems and Disease Patterns

Vilhjálmur Rafnsson

Musculoskeletal Disorders Among Fishermen and Workers in the Fish Processing Industry

Hulda Ólafsdóttir

Commercial Fisheries: Environmental and Public Health Issues

Bruce McKay and Kieran Mulvaney

Tables

Click a link below to view table in article context.

1. Mortality figures on fatal injuries among fishermen

2. The most important jobs or places related to risk of injuries

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

67. Food Industry (11)

67. Food Industry

Chapter Editor: Deborah E. Berkowitz

Table of Contents

Tables and Figures

Overview and Health Effects

Food Industry Processes

M. Malagié, G. Jensen, J.C. Graham and Donald L. Smith

Health Effects and Disease Patterns

John J. Svagr

Environmental Protection and Public Health Issues

Jerry Spiegel

Food Processing Sectors

Meatpacking/Processing

Deborah E. Berkowitz and Michael J. Fagel

Poultry Processing

Tony Ashdown

Dairy Products Industry

Marianne Smukowski and Norman Brusk

Cocoa Production and the Chocolate Industry

Anaide Vilasboas de Andrade

Grain, Grain Milling and Grain-Based Consumer Products

Thomas E. Hawkinson, James J. Collins and Gary W. Olmstead

Bakeries

R.F. Villard

Sugar-Beet Industry

Carol J. Lehtola

Oil and Fat

N.M. Pant

Tables

Click a link below to view table in article context.

1. The food industries, their raw materials & processes

2. Common occupational diseases in the food & drink industries

3. Types of infections reported in food & drink industries

4. Examples of uses for by-products from the food industry

5. Typical water reuse ratios for different industry sub-sectors

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

68. Forestry (17)

68. Forestry

Chapter Editor: Peter Poschen

Table of Contents

Tables and Figures

General Profile

Peter Poschen

Wood Harvesting

Dennis Dykstra and Peter Poschen

Timber Transport

Olli Eeronheimo

Harvesting of Non-wood Forest Products

Rudolf Heinrich

Tree Planting

Denis Giguère

Forest Fire Management and Control

Mike Jurvélius

Physical Safety Hazards

Bengt Pontén

Physical Load

Bengt Pontén

Psychosocial Factors

Peter Poschen and Marja-Liisa Juntunen

Chemical Hazards

Juhani Kangas

Biological Hazards among Forestry Workers

Jörg Augusta

Rules, Legislation, Regulations and Codes of Forest Practices

Othmar Wettmann

Personal Protective Equipment

Eero Korhonen

Working Conditions and Safety in Forestry Work

Lucie Laflamme and Esther Cloutier

Skills and Training

Peter Poschen

Living Conditions

Elías Apud

Environmental Health Issues

Shane McMahon

Tables

Click a link below to view table in article context.

1. Forest area by region (1990)

2. Non-wood forest product categories & examples

3. Non-wood harvesting hazards & examples

4. Typical load carried while planting

5. Grouping of tree-planting accidents by body parts affected

6. Energy expenditure in forestry work

7. Chemicals used in forestry in Europe & North America in the 1980s

8. Selection of infections common in forestry

9. Personal protective equipment appropriate for forestry operations

10. Potential benefits to environmental health

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

69. Hunting (2)

69. Hunting

Chapter Editor: George A. Conway

Table of Contents

Tables

A Profile of Hunting and Trapping in the 1990s

John N. Trent

Diseases Associated with Hunting and Trapping

Mary E. Brown

Tables

Click a link below to view table in article context.

1. Examples of diseases potentially significant to hunters & trappers

70. Livestock Rearing (21)

70. Livestock Rearing

Chapter Editor: Melvin L. Myers

Table of Contents

Tables and Figures

Livestock Rearing: Its Extent and Health Effects

Melvin L. Myers

Health Problems and Disease Patterns

Kendall Thu, Craig Zwerling and Kelley Donham

Case Study: Arthopod-related Occupational Health Problems

Donald Barnard

Forage Crops

Lorann Stallones

Livestock Confinement

Kelley Donham

Animal Husbandry

Dean T. Stueland and Paul D. Gunderson

Case Study: Animal Behaviour

David L. Hard

Manure and Waste Handling

William Popendorf

A Checklist for Livestock Rearing Safety Practice

Melvin L. Myers

Dairy

John May

Cattle, Sheep and Goats

Melvin L. Myers

Pigs

Melvin L. Myers

Poultry and Egg Production

Steven W. Lenhart

Case Study: Poultry Catching, Live Hauling and Processing

Tony Ashdown

Horses and Other Equines

Lynn Barroby

Case Study: Elephants

Melvin L. Myers

Draught Animals in Asia

D.D. Joshi

Bull Raising

David L. Hard

Pet, Furbearer and Laboratory Animal Production

Christian E. Newcomer

Fish Farming and Aquaculture

George A. Conway and Ray RaLonde

Beekeeping, Insect Raising and Silk Production

Melvin L. Myers and Donald Barnard

Tables

Click a link below to view table in article context.

1. Livestock uses

2. International livestock production (1,000 tonnes)

3. Annual US livestock faeces & urine production

4. Types of human health problems associated with livestock

5. Primary zoonoses by world region

6. Different occupations & health & safety

7. Potential arthropod hazards in the workplace

8. Normal & allergic reactions to insect sting

9. Compounds identified in swine confinement

10. Ambient levels of various gases in swine confinement

11. Respiratory diseases associated with swine production

12. Zoonotic diseases of livestock handlers

13. Physical properties of manure

14. Some important toxicologic benchmarks for hydrogen sulphide

15. Some safety procedures related to manure spreaders

16. Types of ruminants domesticated as livestock

17. Livestock rearing processes & potential hazards

18. Respiratory illnesses from exposures on livestock farms

19. Zoonoses associated with horses

20. Normal draught power of various animals

Figures

Point to a thumbnail to see figure caption, click to see the figure in article context.

71. Lumber (4)

71. Lumber

Chapter Editors: Paul Demers and Kay Teschke

Table of Contents

Tables and Figures

General Profile

Paul Demers

Major Sectors and Processes: Occupational Hazards and Controls

Hugh Davies, Paul Demers, Timo Kauppinen and Kay Teschke

Disease and Injury Patterns

Paul Demers

Environmental and Public Health Issues

Kay Teschke and Anya Keefe

Tables

Click a link below to view the table in the article context.

1. Estimated wood production in 1990

2. Estimated production of lumber for the 10 largest world producers

3. OHS hazards by lumber industry process area

Figures

Point to a thumbnail to see figure caption, click to see the figure in article context.

72. Paper and Pulp Industry (13)

72. Paper and Pulp Industry

Chapter Editors: Kay Teschke and Paul Demers

Table of Contents

Tables and Figures

General Profile

Kay Teschke

Major Sectors and Processes

Fibre Sources for Pulp and Paper

Anya Keefe and Kay Teschke

Wood Handling

Anya Keefe and Kay Teschke

Pulping

Anya Keefe, George Astrakianakis and Judith Anderson

Bleaching

George Astrakianakis and Judith Anderson

Recycled Paper Operations

Dick Heederik

Sheet Production and Converting: Market Pulp, Paper, Paperboard

George Astrakianakis and Judith Anderson

Power Generation and Water Treatment

George Astrakianakis and Judith Anderson

Chemical and By-product Production

George Astrakianakis and Judith Anderson

Occupational Hazards and Controls

Kay Teschke, George Astrakianakis, Judith Anderson, Anya Keefe and Dick Heederik

Disease and Injury Patterns

Injuries and Non-malignant Diseases

Susan Kennedy and Kjell Torén

Cancer

Kjell Torén and Kay Teschke

Environmental and Public Health Issues

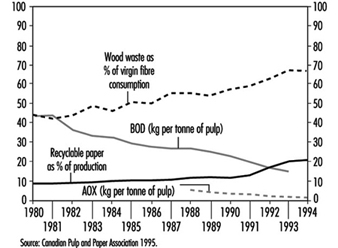

Anya Keefe and Kay Teschke

Tables

Click a link below to view table in article context.

1. Employment & production in selected countries (1994)

2. Chemical constituents of pulp & paper fibre sources

3. Bleaching agents & their conditions of use

4. Papermaking additives

5. Potential health & safety hazards by process area

6. Studies on lung & stomach cancer, lymphoma & leukaemia

7. Suspensions & biological oxygen demand in pulping

Figures

Point to a thumbnail to see figure caption, click to see figure in article context.

General Profile

Overview of the Sector

The beverage industry consists of two major categories and eight sub-groups. The non-alcoholic category is comprised of soft drink syrup manufacture; soft drink and water bottling and canning; fruit juices bottling, canning and boxing; the coffee industry and the tea industry. Alcoholic beverage categories include distilled spirits, wine and brewing.

Evolution of the industry

Although many of these beverages, including beer, wine and tea, have been around for thousands of years, the industry has developed only over the past few centuries.

The beverage products industry, viewed as an aggregate group, is highly fragmented. This is evident by the number of manufacturers, methods of packaging, production processes and final products. The soft drink industry is the exception to the rule, as it is quite concentrated. Although the beverage industry is fragmented, ongoing consolidation since the 1970s is changing that.

Since the early 1900s beverage companies have evolved from regional firms that mainly produced goods for local markets, to today’s corporate giants that make products for international markets. This shift began when companies in this manufacturing sector adopted mass production techniques that let them expand. Also during this time period there were advances in product packaging and processes that greatly increased product shelf life. Air-tight containers for tea prevented absorption of moisture, which is the principle cause of loss of flavour. In addition, the advent of refrigeration equipment enabled lager beers to be brewed during the summer months.

Economic importance

The beverage industry employs several million people worldwide, and each type of beverage grosses billions of dollars in revenue each year. Indeed, in several small, developing countries, the production of coffee is the major support of the entire economy.

Characteristics of the Workforce

Though the ingredients and production of beverages vary, generally the characteristics of those employed in this industry have many commonalties. The process of harvesting raw materials, whether they be coffee beans, barley, hops or grapes, employs low-income, unskilled individuals or families. In addition to being their main source of income, the harvest determines a large part of their culture and lifestyle.

In contrast, the processing of the product involves automated and mechanized operations, usually employing a semi-skilled, blue-collar workforce. In the production facility and warehouse areas, some of the common jobs include packaging and filling machine operator, fork-lift operator, mechanic and manual labourer. The training for these positions is completed onsite with extensive on-the-job instruction. As technology and automation evolve, the workforce diminishes in number and technical training becomes more important. This semi-skilled manufacturing workforce is usually supported by a highly skilled technical group consisting of industrial engineers, manufacturing managers, cost accountants and quality assurance/food safety technicians.

The beverage industry for the most part distributes its products to wholesalers using common carriers. However, soft drink manufacturers usually employ drivers to deliver their products directly to individual retailers. These drivers-salesworkers account for about one-seventh of the workers in the soft drink industry.

The more health-conscious atmosphere in Europe and North America in the 1990s has led to a flat market in the alcoholic beverage industry, with demand shifting to non-alcoholic beverages. Both alcoholic and non-alcoholic beverages, however, are expanding considerably in developing nations in Asia, South America and to some extent Africa. Because of this expansion, numerous local jobs are being created to meet production and distribution needs.

Meatpacking/Processing

Sources of meat slaughtered for human consumption include cattle, hogs, sheep, lambs and, in some countries, horses and camels. The size and production of slaughterhouses vary considerably. Except for very small operations located in rural areas, animals are slaughtered and processed in factory-type workplaces. These workplaces are usually subject to food-safety controls by the local government to prevent bacterial contamination that can cause foodborne illnesses in consumers. Examples of known pathogens in meat include salmonella and Escherichia coli. In these meat processing plants the work has become very specialized, with almost all the work being done on production disassembly lines where the meat moves on chains and conveyors, and each worker does only one operation. Almost all the cutting and processing is still done by workers. Production jobs can require between 10,000 and 20,000 cuts a day. In some large plants in the United States, for example, a few jobs, such as carcass splitting and bacon slicing, have been automated.

Slaughtering Process

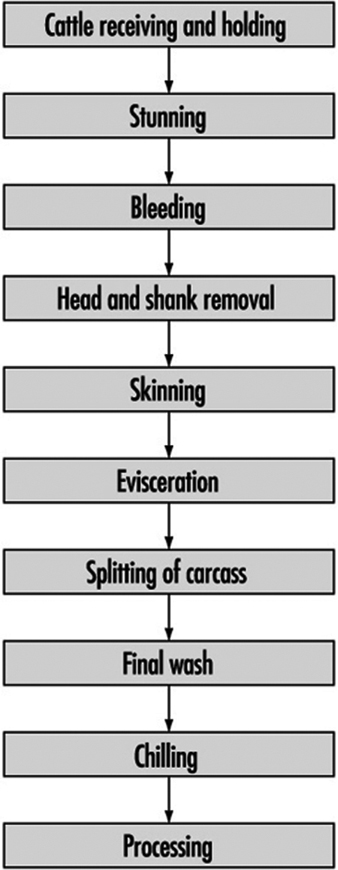

The animals are herded through a holding pen to slaughter (see figure 1). The animal must be stunned before being bled, unless slaughtered in accordance with Jewish or Muslim rites. Usually the animal is either knocked to an unconscious state with a bolt stunner gun or with a stunner gun utilizing compressed air that drives a pin into the head (the medulla oblongata) of the animal. After the stunning or “knocking” process, one of the animal’s hind legs is secured by a chain hooked onto an overhead conveyor which transfers the animal to the next room, where it is bled by “sticking” the jugular arteries in the neck with a sharp knife. The bleeding-out process follows, and the blood is drained through pipes for processing on floors below.

Figure 1. Beef slaughtering flow chart

The skin (hide) is removed by a series of cuts with knives (new air-powered knives are being used in the larger plants for some hide-removal operations) and the animal is then suspended by both hind legs from the overhead conveyor system. In some hog operations, the skin is not removed at this stage. Rather the hair is removed by sending the carcass through tanks of water heated to 58 ºC and then through a dehair machine that rubs the hair off the skin. Any remaining hair is removed by singeing and finally shaving.

The front legs and then the viscera (intestines) are removed. The head is then cut and dropped, and the carcass is split in half vertically along the spinal column. Hydraulic band saws are the usual tool for this job. After the carcass is split, it is rinsed with hot water, and may be steam vacuumed or even treated with a newly developed pasteurization process being introduced in some countries.

Government health inspectors usually inspect after the head removal, the viscera removal and the carcass splitting and final wash.

After this, the carcass, still hanging from the overhead conveyor system, moves to a cooler for chilling over the next 24 to 36 hours. The temperature is usually about 2 ºC to slow bacterial growth and inhibit spoilage.

Processing

Once chilled, the carcass halves are then cut into front and hind quarters. After this, pieces are further divided into prime cuts, depending on customer specifications. Some quarters are processed for delivery as the front or hind quarters without any further significant trimming. These pieces can weigh from 70 to 125 kg. Many plants (in the United States, the majority of plants) conduct further processing of the meat (some plants do only this processing and receive their meat from slaughterhouses). Products from these plants are shipped in boxes weighing approximately 30 kg.

Cutting is done by hand or powered saws, depending on the cuts, usually following trimming operations to remove skin. Many plants also use large grinders for grinding hamburger and other ground meats. Further processing can involve equipment including bacon presses, ham tumblers and extruders, bacon slicers, electric meat tenderizers and smoke houses. Conveyor belts and screw augers are often used to transport product. Processing areas are also kept cool, with temperatures in the 4 °C range.

Offal meats, such as liver, hearts, sweetbreads, tongues and glands, are processed in a separate area.

Many plants also treat the hides before sending them to a tanner.

Hazards and Their Prevention

Meatpacking has one of the highest rates of injury of all industries. A worker may be injured by the moving animals as they are led through the holding pen into the plant. Adequate training must be given to workers on handling live animals, and minimal worker exposure in this process is advised. Stunner guns may prematurely or inadvertently discharge while workers try to still the animals. Falling animals and nervous system reactions in stunned cattle that cause jerking present hazards to workers in the area. Further, many operations utilize a series of hooks, chains and conveyor tram rails to move the product between processing steps, posing the hazard of falling carcasses and product.

Adequate maintenance of all equipment is necessary, especially equipment used to move meat. Such equipment must be checked frequently and repaired as needed. Adequate safeguards for knocking guns, such as safety switches and making sure there is no blow back, must be taken. Workers involved in knocking and sticking operations must be trained on the hazards of this job, as well as provided with guarded knives and protective equipment to prevent injury. For sticking operations this includes arm guards, mesh gloves and special guarded knives.

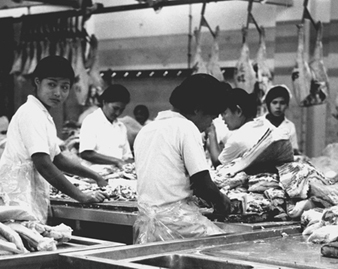

Both in the slaughter and further processing of animals, hand knives and mechanical cutting devices are used. Mechanical cutting devices include head splitters, bone splitters, snout pullers, electric band and circular saws, electric- or air-powered circular-blade knives, grinding machines and bacon processors. These types of operations have a high rate of injury, from knife cuts to amputations, because of the speed at which workers operate, the inherent danger of the tools being used and the often slippery nature of the product from fat and wet processes. Workers can be cut by their own knives and by other workers’ knives during the butchering process (see figure 2).

Figure 2. Cutting and sorting meat without protective equipment in a Thai meat packing factory

The above operations require protective equipment, including protective helmets, footwear, mesh gloves and aprons, wrist and forearm guards and waterproof aprons. Protective goggles may be required during boning, trimming and cutting operations to prevent foreign objects from entering workers’ eyes. Metal mesh gloves must not be used while operating any type of powered or electrical saw. Powered saws and tools must have proper safety guards, such as blade guards and shut-off switches. Unguarded sprockets and chains, conveyor belts and other equipment can pose a hazard. All such equipment must be properly guarded. Hand knives should also have guards to prevent the hand holding the knife from slipping over the blade. Training and adequate spacing between workers is necessary to conduct operations safely.

Workers maintaining, cleaning or unjamming equipment such as conveyor belts, bacon processors, meat grinders and other processing equipment are subject to the hazard of the inadvertent start-up of equipment. This has caused fatalities and amputations. Some equipment is cleaned while running, subjecting workers to the hazard of getting caught in the machinery.

Workers must be trained in safety lockout/tagout procedures. Implementation of procedures that prevent workers from fixing, cleaning or unjamming equipment until the equipment is off and locked out will prevent injuries. Workers involved in locking out pieces of equipment must be trained on procedures for neutralizing all energy sources.

Wet and treacherously slippery floors and stairs throughout the plant pose a serious hazard to workers. Elevated work platforms also pose a falling hazard. Workers must be provided with safety shoes with non-slip soles. Non-slip floor surfaces and roughened floors, approved by local health agencies, are available and should be used on floors and stairways. Adequate drainage in wet areas must be provided, along with proper and adequate housekeeping of floors during production hours to minimize wet and slippery surfaces. All elevated surfaces must also be properly equipped with guard rails both to prevent workers from accidental falls and to prevent worker contact and materials falling from conveyors. Toe boards should also be used on elevated platforms, where necessary. Guardrails should also be used on stairways on the production floor to prevent slipping.

The combination of wet working conditions and elaborate electrical wiring poses a hazard of electrocution to workers. All equipment must be properly grounded. Electrical outlet boxes should be provided with covers which effectively protect against accidental contact. All electrical wiring should be checked periodically for cracking, fraying or other defects, and all electrical equipment should be grounded. Ground fault circuit interrupters should be used where possible.

Lugging of carcasses (which can weigh up to 140 kg) and repetitive lifting of 30 kg boxes of meat ready for shipping can cause back injuries. Cumulative trauma disorders such as carpal tunnel syndrome, tendinitis and tenosynovitis are widespread in the industry. In the United States, for example, meatpacking operations have higher rates of these disorders than any other industry. The wrist, elbow and shoulder are all affected. These disorders can arise from the highly repetitive and forceful nature of the assembly line work in the plants, the use of vibrating equipment in some jobs, the use of dull knives, the cutting of frozen meat and the use of high-pressure hoses in cleaning operations. Prevention of these disorders comes through ergonomic redesign of equipment, use of mechanical assists, vigilant maintenance of vibrating equipment to minimize vibration, and improved worker training and medical programmes. Ergonomic redesign measures include:

- lowering overhead conveyors to reduce repetitive overhead throws on production lines (see figure 3)

- moving horizontal platforms that allow workers to split animals with a minimum of reaches

- providing sharp knives with redesigned handles

- building mechanical assists that reduce the force of a job (see figure 4)

- increased staffing on high-force jobs, assuring properly sized hand tools and gloves and careful design of packing areas to minimize twisting when lifting, as well as to minimize lifting from below the knees and above the shoulders

- vacuum hoists and other mechanical lifting devices to reduce lifting of boxes (see figure 5).

Figure 3. With conveyer belts located beneath worktables, workers can push finished products through a hole in the table instead of having to throw meat over their heads

United Food & Commercial Workers, AFL-CIO

Figure 4. Having paddle bones pulled out by the force of an attached chain rather than manually lessens musculoskeletal hazards

United Food & Commercial Workers, AFL-CIO

Figure 5. The use of vacuum hoists for lifting boxes allows workers to guide boxes rather than load them by hand

United Food & Commercial Workers, AFL-CIO

Aisles and walkways should be dry and free of obstacles so that carrying and transporting heavy loads can be done safely.

Workers should be trained or proper use of knives. Cutting frozen meat should be avoided completely.

Early medical intervention and treatment for symptomatic workers is also desirable. Because of the similar nature of the stressors on jobs in this industry, job rotation must be used with caution. Job analyses must be carried out and reviewed to assure that the same muscle tendon groups are not used in different tasks. In addition, workers must be adequately trained in all jobs in any planned rotation.

Machines and equipment found in meatpacking plants produce a high level of noise. Workers must be provided with ear plugs, as well as hearing examinations to ascertain any potential hearing loss. Further, sound-dampening equipment should be used on machinery where possible. Good maintenance on conveyor systems can prevent unnecessary noise.

Workers can be exposed to toxic chemicals during the cleaning and sanitizing of equipment. Compounds used include both alkaline (caustic) and acid cleaners. These can cause dryness, allergic rashes and other skin problems. Liquids can splash up and burn the eyes. Depending on the type of cleaning compound used, PPE—including eye, face and arm coverings, aprons and protective footwear—must be provided. Hand and eye washing facilities should also be available. High-pressure hoses used to transport hot water for disinfecting equipment can also cause burns. Adequate worker training on the use of such hoses is important. Chlorine in the water used to wash the carcasses can also cause eye, throat and skin irritation. New anti-bacterial rinses are being introduced on the slaughter side to decrease bacteria that can cause foodborne illnesses. Adequate ventilation must be provided. Special care to assure that the strength of the chemicals does not exceed manufacturers’ instructions must be taken.

Ammonia is used as a refrigerant in the industry, and ammonia leaks from pipes are common. Ammonia gas is irritating to the eyes and skin. Mild to moderate exposure to the gas can produce headaches, burning in the throat, perspiration, nausea and vomiting. If escape is not possible, there may be severe irritation of the respiratory tract, producing cough, pulmonary oedema or respiratory arrest. Adequate maintenance of refrigeration lines is key to preventing such leaks. In addition, once an ammonia leak is detected, monitoring and evacuation procedures must be carried out to prevent dangerous exposures.

Carbon dioxide (CO2) in the form of dry ice is used in the packaging area. During this process, CO2 gas may escape from these vats and spread throughout the room. Exposure can cause headaches, dizziness, nausea, vomiting and, at high levels, death. Adequate ventilation must be provided.

Blood tanks present hazards associated with confined spaces if the plant does not utilize a closed piping and processing system for the blood. Toxic substances emitted from decomposing blood and lack of oxygen pose serious hazards to those having to enter and/or clean tanks or work in the area. Prior to entry, the atmosphere must be tested for toxic chemicals, and the presence of adequate oxygen must be assured.

Workers are exposed to infectious diseases such as brucellosis, erysipeloid, leptospirosis, dermatophytoses and warts.

Brucellosis is caused by a bacterium and is transmitted by the handling of infected cattle or swine. Persons infected by this bacterium experience constant or recurring fever, headaches, weakness, joint pain, night sweats and loss of appetite. Limiting the number of infected cattle slaughtered is one key to preventing this disorder.

Erysipeloid and leptospirosis are also caused by bacteria. Erysipeloid is transmitted by infection of skin puncture wounds, scratches and abrasions; it causes redness and irritation around the site of infection and can spread to the bloodstream and lymph nodes. Leptospirosis is transmitted through direct contact with infected animals or through water, moist soil or vegetation contaminated by the urine of infected animals. Muscular aches, eye infections, fever, vomiting, chills and headaches occur, and kidney and liver damage may develop.

Dermatophytosis, on the other hand, is a fungal disease and is transmitted by contact with the hair and skin of infected persons and animals. Dermatophytosis, also know as ringworm, causes the hair to fall out and small, yellowish cuplike crusts to develop on the scalp.

Verruca vulgaris, a wart caused by a virus, can be spread by infectious workers who have contaminated towels, meat, fish knives, work tables or other objects.

Other diseases that are found in meatpacking plants in some countries include Q fever and tuberculosis. The primary carriers of Q fever are cattle, sheep, goats and ticks. Humans are usually infected by inhaling aerosolized particles from contaminated environments. Typical symptoms include fever, malaise, severe headache and muscular and abdominal pain. The incidence of toxoplasma antibodies amongst abattoir workers is high in certain countries.

Dermatitis is also common in meatpacking plants. Exposure to blood and other animal fluids, exposure to wet conditions, and exposure to cleaning compounds used for cleaning/sanitation in facilities can lead to skin irritation.

Infectious diseases and dermatitis can be prevented with personal hygiene that includes ready and easy access to sanitation and hand-washing facilities that contain soap and disposable hand towels, the provision of proper PPE (which may include protective gloves as well as eye and respiratory protection where exposure to airborne animal body fluids is possible), the use of some barrier creams to provide limited protection against irritants, worker education and early medical care.

The kill floor, where the slaughtering, bleeding and splitting of the animal is done, can be especially hot and humid. A properly working ventilation system that removes the hot, humid air and prevents heat stress should be used. Fans, preferably overhead or roof fans, increase air movement. Beverages should be provided to replace fluids and salts lost through sweating, and frequent rest breaks, in a cool area, should be allowed.

There is also a distinctive smell in slaughterhouses, due to a mixture of odours such as those of wet leather, blood, vomit, urine and faeces of animals. This smell spreads throughout the kill floor, offal, rendering and hide areas. Exhaust ventilation is necessary to remove the odours.

Refrigerated work environments are essential in the meatpacking industry. Processing and transporting meat products generally require temperatures at or below 9 °C. Areas such as freezers may require temperatures to go as low as –40 °C. The most common cold-related injuries are frostnip, frostbite, immersion foot and trenchfoot, which occur in localized areas of the body. A serious consequence of cold stress is hypothermia. The respiratory system, the circulatory system and the osteoarticular system can also be affected by overexposure to the cold.

To prevent the consequences of cold stress and reduce the hazards of cold working conditions, workers should wear appropriate clothing, and the workplace should have proper equipment, administrative controls and engineering controls. Multiple layers of clothing provide better protection than single thick garments. Cooling equipment and air distribution systems should minimize air velocity. Unit coolers should be placed as far away from workers as possible, and wind deflectors and barriers should be used to protect workers from windchill.

Injuries and Non-malignant Diseases

Injuries

Only limited statistics are available on accident rates in general in this industry. Compared to other manufacturing industries, the 1990 accident rate in Finland was below the average; in Canada, the rates from 1990 to 1994 were similar to other industries; in the United States, the 1988 rate was slightly above average; in Sweden and Germany, the rates were 25% and 70% above the average (ILO 1992; Workers’ Compensation Board of British Columbia 1995).

The most commonly encountered risk factors for serious and fatal accidents in the pulp and paper industry are the papermaking equipment itself and the extreme size and weight of pulp or paper bales and rolls. In a 1993 United States government study of occupational fatalities from 1979 to 1984 in pulp, paper and paperboard mills (US Department of Commerce 1993), 28% were due to workers being caught in or between rotating rolls or equipment (“nip-points”) and

18% were due to workers being crushed by falling or tumbling objects, especially rolls and bales. Other causes of multiple deaths included electrocution, hydrogen sulphide and other toxic gas inhalation, massive thermal/chemical burns and one case of heat exhaustion. The number of serious accidents associated with paper machines has been reported to decrease with the installation of newer equipment in some countries. In the converting sector, repetitive and monotonous work, and the use of mechanized equipment with higher speeds and forces, has become more common. Although no sector-specific data are available, it is expected that this sector will experience greater rates of over-exertion injuries associated with repetitive work.

Non-Malignant Diseases

The most well documented health problems encountered by pulp mill workers are acute and chronic respiratory disorders (Torén, Hagberg and Westberg 1996). Exposure to extremely high concentrations of chlorine, chlorine dioxide or sulphur dioxide may occur as a result of a leak or other process upset. Exposed workers may develop acute chemical-induced lung injury with severe inflammation of air passages and release of fluid into the air spaces, requiring hospitalization. The extent of damage depends on the duration and intensity of the exposure, and the specific gas involved. If the worker survives the acute episode, complete recovery may occur. However, in less intense exposure incidents (also usually as a result of process upsets or spills), acute exposure to chlorine or chlorine dioxide may trigger the subsequent development of asthma. This irritant-induced asthma has been recorded in numerous case reports and recent epidemiological studies, and current evidence indicates that it may persist for many years following the exposure incident. Workers similarly exposed who do not develop asthma may experience persistently increased nasal irritation, cough, wheezing and reduction in airflow rates. Workers most at risk for these exposure incidents include maintenance workers, bleach plant workers and construction workers at pulp mill sites. High levels of chlorine dioxide exposure also cause eye irritation and the sensation of seeing halos around lights.

Some mortality studies have indicated increased risk of death from respiratory disease among pulp mill workers exposed to sulphur dioxide and paper dust (Jäppinen and Tola 1990; Torén, Järvholm and Morgan 1989). Increased respiratory symptoms have also been reported in sulphite mill workers who are chronically exposed to low levels of sulphur dioxide (Skalpe 1964), although increased airflow obstruction is not normally reported among pulp mill populations in general. Symptoms of respiratory irritation are also reported by workers exposed to high air concentrations of terpenes in turpentine recovery processes often present at pulp mill sites. Soft paper dust has also been reported to be associated with increased asthma and chronic obstructive pulmonary disease (Torén, Hagberg and Westberg 1996).

Exposure to micro-organisms, especially around wood chip and waste piles, debarkers and sludge presses, creates an increased risk for hypersensitivity responses in the lungs. Evidence for this appears to be limited to isolated case reports of hypersensitivity pneumonitis, which can lead to chronic lung scarring. Bagassosis, or hypersensitivity pneumonitis associated with exposure to thermophylic micro-organisms and bagasse (a sugar cane by-product), is still seen in mills using bagasse for fibre.

Other respiratory hazards commonly encountered in the pulp and paper industry include stainless steel welding fumes and asbestos (see “Asbestos,” “Nickel” and “Chromium” elsewhere in the Encyclopaedia). Maintenance workers are the group most likely to be at risk from these exposures.

Reduced sulphur compounds (including hydrogen sulphide, dimethyl disulphides and mercaptans) are potent eye irritants and may cause headaches and nausea in some workers. These compounds have very low odour thresholds (ppb range) in individuals not previously exposed; however, among long-time workers in the industry, odour thresholds are considerably higher. Concentrations in the range of 50 to 200 ppm produce olfactory fatigue, and subjects can no longer detect the distinctive “rotten eggs” odour. At higher concentrations, exposure will result in unconsciousness, respiratory paralysis and death. Fatalities associated with exposure to reduced sulphur compounds in confined spaces have occurred at pulp mill sites.

Cardiovascular mortality has been reported to be increased in pulp and paper workers, with some exposure-response evidence suggesting a possible link with exposure to reduced sulphur compounds (Jäppinen 1987; Jäppinen and Tola 1990). However, other causes for this increased mortality may include noise exposure and shift work, both of which have been associated with increased risk for ischaemic heart disease in other industries.

Skin problems encountered by pulp and paper mill workers include acute chemical and thermal burns and contact dermatitis (both irritant and allergic). Pulp mill workers in kraft process mills frequently experience alkali burns to the skin as a result of contact with hot pulping liquors and calcium hydroxide slurries from the recovery process. Contact dermatitis is reported more frequently among paper mill and converting workers, as many of the additives, defoaming agents, biocides, inks and glues used in paper and paper-product making are primary skin irritants and sensitizers. Dermatitis may occur from exposure to the chemicals themselves or from handling freshly treated paper or paper products.

Noise is a significant hazard throughout the pulp and paper industry. The US Department of Labor estimated that noise levels over 85 dBA were found in over 75% of plants in the paper and allied products industries, compared to 49% of plants in manufacturing in general, and that over 40% of workers were exposed regularly to noise levels over 85 dBA (US Department of Commerce 1983). Noise levels around paper machines, chippers and recovery boilers tend to be well over 90 dBA. Conversion operations also tend to generate high noise levels. Reduction in worker exposure around paper machines is usually attempted by the use of enclosed control rooms. In converting, where the operator is usually stationed next to the machine, this type of control measure is seldom used. However where converting machines have been enclosed, this has resulted in decreased exposure to both paper dust and noise.

Excessive heat exposure is encountered by paper mill workers working in paper machine areas, with temperatures of 60°C being recorded, although no studies of the effects of heat exposure in this population are available in the published scientific literature.

Agricultural Grains and Oilseeds

Several plants in the grass family, including wheat, rye, barley, oats, corn, rice, sorghum and millet, are valuable agricultural commodities, representing the largest effort in production agriculture. Grains provide a concentrated form of carbohydrates and are an important source of food for animals and humans.

In the human diet, grains make up about 60% of the calories and 55% of the protein, and are used for food as well as beverages. Bread is the most commonly recognized food product made from grains, although grains are also important in the production of beer and liquor. Grain is a basic ingredient in the distillation of neutral spirits that produce liquors with the taste and aroma of grain. Grains also are used to make feed for animals, including pets, working animals and animals raised in the production of meat products for human consumption.

Grain production can be traced to the beginning of civilization. In 1996, world production of cereal grains was 2,003,380,000 tonnes. This volume has increased more than 10% since the mid-1980s (FAO 1997).

Three of the major grains produced for their oil, also called oilseeds, are soybean, rapeseed and sunflower. Although ten different types of oilseed crops exist, these three account for the majority of the market, with soybean as the leader. Virtually all oilseeds are crushed and processed to produce vegetable oils and high-protein meals. Much of the vegetable oil is used as salad or cooking oils, and meal is used predominantly in animal feeds. World oilseed production in 1996 was 91,377,790 tonnes, almost a 41% increase since 1986 (FAO 1997).

The production of grains and oilseeds is affected by regional factors such as weather and geography. Dry soils and environments restrict corn production, while moist soils deter wheat production. Temperature, precipitation, soil fertility and topography also affect the type of grain or oilseed that can be successfully produced in an area.

For production of grain and oilseed crops, work falls into four areas: seed bed preparation and planting, harvest, storage and transportation of the crop to market or processing facilities. In modern agriculture, some of these processes have changed completely, but other processes have changed little since early civilization. However, the mechanization of agriculture has created new situations and safety issues.

Hazards and Their Prevention

All tools used in grain harvest—from complex combines to the simple scythe—have one aspect in common: they are hazardous. Harvest tools are aggressive; they are designed to cut, chew or chop plant materials placed into them. These tools do not discriminate between a crop and a person. Various mechanical hazards associated with grain harvesting include shear-point, pull-in, crush-point, entanglement, wrap-point and pinch-point. A combine pulls in cornstalks at a rate of 3.7 metres per second (m/s), too quickly for humans to avoid entanglement, even with a normal reaction time. Augers and PTO units used to move grain, rotate and have wrapping speeds of 3 m/s and 2 m/s, respectively, and also pose an entanglement hazard.

Agricultural workers also can experience noise-induced hearing loss from large-horsepower machinery and equipment used in crop production. Axial-vane fans that force heated air through a bin or storage structure to dry grain can generate noise levels of 110 dBA or more. Since grain-drying units often are located near living quarters and are operated continuously throughout a season, they often result in substantial hearing loss in farmworkers as well as family members over long periods of time. Other sources of noise that can contribute to hearing loss are machinery such as tractors, combines and conveying equipment, and grain moving through a gravity spout.

Agricultural workers also can be exposed to significant suffocation hazards by engulfment either in flowing grain or collapsing grain surfaces. A person caught in grain is almost impossible to rescue because of the tremendous weight of grain. Workers can prevent engulfment in flowing grain by always turning off all power sources to the unloading and transporting equipment before they enter an area and locking shut all gravity flow gates. Engulfment in a collapsed grain surface is difficult to prevent, but workers can avoid the situation by knowing the history of the storage structure and the grain it contains. All workers should follow confined-space entry procedures for physical engulfment hazards when working with grain.

During the harvest, storage and transportation of grains and oilseeds, agricultural workers are exposed to dusts, spores, mycotoxins and endotoxins that can be harmful to the respiratory system. Biologically active dust is capable of producing irritation and/or allergic, inflammatory or infectious responses in the lungs. Workers can avoid or reduce their exposure to dust, or wear personal protective equipment such as mechanical filter respirators or air-supplied respirators in dusty environments. Some handling and storage systems minimize the creation of dust, and additives such as vegetable oils can keep dust from becoming airborne.

In some conditions during storage, grain can spoil and emit gases that pose a suffocation hazard. Carbon dioxide (CO2) can collect above a grain surface to displace oxygen, which can cause impairment in workers if oxygen levels drop below 19.5%. Mechanical filter respirators are useless in these situations.

Another hazard is the potential for fires and explosions that can occur when grains or oilseeds are stored or handled. Dust particles that become airborne when grain is moved create an atmosphere ripe for a powerful blast. Only an ignition source is needed, such as an overheated bearing or a belt rubbing against a housing component. The biggest hazards exist at large port elevators or inland community elevators where huge volumes of grain are handled. Regular preventive maintenance and good housekeeping policies minimize the risk of possible ignition and explosive atmospheres.

Chemicals used at the beginning of the crop production cycle for seed-bed preparation and planting also can pose hazards for agricultural workers. Chemicals can increase soil fertility, reduce competition from weeds and insects and boost yields. The biggest concern for agricultural chemicals hazards is long-term exposure; however, anhydrous ammonia, a compressed liquid fertilizer, can cause immediate injury. Anhydrous ammonia (NH3) is a hygroscopic, or water-seeking, compound, and caustic burns result when it dissolves body tissue. Ammonia gas is a strong lung irritant, but has good warning properties. It also has a low boiling point and freezes on contact, causing another type of severe burn. Wearing protective equipment is the best way to reduce risk of exposure. When exposure occurs, first aid treatment requires immediately flushing of the area with plenty of water.

Grain production workers also are exposed to potential injury from slips and falls. A person can die from injuries in a fall from a height as low as 3.7 m, which is easily exceeded by operator’s platforms on most machinery or grain storage structures. Grain storage structures are at least 9 and up to 30 m tall, reachable only by ladders. Inclement weather can cause slippery surfaces from rain, mud, ice or snow build-up, so the use of guards, handrails and footwear with non-slip soles is important. Devices such as a body harness or lanyard also can be used to arrest the fall and minimize injury.

Production of Fruit Juices

Fruit juices are made from a wide variety of fruits, including oranges and other citrus fruits, apples, grapes, cranberries, pineapples, mangoes and so forth. In many cases, various fruit juices are blended. Usually, the fruit is processed into a concentrate near where it is grown, then shipped to a fruit juice packager. Fruit juices can be sold as concentrates, frozen concentrates (especially orange juice) and as the diluted juice. Often sugar and preservatives are added.

Once received at the processing plant, the oranges are washed, graded to remove damaged fruit, separated according to size and sent to the juice extractors. There the oils are extracted from the peel, and then the juice extracted by crushing. The pulpy juice is screened to remove seeds and pulp, which often end up as cattle feed. If the orange juice is intended for sale as “not from concentrate”, it is then pasteurized. Otherwise the juice is sent to evaporators, which remove most of the water by heat and vacuum, then chilled, to produce the frozen, concentrated orange juice. This process also removes many oils and essences which are blended back into the concentrate before shipping to the juice packager.

The frozen concentrate is shipped to the packager in refrigerated trucks or tankers. Many dairies package orange juice using the same equipment used to package milk. (See the article “Dairy products industry” elsewhere in this volume.) The concentrate is diluted with filtered water, pasteurized and packaged under sterile conditions. Depending on the amount of water added, the final product can be cans of frozen orange juice concentrate or ready-to-serve orange juice.

Poultry Processing

Economic Importance

Chicken and turkey production has increased dramatically in the United States since the 1980s. According to a US Department of Labor report this has been due to a change in consumer eating patterns (Hetrick 1994). A shift from red meat and pork to poultry is due in part to early medical studies.

The rise in consumption correspondingly has spurred an increase in the number of processing facilities and growers and a large rise in levels of employment. For example, the United States poultry industry experienced an increase in employment of 64% from 1980 to 1992. Productivity, in terms of pounds yield per worker, increased 3.1% due to mechanization or automation, as well as an increase in line speed, or birds per work hour. However, in comparison to red meat production, poultry production is still very labour intensive.

Globalization is also ocurring. There are production and processing facilities jointly owned by US investors and China and breeding, grow-out and processing facilities in China export product to Japan.

Typical poultry line workers are relatively unskilled, less educated, often members of minority groups and much lower paid than workers in the red meat and manufacturing sectors. Turnover is unusually high in certain aspects of the process. Live hanging, deboning and sanitation jobs are particularly stressful and have high turnover rates. Poultry processing by its nature is a largely rural-based industry found in economically depressed areas where there is a labour surplus. In the United States many processing plants have an increasing number of Spanish-speaking workers. These workers are somewhat transient, working in the processing plants part of the year. As the region’s crops near harvest, large segments of the workers move outdoors to pick and harvest.

Processing

Throughout the processing of chicken, rigid sanitation requirements must be met. This means that floors must be washed down periodically and often and that debris, parts and fat must be removed. Conveyors and processing equipment must be accessible, washed down and sanitized also. Condensation must not be allowed to accumulate on ceilings and equipment over exposed chicken; it must be wiped down with long-handled sponge mops. Overhead, unguarded radial-blade fans circulate the air in the processing areas.

Because of these sanitation requirements, guarded rotating equipment often cannot be silenced for noise-abatement purposes. Consequently, in the majority of the processing plant’s production areas, there is high noise exposure. A proper and well-run hearing conservation programme is necessary. Not only should initial audiograms and annual audiograms be given, but periodic dosimetry should also be done to document exposure. Purchased processing equipment should have as low an operating noise level as possible. Particular care needs to be taken in educating and training the workforce.

Receiving and live hang

The first step in processing involves off-loading of the modules and destacking the trays onto a conveyor system to the live hang area. Work here is in almost complete darkness, since this has a quieting effect on the birds. The conveyor belt with a tray is at about waist level. A hanger, with gloved hands, must reach and grab a bird by both thighs and hang its feet in a shackle on an overhead conveyor travelling in the opposite direction.

The hazards of the operation vary. Aside from the normal high level of noise, the darkness and the disorienting effect of opposite running conveyors, there is the dust from flapping birds, suddenly sprayed urine or faeces in the face and the possibility of a gloved finger being caught in a shackle. Conveyor lines need to be equipped with emergency stops. Hangers are constantly striking the backs of their hands against neighboring shackles as they pass overhead.

It is not uncommon for a hanger to be required to hang an average of 23 (or more) birds per minute. (Some positions on the hanger’s lines require more physical motions, perhaps 26 birds per minute.) Typically, seven hangers on one line may hang 38,640 birds in 4 hours before they get a break. If each bird weighs approximately 1.9 kg, each hanger conceivably lifts a total of 1,057 kg during the first 4 hours of his or her shift before a scheduled break. The hanger’s job is extremely stressful from both a physiological and psychological standpoint. Reducing workload could lessen this stress. The constant grabbing with both hands, pulling in and simultaneously lifting a flapping, scratching bird at shoulder or head height is stressful to the upper shoulder and neck.

The bird’s feathers and feet can easily scratch a hanger’s unprotected arms. The hangers are required to stand for prolonged periods of time on hard surfaces, which can lead to lower-back discomfort and pain. Proper footwear, possible use of a rump rest stand, protective eyewear, single-use disposable respirators, eyewash facilities and arm guards need to be available for the hanger’s protection.

An extremely important element to ensure the worker’s health is a proper job conditioning programme. For a period of up to 2 weeks, a new hanger must be acclimated to the conditions and slowly work up to a full shift. Another key ingredient is job rotation; after two hours of hanging birds, a hanger may be rotated to a less strenuous position. The division of labour among the hangers may be such that frequent short rest breaks in an air conditioned area are essential. Some plants have tried double crewing to allow crews to work for 20 minutes and rest for 20 minutes, to reduce the ergonomic stressors.

The health and comfort conditions for the hangers are somewhat dependent on the outside weather conditions and the conditions of the birds. If the weather is hot and dry, the birds carry with them dust and mites, which easily become airborne. If the weather is wet, the birds are harder to handle, the hangers’ gloves readily become wet and the hangers must work harder to hold onto the birds. There have been recent developments in reusable gloves with padded backs.

The impact of airborne particulates, feathers, mites and so on may be lessened with an efficient local exhaust ventilation (LEV) system. A balanced system using the push-pull principle, which uses down-draft cooling or heating, would benefit the workers. Additional cooling fans placed about would upset the efficiency of a balanced push-pull system.

Once hung in the shackles, the birds are conveyed to be initially stunned with electricity. The high voltage does not kill them but forces them to hang limply as a rotating wheel (bicycle tyre) guides their neck against a counter-rotating circular cutting blade. The neck is partially severed with the bird’s heart still beating to pump out the remainder of blood. There must be no blood in the carcass. A skilled worker must be positioned to slice those birds the kill machine misses. Because of the excessive amount of blood, the worker must be protected by wearing wet gear (a rain suit) and eye protection. Eye washing or flushing facilities must be made available also.

Dressing

The conveyor of birds then passes through a series of troughs or tanks of circulating hot water. These are called scalders. Water is usually heated by steam coils. The water is usually treated or chlorinated to kill bacteria. This phase allows the feathers to be easily removed. Care must be taken when working around the scalders. Often piping and valves are unprotected or poorly insulated and are contact points for burns.

As the birds exit the scalders, the carcass is passed through a U-shaped arrangement which pulls the head off. These parts are usually conveyed in flowing water troughs to a rendering (or by-products) area.

The line of carcasses passes through machines which have a series of rotating drums fixed with rubber fingers which remove the feathers. The feathers drop into a trench below with flowing water leading to the rendering area.

Consistency in bird weight is extremely critical to all aspects of the processing operation. If the weights vary from load to load, the production departments must adjust their processing equipment accordingly. For example, if lighter-weight birds follow heavier birds through the pickers, the rotating drums may not get all the feathers off. This causes rejects and rework. Not only does it add to the processing costs, but it causes additional ergonomic hand stresses, because someone has to hand pick the feathers using a pincer grip.

Once through the pickers, the line of birds passes through a singer. This is a gas-fired arrangement with three burners on each side, used to singe the fine hairs and feathers of each bird. Care must be taken to assure that the gas piping’s integrity is maintained due to the corrosive conditions of the picking or dressing area.

The birds then pass a hock cutter to sever the feet (or paws). The paws may be conveyed separately to a separate processing area of the plant for cleaning, sizing, sorting, chilling and packaging for the Asian market.

The birds must be rehung on different shackles before they enter the evisceration section of the plant. The shackles here are configured slightly differently, usually longer. Automation is readily available for this part of the process (see figure 1). However, workers need to provide back-up if a machine jams, to rehang dropped birds or to manually cut the feet off with pruning shears if the hock cutter fails to sever properly. From a processing and cost standpoint, it is critical that every shackle be filled. Rehang jobs involve exposure to highly repetitive motions and work involving awkward postures (raised elbows and shoulders). These workers are at increased risk for cumulative trauma disorders (CDTs).

Figure 1. Multi-cut machines reducing repetitive manual work

If a machine goes down or gets out of adjustment, a great deal of effort and stress is applied to get the lines running, sometimes at the expense of workers’ safety. When climbing to access points on the equipment, a maintenance worker may not take the time to get a ladder, instead stepping on top of wet, slippery equipment. Falls are a hazard. When any such equipment is purchased and installed, provisions must be made for easy access and maintenance. Lockout points and shut-offs need to be placed on each piece of equipment. The manufacturer must consider the environment and hazardous conditions under which their equipment must be maintained.

Evisceration

As the conveyor of birds pass out of dressing into a physically separate part of the process, they usually pass through another singer and then through a rotating circular blade which cuts out the oil sac or gland on each bird’s back at the base of the tail. Often such equipment’s blades are free rotating and need to guarded properly. Again, if the machine is not adjusted according to the bird’s weight, workers must be assigned to remove the sac by slicing it off with a knife.

Next, the conveyor line of birds passes through an automatic venting machine, which pushes up on the abdomen slightly while a blade cuts open the carcass without disturbing the bowel. The next machine or part of the process scoops into the cavity and pulls out the unbroken viscera for inspection. In the United States, the next few processing steps may involve government inspectors who check for growths, air sac disease, faecal contamination and a series of other abnormalities. Usually one inspector checks for only two or three items. If there is a high rate of abnormalities, the inspectors will slow the line down. Often the abnormalities do not cause total rejects, but specific parts of the birds may be washed or salvaged from the carcass to increase yield.

The more rejects, the more manual rework involving repetitive motion due to cutting, slicing and so on the production workers must perform. Government inspectors are usually seated on mandated adjustable elevating stands, whereas production workers called helpers, to their left and right, stand on grating or may use an adjustable sit stand if provided. Foot rests, adjustable height platforms, sit stands and job rotation will help relieve the physical and psychological stresses associated with this part of the process.

Once past the inspections, the viscera are sorted as they pass through a liver/heart or giblet harvester. The separated intestines, stomachs, spleens, kidneys and gall bladders are discarded and flushed into a flowing trench below. The heart and liver are separated and pumped to separate sorting conveyors, where workers inspect and pick by hand. The remaining intact livers and hearts are pumped or carried to a separate processing area to be bulk-packed by hand or later recombined in a giblet pack for stuffing by hand into the cavity of a whole bird for sale.

Once the carcass clears the harvester, the bird’s crop is augured out; each body cavity is probed by hand to pull out the remaining viscera and gizzard if necessary. The worker uses each hand in a separate bird as the conveyor passes in front. A suction device is often used to vacuum out any remaining lungs or kidneys. Frequently, due to the bird’s habit of ingesting small pebbles or pieces of litter during grow-out, a worker will reach into the bird’s cavity and receive painful puncture wounds in the tips of the fingers or under the finger nails.

The small wounds, if not treated properly, run the risk of serious infection since the bird’s cavity still is not cleaned of bacteria. Since tactile sensitivity is necessary for the job, there are no gloves yet available to prevent these frequent incidents. A tight-fitting surgeon’s type glove has been tried with some success. The line pace is so fast that it does not allow the worker to carefully insert his or her hands.

Finally, the carcass’s neck is removed by machine and harvested. The birds go through a bird washer which uses chlorinated spray to wash out excess viscera inside and outside each bird.

Throughout the dressing and evisceration, workers are exposed to high levels of noise, slippery floors and high ergonomic stress on kill, scissor and packaging jobs. According to a NIOSH study, rates of CTDs documented in poultry plants can range from 20 to 30% of workers (NIOSH 1990).

Chiller operations

Depending on the process, necks are pumped to a open-surfaced chiller tank with rotating arms, paddles or augers. These open tanks pose a serious threat to the safety of the worker during operation and need to be properly guarded by removable covers or grills. The tank’s cover must allow for visual inspection of the tank. If a cover is removed or lifted, interlocks must be provided to shut off the rotating arms or auger. The chilled necks are either bulk-packed for later processing or taken to the giblet wrap area for recombining and wrapping.

Once through evisceration, the conveyor lines of birds are either dropped into large, open-surfaced horizontal chilling tanks or, in Europe, pass through refrigerated, circulating air. These chillers are fitted with paddles which slowly rotate through the chiller, bringing down the bird’s body temperature. The chilled water is highly chlorinated (20 ppm or greater) and aerated for agitation. Bird carcass residence time in the chiller may be up to an hour.

Due to the high levels of free chlorine released and circulated, workers are exposed and may experience symptoms of eye and throat irritation, coughing and shortness of breath. NIOSH conducted several studies of eye and upper respiratory irritation in poultry processing plants, which recommended that levels of chlorine be monitored and controlled closely, that curtains be used to contain the liberated chlorine (or an enclosure of some sort should surround the open surface of the tank) and that an exhaust ventilation system should be installed (Sanderson, Weber and Echt 1995).

The resident time is critical and a matter of some controversy. Upon exiting evisceration, the carcass is not completely clean, and the skin pores and feather follicles are open and harbour disease-causing bacteria. The main purpose of the trip through the chiller is to chill the bird quickly to reduce spoilage. It does not kill bacteria, and the risk of cross contamination is a serious public health issue. Critics have called the chiller bath method “faecal soup”. From a profit perspective, a side benefit is the fact that the meat will absorb the chiller water like a sponge. It adds almost 8% to the market weight of the product (Linder 1996).

Upon exiting the chiller, the carcasses are deposited on a conveyor or shaker table. Specially trained workers called graders inspect the birds for bruises, skin breaks and so on and rehang the birds on separate shackle lines travelling in front of them. Downgraded birds may travel to different processes for parts recovery. Graders stand for prolonged periods handling chilled birds, which can result in numbness and hand pain. Gloves with liners are worn not only to protect the hands of workers from the chlorine residue, but also to provide some degree of warmth.

Cut-up

From grading the birds travel overhead to different processes, machines and lines in an area of the plant called second or further processing. Some machines are hand fed with two-handed trips. Other, more modern European equipment, at separate stations, may remove the thighs and wings and split the breast, without being touched by the worker. Again, consistency in bird size or weight is critical to the successful operation of this automated equipment. Rotating circular blades must be changed every day.

Skilled maintenance technicians and operators must be attentive to the equipment. Access to such equipment for adjustment, maintenance and sanitation needs to be frequent, requiring stairs, not ladders, and substantial work platforms. During blade changing, handling needs to be cautious because of the slipperiness due to fat build-up. Special cut- and slip-resistant gloves with the fingertips removed protect most of the hand, while the tips of the fingers can be used to manipulate the tools, bolts and nuts used for replacement.

Evolving consumer tastes have affected the production process. In some cases, the products (e.g., drumstick, thighs and breasts) are required to be skinless. Processing equipment has been developed to efficiently remove skin so workers do not have to do so by hand. However, as automated processing equipment is added and lines are rearranged, conditions become more crowded and awkward for workers to get around, manoeuvre floor jacks and carry totes, or plastic tubs, of iced product weighing over 27 kg over slippery, wet floors.

Depending on the customer demand and product mix sales, workers stand facing fixed-height conveyors, selecting and arranging product on plastic trays. The product travels in one direction or drops from a chute. The trays arrive on overhead conveyors, descending so the workers can grab a stack and set them in front for easy reach. Product defects may be either placed on a counter-flow conveyor below or hung in a shackle travelling in the opposite direction overhead. Workers stand for prolonged periods of time almost shoulder to shoulder, perhaps separated only by a tote into which defects or waste are dropped. Workers need to be provided with gloves, aprons and boots.

Some products may be bulk-packed in cartons covered with ice. This is called ice pack. Workers fill cartons by hand onto scales and manually transfer them to moving conveyors. Later in the ice pack room, ice is added, cartons recovered and the cartons removed and stacked manually on pallets ready for shipment.

Some workers in cut-up are also exposed to high levels of noise.

Deboning

If the carcass is destined for deboning, the product is tanked out in large aluminium bins or cardboard boxes (or gaylords) mounted on pallets. Breast meat must be aged for a certain number of hours before processing either by machine or hand. Fresh chicken is difficult to cut and trim by hand. From an ergonomic standpoint, meat ageing is a key point in helping to reduce repetitive motion injuries to the hand.

There are two methods used in deboning. In the manual method, once ready, carcasses with only the breast meat remaining are dumped into a hopper leading to a conveyor. This section of the line’s workers must handle each carcass and hold them against two horizontal, in-running textured skinner rolls. The carcass is rolled over the rolls as the skin is pulled away and down to a conveyor below. There is a risk of workers becoming inattentive or distracted and having their fingers pulled into the rollers. Emergency stop (E-stop) switches need to be provided within easy reach of either the free hand or knee. Gloves and loose clothing cannot be worn around such equipment. Aprons (worn snugly) and protective eyewear must be worn due to the possibility of bone chips or fragments being thrown.

The next step is performed by workers called nickers. They hold a carcass in one hand and make a slice along the keel (or breastbone) with the other. Sharp, short-bladed knives are normally used. Stainless steel mesh gloves are usually worn over a latex- or nitrile-gloved hand holding the carcass. Knives used for this operation do not need to have a sharp point. Protective eye wear needs to be worn.

The third step is performed by the keel pullers. This may be done manually or with a jig or fixture where the carcass is guided over an inexpensive “Y” fixture (made out of stainless steel rod stock) and pulled toward the worker. The working height of each fixture needs to be adjusted to the worker. The manual method simply requires the worker to use a pincer grip with a gloved hand and pull the keel bone out. Protective eyewear must be worn as described above.

The fourth step requires hand filleting. Workers stand shoulder to shoulder reaching for breast meat as it travels on shackle trays in front of them. There are certain techniques that must be observed for this part of the process. Proper job instruction and immediate correction when errors are observed are necessary. Workers are protected with a chain or mesh glove on one hand. In the other, they hold an extremely sharp knife (with a tip that may be too sharply pointed).

The work is fast paced, and workers who get behind are pressured to take short cuts, such as reaching across in front of the associate next to them or reaching for and/or stabbing a piece of meat travelling by out of their reach. Not only does the knife puncture reduce the quality of the product, but it also results in serious injury to fellow workers in the form of lacerations, which are often subject to infection. Protective plastic arm guards are available to prevent this frequent type of injury.

As the fillet meat is replaced on the conveyor shackle, it is picked off by the next section of workers, called trimmers. These workers must trim excess fat, missed skin and bones out of the meat using sharp and adjusted shears. Once trimmed, the finished product is either tray packed by hand or dropped into bulk bags and placed into cartons for restaurant use.

The second method of deboning involves automatic processing equipment developed in Europe. As with the manual method, bulk boxes or tanks of carcasses, sometimes with wings still attached, are loaded into a hopper and chute. Carcasses may then be picked manually and placed into segmented conveyors, or each carcass must be placed manually onto a shoe of the machine. The machine moves rapidly, carrying the carcass through a series of fingers (to remove skin), cutting blades and slitters. All that remains is a meatless carcass that is bulked out and used elsewhere. Most of the manual line’s positions are eliminated, except for the trimmers with scissors.